1

Case Situation

A semiconductor manufacturing plant generates a large amount of wastewater containing heavy metals during production, including copper, nickel, zinc, and lead, which pose serious potential hazards to the environment. The plant’s original wastewater treatment system, while capable of removing some pollutants, is ineffective in removing heavy metals, resulting in wastewater that cannot meet discharge standards. The plant is seeking suitable treatment methods for semiconductor heavy metal wastewater.

2

Wastewater Site Issues

1. The original wastewater treatment system has limited capacity for heavy metal removal, and the concentration of heavy metals in the treated wastewater is still far above discharge standards.

2. The original treatment process is complex, cumbersome to operate, and inefficient, failing to meet the production needs of the plant.

3. Due to poor treatment results, frequent replacement of reagents and filter materials is required, leading to a significant increase in operating costs.

3

Original Treatment Method

The plant originally used chemical precipitation to treat heavy metal wastewater, but due to improper reagent selection and operational control, the precipitation effect was poor, resulting in low heavy metal removal rates. Additionally, this method tends to generate a large amount of sludge containing heavy metals, which requires further treatment, increasing treatment costs and difficulties.

4

Wastewater Solution

To address the above issues, engineers proposed an improved solution based on chemical precipitation, introducing a heavy metal capturing agent, combined with the following process:

1. Select a highly efficient and specific heavy metal capturing agent that can selectively capture and remove different heavy metals in the wastewater, with rapid reactions, significantly reducing treatment time, and producing relatively less sludge, thereby lowering subsequent treatment costs; the dosing control is simple and easy to operate, reducing the skill requirements for operators.

2. Simplify the process flow, optimize operational parameters, and improve treatment efficiency. At the same time, strengthen the control of reagent dosing and mixing effects to ensure that reagents fully react with heavy metals in the wastewater.

3. By optimizing the reagent formulation and operational conditions, reduce the amount of sludge generated. For the generated sludge, appropriate solid-liquid separation technologies are employed to lower subsequent treatment costs.

5

Treatment Results

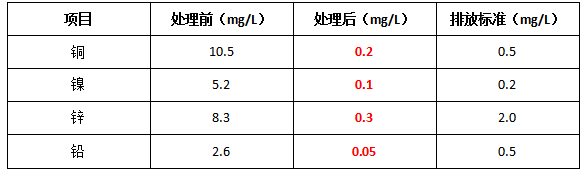

After implementing the solution we provided, the concentration of heavy metals in the wastewater was significantly reduced. Below is a comparison of data before and after treatment:

The data shows that after implementing our semiconductor heavy metal wastewater treatment solution, the concentration of heavy metals in the wastewater is below discharge standards, meeting environmental protection requirements.

If you encounter issues with wastewater exceeding standards, you can contact us online, and we will develop a “one-stop” wastewater solution for you!

Share

Like

View