This article provides a detailed discussion on the application of intelligent IoT technology in coal mining machines. It first introduces the characteristics and advantages of intelligent IoT technology. Further analysis is conducted on the classification of coal mining machines and the existing issues they face. The focus then shifts to the application of intelligent sensor technology, data collection and transmission technology, data analysis and mining technology, intelligent control technology, and intelligent safety monitoring technology in coal mining machines, along with methods for evaluating application effectiveness. Finally, the article looks ahead to the application prospects, technological development directions, potential problems, and challenges.

Introduction

In recent years, intelligent manufacturing technology has developed rapidly. By utilizing cloud computing, big data, artificial intelligence, and digital twin technologies, the manufacturing industry has achieved intelligence and diversified methods, thereby promoting innovation, coordination, green, open, and shared development. In the coal industry, the development of smart mines is essential, and IoT, big data, artificial intelligence, and cloud computing technologies are key supports for establishing smart mines. These technologies help transition from trial-and-error control to precise control and from static control to dynamic control. In fully mechanized mining equipment, coal mining machines directly act on the coal rock to be mined, while scraper conveyors and hydraulic supports assist the coal mining machines in the cutting and loading processes. The cutting trajectory of the coal mining machine affects the posture of the scraper conveyor, while the top plate cutting trajectory determines the support space of the hydraulic supports, and the operating trajectory reflects the linearity of the scraper conveyor’s movement path. Therefore, applying intelligent IoT technology to the upgrading and transformation of coal mining machines has significant practical significance and application value.

Previous research results have mainly focused on theoretical studies of key technologies such as intelligent monitoring, intelligent sensors, intelligent control methods, and artificial intelligence algorithms. However, the relevant technical architecture system and platform construction paths are not yet very clear. This article aims to explore the application of intelligent IoT technology in coal mining machines to address the issues faced by coal mining machines during the coal mining process and to improve their safety and efficiency.

1. Structure of Coal Mining Machines and Existing Issues

Coal mining machines are widely used in coal mining, primarily completing coal extraction and collection by cutting coal rock and transporting it to transportation equipment. Depending on their structure and working principle, coal mining machines can be classified into various types, such as shearers, drum-type, and hydraulic support types. Shearer-type coal mining machines primarily use a shearing method to cut coal rock.

(1) Structure of Coal Mining Machines

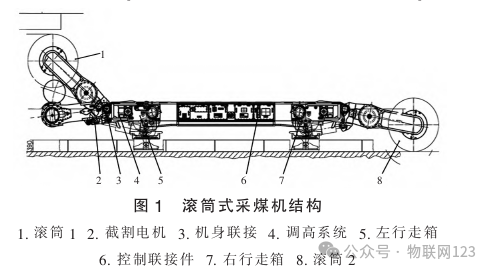

Typically, a coal mining machine consists of a cutting part, loading part, walking part, motor, operation control system, and auxiliary devices. Among these components, the motor, operation control system, and auxiliary devices belong to the electrical system, whose main function is to provide power to other components and monitor the operating parameters of each part. The structure of a drum-type coal mining machine is shown in Figure 1.

(2) Existing Issues of Coal Mining Machines

Despite the important role of coal mining machines in coal production, there are still some issues during their use. On one hand, coal mining machines are prone to component wear and failures during prolonged operation, necessitating regular maintenance and repairs to ensure normal operation; on the other hand, there are also safety hazards during the production process, such as significant noise and vibration generated by the coal mining machines, which can affect the surrounding environment and the stability of equipment.

To address the above issues, introducing intelligent control technology and IoT technology to achieve intelligent monitoring and control of coal mining machines can ensure their safety and efficiency in a short time.

2. Application of Intelligent IoT Technology in Coal Mining Machines

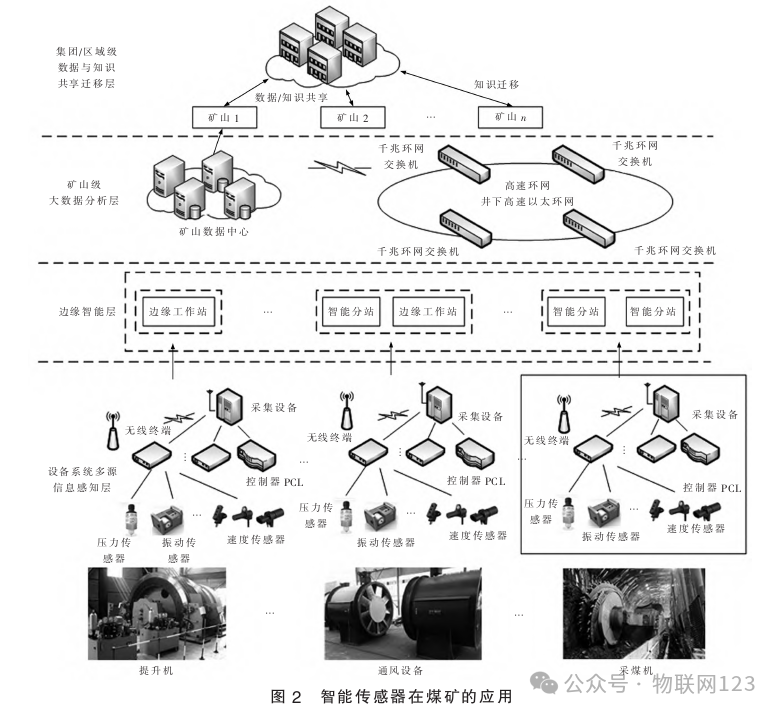

(1) Application of Intelligent Sensor Technology in Coal Mining MachinesIntelligent sensor technology can collect various operational status information of coal mining machines in real-time and transmit it to the control system and data analysis system of the coal mining machine, greatly enhancing the safety and efficiency of the coal mining machine. Additionally, by installing sensors for temperature, vibration, current, pressure, etc., monitoring of various parts of the coal mining machine can be achieved, allowing for timely detection of anomalies and corresponding measures to be taken. The application of intelligent sensors in coal mines is shown in Figure 2, where the inner part of the frame utilizes sensors to collect the status of the coal mining machine.

(2) Application of Data Collection and Transmission Technology in Coal Mining MachinesData collection and transmission technology can collect various operational data of coal mining machines and coal seam data, and upload this information to the cloud for storage, analysis, and processing through wireless transmission technology, enabling remote monitoring and management of the operational status of coal mining machines, thereby improving their safety and production efficiency.

(3) Application of Data Analysis and Mining Technology in Coal Mining MachinesData analysis and mining technology can process the data collected by coal mining machines, enabling intelligent analysis and prediction of the operational status of coal mining machines. By analyzing the operational data of coal mining machines, patterns and anomalies can be identified, allowing for timely measures to be taken to enhance safety and production efficiency.

(4) Application of Intelligent Control Technology in Coal Mining MachinesIntelligent control technology is one of the core technologies in intelligent IoT technology, capable of real-time control of coal mining machine operations, improving their efficiency and safety. Intelligent control technology can monitor and analyze the status of coal mining machines by collecting sensor data, achieving intelligent control and autonomous decision-making. The application of intelligent control technology allows coal mining machines to automatically adjust working parameters such as speed, force, and angle under different working conditions, adapting to various mining environments and coal seam characteristics, thus enhancing stability and efficiency.

In recent years, intelligent control technology has been widely applied in coal mining machines. For example, intelligent control methods based on artificial neural networks have been successfully applied to the walking control, cutter head speed control, and coal seam detection of coal mining machines; simultaneously, intelligent control technologies based on fuzzy control and genetic algorithms have also been applied to cutter head speed control and walking direction control of coal mining machines, achieving good results.

(5) Application of Intelligent Safety Monitoring Technology in Coal Mining MachinesAs a key piece of equipment in coal mining production, the safety of coal mining machines is a crucial guarantee for coal mining production. Intelligent safety monitoring technology can conduct real-time monitoring and early warning of the operational status of coal mining machines, promptly identifying and resolving potential safety issues, thereby enhancing the safety of coal mining machines. Intelligent safety monitoring technology collects operational status data of coal mining machines, performs data analysis and processing, and identifies abnormal states and faults, thus achieving real-time monitoring and early warning of coal mining machines.

3. Evaluation Methods for the Application Effectiveness of Intelligent IoT Technology in Coal Mining Machines

The evaluation of the application effectiveness of intelligent IoT technology in coal mining machines is a quantitative assessment of the effectiveness of this technology, serving as an important means to enhance the intelligence level of coal mining machines. The choice of evaluation methods and the accuracy of experimental results directly relate to the credibility of the evaluation results.

(1) Field Testing MethodUtilizing real coal mining machines and field environments, various performance tests are conducted on coal mining machines, including aspects such as operational status, work efficiency, and safety. The advantage of this method lies in its authenticity and reliability, but it requires a significant amount of time and resources;

(2) Simulation Testing MethodThis method employs computer simulation technology to simulate the working status of coal mining machines under different working environments, thereby evaluating the performance of intelligent IoT technology. The advantage of this method is its low cost and high efficiency, but it is essential to ensure the authenticity of the simulated environment;

(3) Comparative Testing MethodThis method involves comparative testing with traditional coal mining machines, comparing the differences in efficiency, safety, energy conservation, etc., between the two technologies. The advantage of this method is its intuitive comparison, but it is necessary to ensure the consistency of the comparative objects.

4. Conclusion

This article provides a detailed introduction to the application of intelligent IoT technology in coal mining machines. By analyzing the applications of intelligent sensor technology, data collection and transmission technology, data analysis and mining technology, intelligent control technology, and intelligent safety monitoring technology in coal mining machines, it proposes the application prospects and development directions of intelligent IoT technology in the field of coal mining machines. Although intelligent IoT technology has made certain progress in the field of coal mining machines, there are still some problems and challenges:

(1) Data Security IssuesIn the application of IoT technology, the massive amount of data generated by coal mining machines poses a challenge for secure storage and transmission of this data;

(2) System Complexity IssuesThe application of IoT technology in coal mining machines involves the collaborative operation of multiple systems and devices, requiring good interconnection and collaboration between systems. However, in reality, the compatibility and interoperability between different devices are not very good, which brings some complex issues to the application of IoT technology in coal mining machines.

Therefore, in future research, it is necessary to further strengthen the study of these issues to promote the application development of intelligent IoT technology in the field of coal mining machines, applying it to more practical production scenarios to verify its feasibility and application effectiveness.

References:

[1] Liu Ning, Zheng Danyang. Analysis of the Application of Intelligent IoT Technology in Coal Mining Machines [J]. Coal Mine Machinery, 2024, 45(01): 149-151.

| The images and text used in this article are all reprinted. If there are any copyright issues, please inform us immediately, and we will confirm and delete the content based on the proof materials you provide. The content of this article represents the author’s personal views and does not represent the views or positions of IoT 123. |

Special Reminder:

IoT Professional CommunicationGroupWe welcome individuals related to the IoT industry to join, and we also welcome various social butterflies, experts, and seniors to join the group. In addition tonot posting sensitive content, pornographic content, and excessive promotional content, other topics can be freely discussed~——Communication QQ Group 724511126,Friends joining the group, please note: Name – Organization – Research Direction (without notes, please forgive us for not passing), and you will be invited to join the group after the editor’s review.!