Dear Automation Experts, today we will unveil how to keep your PLC clock accurate, as reliable as a Swiss watch! Are you ready? Let’s embark on this journey of time synchronization.

-

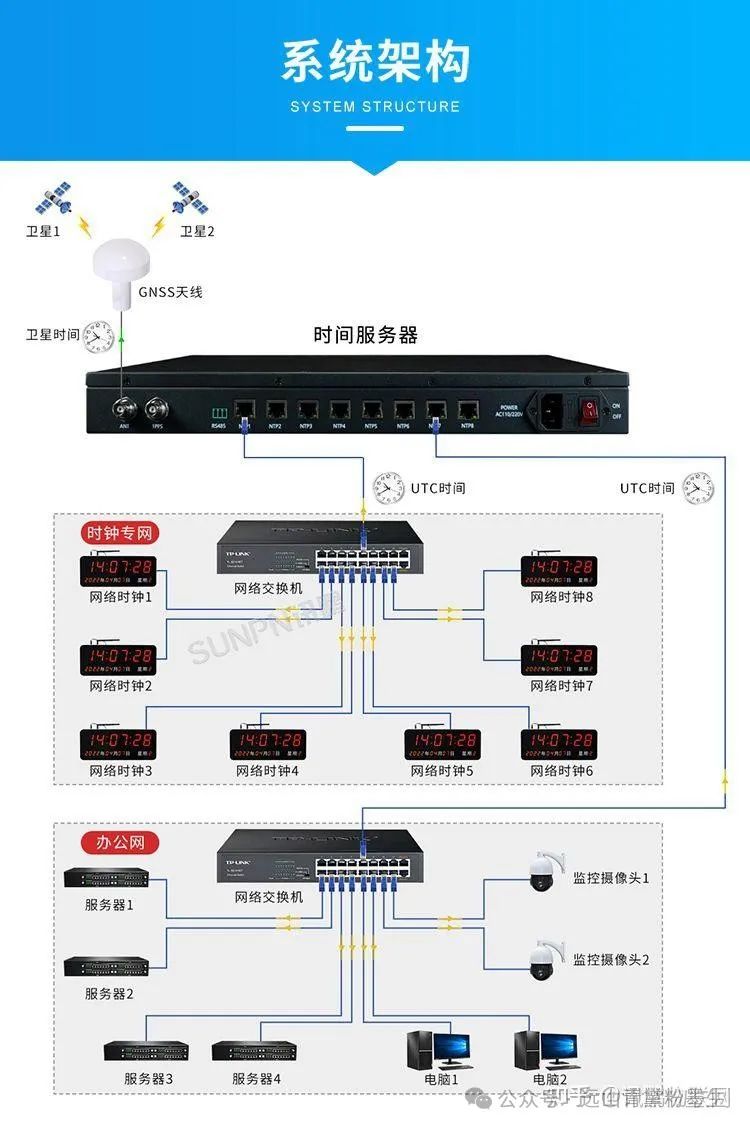

NTP Server Synchronization

The Network Time Protocol (NTP) is one of the most commonly used time synchronization methods.

The Network Time Protocol (NTP) is one of the most commonly used time synchronization methods.// Assume using MC protocol for communication

MOVP H1 D1000 // Set operation code: time synchronization

MOVP K1 D1001 // Select NTP server 1

MOVP K24 D1002 // Set synchronization interval to 24 hours

DMOVP K0 D1003 // Clear synchronization result storage

RST M100 // Reset synchronization completion flag

LD SM412 // Use 0.001 second clock pulse

ANDP M101 // M101 is the trigger condition to start synchronization

EP V // Rising edge detection

SET M100 // Set synchronization in progress flag

FIFOW D1000 K5 U3\

G39 // Send synchronization request to communication module

LD M100 // Check if synchronization is complete

ANI X20 // X20 is the communication completion signal (assumed)

AND= D1003 K0 // Check if synchronization was successful

RST M100 // Reset synchronization in progress flag

SET M102 // Set synchronization success flag

-

GPS Module Synchronization

// Assume GPS data is received via serial port

LD X0 // X0 is the signal for receiving GPS data

MOVP K4 D2000 // Select UTC time data

RST M200 // Reset GPS synchronization flag

BINDA D2001 D2010 // Convert year

BINDA D2002 D2011 // Convert month

BINDA D2003 D2012 // Convert date

BINDA D2004 D2013 // Convert hour

BINDA D2005 D2014 // Convert minute

BINDA D2006 D2015 // Convert second

// Update PLC clock

MOVP D2010 SD210 // Update year

MOVP D2011 SD211 // Update month

MOVP D2012 SD212 // Update date

MOVP D2013 SD213 // Update hour

MOVP D2014 SD220 // Update minute (high 8 bits)

MOVP D2015 SD220 // Update second (low 8 bits)

SET M200 // Set GPS synchronization completion flag

-

Radio Time Signal Receiver

Some regions provide high-precision radio time signals (such as DCF77, WWVB, etc.).

Some regions provide high-precision radio time signals (such as DCF77, WWVB, etc.).

Implementation Steps: a) Install a compatible radio time receiver. b) Connect the receiver to the PLC’s digital input. c) Program the PLC to decode the time signal and update the internal clock.

-

Master-Slave PLC Synchronization

-

HMI or SCADA System Synchronization

-

External Precision Clock Module

Use specialized high-precision clock modules as time sources.

Use specialized high-precision clock modules as time sources.-

Manual Synchronization and Calibration

-

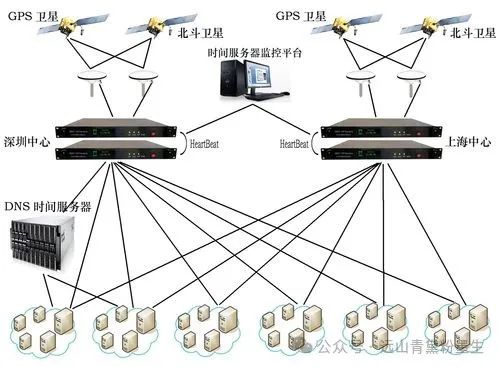

Redundant Synchronization: Use a combination of multiple methods, such as primarily using NTP, with GPS as a backup. -

Timezone Handling: Pay attention to timezone conversions, especially in systems across time zones. -

Daylight Saving Time Adjustment: Program automatic handling of daylight saving time changes (if applicable). -

Synchronization Frequency Optimization: Adjust synchronization frequency based on the drift rate of the PLC clock. -

Error Handling: Implement robust error detection and handling mechanisms to prevent erroneous time from contaminating the system. -

Logging: Record each synchronization operation for subsequent analysis and troubleshooting. -

Performance Considerations: Ensure that frequent time synchronization does not significantly impact the PLC’s primary control functions.