The industrial internet is a strategic infrastructure for new industrialization and an important driving force for developing new productive forces. As the underlying communication technology of the industrial internet, the industrial IoT is the core technology for the safe operation of industrial automation systems.

How does the industrial IoT make every industrial product “addressable, communicable, and controllable”? How can we ensure precise clock synchronization and real-time scheduling between devices? How can we achieve deep integration between different factory networks and the internet?

Recently, with these questions in mind, a reporter from Chongqing Daily visited the Ministry of Education’s Key Laboratory of Industrial IoT and Networked Control, built with the support of our university, to seek answers.

▲ The Key Laboratory of Industrial IoT and Networked Control at our university, where staff explain relevant technological achievements.

Comprehensive Connection of “People, Machines, and Things”

You might be chatting with an instrument

“In the early days of chatting on QQ, there was a joke that said, ‘The one chatting with you might be a cat or a dog.’ In the industrial internet, the one chatting with you might also be an instrument.” Standing in front of the demonstration case of the “IPv6 Interoperability and Integration Technology Testing Platform for Production Networks Targeting Typical Industries” in the exhibition hall on the third floor of our university’s Information Science Building, Director Wang Heng joked with the reporter.

▲ Director Wang Heng of the Key Laboratory of Industrial IoT and Networked Control at our university explains relevant technological achievements.

This scenario is not a joke. Since the first half of 2017, this technology, then called “Fully Connected Manufacturing Network,” has been demonstrated and applied at the Chongqing Iron and Steel (Group) Co., Ltd. located in Changshou District.

In the 10 square kilometer area of the Chongqing Iron and Steel plant, Wang Heng and his laboratory team installed nearly a hundred data monitoring instruments in ten production workshops across the plant and connected them into a “network” using IoT core chips.

“The industrial IoT mainly enhances the informationization level of manufacturing by supporting interaction and interconnection between devices,” Wang Heng said. However, achieving interoperability between devices with different network interfaces is extremely challenging. On one hand, traditional control networks adopt a layered system structure, which has limitations in integration, coordination, and management, making it difficult to meet the requirements for seamless integration of the underlying IoT with the internet in industrial internet and smart manufacturing. On the other hand, many automated production lines predominantly use industrial wired networks, which incur high wiring costs, leading to expensive installation and maintenance costs for the entire automation system.

After seven years of continuous upgrades and transformations, the “Fully Connected Manufacturing Network” technology has evolved into the “IPv6 Interoperability and Integration Technology for Production Networks,” achieving the goal of making every industrial product “addressable, communicable, and controllable.” It can not only monitor the health status of production equipment at any time but also analyze and predict various data, providing timely “prescriptions” for equipment “conditions.”

“For example, if we input ‘Please report the current operating status of the No. 1 dry coke collection station’ in the system dialog box, the plant’s parameter collection system can immediately report the temperature, humidity, gas concentration, and other information from that collection station. These dialogues are not manually input; they are ‘spoken’ by the instruments responsible for data monitoring in the plant,” Wang Heng described.

Because this technology allows industrial equipment and networks to operate stably even in harsh production environments, manufacturers have reported that it acts as a “stabilizing force” for smart workshop production.

Research and Development of Key Technologies for Autonomous and Controllable Industrial Networks

Unifying Clock and Data Timestamps for All Factory Equipment

Ensuring Synchronization and Coordination

At the digital factory of Chongqing Mengxun Electronic Technology Co., Ltd. located in the Chayuan area of Nan’an District, rows of blue smart LED screens of various sizes display real-time product information, completion rates, and quality rates; intelligent robotic arms autonomously rotate to accurately place finished smart communication modules onto smart shelves; and tall automated production lines are neatly arranged, with intelligent robots performing labeling, inspection, board separation, and sorting actions in a coordinated and seamless manner.

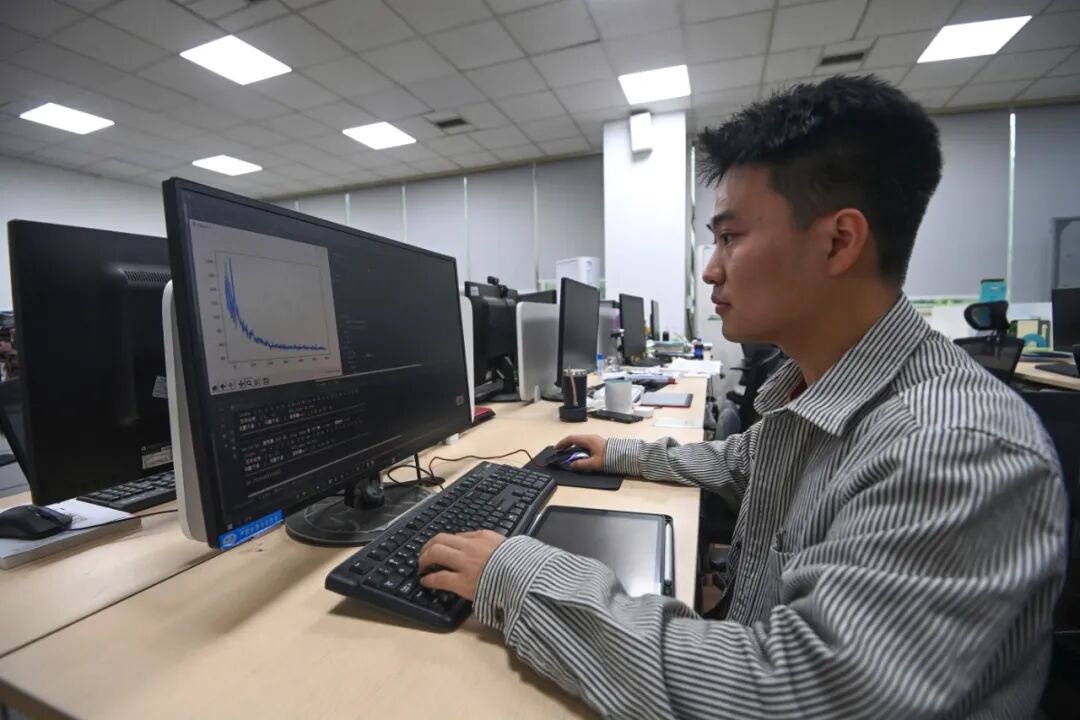

▲ Students at the Key Laboratory of Industrial IoT and Networked Control at our university are engaged in research work.

As a company primarily engaged in processing services for radio communications and automotive electronics, the digital transformation and intelligent upgrade of Mengxun Electronic Technology Co., Ltd. rely on the key technologies for autonomous and controllable industrial networks developed by the laboratory team.

Wang Heng explained that this technology achieves time synchronization, real-time scheduling, high availability redundancy, security, and heterogeneous real-time interconnection in industrial networks, improving the operational efficiency of Mengxun’s smart factory by 15% and reducing operational costs by 10%.

“Factory equipment encounters various issues during operation, just like in our daily work. If we agree to meet at nine o’clock tomorrow morning, first, if your clock is slow, you won’t be able to attend the meeting on time; secondly, if the meeting involves company secrets, we must ensure that team members do not disclose the meeting information; thirdly, if we have a meeting in hot weather, we need to turn on the air conditioning or fans to ensure normal work conditions,” Wang Heng said. Through this key technology, the factory has achieved unified clock and data timestamps for all equipment, ensuring that all data collected by different devices at the same time are tagged with the same timestamp before transmission.

Additionally, this technology securely transmits sensitive production information within the industrial network, allowing devices and systems to communicate in a common “language” using a unified next-generation internet protocol (IPv6), enabling interoperability among heterogeneous industrial networks, real-time data transmission and exchange, and ensuring that computational power benefits every corner, making every device intelligent.

Currently, this technology has been widely and scaled in industrial enterprises, benefiting countries involved in the “Belt and Road” initiative, and is used in remote control systems for hydropower stations in Vietnam, Turkey, and Pakistan.

An Important Source for Global IoT Standard Development

Leading the Development of 7 International Standards

Leading the Development of 18 National Standards

In addition to various technologies, since its establishment in 2011, the laboratory team has also led the development of 7 international standards and 18 national standards in the field of industrial IoT.

“Through our research, we found that so far, the entire industrial IoT industry has dozens of communication protocols, including some proprietary protocols, lacking a unified interoperability standard and specification, which hinders the ultimate goal of achieving interconnectivity among all things in the IoT development,” said Wei Min, an expert from the International IoT Standard Committee and a key member of the Key Laboratory of Industrial IoT and Networked Control, as well as the Dean of the School of Automation/Industrial Internet at our university. To address this critical issue in IoT development, the laboratory actively participates in the formulation of international and national standards, becoming an important source for global IoT standard development.

For instance, in 2022, the “IoT – Energy Management Application Framework for Factory Facilities” edited by the laboratory team was released, becoming the world’s first international standard for factory energy consumption management in the IoT.

The national standard in the field of IoT, “IoT System Interoperability Part 2: Network Connectivity,” led by the laboratory team, has been directly adopted by seven countries, including the UK, Canada, Australia, Denmark, and the Netherlands, and recommended for use by the German Industry 4.0 standardization organization…

▲ The Key Laboratory of Industrial IoT and Networked Control at our university showcases relevant technological achievements.

“The new generation of technological revolution aims to connect all equipment in factories through IoT technology, allowing them to communicate freely like mobile phones do with each other,” Wang Heng revealed. In the next steps, the laboratory will continue to rely on our university’s School of Automation and key disciplines such as Control Science and Engineering, and Instrument Science and Technology, closely aligning with national strategic needs to tackle key core technologies that restrict the development of industrial IoT, such as intelligent perception, synchronization, scheduling, and heterogeneous integration, and to overcome challenges related to autonomous, secure, and controllable intelligent chips and time-sensitive networks, proposing tailored solutions for typical industry applications such as smart manufacturing and intelligent connected vehicles.

Disclaimer: The media center of Chongqing University of Posts and Telecommunications publishes articles, except for those marked as original content, the remaining text and images are sourced from the internet and major mainstream media. Copyright belongs to the original author. If you believe the content infringes on your rights, please leave a message in the background, and we will contact you for deletion.

Recommended Reading

▲ Li Xiang Chongyou | Jiang Sijia: From “Three Questions of the Olympics” to Building a Strong Sports Nation

▲ The school holds an expanded meeting of the Standing Committee of the Party Committee to study and deploy the education work of party discipline.

▲ One Picture Understands | “Regulations on Disciplinary Actions of the Communist Party of China”

Source / Chongqing Daily