Introduction

In the field of industrial automation, the touch screen host computer plays a crucial role as an important interface for human-machine interaction. While traditional PLC-mounted touch screens are powerful, they have certain limitations in flexibility and scalability.

To meet the demand for efficient and flexible control in modern industrial automation, this article will introduce a C# industrial touch screen host computer case.

This system not only has powerful functions but also supports various communication methods and database connections, capable of meeting diverse needs in different industrial scenarios.

Project Overview

The project is an industrial touch screen host computer system developed based on C#, replacing traditional PLC-mounted touch screens and providing a more efficient and flexible control solution.

The system adopts a multi-threaded programming approach, ensuring smooth and stable operations.

Here are the main functions and features of the system:

1. Pure Source Code: Provides complete source code for customization and expansion based on specific needs.

2. Replaces Traditional PLC-Mounted Touch Screens: Powerful functionality allows it to directly replace traditional PLC-mounted touch screens, enhancing the user experience.

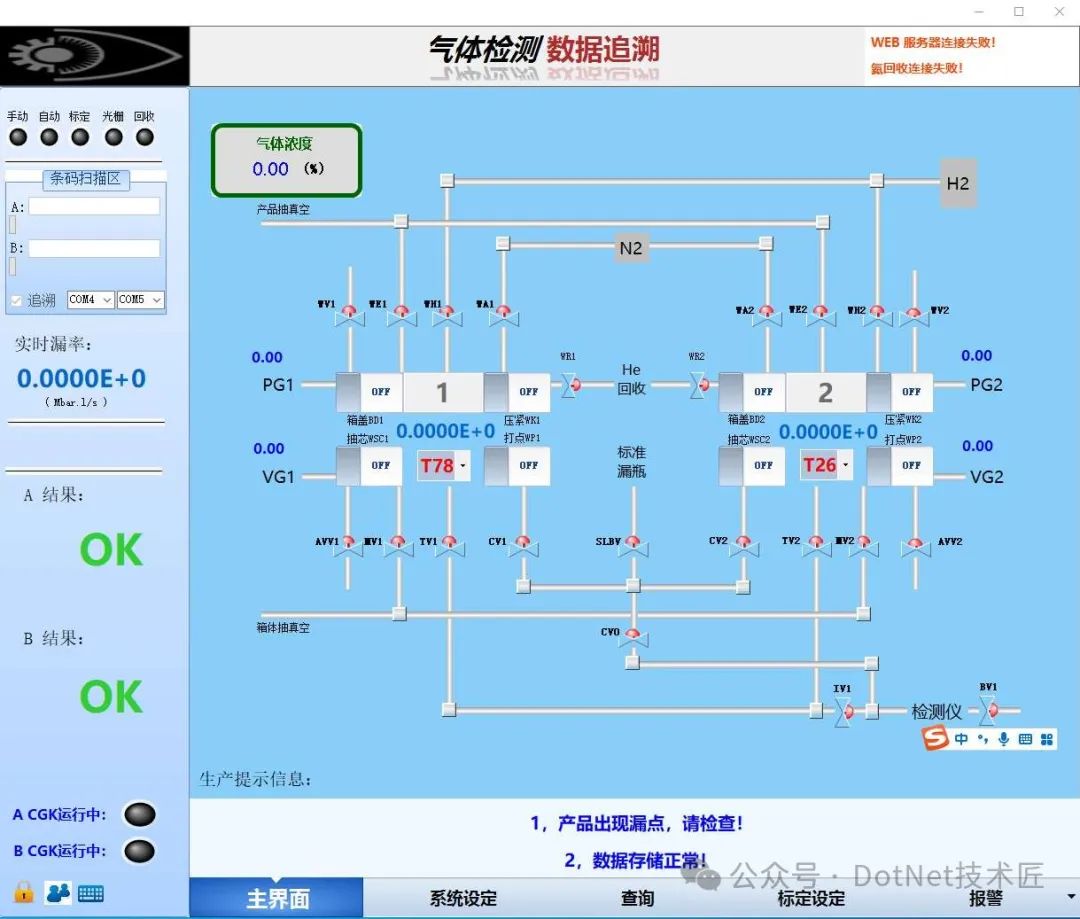

3. Direct Communication Between Industrial Control Screen and PLC: Supports direct communication between the industrial control screen and PLC, simplifying system architecture.

4. Multi-Level Tabs: Supports multi-level tabs for easy management and switching between different operation interfaces.

5. Flexible Communication Methods: Allows free setting of serial or Ethernet communication to adapt to different communication environments.

6. Rich Functional Pages:

-

Home Page: Displays the main functions and status of the system.

-

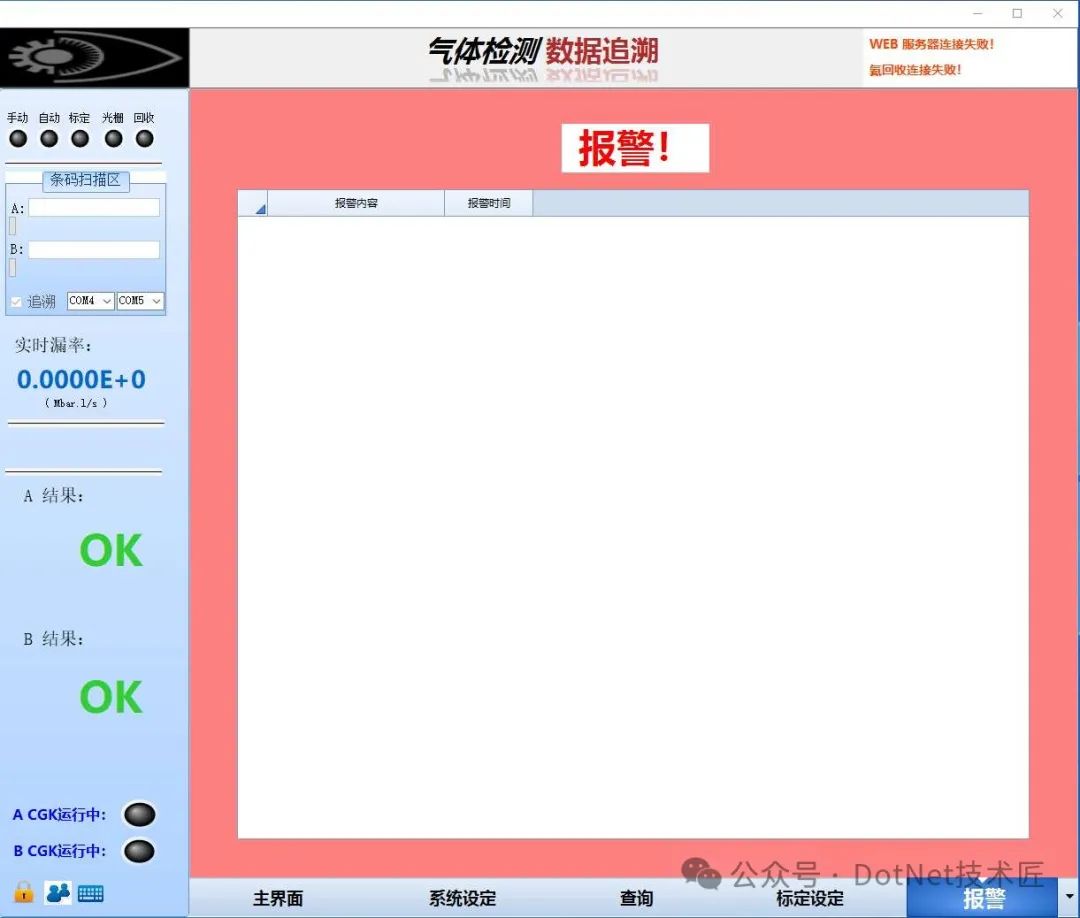

Alarm Page: Displays real-time system alarm information for quick problem identification.

-

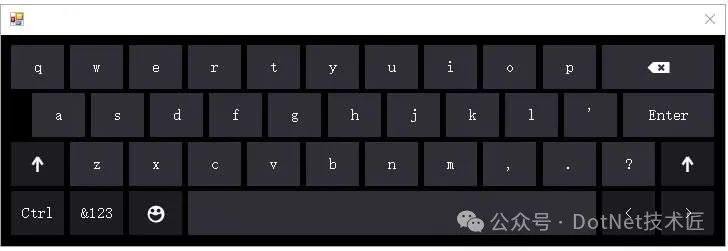

Touch Keyboard Simulation Input: Provides a touch keyboard simulation input feature for user data entry.

-

System Settings Page: Allows users to configure and set system parameters.

-

Historical Query Page: Supports historical data queries for user tracking and analysis.

-

Calibration Settings Page: Provides calibration functions to ensure measurement accuracy.

7. Free All Controls: Provides all necessary controls without additional purchases.

8. Supports Siemens PLC: The system is optimized to support Siemens PLC, ensuring compatibility and stability.

9. Register OPC DA Component: Registers the opcdaauto.dll component for OPC communication.

10. Install KepServerEx5: Supports the installation of KepServerEx5 to extend communication protocol support.

11. Link to Other Databases: Can link to other databases for convenient data storage and management.

12. User Login Page: Provides user login functionality, supporting multi-user management and permission control.

13. FLASHFORM Page: Supports FLASHFORM pages to enhance user interface interactivity.

14. User Editing Page: Includes various permission settings for system administrators to manage users.

15. Multi-Threaded Programming: Adopts a multi-threaded programming approach to ensure efficient system operation.

16. WEBSERVICE Data Integration: Supports WEBSERVICE data integration for convenient data exchange with other systems.

17. Network Detection: Provides network detection functionality to ensure stable network connections.

User Guide

Environment Preparation

Install Visual Studio 2019 or higher.

Register <span>opcdaauto.dll</span> component.

Install KepServerEx5.

Configure PLC communication parameters to ensure normal communication between PLC and host computer.

Common Issues

1. Communication Issues

Ensure that the communication parameters for PLC and host computer are configured correctly.

Check if the network connection is normal; restart the KepServerEx5 service if necessary.

2. Permission Issues

Ensure that the user running the application has sufficient permissions.

Check if the user login functionality is normal and ensure user permissions are set correctly.

3. Performance Issues

Optimize multi-threaded code to ensure smooth system operation.

Check system resource usage and optimize resources if necessary.

Project Results

Conclusion

The C# industrial touch screen host computer system introduced in this article not only has powerful functions but also supports various communication methods and database connections, capable of meeting diverse needs in different industrial scenarios. The system adopts a multi-threaded programming approach, ensuring smooth and stable operations.

By providing complete source code, it can be customized and expanded according to specific needs, enhancing the system’s applicability and flexibility.

I hope this introduction can provide useful references and insights for development in the field of industrial automation, helping everyone quickly achieve efficient and flexible industrial automation control solutions.

Author: Small Code Craftsman

Open Source Most Comprehensive and Dazzling 100+ Big Data Visualization Screens

.NET Completely Open Source WMES System Covering MES and WMS

.NET 8.0 Practical Case Open Source Industrial Internet MES System Full Stack Code

.NET + Avalonia Cross-Platform Smart Driving Test System (Supports AI Q&A)

Found it helpful? Please share it so more people can benefit

Follow DotNet Technology Craftsman to enhance technical skills together