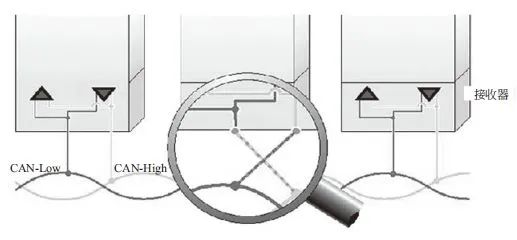

5. Short Circuit of CAN L to Power (Positive)

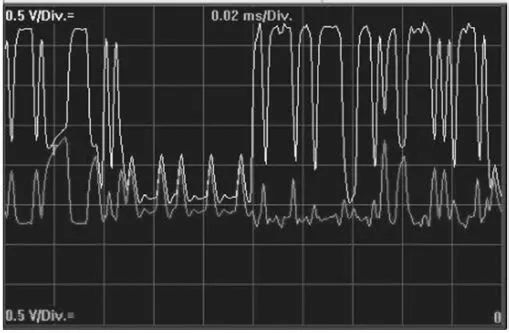

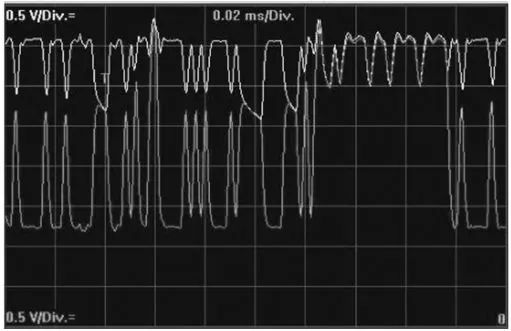

6. Open Circuit of CAN H

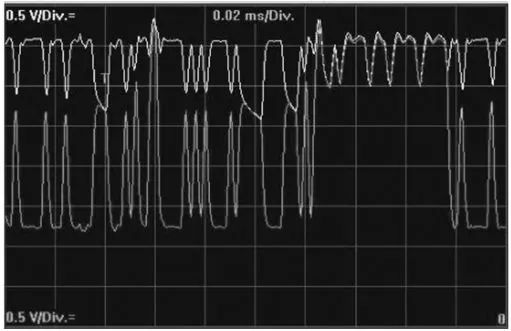

7. Open Circuit of CAN L

Source | Wiring Engineer

Click the mini-program below to see more repair cases

Source | Wiring Engineer

Click the mini-program below to see more repair cases