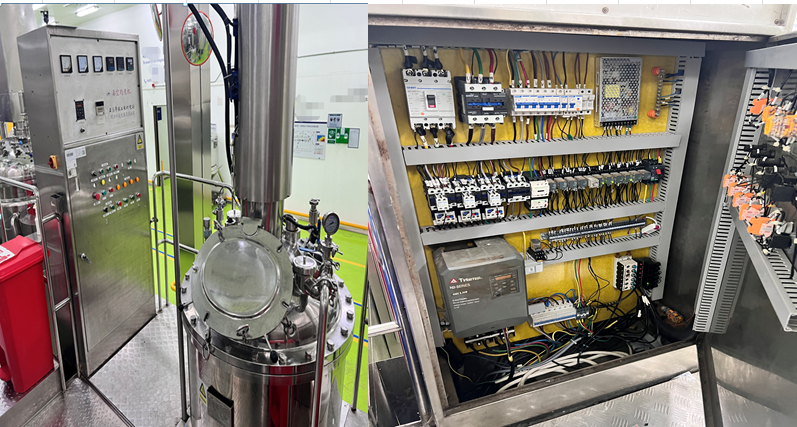

In the wave of industrial development, electrical control systems have always been the core force driving the improvement of production efficiency. From traditional button control to today’s PLC+HMI intelligent control, each technological iteration brings a qualitative leap. Today, let us step into the world of electrical transformation,exploring the secrets of upgrading button control to PLC+HMI control, unlocking a new future for industrial automation!Electrical transformation of equipment requires careful collection of various information, analyzing each aspect until fully understood.1 Hardware TransformationBefore Transformation After Transformation

After Transformation

2 Motor Types (Less Common)Multi-speed three-phase asynchronous motor

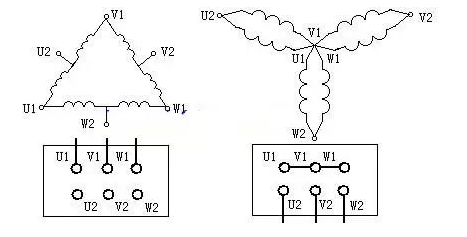

2 Motor Types (Less Common)Multi-speed three-phase asynchronous motor The stator winding of a three-phase dual-speed asynchronous motor has two connection methods:Δconnection and YY connection, as shown in the figure below.Wiring diagram of the stator winding of a three-phase dual-speed asynchronous motor

The stator winding of a three-phase dual-speed asynchronous motor has two connection methods:Δconnection and YY connection, as shown in the figure below.Wiring diagram of the stator winding of a three-phase dual-speed asynchronous motor Wiring Diagram

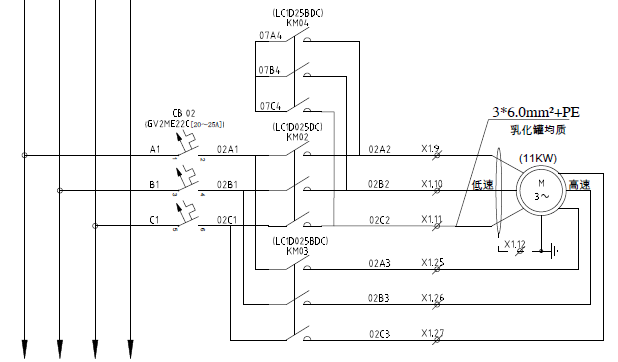

Wiring Diagram Deltaconnection for low-speed operation at 1460 RPM, contactor KM02 coil is powered for operation.Starconnection for low-speed operation at 1460 RPM, contactors KM03 and KM04 coils are powered for operation.Please note: KM02 and KM03 need to be interlocked; it is best to use 2 thermal relays for high and low speed.3. Frequency Converter (Less Common)3.1 TECO T310 Frequency Converter

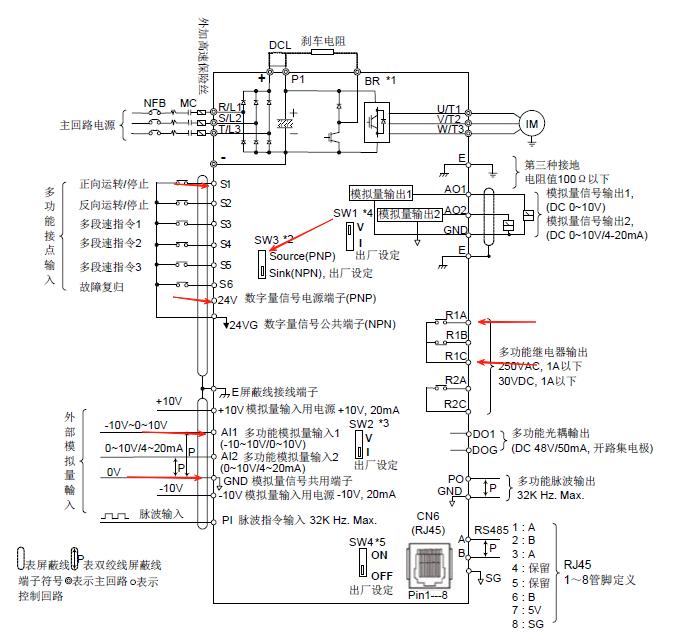

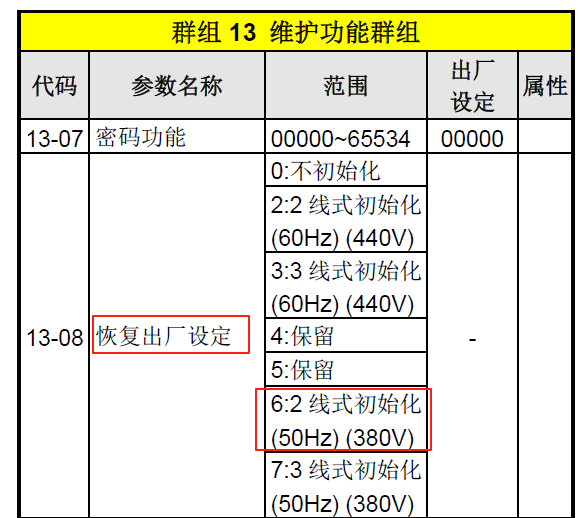

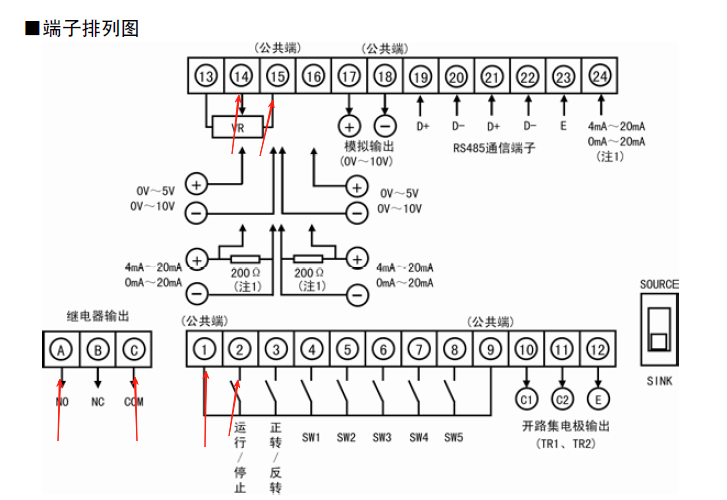

Deltaconnection for low-speed operation at 1460 RPM, contactor KM02 coil is powered for operation.Starconnection for low-speed operation at 1460 RPM, contactors KM03 and KM04 coils are powered for operation.Please note: KM02 and KM03 need to be interlocked; it is best to use 2 thermal relays for high and low speed.3. Frequency Converter (Less Common)3.1 TECO T310 Frequency Converter Using external terminal control:Start/Stop signal: S1, 24V. Use PNP signal, switch SW3 must be set to PNP.Speed setting: GND, AI1. 0~10V Please pay attention to the polarity.Fault: R1A, R1C.Specific Parameters:13-08 = 6 Restore factory settings

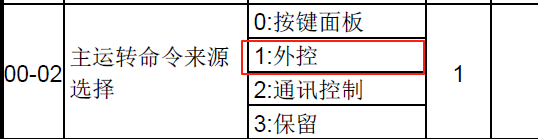

Using external terminal control:Start/Stop signal: S1, 24V. Use PNP signal, switch SW3 must be set to PNP.Speed setting: GND, AI1. 0~10V Please pay attention to the polarity.Fault: R1A, R1C.Specific Parameters:13-08 = 6 Restore factory settings 00-02 = 1 External terminal control

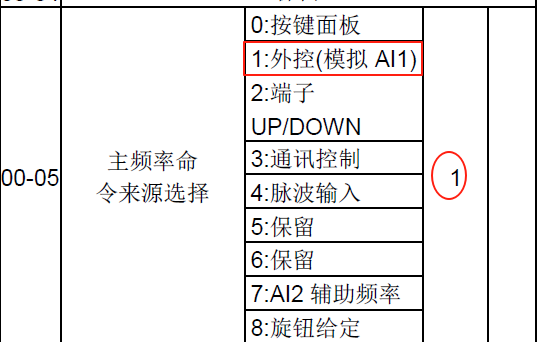

00-02 = 1 External terminal control 00-05 = 1 External (analog AI1)

00-05 = 1 External (analog AI1) 3.2 Panasonic VF200 Frequency Converter

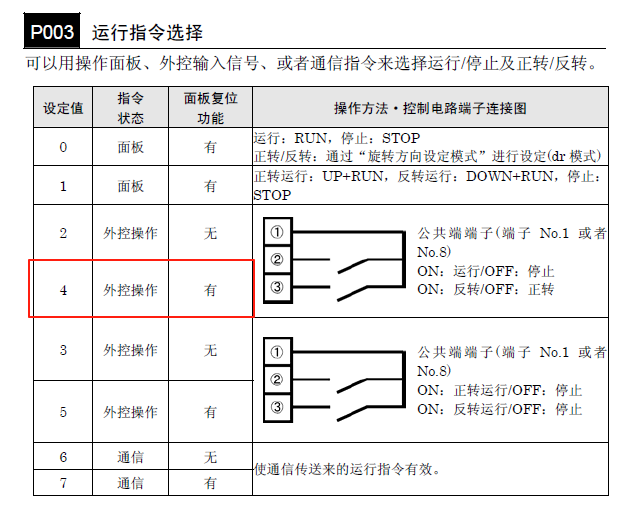

3.2 Panasonic VF200 Frequency Converter Using external terminal control:Start/Stop signal: 1, 2.Speed setting: 14+, 15-,Please pay attention to the polarity.Fault: A, C.Specific Parameters:P003 = 4 External control

Using external terminal control:Start/Stop signal: 1, 2.Speed setting: 14+, 15-,Please pay attention to the polarity.Fault: A, C.Specific Parameters:P003 = 4 External control P004 = 4 External operation 0-10V

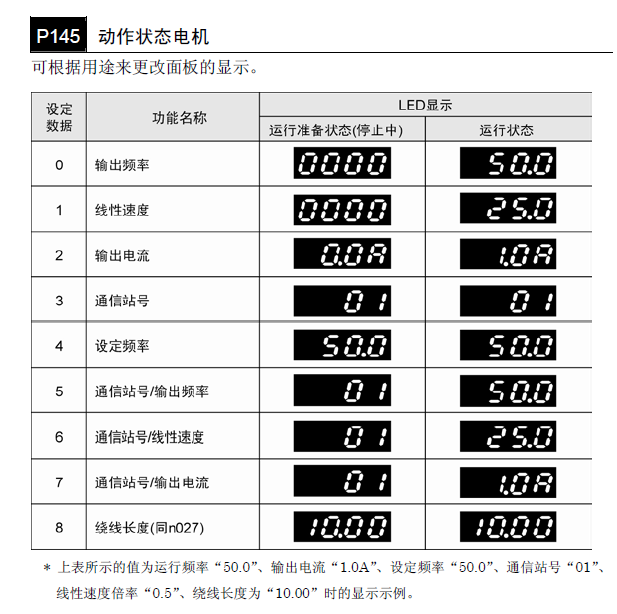

P004 = 4 External operation 0-10V P145 Action status of the motor, content displayed after running on the interface.Can display frequency, speed, current, etc.

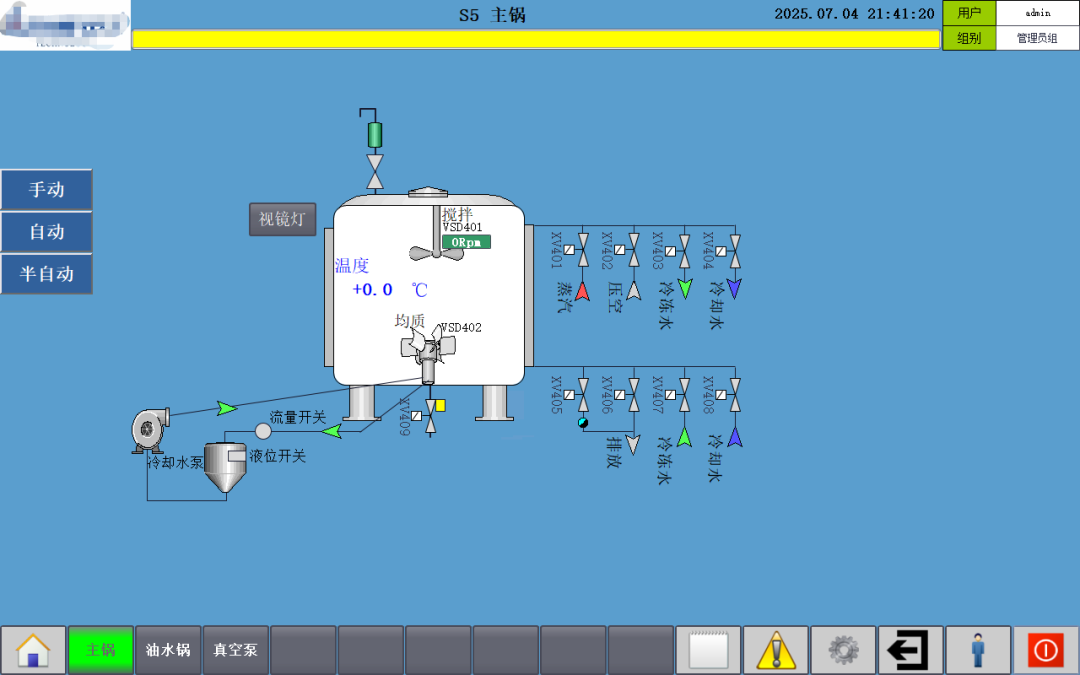

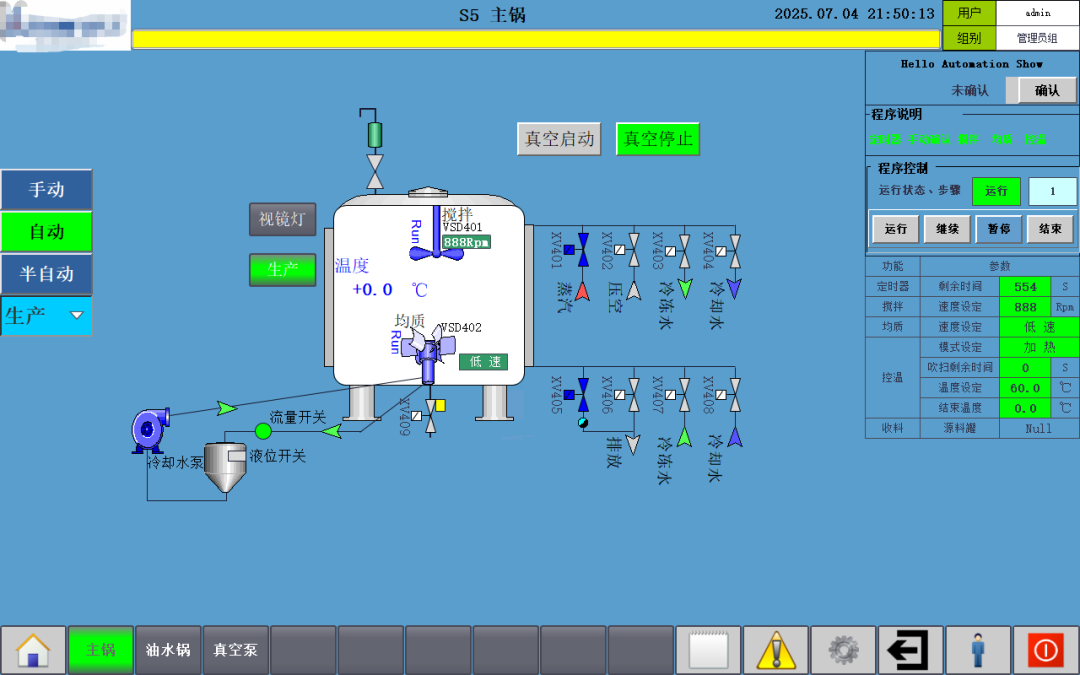

P145 Action status of the motor, content displayed after running on the interface.Can display frequency, speed, current, etc. 4. HMI Screen DisplayMain Screen

4. HMI Screen DisplayMain Screen Motor Drive Panel

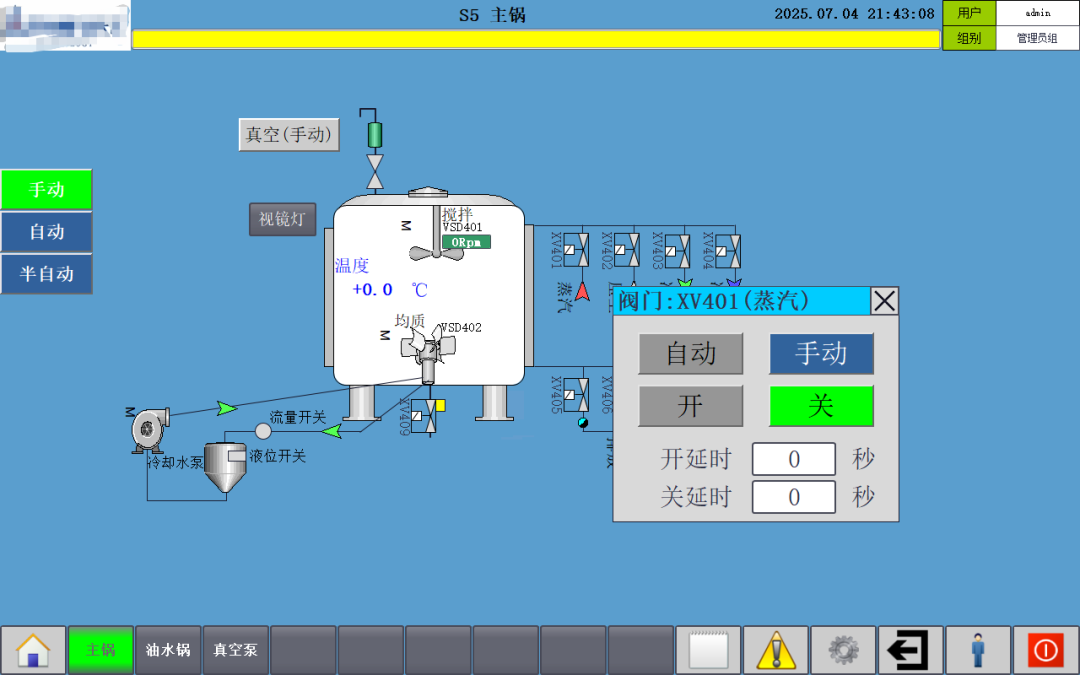

Motor Drive Panel Valve Drive Panel

Valve Drive Panel Automatic Recipe Interface

Automatic Recipe Interface Automatic Recipe Program Running

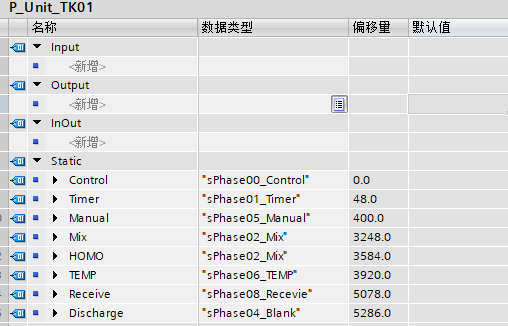

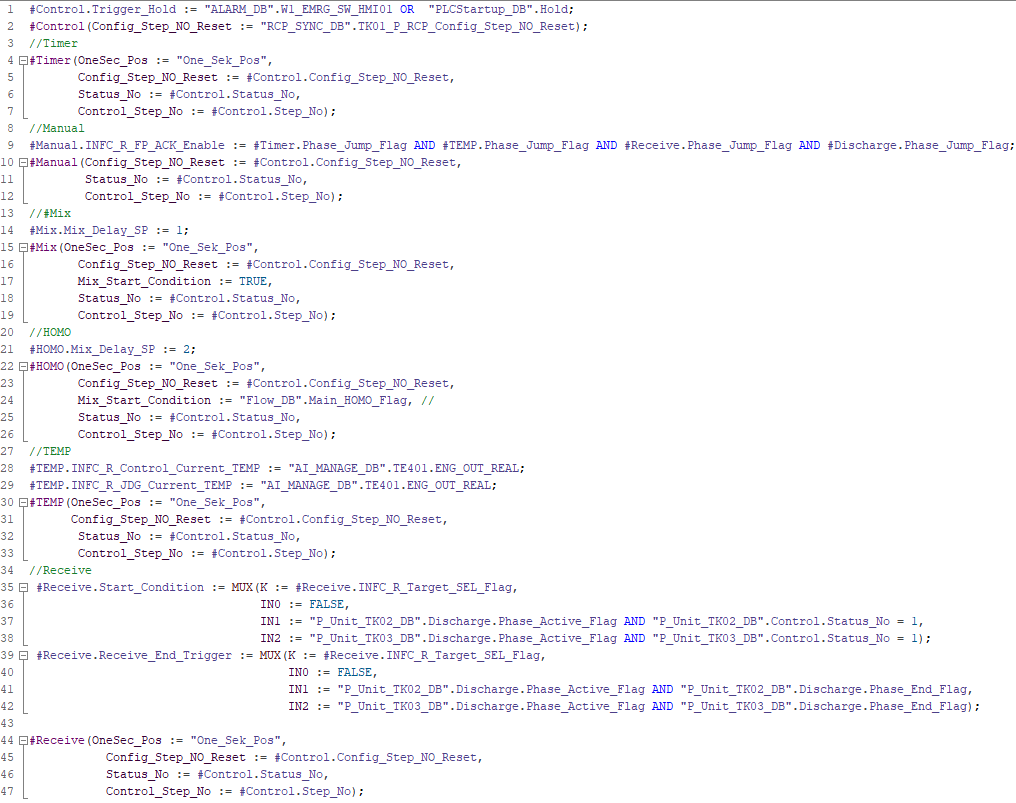

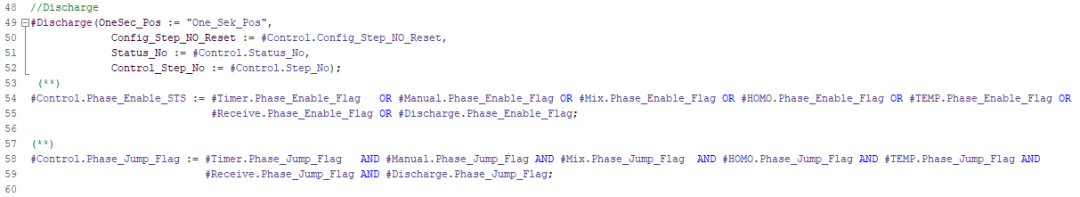

Automatic Recipe Program Running 5. Code Display (Modular Programming))

5. Code Display (Modular Programming))

Alright, this concludes our explanation for this session. Feel free to leave comments and discuss in the comment section.

On WeChat, reply with the keyword “Electrical Transformation” in the chat interface to obtain materials(not involving programming parts!).Previous Reviews:

| Implementation and Display of Audit Operation Records Based on TIA Portal Comfort Touch Screen |

| Siemens PLC1200/1500 Dynamic Encryption Timing Collection Program: Efficiently Ensuring Project Payments |

| Solution for Missing Panel Image Prompt When Downloading TIA Portal WinCC (No Update Package Required) |

| Siemens S7-1200 and S7-200 CN Modbus RTU Communication |

| Dynamic Display of Secondary Confirmation Window Position for Siemens TP Series Panels |

| New Ways to Access Automation Show Content, Thank You for Being with Us! |