Project Development Background

The construction of the track inspection robot is realized through an intelligent track inspection robot based on 5G communication technology, equipped with data collectors and real-time intelligent analysis software, to achieve gas and combustible gas detection, and eliminate safety hazards alarms. It creates a standardized, modernized, and intelligent security inspection program. It improves inspection efficiency and also reduces costs and saves operational costs.

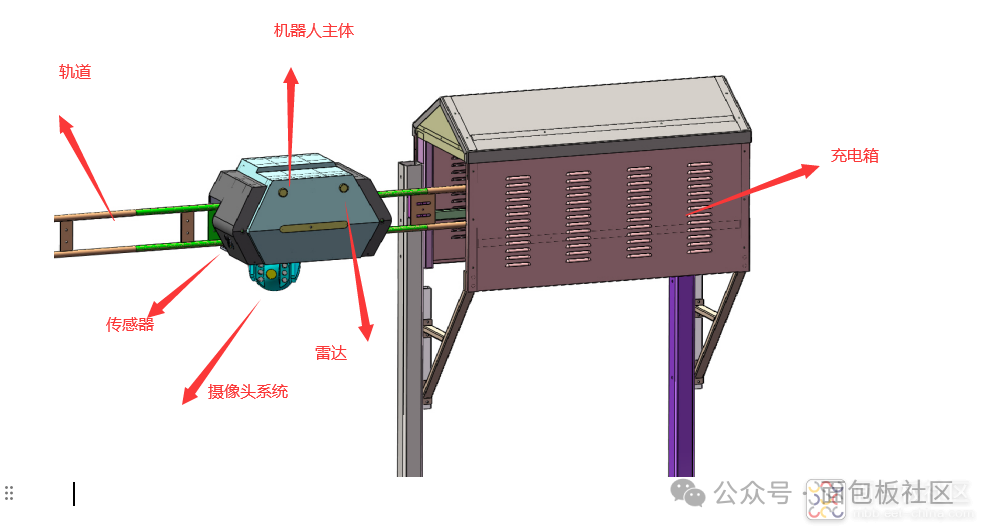

The suspended track inspection robot mainly consists of the robot body, charging box, track department, and camera sensor system. The entire system can be used for inspections in enterprise parks, campus parks, chemical factories, substations, high-speed railways, and mines. By using overhead tracks to avoid human interference, the safety is extremely high, and various sensor system modules can be replaced to adapt to different inspection scenarios. The communication system is based on 5G/4G, Lora modules, and bridge modules to achieve real-time control online or offline without operator networks.

Embedded System Hardware Design

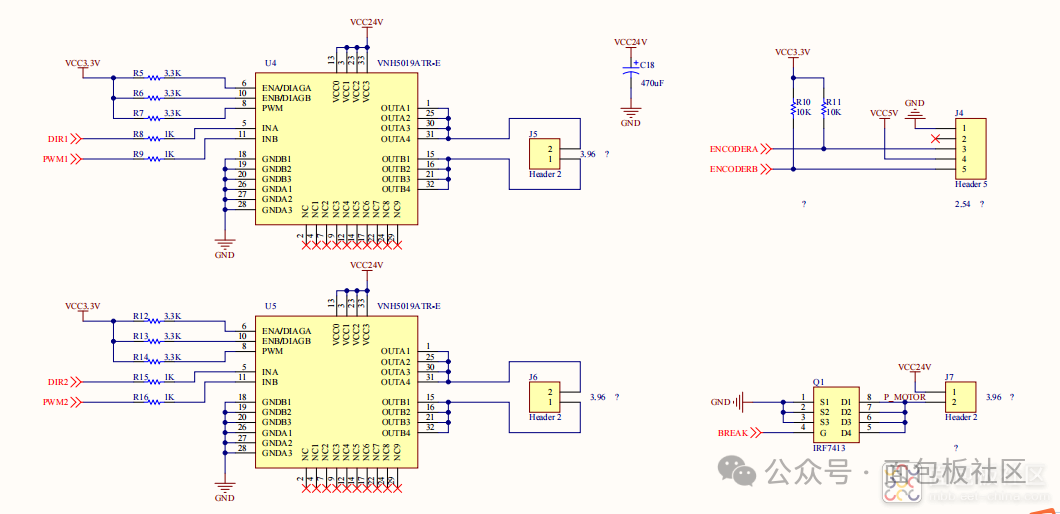

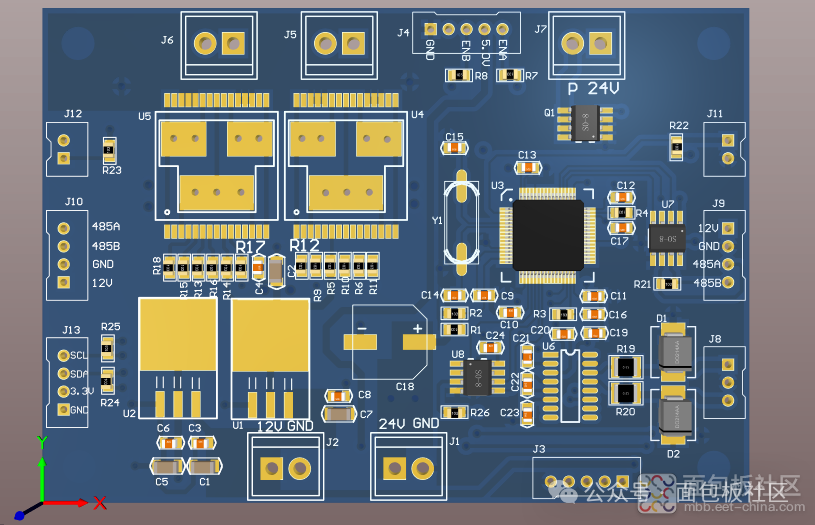

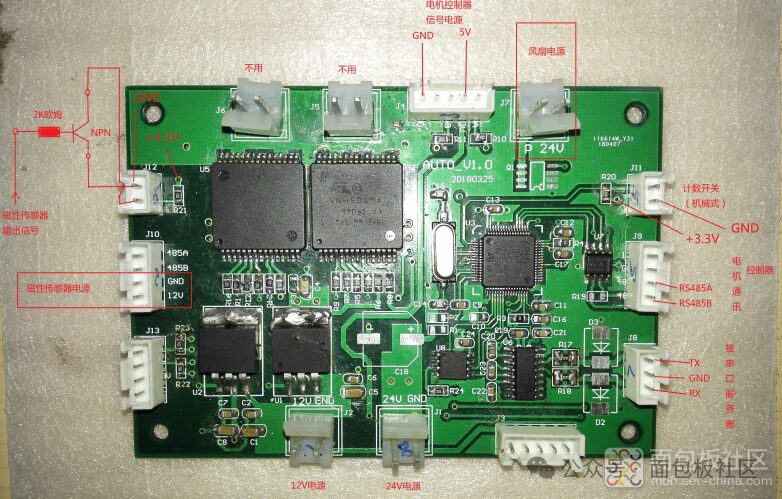

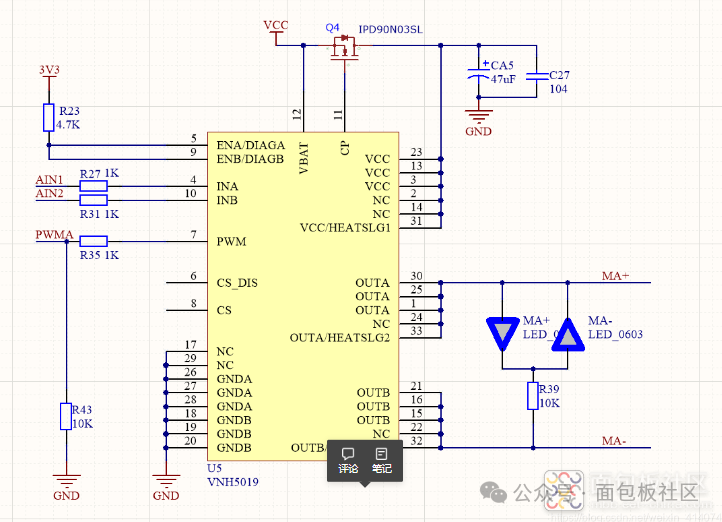

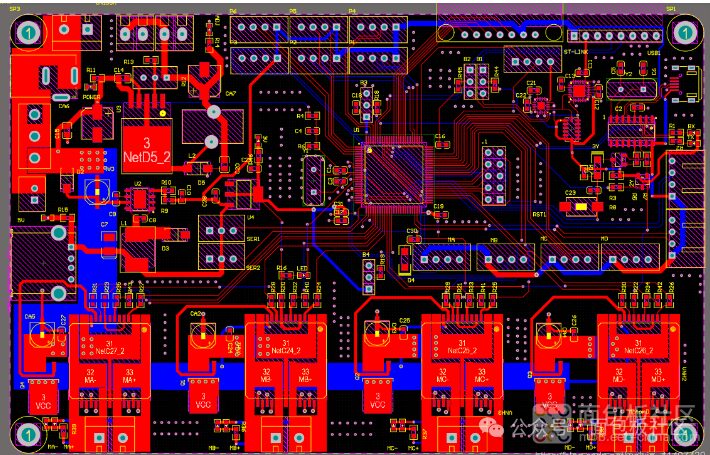

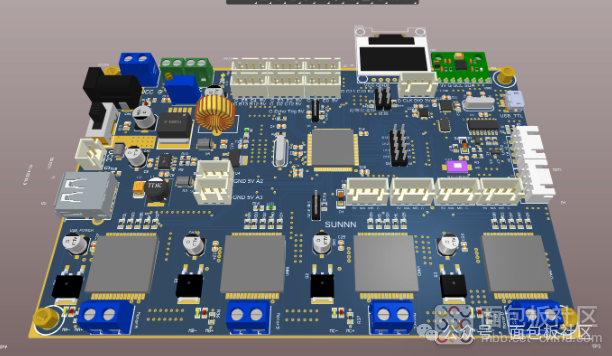

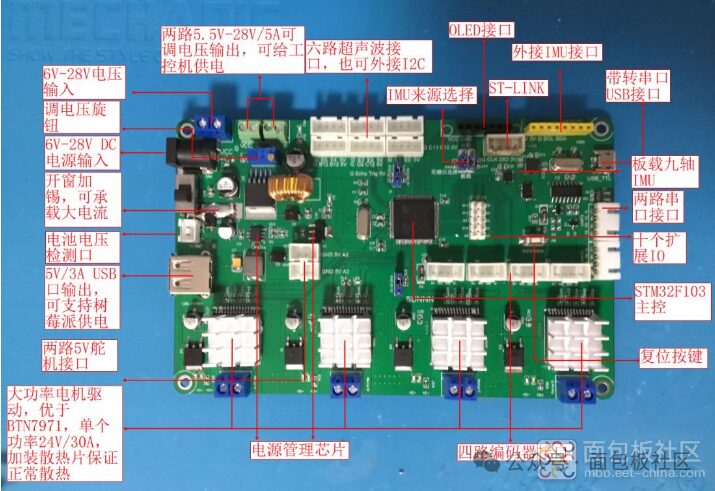

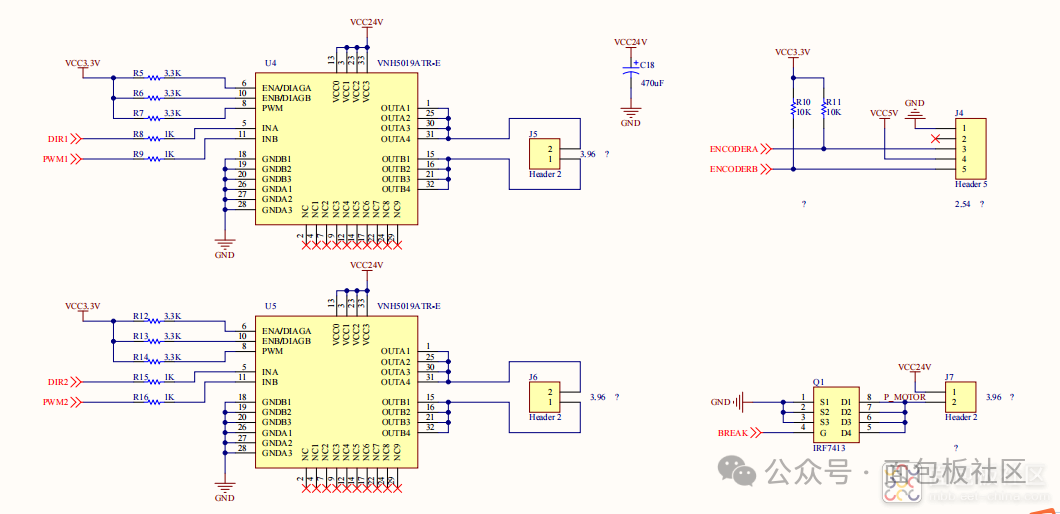

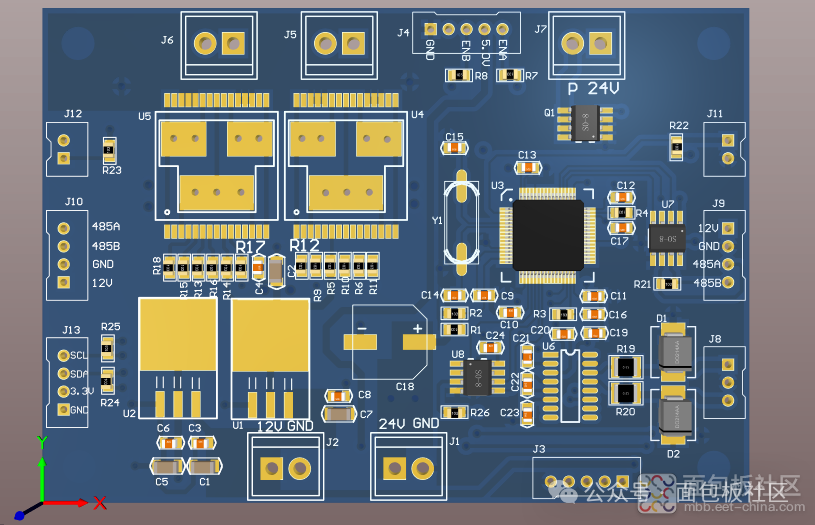

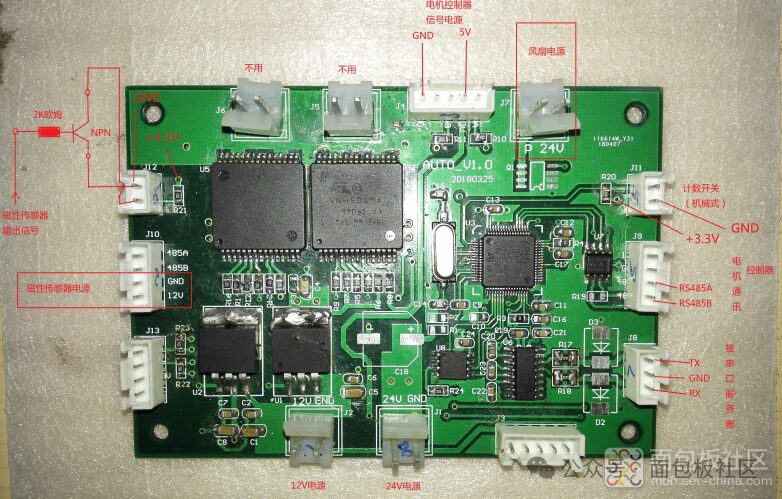

The main control circuit board uses the STM32 microcontroller, and the motor driver chip used in the initial project is BTN7971A. VHN5019A is a full-bridge motor driver, AEC-Q100 certified. The MultiPowerSO-30 package is designed for harsh automotive environments and provides higher thermal performance due to the use of exposed chip pads. It is suitable for various automotive-grade motor applications. This device includes a dual single-chip high-side driver and two low-side switches. The high-end driver switch is designed using STMicroelectronics’ well-known and proven proprietary VIPower® M0 technology, which allows the effective integration of a true low-power MOSFET on the same chip with intelligent signal/protection circuits. The input signals INA and INB of the VNH5019ATR-E three chips are assembled on an electrically isolated lead frame and can be directly connected to the microcontroller to select motor direction and braking conditions.

Another IC from ST is the VNH5019 full-bridge motor driver IC, which is inexpensive, can drive one DC motor with one chip. Four chips can drive four motors. The driver does not need to be connected with a dedicated bus; it only requires two digital pins to control direction, one PWM pin to control speed, and one analog pin (optional) to read the current flowing through the motor.

Software Design:The main controller uses the Cortex-M3 core STM32F103. There are a total of 8 timers inside the controller, where TIM1_CH1 and TIM8_CH1 are high-level control timer pins. TIM1_CH1 is used for motor encoder counting. TLM8_CH1 is used for servo control reference timing. General timer pins TIM2 CH1, TIM3 CH1, TIM4_CH1, and TIM5_CH1 are used for generating PWM for motor and servo drive circuits. The PA0 and PB0 pins that trigger the EXIT0 interrupt are used for motor overcurrent interrupt protection.

Another IC from ST is the VNH5019 full-bridge motor driver IC, which is inexpensive, can drive one DC motor with one chip. Four chips can drive four motors. The driver does not need to be connected with a dedicated bus; it only requires two digital pins to control direction, one PWM pin to control speed, and one analog pin (optional) to read the current flowing through the motor.

Software Design:The main controller uses the Cortex-M3 core STM32F103. There are a total of 8 timers inside the controller, where TIM1_CH1 and TIM8_CH1 are high-level control timer pins. TIM1_CH1 is used for motor encoder counting. TLM8_CH1 is used for servo control reference timing. General timer pins TIM2 CH1, TIM3 CH1, TIM4_CH1, and TIM5_CH1 are used for generating PWM for motor and servo drive circuits. The PA0 and PB0 pins that trigger the EXIT0 interrupt are used for motor overcurrent interrupt protection.

#include "pwm.h"void TIM1_Int_Init(u16 arr, u16 psc){ TIM_TimeBaseInitTypeDef TIM_TimeBaseStructure; TIM_OCInitTypeDef TIM_OCInitStructure; GPIO_InitTypeDef GPIO_InitStructure; RCC_APB2PeriphClockCmd(RCC_APB2Periph_TIM1, ENABLE); RCC_APB2PeriphClockCmd(RCC_APB2Periph_GPIOA, ENABLE); GPIO_InitStructure.GPIO_Pin = GPIO_Pin_8 | GPIO_Pin_9 ; GPIO_InitStructure.GPIO_Mode = GPIO_Mode_AF_PP; GPIO_InitStructure.GPIO_Speed = GPIO_Speed_50MHz; GPIO_Init(GPIOA, &GPIO_InitStructure); TIM_TimeBaseStructure.TIM_Period = arr; //When the timer counts from 0 to 999, it is 1000 times, which is a timing cycle TIM_TimeBaseStructure.TIM_Prescaler = psc; TIM_TimeBaseStructure.TIM_ClockDivision = TIM_CKD_DIV1; //Set clock division coefficient: no division TIM_TimeBaseStructure.TIM_CounterMode = TIM_CounterMode_Up; //Up counting mode TIM_TimeBaseInit(TIM1, &TIM_TimeBaseStructure); TIM_OCInitStructure.TIM_OCMode = TIM_OCMode_PWM1; //Configure as PWM mode 1 TIM_OCInitStructure.TIM_OutputState = TIM_OutputState_Enable; // TIM_OCInitStructure.TIM_OutputNState = TIM_OutputNState_Enable; TIM_OCInitStructure.TIM_Pulse = 0; //Set switching value, when the counter counts to this value, a level switch occurs. TIM_OCInitStructure.TIM_OCPolarity = TIM_OCPolarity_High; //When the timer count value is less than CCR1_Val, a high level is generated TIM_OC1Init(TIM1, &TIM_OCInitStructure); //Enable channel 1 TIM_OC1PreloadConfig(TIM1, TIM_OCPreload_Enable); TIM_OCInitStructure.TIM_OutputState = TIM_OutputState_Enable; TIM_OCInitStructure.TIM_Pulse = 0; //Set switching value, when the counter counts to this value, a level switch occurs TIM_OC2Init(TIM1, &TIM_OCInitStructure); //Enable channel 2 TIM_OC2PreloadConfig(TIM1, TIM_OCPreload_Enable); TIM_ARRPreloadConfig(TIM1, ENABLE); // Enable TIM1 reload register ARR TIM_CtrlPWMOutputs(TIM1, ENABLE); TIM_Cmd(TIM1, ENABLE);}

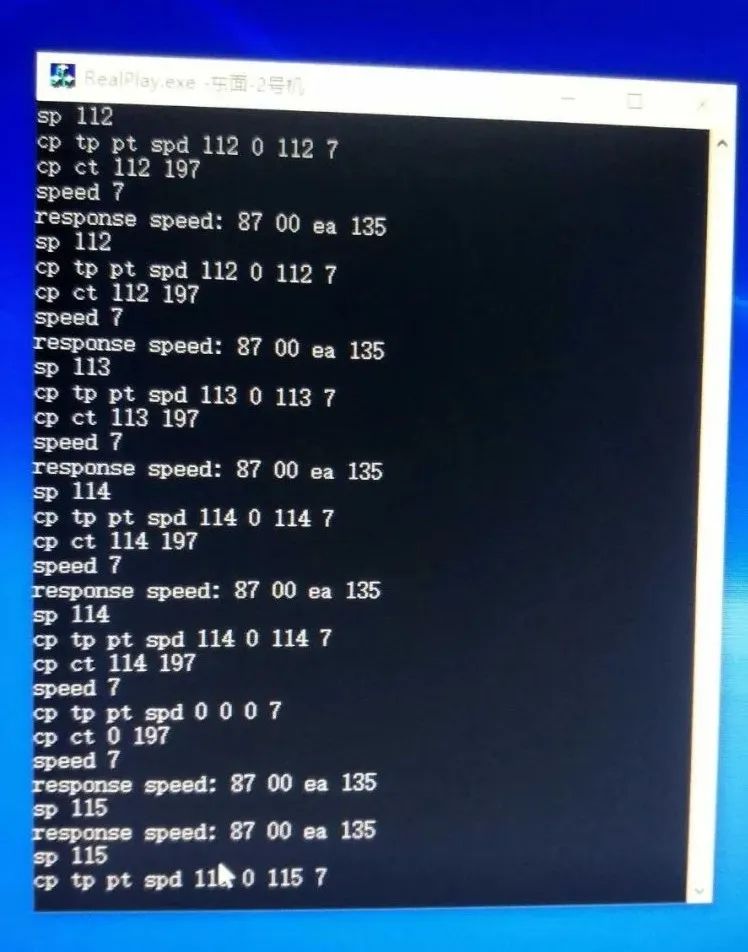

Based on the actual operation needs, the PC upper computer gives the robot inspection speed and inspection position through Ethernet to serial port conversion. The motor speed is compared with the set speed value and the collected value from the incremental encoder, and closed-loop control is achieved through the speed PID algorithm. The robot’s position is mainly fed back by the absolute encoder to adjust the speed of the servo rotation according to the action time requirements. The software for the robot motor control system needs to achieve the following functions:

◆ The upper computer specifies the speed, inspection position, and inspection time settings, and position point settings; ◆ The motor speed must be continuously adjustable and have good static and dynamic performance. The speed adjustment uses the PI algorithm; ◆ The robot should quickly reach the specified angle, with position feedback as an adjustment for the motor’s specified speed; ◆ It must have certain fault protection functions. When the motor stalls, the current is too high, and the servo touches the limit switch, it is required to stop the drive module from working.

For the above functions to be achieved, the application program design can be divided into the following tasks: 1) Startup task. Initialize the system, create the initial motor state, then delete itself, and let the startup task enter sleep mode. 2) Motor and servo protection task. This is used to respond to external interrupts during overcurrent or limit switch actions, entering interrupt status by sending task signals, and the task program detects the signal validity and responds to the task, stopping output. The task priority is set to level 0. 3) Upper computer specified task. This is used for upper computer control of motors and servos, with a task priority set to level 1. When data is input into the upper computer data register, an interrupt is generated, and the received bytes are sent to the buffer and release the signal for the upper computer specified task; when the task detects the signal validity, it starts execution, parsing the corresponding byte information into the corresponding motor speed and servo angle position information and assigning values to the corresponding variables. 4) Motor speed control task. This is for closed-loop speed control of the motor, with a task priority set to level 2. 5) Servo control task. This is used to control the servo to reach the specified position within the specified time, with a task priority set to level 3.

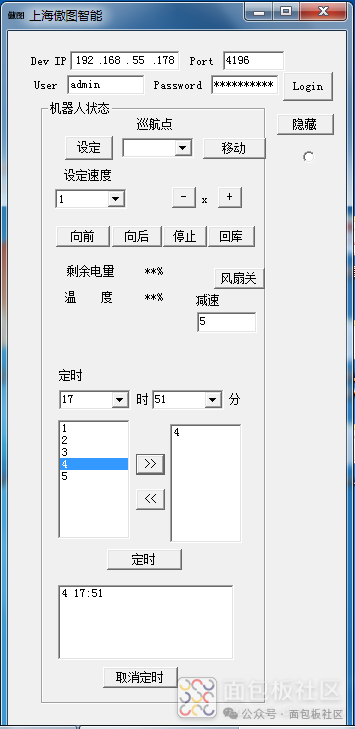

A PC-side application developed based on C++ QT displays the robot’s position and monitors video robot control software in real-time through Ethernet, showing battery power; displaying the internal temperature of the robot; controlling the fan switch; controlling the robot’s operation, with manual mode and automatic cruising mode timed mode:

1) Manual mode control is relatively simple, first set the speed generally designed in 3 levels, and then press forward, backward, stop, and return to the library, the robot will make corresponding actions.

2) In automatic mode, first run manually once, set the cruising point based on Realplay data or visual reference, with the east maximum at 210 and the north maximum at 172. Then set the inspection time segment, and the robot will automatically cruise.

PTZ Control Introduction:

Control the PTZ to rotate in 8 directions using arrow keys, and control the speed of rotation using a slider. Click to start automatic scanning of the PTZ, and click again to stop automatic scanning. The PTZ control interface provides many shortcut keys for the ball machine functions, including 3D positioning, auxiliary focusing, light wiper control, manual tracking, one-click monitoring, one-click cruising, ball machine menu invocation, manual de-icing, etc. Click to view other shortcut keys.

Author: abner_ma, Source: Breadboard Community Link: https://mbb.eet-china.com/forum/topic/139259_1_1.html Declaration: This article is original by community users, and the content does not represent the views and positions of this account.

👉Improving Low Power Design, These 3 Tips Are Often Overlooked

👉7 Methods to Improve Power Supply Design Efficiency

👉The Principles of Motor Rotation and Generation