Welcome to Follow the China In Vitro Diagnostics Network CAIVD

(1) Overview of Biochemical Diagnostic Instruments

The biochemical analyzer (生化分析仪) is also known as a biochemical instrument, which uses the principles of photoelectric colorimetry and biochemical analysis methods to measure specific chemical components in body fluids. Due to its fast measurement speed, high accuracy, and low reagent consumption, it has been widely used in various hospitals, epidemic prevention stations, and family planning service stations.

The fully automated biochemical analyzer is one of the most commonly used important analytical instruments in clinical testing, primarily used to determine various biochemical indicators in serum, plasma, or other body fluids, such as glucose, albumin, total protein, cholesterol, and transaminases. It plays a significant role in auxiliary diagnosis, efficacy testing, health checks, and drug abuse detection, making it an indispensable clinical testing device in medical and disease control units at all levels, as well as a commonly used instrument in epidemic prevention, quarantine, and biological research. Its clinical application range is expanding rapidly, making it one of the fastest-growing fields in the global medical device industry today.

Biochemical analysis is one of the important means of modern medical clinical diagnosis and disease prevention. The automated biochemical analyzer can continuously and periodically monitor various types of analytical determinations. In addition to general biochemical project determinations, it can also measure certain special compounds such as hormones, immunoglobulins, and drug concentrations. By integrating the biochemical analysis results of blood and other body fluids with other clinical data, it provides a basis for diagnosing diseases and appropriately evaluating organ function, while also identifying complications and determining future treatment benchmarks and measures.

In contemporary hospitals, the automated biochemical analyzer is one of the most basic and indispensable medical devices for disease diagnosis, condition monitoring, efficacy observation, prognosis judgment, and prevention. Diagnoses of acute pancreatitis, diabetic ketoacidosis, myocardial infarction, uremia, and acid-base balance disorders caused by dehydration or edema in emergency situations all rely on biochemical analyzers. Tests for liver function, kidney function, protein balance, lipid metabolism, glucose metabolism, potassium, sodium, chloride, calcium, phosphorus, magnesium, and trace elements are all conducted by biochemical analyzers. The results obtained from biochemical analyzers affect the overall medical quality of the hospital and are crucial for the safety of patients.

(2) Principles of Biochemical Diagnostic Instruments

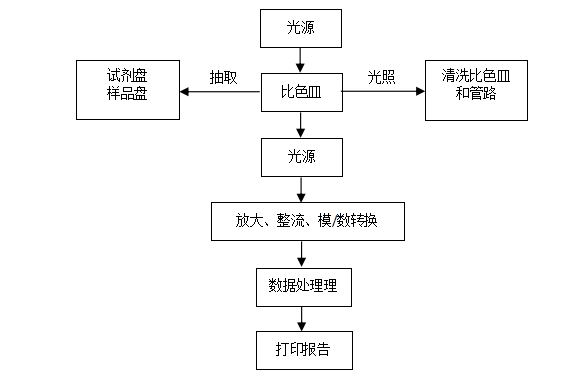

The automated biochemical analyzer is a high-tech product that integrates optics, mechanics, electricity, and fluidics. It can be roughly divided into four parts: sample introduction system, optical system, control system, and data processing system. The sample introduction system is a prerequisite for analysis, the optical system is the core of the entire instrument, the control system ensures analysis, and the data processing system extends functionality. Currently, the vast majority of biochemical analyzers work based on the principle of photoelectric colorimetry, and their structure can be roughly seen as consisting of a photoelectric colorimeter or spectrophotometer combined with a microcomputer.

In terms of structural composition, the biochemical analyzer consists of a sample holder, sampling device, reaction pool or reaction pipeline, heater, detector, microprocessor, printer, and functional monitoring device. The specific working principle is as follows: a monochromatic light beam illuminates the colored liquid in the colorimetric cuvette, and the absorption of light energy by the measured sample is detected by a detector, which converts the light signal into a corresponding electrical signal. This signal is amplified, rectified, and converted into a digital signal, which is sent to the computer. At the same time, the computer controls the drive power to operate the filter wheel and sample tray, and processes, computes, analyzes, and saves the measurement data based on the user’s selected working mode. The printer simultaneously prints the corresponding results, and finally, after measuring each group of samples, the colorimetric cuvette is cleaned.

Working Principle of Biochemical Analyzers

(3) Classification of Biochemical Diagnostic Instruments

Since the first fully automated biochemical analyzer was successfully produced by Technicon in the United States in 1957, various models and functions of fully automated biochemical analyzers have emerged, marking an important step towards the automation of clinical biochemical testing in hospitals. To date, the development of biochemical analyzers has been very rapid, with diverse classification methods, generally categorized as follows.

01

Classification by Degree of Automation

(1) Semi-Automatic Biochemical Analyzers

In the analysis process, some operations need to be performed manually (such as adding samples, heating, aspirating colorimetric solutions, recording results, etc.), while other operations can be automatically completed by the instrument. Such instruments are referred to as semi-automatic biochemical analyzers. Their characteristics include small size, simple structure, high flexibility, and low cost.

(2) Fully Automatic Biochemical Analyzers

The entire process from sample addition to outputting test results is completely automated by the instrument; the operator only needs to place the sample in a specific location on the analyzer and start the instrument to receive the test report without any manual intervention. Since there are no manual operation steps in the analysis, subjective errors are minimal, and due to the automatic reporting of abnormal situations and self-correction of working states, systematic errors are also reduced.

02

Classification by Structure and Principle

(1) Continuous Flow (Pipeline) Analyzers

Continuous flow analyzers refer to those where the chemical reaction of each sample to be tested with the reagent is completed while flowing through the same pipeline. These instruments can generally be divided into air-segmented systems and non-segmented systems. The air-segmented system refers to using a small segment of air to separate each sample, reagent, and mixed reaction liquid, while the non-segmented system relies on reagent blanks or buffer solutions to separate the reaction liquids of each sample. Among pipeline analyzers, the air-segmented system is the most common.

(2) Discrete Analyzers

Discrete analyzers are programmed according to manual operation methods, replacing manual operations with rhythmic mechanical operations, with each step linked by conveyor belts, operating sequentially. The chemical reactions of each sample to be tested with the reagent are completed in their respective reaction cups.

(3) Centrifugal Analyzers

Centrifugal analyzers refer to those where each sample to be tested is mixed with the reagent under the action of centrifugal force in their respective reaction chambers, completing the chemical reaction and measurement almost simultaneously, resulting in higher analysis efficiency.

(4) Dry Film Analyzers

Dry film analyzers refer to those where reagents are solidified on a carrier such as film or filter paper, with each sample to be tested added to the corresponding test strip for reaction and measurement. Their advantages include quick operation and portability, and they are now commonly used in emergencies and field tests.

(5) Bag Analyzers

Bag analyzers refer to those that use reagent bags instead of reaction cups and colorimetric cups, with each sample to be tested reacting and being measured within their respective reagent bags.

03

Classification by Reagent and Instrument Compatibility

(1) Closed Systems

Instruments and reagents are bundled for sale and use, generally specified by the instrument manufacturer, and cannot use reagents from other manufacturers.

(2) Open Systems

Instruments and reagents are sold and used separately, with no specified reagent brand by the instrument manufacturer, allowing users to choose freely.

04

Classification by International Testing Standards

(1) Small Instruments

Small instruments are generally single-channel and have a slower testing speed.

(2) Medium Instruments

Medium instruments are generally multi-channel, capable of testing 2-10 items simultaneously, with some instruments allowing for arbitrary selection of test items while others do not.

(3) Large Instruments

Large instruments are generally multi-channel, capable of testing more than 10 items simultaneously, with the ability to freely select analysis items.

05

Classification by Testing Channels

(1) Single-Channel Biochemical Analyzers

Single-channel biochemical analyzers can only test one item at a time, but the item can be changed, with a slower testing speed.

(2) Multi-Channel Biochemical Analyzers

Multi-channel biochemical analyzers can test multiple items simultaneously.

(4) Development History of Biochemical Diagnostic Instruments

Biochemical analyzers have evolved from the earliest spectrophotometers to semi-automatic biochemical analyzers, and now to the widely used fully automatic biochemical analyzers, going through three stages.

First Generation: The spectrophotometer, which uses ultraviolet light, visible light, infrared light, and laser to measure the absorption spectrum of substances, is a method for qualitative and quantitative analysis of substances and structural analysis, known as spectrophotometry or spectrophotometric technology. The advantages of spectrophotometers include direct reading of absorbance, simple operation, and low cost; however, they cannot directly calculate concentration values, have large errors, and few detectable items.

Second Generation: Semi-automatic biochemical analyzers, where some operations (such as adding samples, heating, aspirating colorimetric solutions, recording results, etc.) need to be performed manually, while others can be automated. These instruments are characterized by small size, simple structure, and high flexibility, capable of being used independently or in conjunction with other instruments, and are inexpensive.

Third Generation: Fully automatic analyzers, where the entire process from sample addition to outputting results is entirely automated. The operator only needs to place the sample in a specific location on the analyzer and start the instrument to receive the test report. Fully automatic biochemical analyzers have more reagent and sample positions than semi-automatic ones, with faster testing speeds, eliminating errors caused by manual reagent addition, and better accuracy and repeatability.

01

International Development History of Biochemical Analyzers

In the early 19th century, the most primitive manual methods were used to complete a very small number of biochemical indicator tests. During this stage, the methods of loading samples and reagents mainly involved using pipettes, leading to extremely low work efficiency and significant errors. In the 1950s, with the emergence of automatic diluters, the loading of liquids was automated or semi-automated, and semi-automatic colorimeters were gradually used, completing sample colorimetric determinations using fixed flow colorimetric cups.

In 1957, Technicon in the United States manufactured the world’s first biochemical analyzer based on the design of Professor Skeggs, leading to a rapid emergence of various models and functions of fully automatic biochemical analyzers. In 1965, the discrete automatic analyzer was born, with a working principle similar to manual operations, where samples were processed in separate reaction cups.

The 1970s opened up reflective light analyzers paired with dry chemical reagents, improving the accuracy, precision, multifunctionality, and analysis speed of biochemical analysis. The application of analytical techniques such as spectroscopic technology, centrifugation technology, chromatography, electrophoresis, radioactive nuclides, and immunological techniques has significantly promoted the rapid development of various clinical biochemical testing instruments. In the early 1980s, TECHNICON invented a method to overcome cross-contamination between samples, raising the level of automatic biochemical analyzers to a new height. In the late 1980s, dry chemical analyzers using solid-phase enzymes, ion-selective electrodes, and multi-layer membranes were developed. Since the 1990s, with technological advances, biochemical analyzers have been developed towards more functional completeness, with an increasing number of detectable items and higher accuracy and precision, better meeting the various requirements of laboratory management.

02

Development History of Biochemical Analyzers in China

Starting in the mid-1970s, the Shanghai Medical Device Research Institute, Beijing Medical Instruments Research Institute, Beijing Analytical Instrument Factory, and Beijing Biochemical Instrument Factory developed continuous flow, discrete, and centrifugal biochemical analyzers. Although domestic biochemical analyzers with independent intellectual property rights were developed at that time, the quality was subpar, and even those that were prototyped did not reach the market, with most such instruments in use still relying on imports.

In 1972, the Italian Embassy in China donated a continuous flow automatic biochemical analyzer to Peking Union Medical College Hospital; in 1975, Tianjin Medical University Second Hospital imported a two-channel continuous flow automatic biochemical analyzer from the Italian company Carlo Erba. Based on the study of these two instruments, Beijing Biochemical Instrument Factory launched a three-channel continuous flow automatic biochemical analyzer, which won a national science and technology conference award in 1978, but unfortunately did not see market effects.

During the widespread use of automatic biochemical analyzers in Chinese clinical chemistry laboratories, the most significant impact came from the MicroLab semi-automatic biochemical analyzer introduced by the Dutch company Vital around 1986, with thousands of units imported. To narrow the gap between domestic clinical laboratories’ automation processes and those of developed countries, developing fully automatic biochemical analyzers became the top priority in domestic laboratory medicine at that time.

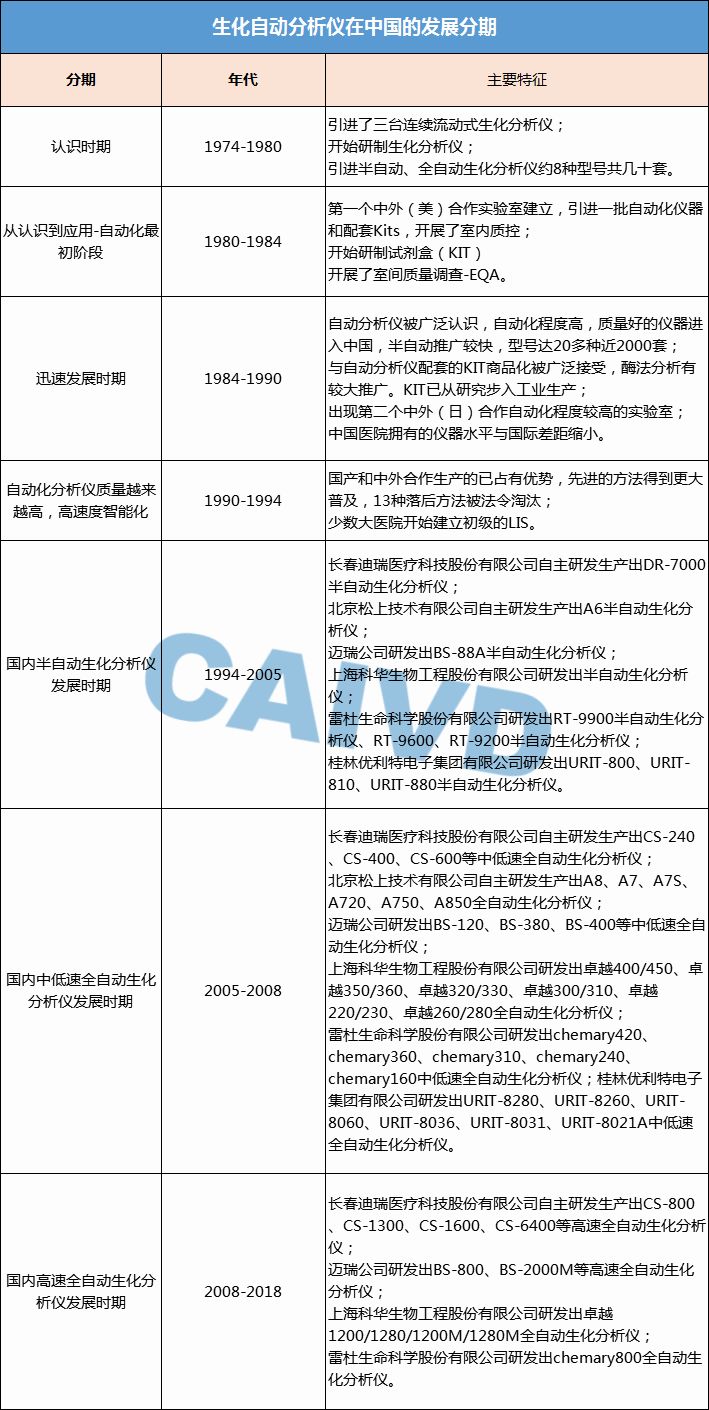

Since the 1990s, through persistent efforts, various models of semi-automatic and fully automatic biochemical analyzers have been independently developed in China. The development of clinical chemical testing automation in China can be summarized into seven periods, as shown in the figure below.

(5) Main Circulating Products in the Biochemical Diagnostic Instrument Market

With the continuous development of fully automatic biochemical analyzers and the increasing testing speed, we classify fully automatic biochemical analyzers based on testing speed into several categories: ≤300T/H, 300-400T/H, 400-600T/H, 600-800T/H, >800 T/H, etc.

(6) Market Capacity of Biochemical Diagnostic Instruments

According to industry data and market sales statistics from various sub-companies, the biochemical market capacity was approximately 10.3 billion RMB in 2016, and about 11.3 billion RMB in 2017, with a growth rate of approximately 9%. In the domestic IVD sub-sector, the traditional biochemical market share is gradually declining, and the growth rate is decreasing. As domestic biochemical testing matures and stabilizes, the subsequent market growth rate will gradually slow down. Imported brands are mainly dominated by Roche and Beckman, accounting for about one-quarter of the market, while the rest is mostly domestic brands. The expected market growth rate in the biochemical field in 2017 is around 10%, and the entire market has turned into a blue ocean market, with most brands experiencing sluggish growth for various reasons.

Looking at the domestic market, the domestic replacement rate of biochemical products is close to 50%. There are many manufacturers, with over 200 companies related to clinical biochemistry registered according to CFDA statistics. However, imported manufacturers still dominate large tertiary hospitals and other quality clients. Most fully automatic biochemical analyzers in top-tier hospitals are basically monopolized by foreign companies. This is mainly due to the involvement of optics, mechanics, electricity, software, fluid control, temperature control, and biochemical analysis, which requires comprehensive technology, complex system structure, strict control timing requirements, and high reliability and precision. With the successful development of domestic biochemical diagnostic reagents and instruments, domestic biochemical analyzers have rapidly promoted their application in hospitals below the tertiary level. Currently, some quality domestic biochemical manufacturers have gradually penetrated the high-end domestic market, such as Mindray, Kehua, and Dirui.

Foreign fully automatic biochemical analyzers have become very mature in technology after years of development, with companies like Roche, Beckman, Abbott, Siemens, Johnson & Johnson, and Hitachi all launching high-performance, high-speed, modular biochemical instruments that can be linked with immunoassays. Domestic biochemical analyzers started later, with a weak technological foundation. Currently, domestic companies such as Mindray, Kehua, and Dirui have successfully produced biochemical instruments that can compete with foreign companies, primarily targeting the mid and low-end markets; while domestic enterprises such as InnoHua, Jinrui, Pukang, and Tekang focus on the low-end market. From the market situation, large hospitals and laboratories generally prioritize foreign brands of fully automatic biochemical analyzers due to their higher requirements for technical parameters, performance, and brand. Meanwhile, small and medium hospitals tend to consider cost factors more heavily, generally opting for small and medium-sized biochemical analyzers. Thus, it can be seen that the domestic high-end market is still dominated by foreign brands. As foreign brand product lines penetrate deeper into the market, competition in the small and medium hospital market will become more intense.

More Exciting Content on In Vitro Diagnostics

Please Click on the Large Image, Long Press to Identify the QR Code Below to View

Notice

In the spirit of “Inclusiveness and Serving the Public,” the China In Vitro Diagnostics Network CAIVD group has been established, and we welcome professionals in in vitro diagnostics and laboratory medicine to join the group and speak freely. Please Click on the Large Image, Long Press to Identify the QR Code Below to Join the Group.

Source:China In Vitro Diagnostics Development Blue Book

Contributed and Edited by: Yishui

Proofread by:Bonnie

Editor:Scorpio

1

Recommended Reading

-

Seventh China In Vitro Diagnostics Industry Development Conference – First Notice

-

2019 Annual Meeting of the Medical Testing Industry Branch of the National Health Industry Enterprise Management Association and the Review (Final) Meeting of the “China In Vitro Diagnostics Industry Development Blue Book” 2018

-

Release of Information Business Coding Rules and Methods for Designated Medical Institutions (with Diagram)

-

Analysis Series on the Development of Biochemical Diagnostic Technology and Products – Biochemical Diagnostic Reagents

-

Tuberculosis Classification