Du Yongjie 1,Lu Yi 1,Zhao Jing 2

(1.China Jiliang University, School of Measurement and Testing Engineering, Hangzhou, Zhejiang 310018;2.Hangzhou Woolay Intelligent Technology Co., Ltd., Hangzhou, Zhejiang 310018)

Abstract: Currently, the liquid level measurement of asphalt tanks at mixing stations mainly relies on manual estimation and float measurement. To address the issues of large measurement errors and the inability to automatically collect data, this paper designs a cloud-based asphalt tank liquid level monitoring system. The system consists of sensors, a monitoring host, RabbitMQ (message broker software), and an asphalt tank monitoring cloud platform. Pressure transmitters and temperature transmitters are used to obtain asphalt liquid level and temperature information, which is then transmitted to an A/D converter and input into an STM32 microcontroller. The information is uploaded to the RabbitMQ message queue via the NB-IoT (Narrowband Internet of Things) network, parsed, and stored in a database. Finally, the data from the database is statistically processed and displayed on the asphalt tank monitoring cloud platform. Calibration experiments show that the measurement accuracy of the asphalt liquid level is better than 5 cm, meeting the requirements for asphalt tank liquid level measurement. The calculated asphalt quality can provide relevant data for the asphalt inventory management and procurement of mixing stations.

Keywords: Liquid Level Monitoring; Asphalt Tank; Cloud Platform; System Design; Data Collection; Information Upload; Remote Monitoring; Calibration Experiment

Classification Number: TN931+.3-34;TP277 Document Identification Code: A

Article Number: 1004-373X(2022)02-0011-05

0 Introduction

The asphalt tank at the mixing station is a device specifically used for storing asphalt. To grasp the liquid level information of the asphalt tank in real-time, continuous measurement of the asphalt liquid level is very important. By monitoring the liquid level of the asphalt tank, the daily consumption of asphalt at the mixing station can be analyzed. Traditional asphalt mixing stations use manual estimation and float measurement for the liquid level of asphalt tanks, lacking electronic data output, making online monitoring difficult. Current measurement solutions mainly include: Guan Xuezhong et al. measure the liquid level of oil tanks based on the principle of ultrasonic distance measurement[1], but the speed of ultrasonic propagation is easily affected by asphalt vapor, and the high internal temperature of the asphalt tank significantly impacts ultrasonic propagation; Liu Peng utilizes radar distance measurement principles for liquid level measurement[2], but the high-temperature vapor inside can condense on the sensor surface, affecting measurement results and even causing complete failure, resulting in high maintenance costs. This paper’s system uses a single flange pressure transmitter to collect asphalt tank liquid level information, which has low maintenance costs and is unaffected by high-temperature vapor.

After collecting the liquid level information, it needs to be uploaded to the cloud platform. Mixing stations are often located in suburban areas, far from base stations, where 2G/3G/4G network signals are poor and costs are high. However, NB-IoT has high gain, wide coverage, and low monthly fees, which can effectively solve signal and cost issues. In the same base station scenario, NB-IoT can increase the number of connected devices by 50 to 100 times compared to other wireless communication technologies. In the future, as the number of IoT devices increases, NB-IoT devices will not be affected[3-4]. Considering the network environment, module costs, power consumption, and traffic fees at the mixing station site, this system ultimately chooses the NB-IoT network.

With the development of cloud computing[5-6] and big data technology[7] , companies can remotely monitor various data during the production process at the mixing station through the cloud platform, controlling material ratios and formulating production plans based on monitoring data[8]. By monitoring the production process, the production quality of the mixing station can be improved.

Based on NB-IoT communication technology and cloud computing technology, this paper designs and develops an asphalt tank liquid level monitoring system that monitors the liquid level and quality of asphalt in real-time, enabling the asphalt mixing station to comprehensively grasp inventory information and providing solutions for fine control of material costs for enterprises[9].

1 Overall System Design

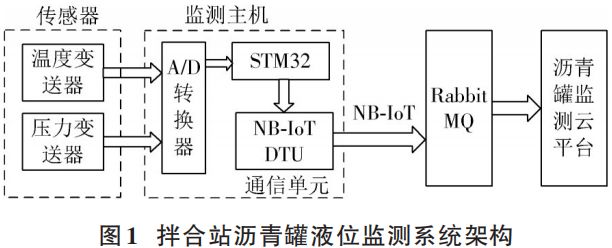

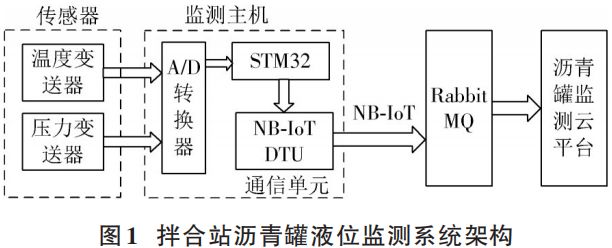

The asphalt tank liquid level monitoring system consists of sensors, a monitoring host, RabbitMQ, and an asphalt tank monitoring cloud platform. The architecture of the asphalt tank liquid level monitoring system is shown in Figure 1.

When measuring the liquid level of asphalt with a pressure transmitter, the sensing diaphragm needs to be in direct contact with the asphalt liquid. However, asphalt liquid is viscous and high-temperature, and the sensing diaphragm of ordinary pressure transmitters has a small space, making it very easy for asphalt liquid to adhere to the inner wall, leading to inaccurate measurement results or even complete failure. Therefore, this paper considers using a single flange pressure transmitter, which has a pressure sensing diaphragm with a pressure pipe set outside, and contains silicon oil inside, blocking direct contact between the asphalt liquid and the sensor, greatly improving the stability of the sensor. The measured data will not experience significant fluctuations or stagnation.

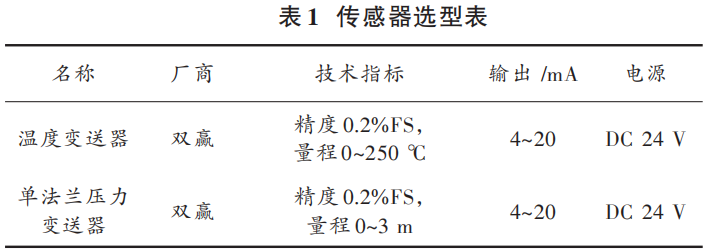

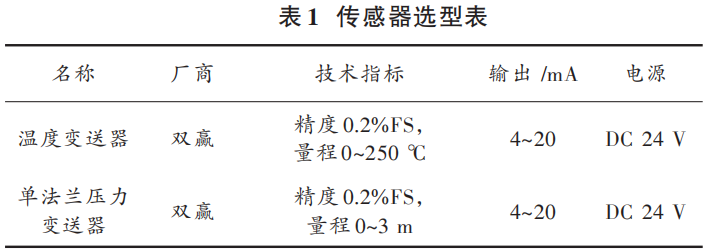

The paper collects asphalt pressure and temperature information through pressure transmitters and temperature transmitters; then the information is converted into a 4-20 mA current signal through the built-in circuit, and transmitted to the STM32 for on-site data collection of the asphalt tank liquid level monitoring system. Since the density and viscosity of asphalt are greatly affected by temperature, the temperature needs to reach above 130 ℃ to accurately calculate the liquid level based on pressure and asphalt density. Therefore, this paper needs to simultaneously collect asphalt temperature and pressure, with the temperature inside the asphalt tank ranging from 130~190 ℃, and the height of the asphalt tank in this monitoring system is 2.35m, with sensor selection shown in Table 1.

When measuring the liquid level of asphalt with a pressure transmitter, the sensing diaphragm needs to be in direct contact with the asphalt liquid. However, asphalt liquid is viscous and high-temperature, and the sensing diaphragm of ordinary pressure transmitters has a small space, making it very easy for asphalt liquid to adhere to the inner wall, leading to inaccurate measurement results or even complete failure. Therefore, this paper considers using a single flange pressure transmitter, which has a pressure sensing diaphragm with a pressure pipe set outside, and contains silicon oil inside, blocking direct contact between the asphalt liquid and the sensor, greatly improving the stability of the sensor. The measured data will not experience significant fluctuations or stagnation.

The paper collects asphalt pressure and temperature information through pressure transmitters and temperature transmitters; then the information is converted into a 4-20 mA current signal through the built-in circuit, and transmitted to the STM32 for on-site data collection of the asphalt tank liquid level monitoring system. Since the density and viscosity of asphalt are greatly affected by temperature, the temperature needs to reach above 130 ℃ to accurately calculate the liquid level based on pressure and asphalt density. Therefore, this paper needs to simultaneously collect asphalt temperature and pressure, with the temperature inside the asphalt tank ranging from 130~190 ℃, and the height of the asphalt tank in this monitoring system is 2.35m, with sensor selection shown in Table 1.

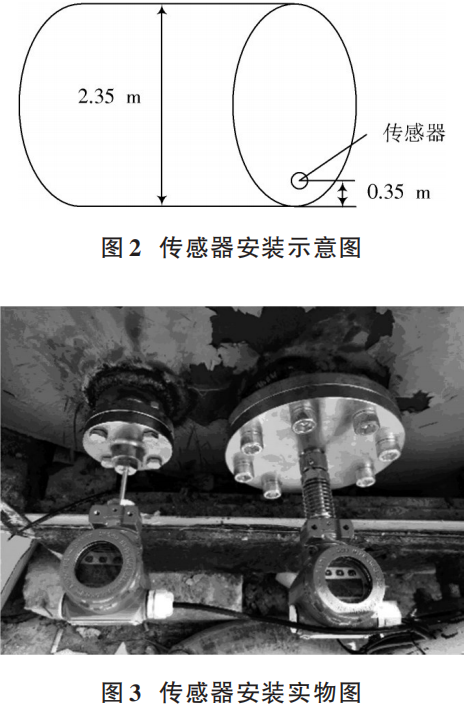

The asphalt tank is a horizontal cylinder; for convenient installation and maintenance, the sensor is installed on the side wall of the asphalt tank, 0.35 m above the bottom. The sensor installation position is shown in Figures 2 and 3.

The asphalt tank is a horizontal cylinder; for convenient installation and maintenance, the sensor is installed on the side wall of the asphalt tank, 0.35 m above the bottom. The sensor installation position is shown in Figures 2 and 3.

1.2 Communication Unit

The NB-IoT data transmission terminal uses a certain company’s N560NB-IoTDTU, which includes a heartbeat packet function, allowing the device to remain online as long as it is powered. By setting the RabbitMQ domain name and message queue name, information upload can be realized[10]. The power supply voltage range is DC 6~24V, and this system uses DC 24 V for power supply. The serial data interface supports RS 232, RS 485, and TTL, with a serial baud rate of 1200~115200b/s.

The entire system’s data transmission structure includes both local data transmission and cloud data transmission, as shown in Figure 4. After the monitoring host’s STM32 microcontroller receives the converted digital signal, it will package the data, bundling the temperature and pressure information collected at the same time together. The STM32 interacts with the NB-IoT data transmission terminal for command and data exchange via the RS 232 protocol. Data is uploaded to the RabbitMQ server through the NB-IoT network. During transmission, there may be brief disconnections, but the transmitter continues to send data to the STM32 microcontroller, which needs to temporarily store the data in its memory until the network is normal again to upload the data. After receiving the data, the RabbitMQ server retrieves the information from the corresponding message queue and stores the obtained information in the SQL Server database.

1.3 Asphalt Tank Monitoring Cloud Platform

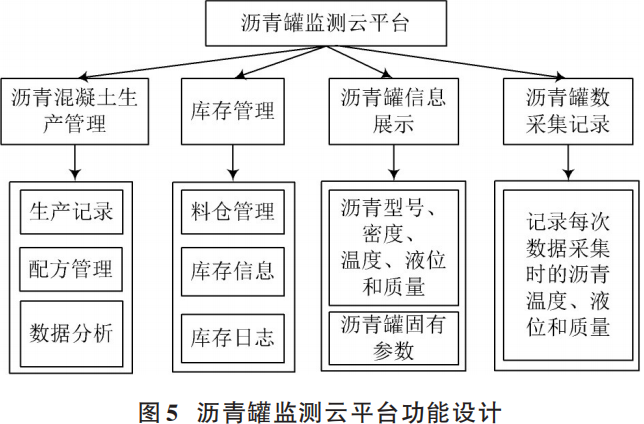

Monitoring the liquid level of the asphalt tank is essentially to ensure the production of asphalt concrete. By setting up an ODBC on the upper computer in the asphalt mixing station control room to access the database[11], production record data is collected from the asphalt concrete production control system, including the quality of asphalt consumed for each batch of asphalt concrete. Using the quality of asphalt consumed in production records as a standard value can calibrate the asphalt quality calculated by this system, achieving error compensation for the system. The functional design of the cloud platform is shown in Figure 5.

The asphalt tank monitoring cloud platform includes the following functions:

1) Asphalt Concrete Production Management: Divided into production records, formula management, and data analysis. Production records include the consumption quality and ratio of various raw materials, and based on production needs, asphalt concrete production formulas can be set on the cloud platform, which are then issued to the operation room of the mixing station.

2) Inventory Management: Records every asphalt outflow and inflow information, including asphalt type and tank number, helping the mixing station to reasonably control asphalt inventory levels.

3) Asphalt Tank Information Display: Displays asphalt type, density, temperature, liquid level, and quality, as well as inherent parameters of the asphalt tank.

4) Asphalt Tank Data Collection Records: Stores the asphalt temperature, liquid level, and quality collected at all time points in the database for daily asphalt consumption analysis.

2 Hardware Design

2.1 Monitoring Host Design

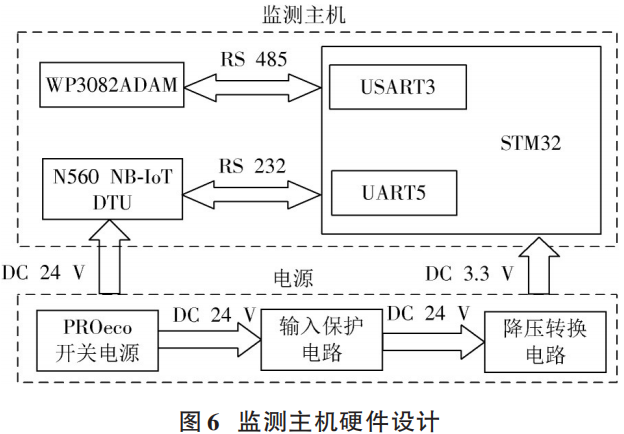

The monitoring host includes a main control board based on STM32, N560 NB-IoT DTU, and A/D converter WP3082ADAM. This system uses the ARM Cortex-M3 core STM32F103RCT6 as the control chip, whose excellent performance is very suitable for the control unit of the monitoring host. The hardware design of the monitoring host is shown in Figure 6, WP3082ADAM converts the 4-20 mA signal output from the transmitter into a digital signal, which is then transmitted to the STM32 main control board via RS 485, and then the signal is transmitted to the N560 NB-IoT DTU via RS 232.

The WP3082ADAM used in this system is an A/D converter with 8-channel single-ended analog input (DC type 4-20 mA). It uses the RS 485 Modbus RTU standard communication. The A/D conversion bit is 12, and the analog input accuracy is ±0.02 mA. The external power supply for this device is DC 9 V~30 V /2 W, fully meeting the needs for collecting asphalt tank liquid level and temperature signals.

The RS 485 communication module uses the MAX1487 chip, which operates in half-duplex mode, capable of eliminating most interference, and the receiver can detect small signals of 200 mV.The RS 232 communication module uses the MAX3232 chip, which utilizes two charge pumps to achieve complete RS 232 performance. The MAX3232 can maintain data transmission rates above 120 Kb/s, while maintaining normal RS 232 levels.

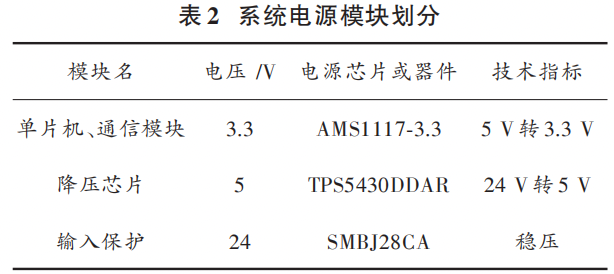

2.2 Power Supply Module

The power supply module is divided into switching power supply, input protection, and step-down conversion. The switching power supply converts 220V AC to 24V DC, supplying power to the NB-IoT terminal and the A/D converter. The step-down conversion circuit converts 24V DC to DC 3.3V, supplying power to the RS 485, RS 232 communication modules, and STM32. The power supply requirements for each module are shown in Table 2.

When the circuit is subjected to instantaneous voltage surges, the transient suppression diode in the input protection circuit can instantly change from high-resistance to low-resistance characteristics, absorbing energy to stabilize the input voltage[13], preventing damage to the circuit due to surges.

3 Experimental Results Analysis

3.1 Monitoring System Data Display

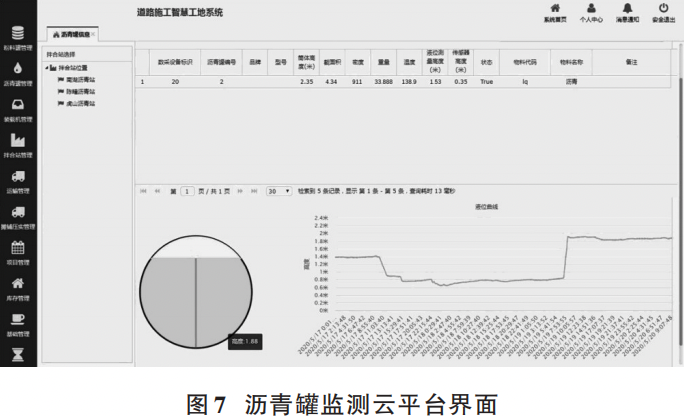

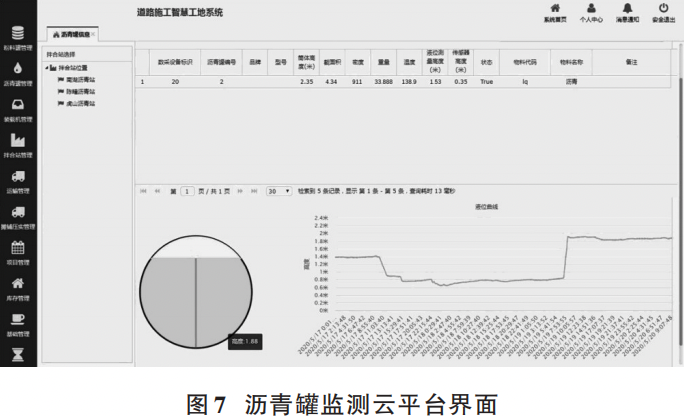

The asphalt tank monitoring cloud platform interface includes the main interface and sub-interfaces. The main interface displays the real-time status of the asphalt tank, liquid level height chart, and liquid level curve chart, while the sub-interface contains functions of other modules. The main interface is shown in Figure 7.

3.2 Asphalt Liquid Level Measurement Principle

According to the principle of hydrostatic liquid level measurement, the static pressure of asphalt is related to the liquid level and density of asphalt. The pressure formula is:

Where: P is the static pressure exerted by the asphalt on the pressure transmitter; ρ is the density of the asphalt liquid; g is the acceleration due to gravity, taken as 9.8 m/s2; h is the vertical distance from the pressure transmitter to the surface of the asphalt liquid.

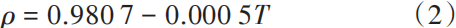

The default density value used by the chip in the pressure transmitter is 1 g/cm3, but the density of asphalt changes with temperature, and the density of asphalt liquid varies among different batches and types. Therefore, it is necessary to convert to obtain the actual liquid level value. The asphalt type used in the calibration experiment is 70# asphalt, and the relationship between the density of asphalt and temperature provided by the asphalt supplier is:

Where: ρ is the density of the asphalt liquid; T is the temperature of the asphalt liquid. The temperature of the asphalt is measured by the temperature transmitter, and then the actual liquid level is calculated based on the asphalt density and the relationship with the liquid level measured by the pressure transmitter.

3.3 Calibration Experiment of Monitoring System Asphalt Liquid Level

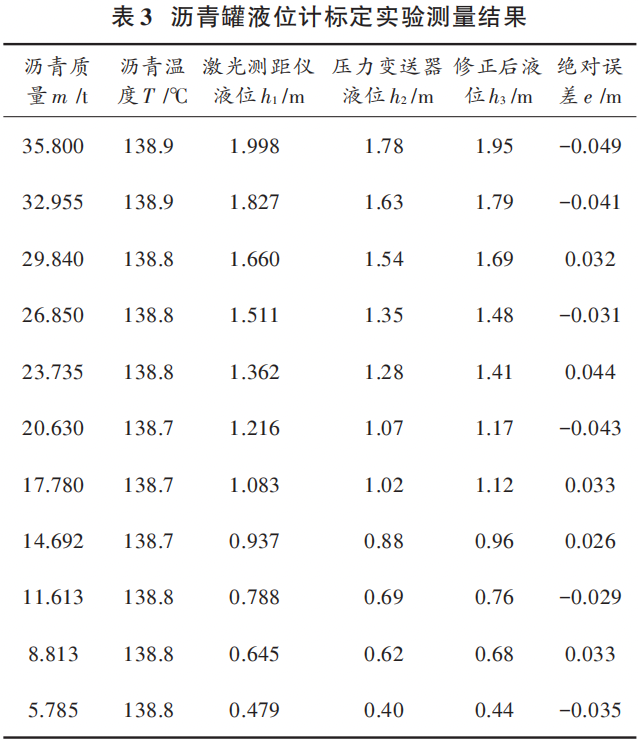

To complete the calibration experiment of the asphalt liquid level, data collection software was installed in the asphalt mixing station control room to read the quality of asphalt used for each batch of asphalt concrete during production. A laser distance meter was used to measure the asphalt liquid level, which was compared with the level measured by the pressure transmitter. The accuracy of the laser distance meter is ±1.5 mm, which meets the calibration accuracy requirements of this system. The volume of the asphalt tank at the mixing station is 43m3. During production at the asphalt mixing station, the metering hopper weighs the asphalt used each time, and the quality obtained from the metering hopper serves as the standard value. The experimental steps are as follows:

1) Completely empty the asphalt inside the tank, including any residual asphalt on the inner walls. When the asphalt tank is empty, adjust the pressure transmitter to display the liquid level as 0m.

2) The asphalt transport vehicle fills the asphalt tank until the liquid level reaches 2m, then stops loading. The weight difference of the asphalt transport vehicle entering and exiting the station, measured by the weighing scale at the mixing station, is 35.8t, indicating that the quality of asphalt loaded is 35.8t, and the temperature transmitter measures the asphalt temperature at 138.9℃, calculating the density of asphalt to be 0.911 g/cm3. Production of asphalt mixture begins when the cumulative asphalt usage reaches around 3t. After the pressure transmitter shows stable liquid level values, the liquid level is recorded, and a measurement is taken with the laser distance meter.

The measurement results are shown in Table 3, where m is the total quality of asphalt in the tank, h3 is the corrected value of the pressure transmitter liquid level, and e is the absolute error between the corrected pressure transmitter liquid level and the laser distance meter liquid level.

The temperature change of asphalt is ±0.2 ℃, and the impact on asphalt density is negligible. Taking the laser distance meter measured asphalt liquid level as the reference, the absolute value of the absolute error between the pressure transmitter liquid level and the laser distance meter measured liquid level is at most 0.049m, which meets the accuracy requirements for asphalt liquid level measurement.

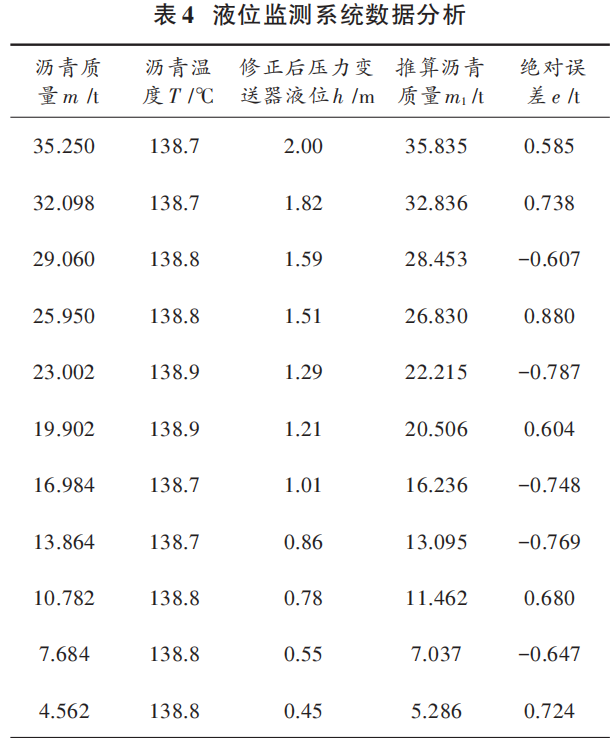

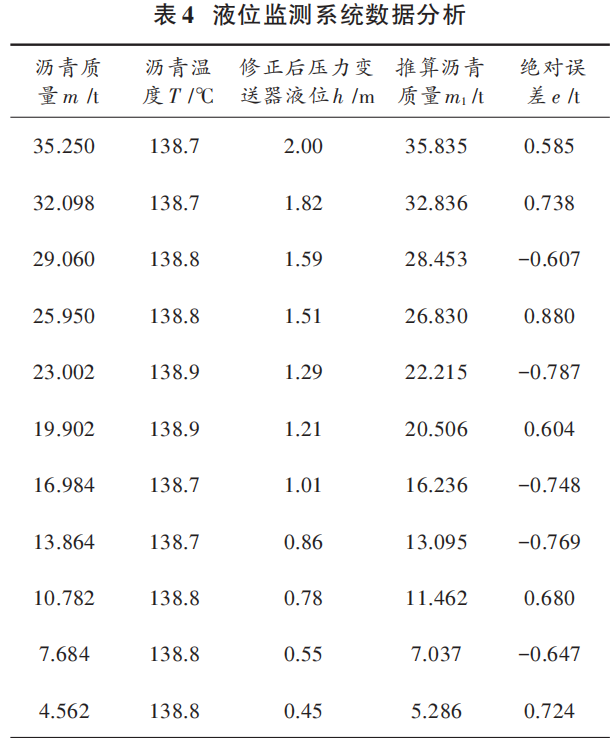

3.4 Data Analysis of the Monitoring System After Calibration

After completing the calibration of the monitoring system’s liquid level, a second measurement of the asphalt liquid level is conducted, and the asphalt quality is calculated. The experimental steps are the same as in Section 3.3, with the second loading of asphalt conducted by the asphalt transport vehicle. The quality of asphalt loaded is 35.25 t, and the temperature transmitter measures the asphalt temperature at 138.9 ℃, calculating the density of asphalt to be 0.911 g/cm3. Based on the liquid level measured by the pressure transmitter, combined with the asphalt density and the dimensions of the asphalt tank, the asphalt quality m1 is calculated. The measurement results are shown in Table 4, where e is the absolute error between the estimated asphalt quality and the actual asphalt quality.

The absolute value of the absolute error between the asphalt quality calculated from the liquid level measured by the pressure transmitter and the actual value is at most 0.88 t. The source of error is from the asphalt liquid level measurement error. Additionally, since asphalt liquid is not a pure liquid, some asphalt may solidify, leading to errors in the calculation of asphalt quality. However, the calculated asphalt quality can still serve as a reference for asphalt procurement and provide data for production planning.

This system uses a single flange pressure transmitter to measure asphalt liquid level, solving the impact of high-temperature vapor and asphalt coking on the sensor. It uploads measurement data via the NB-IoT network, addressing issues of poor network environment and high costs. By integrating cloud computing technology, secure and stable remote monitoring is achieved. Testing on-site at the asphalt mixing station indicates that the asphalt liquid level measurement meets accuracy requirements. The calculated asphalt quality improves inventory management and provides technical support for the refined management of the mixing station.

Note: The corresponding author of this paper is Lu Yi.

[1] Guan Xuezhong, Sun Zhanwen. Wireless Monitoring System for Oil Tank Liquid Level Based on Microcontroller[J]. Automation Technology and Applications, 2020, 39(2):138-142.

[2] Liu Peng. Discussion on the Application of Radar Level Gauge in the Petrochemical Industry[J]. Oil Depot and Gas Station, 2012, 21(5):31-34.

[3] Yang Youliang, Chen Yuqing, Ma Cuihong. Research on a Prepaid Gas Meter Device Using NB-IoT Technology[J]. Modern Electronic Technology, 2020, 43(12):91-94.

[4] Wang Yingqiang, Zhang Weigang, Wang Honggang. Design of an Agricultural Data Collection System Based on NB-IoT[J]. Computer Technology and Development, 2020, 30(2):206-210.

[5] Luo Junzhou, Jin Jiahui, Song Aibo, et al. Cloud Computing: Architecture and Key Technologies[J]. Journal of Communications, 2011, 32(7):3-21.

[6] Lin Chuang, Su Wenbo, Meng Kun, et al. Cloud Computing Security: Architecture, Mechanisms, and Model Evaluation[J]. Journal of Computer Science, 2013, 36(9):1765-1784.

[7] Zhang Yin, Chen Min, Liao Xiaofei. Current Status and Prospects of Big Data Applications[J]. Computer Research and Development, 2013, 50(z2):216-233.

[8] Fan Wenjie. Information Management of Railway Concrete Mixing Stations in the Context of Big Data[J]. China Informatization, 2018(4):80-82.

[9] Yan Chengfei. Analysis of Factors Affecting Production Yield and Cost in Asphalt Mixing Stations[J]. Enterprise Technology Development, 2014, 33(18):159-160.

[10] Yu Yongcheng, Weng Qiuhua, Duan Qing, et al. Research on the Application of RabbitMQ in Meteorological Communication Systems[J]. Computer Technology and Development, 2020, 30(4):216-220.

[11] He Mingqing. Research on Report Solutions Based on Database for Injection Station Control Systems[J]. China Equipment Engineering, 2020(13):224-225.

[12] Xu Tianzong. Data Collection Platform Based on Power Line Carrier for Coal Mine Longwall Mining Face[D]. Qingdao: Shandong University of Science and Technology, 2017.

[13] Wang Jun, Li Yong, Lu Bing, et al. Simulation of the Effect of Transient Voltage Suppression Diodes on the Explosive Characteristics of Semiconductor Bridge Transducers[J]. Energetic Materials, 2019, 27(10):837-844.

The absolute value of the absolute error between the asphalt quality calculated from the liquid level measured by the pressure transmitter and the actual value is at most 0.88 t. The source of error is from the asphalt liquid level measurement error. Additionally, since asphalt liquid is not a pure liquid, some asphalt may solidify, leading to errors in the calculation of asphalt quality. However, the calculated asphalt quality can still serve as a reference for asphalt procurement and provide data for production planning.

This system uses a single flange pressure transmitter to measure asphalt liquid level, solving the impact of high-temperature vapor and asphalt coking on the sensor. It uploads measurement data via the NB-IoT network, addressing issues of poor network environment and high costs. By integrating cloud computing technology, secure and stable remote monitoring is achieved. Testing on-site at the asphalt mixing station indicates that the asphalt liquid level measurement meets accuracy requirements. The calculated asphalt quality improves inventory management and provides technical support for the refined management of the mixing station.

Note: The corresponding author of this paper is Lu Yi.

[1] Guan Xuezhong, Sun Zhanwen. Wireless Monitoring System for Oil Tank Liquid Level Based on Microcontroller[J]. Automation Technology and Applications, 2020, 39(2):138-142.

[2] Liu Peng. Discussion on the Application of Radar Level Gauge in the Petrochemical Industry[J]. Oil Depot and Gas Station, 2012, 21(5):31-34.

[3] Yang Youliang, Chen Yuqing, Ma Cuihong. Research on a Prepaid Gas Meter Device Using NB-IoT Technology[J]. Modern Electronic Technology, 2020, 43(12):91-94.

[4] Wang Yingqiang, Zhang Weigang, Wang Honggang. Design of an Agricultural Data Collection System Based on NB-IoT[J]. Computer Technology and Development, 2020, 30(2):206-210.

[5] Luo Junzhou, Jin Jiahui, Song Aibo, et al. Cloud Computing: Architecture and Key Technologies[J]. Journal of Communications, 2011, 32(7):3-21.

[6] Lin Chuang, Su Wenbo, Meng Kun, et al. Cloud Computing Security: Architecture, Mechanisms, and Model Evaluation[J]. Journal of Computer Science, 2013, 36(9):1765-1784.

[7] Zhang Yin, Chen Min, Liao Xiaofei. Current Status and Prospects of Big Data Applications[J]. Computer Research and Development, 2013, 50(z2):216-233.

[8] Fan Wenjie. Information Management of Railway Concrete Mixing Stations in the Context of Big Data[J]. China Informatization, 2018(4):80-82.

[9] Yan Chengfei. Analysis of Factors Affecting Production Yield and Cost in Asphalt Mixing Stations[J]. Enterprise Technology Development, 2014, 33(18):159-160.

[10] Yu Yongcheng, Weng Qiuhua, Duan Qing, et al. Research on the Application of RabbitMQ in Meteorological Communication Systems[J]. Computer Technology and Development, 2020, 30(4):216-220.

[11] He Mingqing. Research on Report Solutions Based on Database for Injection Station Control Systems[J]. China Equipment Engineering, 2020(13):224-225.

[12] Xu Tianzong. Data Collection Platform Based on Power Line Carrier for Coal Mine Longwall Mining Face[D]. Qingdao: Shandong University of Science and Technology, 2017.

[13] Wang Jun, Li Yong, Lu Bing, et al. Simulation of the Effect of Transient Voltage Suppression Diodes on the Explosive Characteristics of Semiconductor Bridge Transducers[J]. Energetic Materials, 2019, 27(10):837-844.

Author Information:

Du Yongjie(1995—),male, from Lishui, Zhejiang, master’s student, research direction is precision detection technology.

Lu Yi(1979—),male, from Yangzhou, Jiangsu, doctoral student, associate professor, research direction is precision detection technology and automated testing of automotive parts.

Zhao Jing(1980—),female, company director, engineer, research direction is precision detection technology.

-End-

Click the link below to view historical articles

Good papers are “revised”!

CNKI’s continuous price increase is suspected of monopoly; how should academia and business balance?

Directory of Modern Electronic Technology 2019, Issue 12

Which universities published the most SCI papers and authorized patents in 2017?

Modern Electronic Technology Selected in the Overview of Core Chinese Journals

Academician of the Chinese Academy of Sciences: The dominance of SCI in papers stifles scientific creativity

How to write a “Nature” article overnight, listen to what the academicians have to say!

👇Scan the code to enter the “Modern Electronic Technology Fan Group”

Come scan the code to join the group~