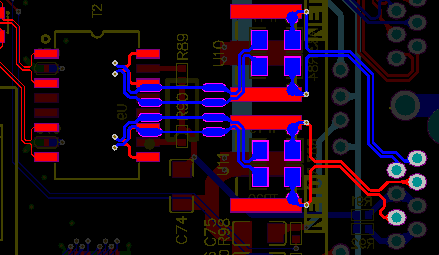

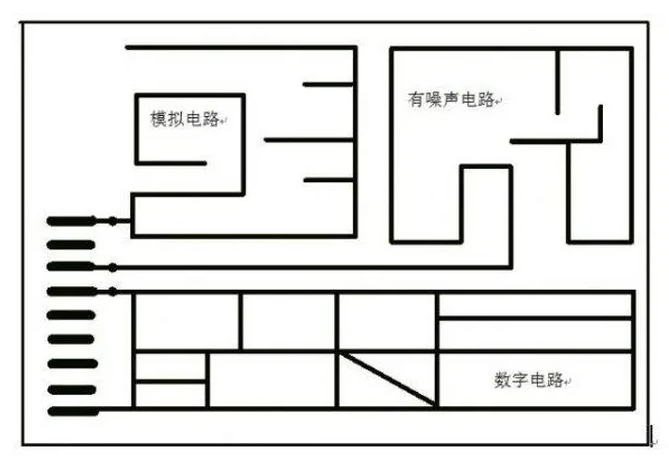

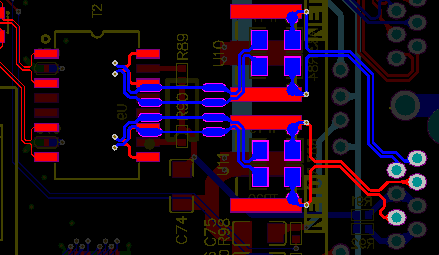

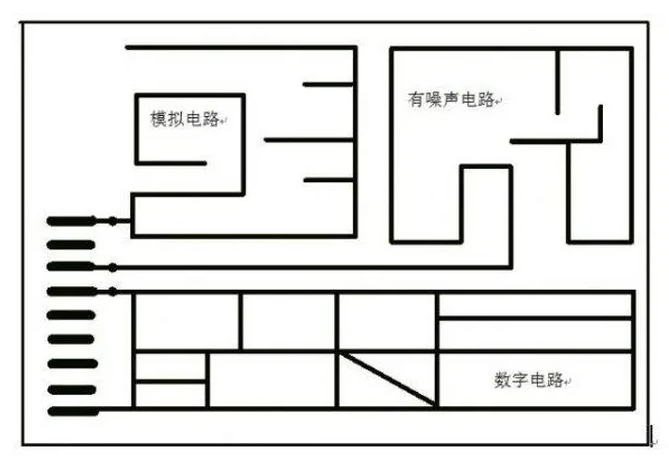

(1) Pre-divide digital, analog, and DAA signal wiring areas on the PCB.

(2) Separate digital and analog components and place them in their respective wiring areas.

(3) Keep high-speed digital signal traces as short as possible.

(4) Keep sensitive analog signal traces as short as possible.

(5) Reasonably allocate power and ground.

(6) Separate DGND, AGND, and the actual ground.

(7) Use wide traces for power and critical signal wiring.

(8) Power and ground lines should be as radial as possible, and signal lines should not form loops.

(9) Place digital circuits near parallel bus/serial DTE interfaces, and DAA circuits near telephone line interfaces.

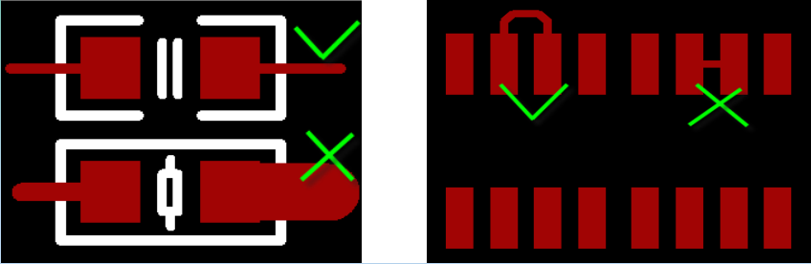

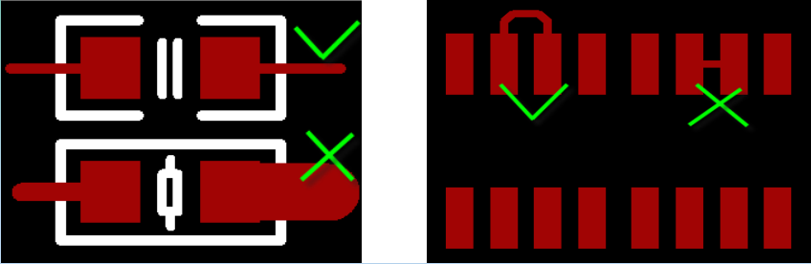

(10) Small discrete component traces must be symmetrical, and closely spaced SMT pad leads should connect from outside the pads, not directly in the middle of the pads.

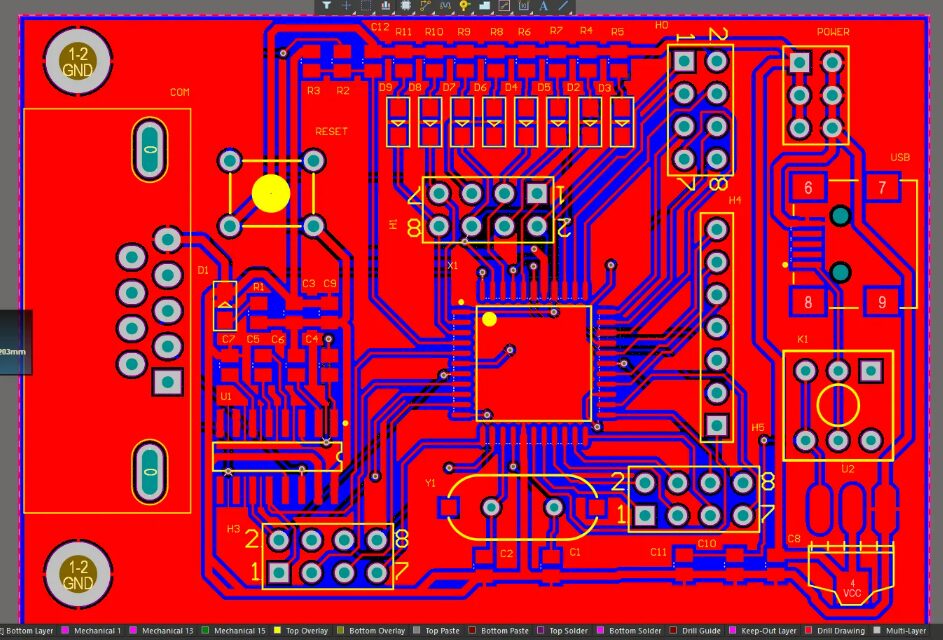

(11) Prioritize critical signal lines: Power, small analog signals, high-speed signals, clock signals, and synchronous signals are prioritized.

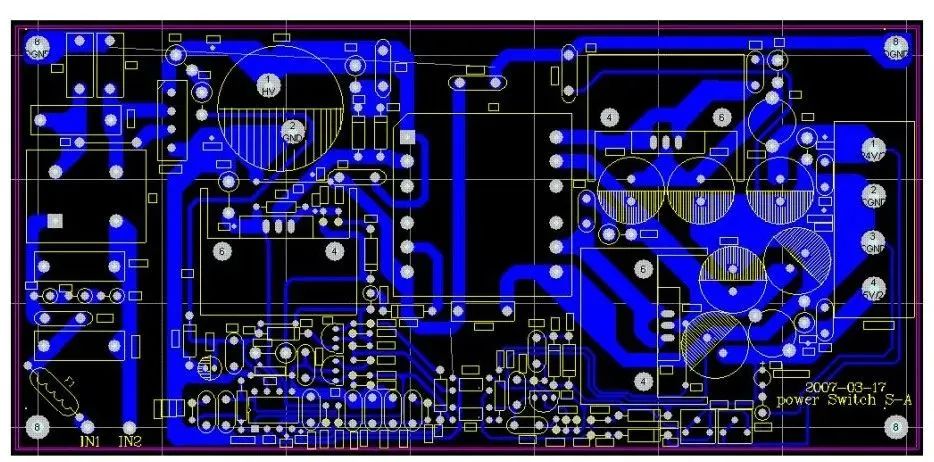

(12) Wiring density priority principle: Start wiring from the components with the most complex connections on the board. Begin wiring from the densest areas on the board.

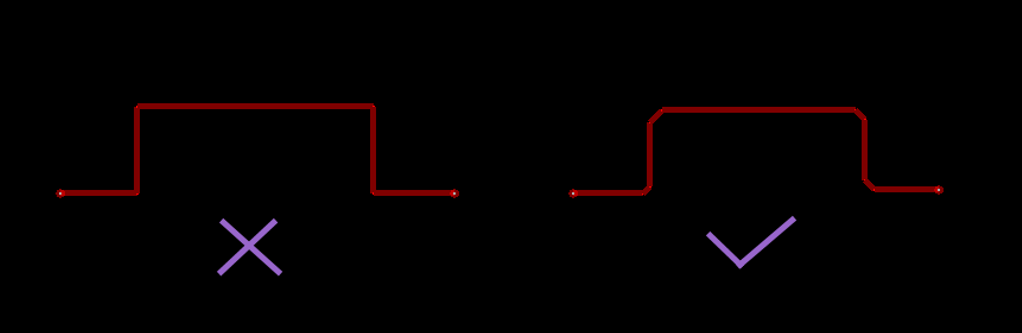

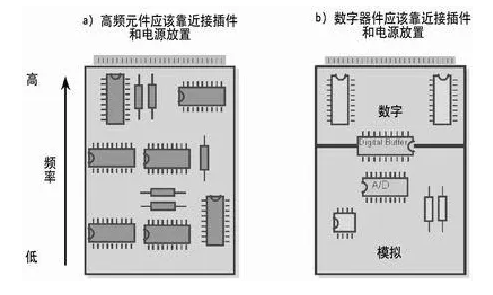

(13) Avoid sharp angles and right angles in PCB design to prevent unnecessary radiation, and also to improve PCB manufacturing performance.

(14) There should be no through-holes on SMT pads to avoid solder paste loss, which can lead to component soldering issues. Important signal lines must not cross between pins.

PCB High-Frequency Circuit Wiring

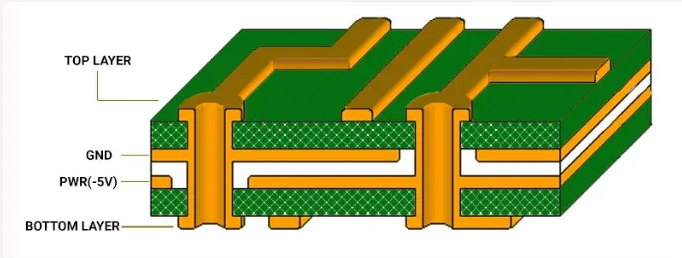

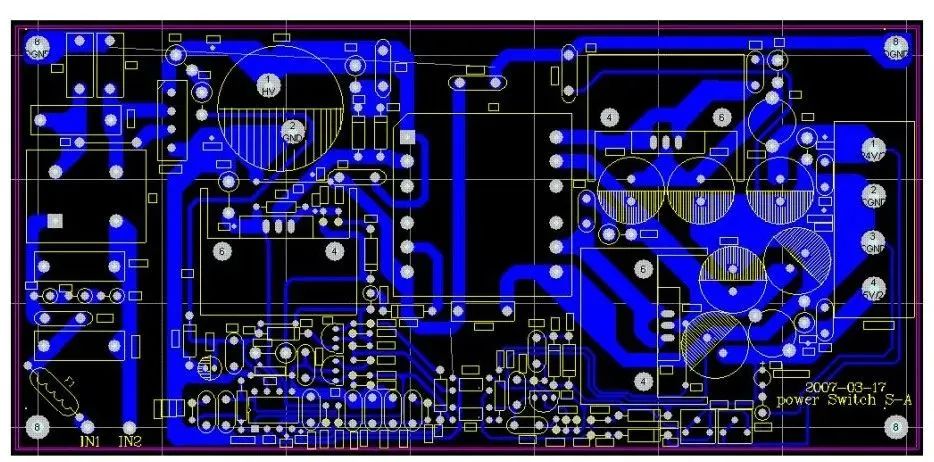

(1) Reasonably choose the number of PCB layers. Using an intermediate power layer (vcc layer) and ground layer (Gnd layer) can provide shielding, effectively reducing parasitic inductance and capacitance, and can significantly shorten wiring length, reducing cross-interference between signals.

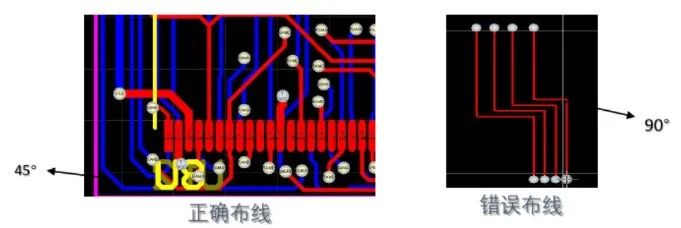

(2) Wiring method: Must follow 45° corner angles, avoid 90° corners. As shown below:

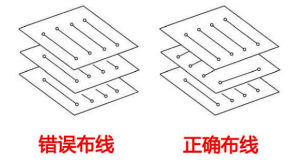

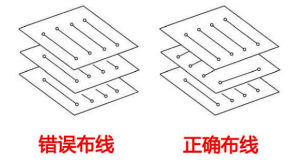

(3) Inter-layer wiring direction: Should be mutually perpendicular, if the top layer is horizontal, then the bottom layer should be vertical to reduce signal interference.

(4) Grounding: Ground important signals to significantly improve the signal’s anti-interference capability, and also ground multiple interfering signals to prevent them from interfering with other signals.

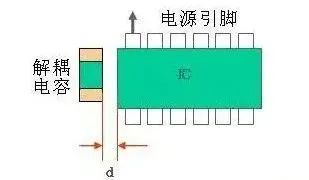

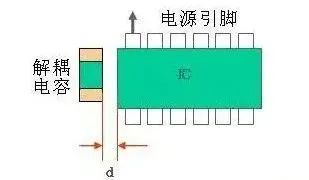

(5) Decoupling capacitors: Add decoupling capacitors at the power end of the IC.

(6) High-frequency choke: When there are common grounds for digital and analog, add high-frequency choke components between them, generally using high-frequency ferrite beads with a wire passing through the center hole.

(7) Copper pouring: Increasing the area of grounding can also reduce signal interference. (During copper pouring, dead copper needs to be removed.)

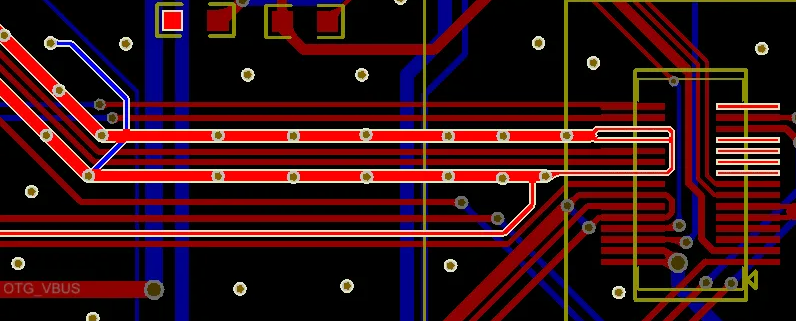

(8) Trace length: Shorter trace lengths are better, as this reduces interference. Of course, not all traces should only pursue short lengths, such as DDR traces, which emphasize equal lengths between clock, address, and data traces, so you will see many deliberately snake-shaped traces to increase length.

Wiring of Special Components

(1) High-frequency components: The shorter the connections between high-frequency components, the better, try to reduce the distributed parameters and mutual electrical interference, and easily interfered components should not be too close to each other.

(2) Components with high potential differences: Increase the distance between components with high potential differences and connections to avoid accidental short circuits damaging components. To avoid creeping discharge, generally, the distance between copper foil lines with a 2000V potential difference should be greater than 2mm.

(3) Heavy components: Overly heavy components should be fixed with a bracket.

(4) Heating and temperature-sensitive components: Ensure that heating components are kept away from temperature-sensitive components. High-heat devices should be evenly distributed.

Important Parameters for PCB Wiring Design

(1) Copper trace (Track) width: Single-sided board 0.3mm, double-sided board 0.2mm;

(2) Minimum gap between copper foil lines: single-sided board 0.3mm, double-sided board 0.2mm;

(3) Minimum distance of copper foil lines from PCB edge is 1mm, components from PCB edge is 5mm, pads from PCB edge is 4mm;

(4) The diameter of the pad for mounting components through holes is generally twice the inner diameter of the pad.

(5) Electrolytic capacitors should not be placed near heating components, such as high-power resistors, transformers, high-power transistors, three-terminal voltage regulators, and heat sinks. The distance between electrolytic capacitors and these components should not be less than 10mm.

(6) There should be no copper foil lines (except for grounding) and components within 5mm radius of screw holes.

(7) In large-area PCB designs (greater than 500㎡), to prevent PCB bending during soldering, leave a gap of 5mm to 10mm in the middle of the PCB without placing components to accommodate a bar to prevent bending.

(8) Each PCB should have a hollow arrow marking the direction through the soldering furnace.

(9) When wiring, the orientation of DIP packaged ICs should be perpendicular to the direction of the soldering furnace, and should not be parallel to avoid solder bridging.

(10) When transitioning wiring direction from vertical to horizontal, it should enter at a 45° angle.

(11) Power line width should not be less than 18mil; signal line width should not be less than 12mil; CPU input/output lines should not be less than 10mil (or 8mil); line spacing should not be less than 10mil.

(12) The wiring on the board should be appropriately dense; if the density difference is too great, it should be filled with mesh copper foil, with a grid size greater than 8mil (or 0.2mm).

(13) The wiring area should be marked within ≤1mm from the PCB edge, and wiring is prohibited within 1mm around mounting holes.

(14) There should be warning marks printed on the silkscreen layer near components such as fuses, fuse resistors, AC220V filter capacitors, transformers, etc.

(15) The distance between the live line and neutral line in the AC220V power section should not be less than 3mm. The distance between any wire in the 220V circuit and low-voltage components, pads, and tracks should not be less than 6mm, and high-voltage markings should be printed, with a thick silkscreen line separating weak and strong electricity to warn maintenance personnel to exercise caution.

Copyright statement: This article’s copyright belongs to the original author and does not represent the association’s views. Articles promoted by the “Jiangxi Province Electronic Circuit Industry Association” are for sharing purposes only and do not represent our position. If there are copyright issues, please contact us for removal.