Introduction

In the field of industrial automation, Programmable Logic Controllers (PLCs) serve as core control devices, and their stable operation directly affects production efficiency and equipment safety. However, various failures are inevitable during long-term operation.

Today, PHM has compiled information on common types of PLC failures, their causes, and quick handling methods, hoping to assist engineers in efficiently solving problems. Let’s take a look!1. Power Supply Failures

· Failure Phenomenon: PLC indicator light is off, unable to start

operation, module unexpectedly loses power.

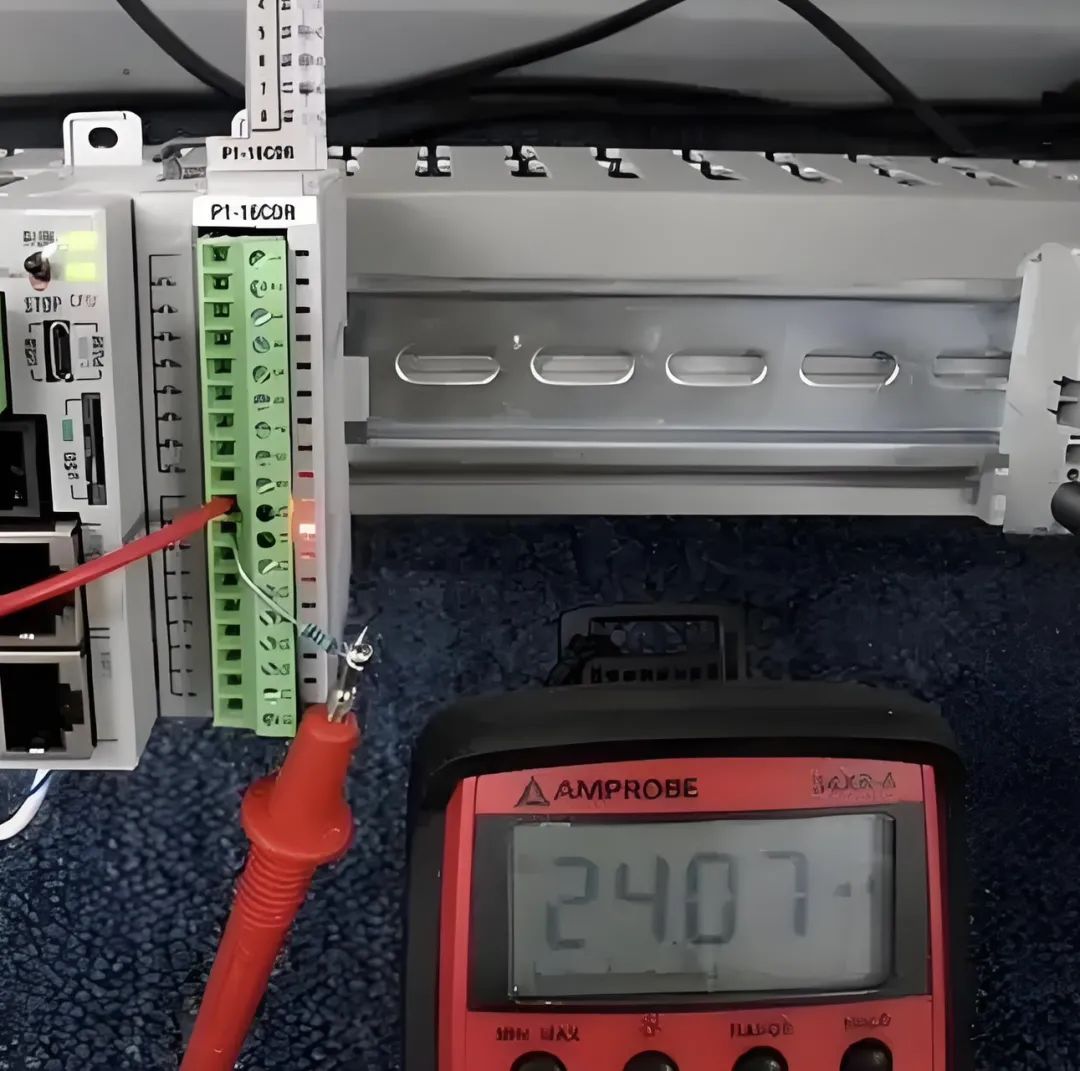

· Common Causes: 1. Unstable power supply voltage (too high/too low) or power outage. 2. Power module damage (e.g., aging of filter capacitors). 3. Loose or short-circuited terminal connections. · Handling Methods: · Check if the input voltage is within the rated range

(e.g., 24VDC±10%).

· Use a multimeter to measure whether the power module output is normal, replace if necessary.

· Re-tighten the power line terminals, check for short circuits and

repair.

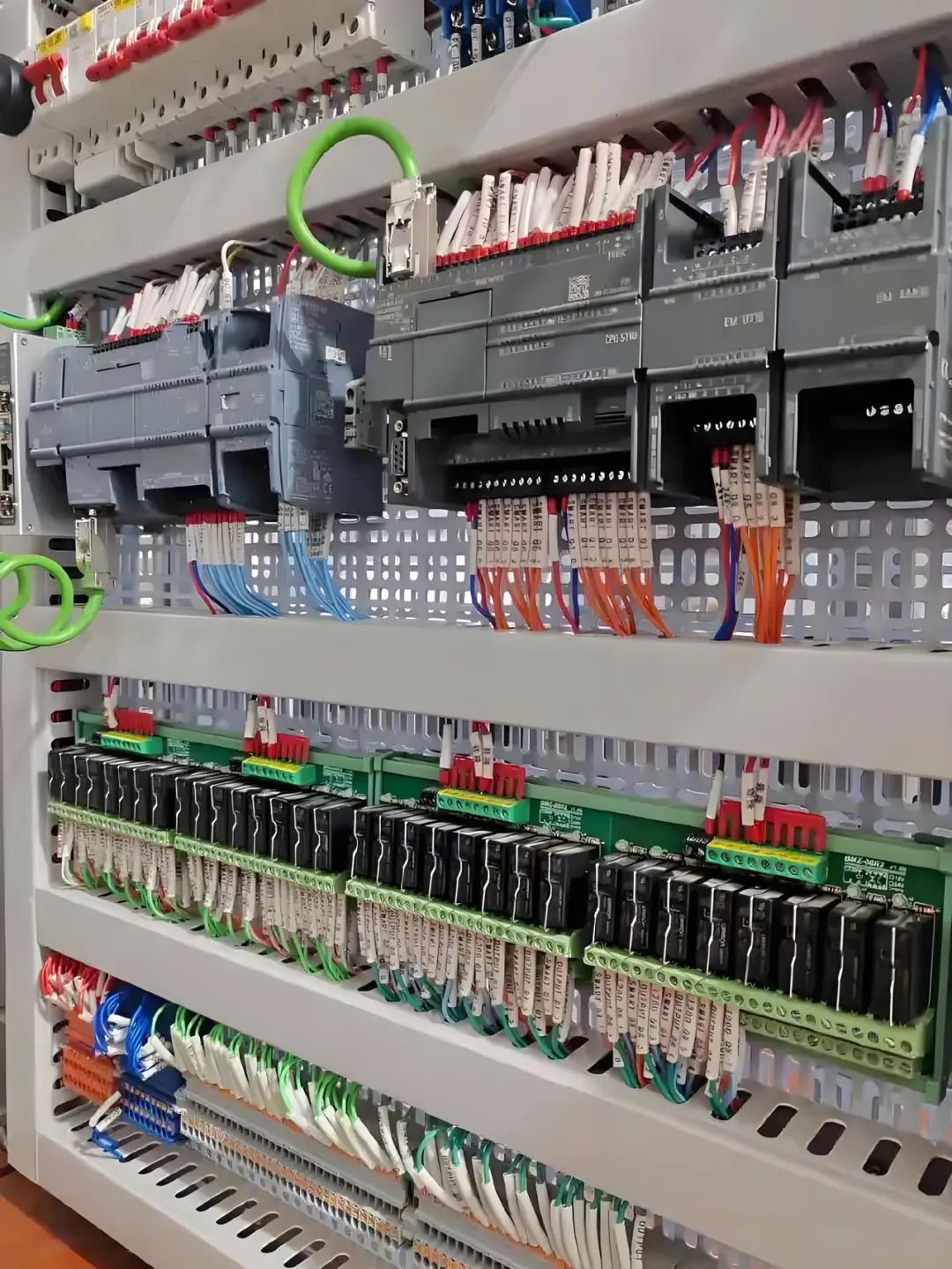

2. Input/Output (I/O) Failures· Failure Phenomenon: No response from input signals, output devices

not functioning, abnormal indicator lights. · Common Causes: 1. Input side issues: sensor damage, broken wires,

poor contact of contacts. 2. Output side issues: overload (e.g., relay burned

out), external device short circuit. 3. I/O module hardware failure (e.g., channel burned out).

· Handling Methods: · Input fault troubleshooting: · Use a multimeter to check if the sensor signal is normal. · Check if the input terminal connections are loose or broken. · Output fault troubleshooting: · Confirm if the load power exceeds limits, replace damaged

relays or contactors.

· Check if the output lines are short-circuited or grounded. · If a single point failure occurs, temporarily replace with a backup channel

(program modification required).

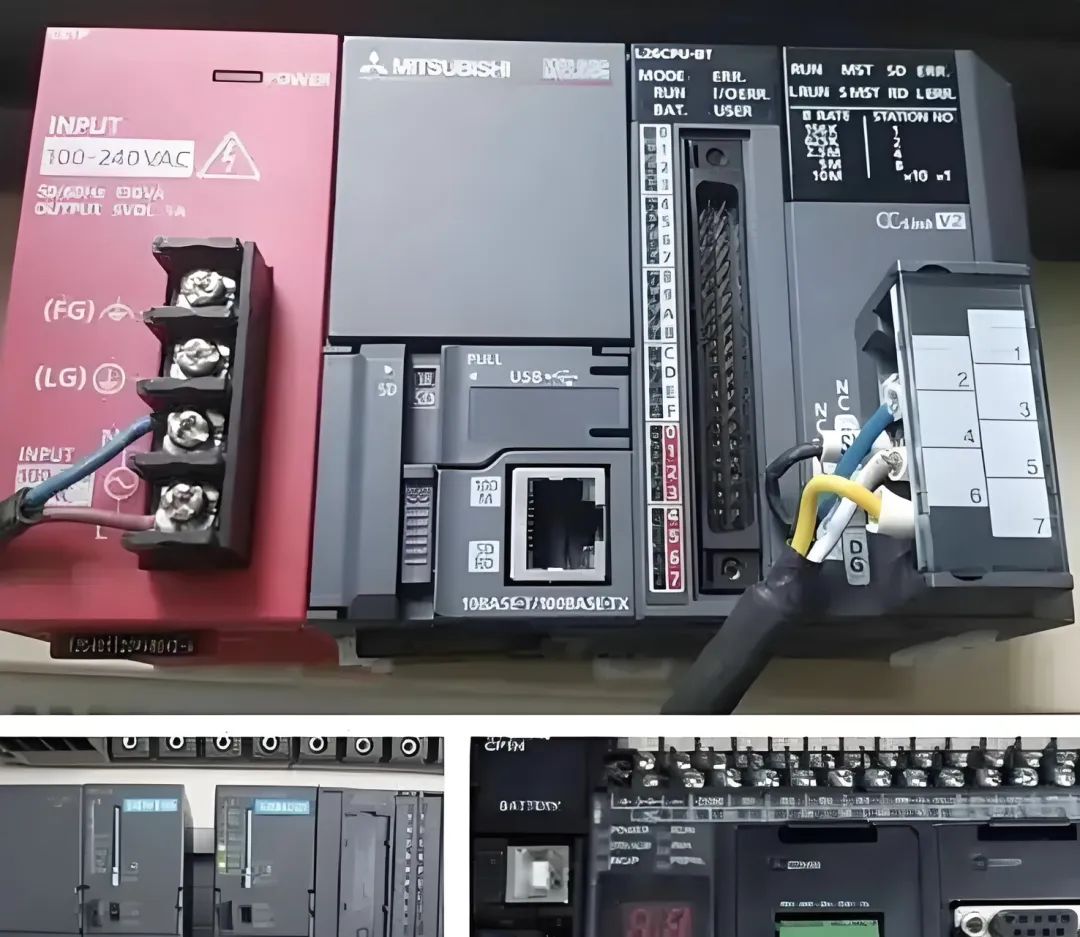

3. Communication Failures· Failure Phenomenon: Communication interruption between PLC and upper computer, touch screen, or

other devices. · Common Causes: 1. Damaged communication cables (e.g., broken wires, shielding layer damage). 2. Incorrect communication port configuration (inconsistent baud rate, station number).

3. Interference signals (e.g., ungrounded, nearby high-power devices). ·Handling Methods: · Check physical connections: replace communication cables, ensure

plugs are secure. · Verify communication parameters (e.g., Modbus address,

RS485 wiring polarity). · Increase shielding measures, separate communication lines from power lines

during wiring, and ensure proper grounding.

4. Program Execution Anomalies· Failure Phenomenon: PLC freezes, program lags, logical errors.

· Common Causes: 1. Program logic errors (e.g., infinite loops, address conflicts). 2. Scanning cycle too long (program capacity too large). 3. Memory failure (battery failure leading to program loss). · Handling Methods: · Monitor program execution through programming software, check for logical conflicts.

· Optimize program structure, reduce redundant code. · Regularly replace PLC batteries, back up programs to a computer

or storage card.

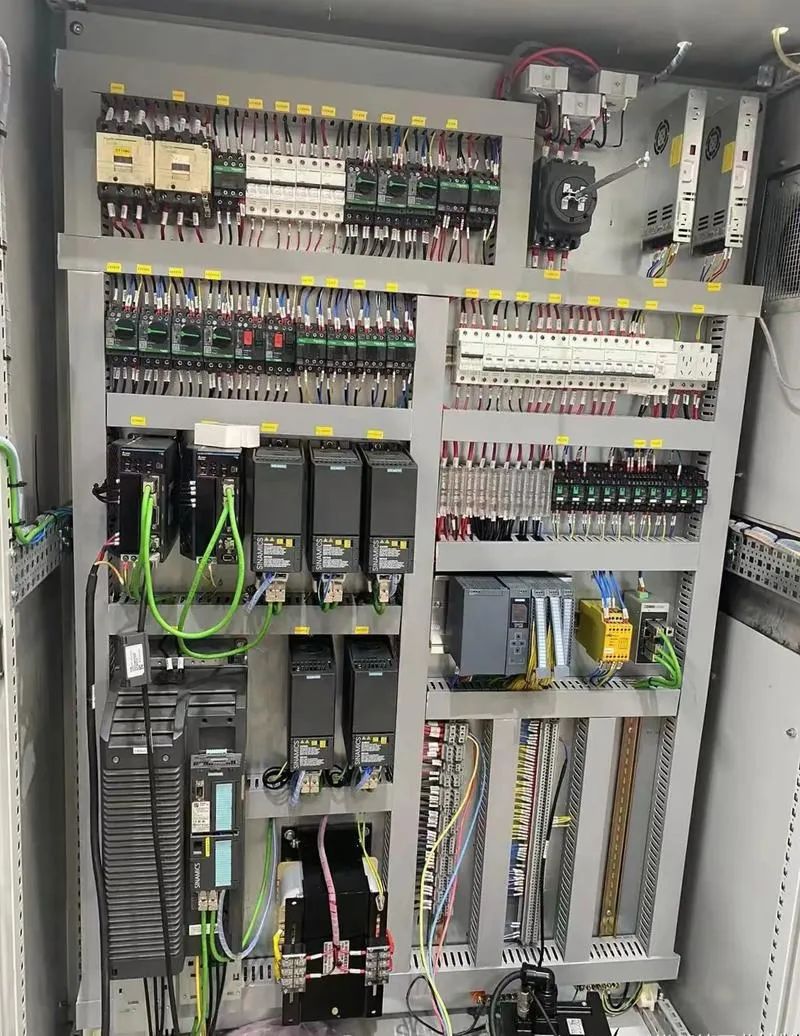

5. Failures Caused by Environmental Factors

· Failure Phenomenon: PLC frequently restarts, module damage. · Common Causes: 1. High temperature/humidity (poor heat dissipation leading to component aging). 2. Vibration causing loose connections or component detachment. 3. Dust or corrosive gas intrusion. Handling Methods: · Install cooling fans or air conditioning, control the environment temperature between

0~55℃. · Use shockproof cabinets to secure PLCs, regularly check fasteners. · In harsh environments, select PLCs with high protection ratings

(e.g., IP65), and seal the cabinet. Preventive Maintenance Recommendations1. Regular Checks: Clean PLC surface dust monthly,

check terminal connections. 2. Program Backup: Immediately back up after modifying programs,

to avoid data loss. 3. Spare Parts Reserve: Keep critical components like power modules, I/O modules

in stock. 4. Log Records: Record failure phenomena and handling processes for

subsequent analysis.

Conclusion:

PLC fault troubleshooting should follow the four-step method of “observing phenomena, checking hardware, measuring signals, analyzing programs.” Mastering common failure causes can significantly reduce downtime and ensure stable production operation!Tip: When encountering complex issues, refer to the PLC manual’s fault code table first, or contact the equipment manufacturer’s technical support!

【Interactive Topic】

What experiences and skills do you have in handling PLC failures? Or are there other knowledge points you need to understand? Feel free to leave a message to PHM!💡

Office Address: Shenzhen Hongguan Technology Park A6/3F Equipment Health Management Center Office

Contact Number: 568-83954