3

D

Acoustic technology brings new options for 3D printing.

Currently, most 3D printing methods rely on photo (light) or thermal activation reactions for precise manipulation of polymers. A new platform technology called direct sound printing (DSP) uses sound waves to create new objects, potentially providing a third option.

This process is described in a paper published in *Nature Communications*. It demonstrates how focused ultrasound can be used to generate sonochemical reactions in tiny cavitation regions (essentially tiny bubbles). Extreme temperatures and pressures lasting trillionths of a second can produce complex geometries that existing technologies cannot manufacture.

“Ultrasound frequencies have been used for destructive process programs, such as focused ultrasound laser ablation of tissues and tumors. We wanted to use them to create something,” said Muthukumaran Packirisamy, a professor in the Department of Mechanical, Industrial and Aerospace Engineering at the Gina Cody School of Engineering and Computer Science and the corresponding author of the paper.

Mohsen Habibi, a research assistant at Concordia’s Photonic Bio-Micro Systems Laboratory, is the lead author of the paper. His lab colleagues and PhD students Shervin Foroughi and former master’s student Vahid Karamzadeh are co-authors.

The image originally appeared in *Nature Communications*

Ultra-Precise Reactions

As the researchers explained, DSP relies on chemical reactions generated by pressure fluctuations within tiny bubbles suspended in a liquid polymer solution.

“We found that if we use a certain type of ultrasound with specific frequency and power, we can create very localized and concentrated chemical reaction zones,” said Habibi. “Essentially, the bubbles can act as reactors to drive the chemical reactions, converting liquid resin into solid or semi-solid materials.

The reactions caused by the ultrasound waves directed oscillations within the micro-bubbles are intense, although they only last for picoseconds. Temperatures in the cavities can reach around 15,000 K, with pressures exceeding 1,000 bar (the pressure at Earth’s surface is about 1 bar). The reaction time is so short that surrounding materials are unaffected.

The researchers experimented with a polymer used in additive manufacturing called polydimethylsiloxane (PDMS). They used a transducer to generate an ultrasound field that passes through the shell of the building material, curing the target liquid resin and depositing it onto a platform or other previously cured objects. The transducer moves along a predetermined path, ultimately creating the desired product pixel by pixel. The parameters of the microstructures can be manipulated by adjusting the duration of the ultrasound frequency and the viscosity of the materials used.

Versatile and Specific

The authors believe that the versatility of DSP will benefit industries that rely on highly specific and precise equipment. For example, the polymer PDMS is widely used in the microfluidics industry, where manufacturers require controlled environments (clean rooms) and complex photolithography techniques to manufacture medical devices and biosensors.

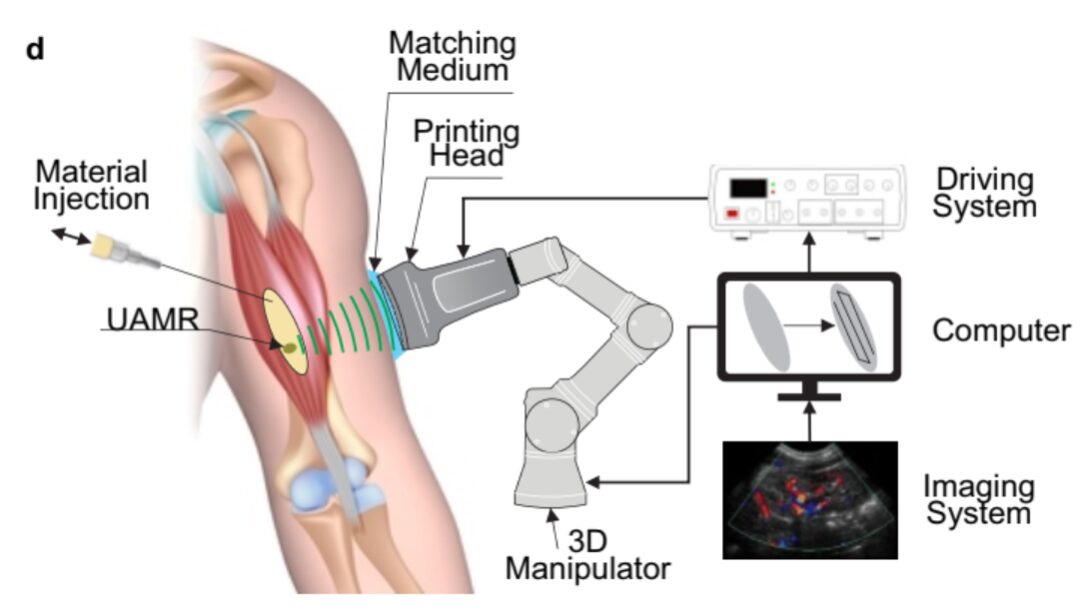

Aerospace engineering and maintenance could also benefit from DSP, as ultrasound can penetrate opaque surfaces like metal shells. This could allow maintenance personnel to repair components located deep within an aircraft fuselage, which are inaccessible to printing technologies that rely on light-activated reactions. DSP could even provide medical applications for remote in-body printing in humans and other animals.

“We have demonstrated that we can print a variety of materials, including polymers and ceramics,” Packirisamy said, “Next, we will try polymer-metal composites, and ultimately we hope to print metals using this method.”

This research was funded by ALIGO INNOVATION, Concordia, and the Quebec Natural Sciences and Engineering Research Council (FRQNT).

Source

concordia

Research Journey, Small Voice Accompanies You

WeChat ID|ioa-lib

Tel|010-82547858