Author: onsemi Analog and Mixed Signal Division (AMG) Product Marketing EngineerHideo Kondo

The potential of interconnected electrochemical sensors is immense, promising to enhance scientific understanding and improve our quality of life. In today’s world, sensor solutions are ubiquitous, such as wearable devices for monitoring blood glucose levels in diabetic patients, gas detectors to assess environmental pollutants, histamine sensors to improve food safety, and indispensable potentiostats or corrosion sensors in industrial environments.

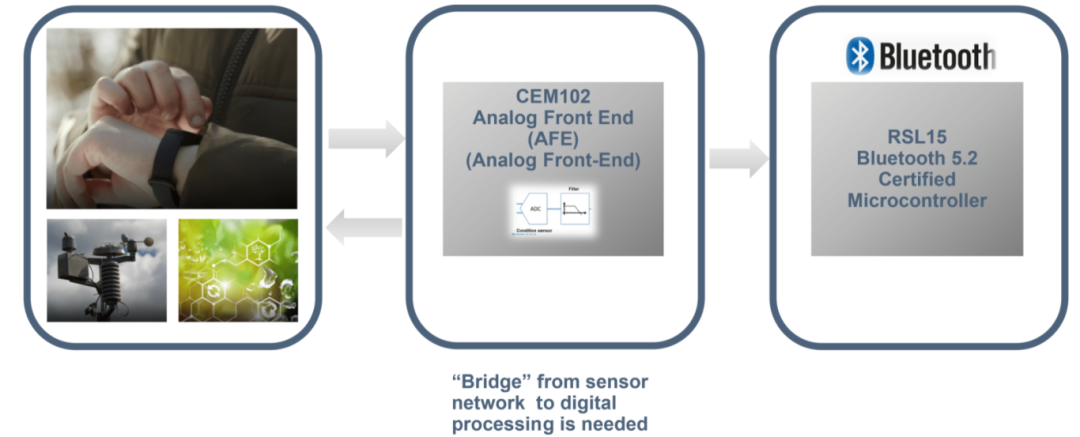

Figure 1: onsemi‘s CEM102 + RSL15 platform expands electrochemical sensing technology into smart healthcare and environmental science fields

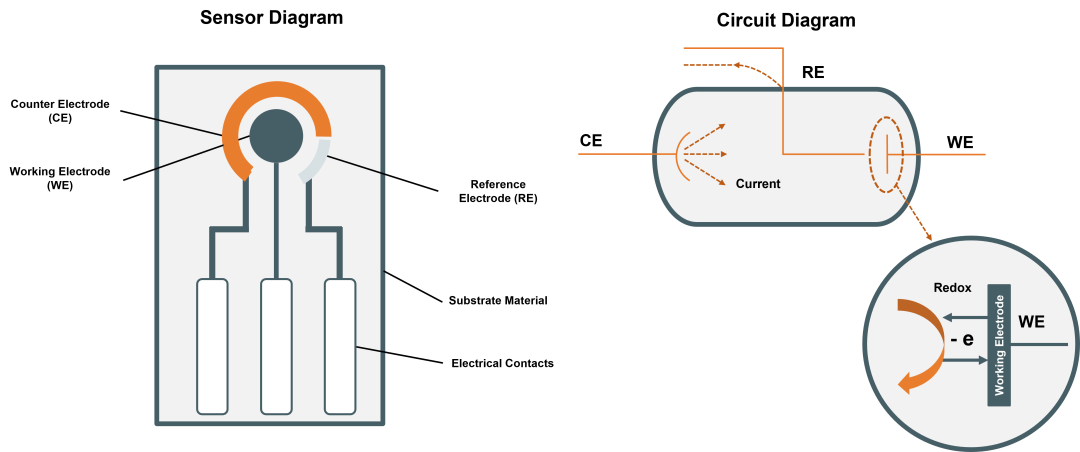

In electronic engineering, a typical setup of an electrochemical sensor includes a three-electrode system (Figure 2).

Figure 2: The left image visually shows a typical commercial electrochemical sensor, while the right image depicts a redox reaction

The core of the sensor consists of three parts: the working electrode, counter electrode, and reference electrode (see Figure 2). The working electrode (WE) is the component where the electrochemical reaction occurs, initiating electron flow and generating current. The counter electrode (CE) balances the redox reaction of the WE for accurate sensing; the reference electrode (RE) measures the WE potential and provides feedback for the CE voltage.

Finally, the current generated by the WE is converted into voltage. With additional digital processing and wireless communication technology, we can build more powerful interconnected solutions to help you understand your surroundings and your body better.

Electrochemical sensors are critical for many remote patient monitoring applications. For instance, diabetes is a chronic disease affecting 1 in 11 people globally, and continuous glucose monitoring (CGM) is an essential part of diabetes management. The CGM device market is expected to grow at a compound annual growth rate (CAGR) of 9% from 2023 to 2032.

In environmental monitoring applications, electrochemical sensors are often used to detect gases such as carbon monoxide, hydrogen sulfide, nitrogen oxides, and sulfur oxides. In the food production sector, factories use handheld portable devices and large automated electrochemical detection solutions to ensure food production is delicious, free of allergens, and harmful chemicals.

Using AFE devices with electrochemical sensors enables accurate measurements, ensuring smooth medical and industrial processes while enhancing scientific knowledge. For example, wearable or portable medical devices can continuously monitor blood glucose levels remotely, providing valuable insights for researchers to accelerate innovation and benefit people worldwide.

onsemi recently released the CEM102, an advanced micro AFE capable of high-precision measurement of electrochemical information and amperometric current.The CEM102 is designed to work with the RSL15 Bluetooth 5.2 certified wireless microcontroller, which utilizes secure Bluetooth Low Energy technology with very low power consumption. The combination allows designers to develop more precise, lower-power, and compact devices for sensing applications.

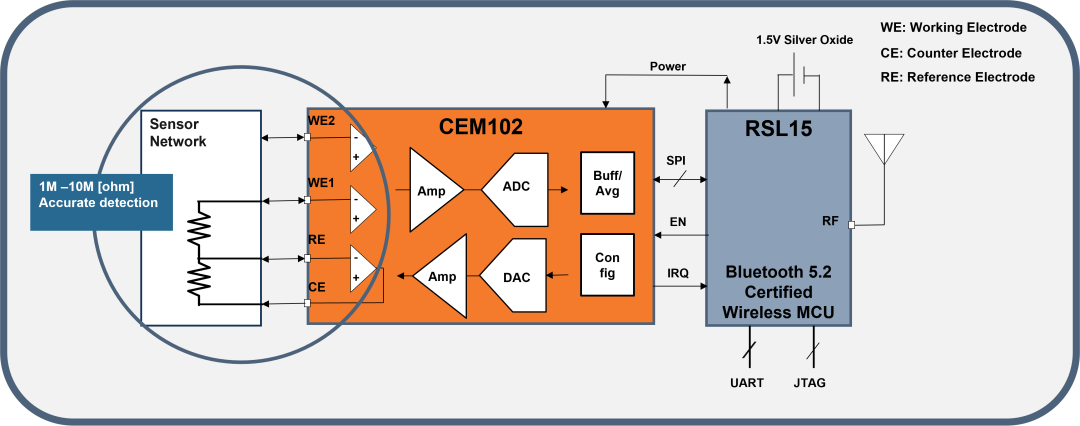

Figure 3: onsemi’s CEM102 AFE + RSL15 combination solution provides high-precision electrochemical measurement results and wireless communication

Compared to standalone solutions, onsemi’s CEM102 + RSL15 combination solution offers higher accuracy, lower noise, and lower power consumption.The combination solution simplifies the bill of materials (BoM) and increases configuration flexibility, ultimately freeing up more development resources. More importantly, the flexibility of this solution makes it suitable not only for electrochemical measurement-based sensors but also for various sensors requiring accurate measurement of small currents.

The CEM102 + RSL15 platform supports two battery options: 1.3 V – 1.65 V and 2.375 V – 3.6 V. In active measurement mode with continuous conversion at 18-bit ADC, this platform consumes only 3.5 uA of current. This means that a 3 mAh battery can last up to 14 days, demonstrating excellent market performance.

With a compact package size of 1.884×1.848 mm and the ability to operate with 1 to 4 electrodes, it helps create smaller, more efficient wearable medical monitoring solutions, further improving user experience.

To simplify development, the CEM102 + RSL15 platform provides advanced hardware, extensive development support, firmware, software, and iOS, Android™ demo applications for continuous monitoring across multiple sensors (Figure 4).

Figure 4: Demo application designed by onsemi for the CEM102 evaluation board

Various accurate detection and measurement techniques for chemical currents open the door to new scientific advancements. With its compact size and ultra-low power consumption, this combination solution can further reduce the size of all terminal applications and extend their battery life. The solutions provided by the CEM102 and RSL15 platforms help engineers create compact, flexible, and cost-effective connected products for applications such as medical monitoring, like blood glucose monitoring devices, thereby helping patients effectively regulate blood sugar, reduce diabetes-related risks, and better integrate into our lives.

Electrochemical sensors are widely used in healthcare, environmental monitoring, and industrial safety fields, playing a crucial role in promoting social development. The potential of this technology far exceeds its current applications, and cutting-edge platforms like onsemi’s are sure to significantly advance scientific research and further explore new application scenarios.

To learn more about the CEM102 or explore onsemi’s sensing solutions, please click to read the original text.

⭐ Give a star so you can spot me in the crowd ⭐