On June 20, the General Manager of Weinan High-tech Zone Torch Technology Development Co., Ltd., Cheng Kai, was a guest on “Environmental Hotline” to communicate with the audience about related work.

The Concept of 3D Printing

3D printing is a manufacturing technology, scientifically known as “additive manufacturing.” Its technical principle is completely different from traditional manufacturing technologies, such as casting, forging, drilling, and cutting, which require material removal or alteration of material forms. Instead, it constructs three-dimensional objects by stacking materials layer by layer, similar to building a house with blocks, but with plastic filaments, metal powders, or even construction materials like concrete.This technology breaks the design constraints of traditional manufacturing, achieving unprecedented design freedom and personalized, customized production. Currently, the application of 3D printing technology in our daily production and life is continuously expanding, including medical implants, industrial molds, aerospace components, and cultural tourism commemorative products, making it one of the essential key technologies in modern manufacturing.

Company and Park Overview

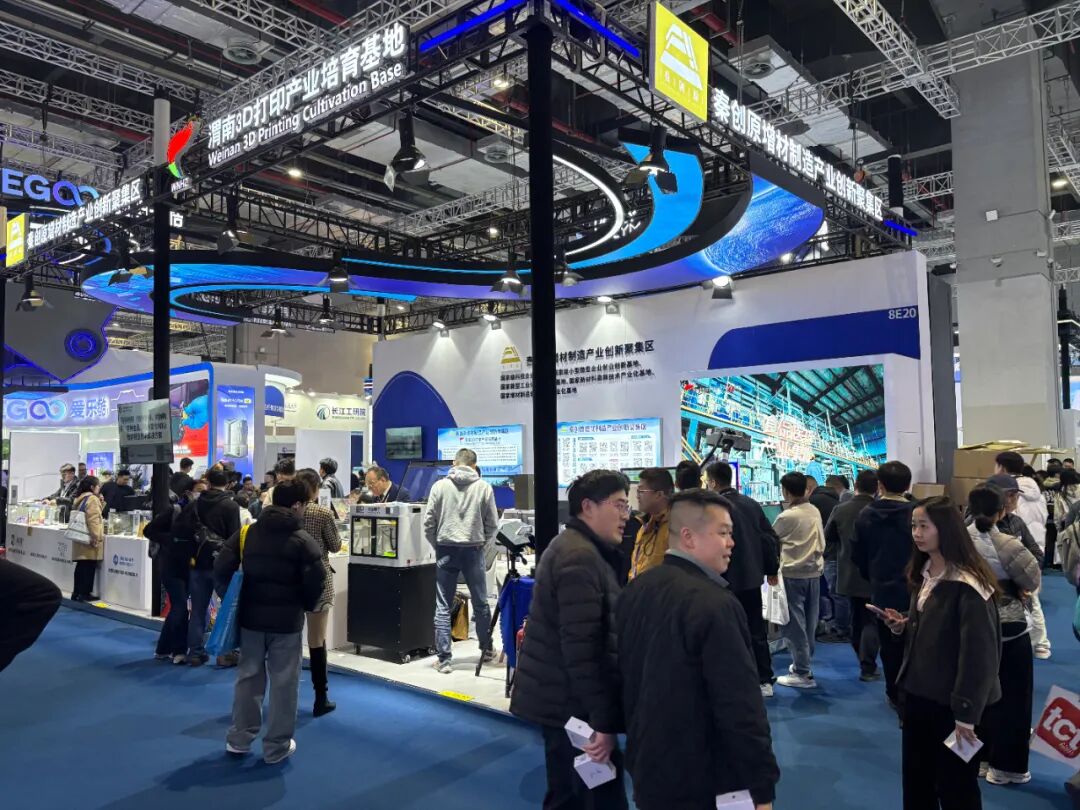

The Weinan High-tech Zone 3D Printing Industry Cultivation Base (referred to as the Park) is mainly constructed, operated, and managed by Torch Company. The company is a state-owned enterprise under the Weinan High-tech Zone Management Committee and is a wholly-owned subsidiary of the Weinan High-tech Investment Development Group. It has seven business departments, including party and mass work, project services, enterprise services, investment promotion, and planning, and is a council member of the National Additive Manufacturing Industry Alliance and an executive council member of the Shaanxi Province Additive Manufacturing Industry Alliance.

The park was established in 2013 and has been recognized by the Ministry of Industry and Information Technology and the Ministry of Science and Technology as a national new industrialization industry demonstration base, a national small and micro enterprise innovation and entrepreneurship demonstration base, and a national Class A technology business incubator, among other honors. The park covers an area of approximately 520 acres and is divided into four functional sections, including the first phase technology business incubator, which mainly provides office, research and development, and small-scale testing support for some start-up companies and entrepreneurial teams; the second phase additive manufacturing industrial park, which focuses on the national innovation center approved by the Ministry of Industry and Information Technology in our province— the National Additive Manufacturing Innovation Center, undertaking some major technological achievements for transformation and industrialization; the third phase is the additive manufacturing technology achievement transformation demonstration center, mainly responsible for the industrialization of research results from universities and research institutes inside and outside the province and the introduction of key enterprises; the fourth phase is a specific industrial area mainly focused on the research and application of military products. Currently, the park has basically formed a collaborative development system for the entire additive manufacturing industry chain, including software modeling, material preparation, equipment manufacturing, product printing, and technical services, and has become the largest additive manufacturing industry development cluster in the central and western regions of China..

Park Domains

Additive Manufacturing Software Systems Domain, led by companies such as Lingzhi 3D, Shenzhou Dexin, Keri Aomai, and Tongke Lianying (Weinan), focuses on the development of supporting software such as reverse engineering and 3D inspection software, 3D scanning software, data processing software, data conversion software, process control software, and online detection and monitoring systems, helping to enhance China’s core software supply capacity and level for additive manufacturing.

Additive Manufacturing Specialized Materials Domain, led by companies such as Yingbo Metal, Huahai New Materials, Shaanxi Unico, and Feibo Technology, focuses on the research and preparation of over 30 types of high-quality, high-performance specialized series materials, including titanium, nickel, aluminum, cobalt-chromium alloys, tool steel, tantalum-niobium metals, polyether ether ketone, fiberglass, carbon fiber, nylon, and other non-metallic and metallic specialized materials for large-scale preparation.

Additive Manufacturing Metal and Non-metal Equipment Domain, led by companies such as Plitex (Weinan), Shaanxi Zhitou, Shaanxi Jugao, Shaanxi Baipusheng, and Shaanxi Feifanshi, focuses on the research and production of over 20 types of high-quality, high-stability additive manufacturing equipment, including laser selective melting equipment, cladding deposition equipment, arc additive equipment, solid-state additive manufacturing equipment, high-performance fiber-reinforced composite material equipment, and high-precision biological 3D printing devices.

Additive Manufacturing Product Technical Services and Application Domain, led by companies such as Mark Medical, Zhongchuang Tejing, Jiete Intelligent, Huiju Thermal Flow, and Shaanxi Jinbenyue, focuses on the development and promotion of products such as human cardiovascular medical aids, 3D printed personalized orthopedic implants, bionic tissue repair 3D printed scaffolds, large-size casting sand mold additive manufacturing, and 3D printed complex internal flow channel surface finishing, accelerating the industrial application of additive manufacturing technology in various fields.

Key Work Progress in the Cluster Area

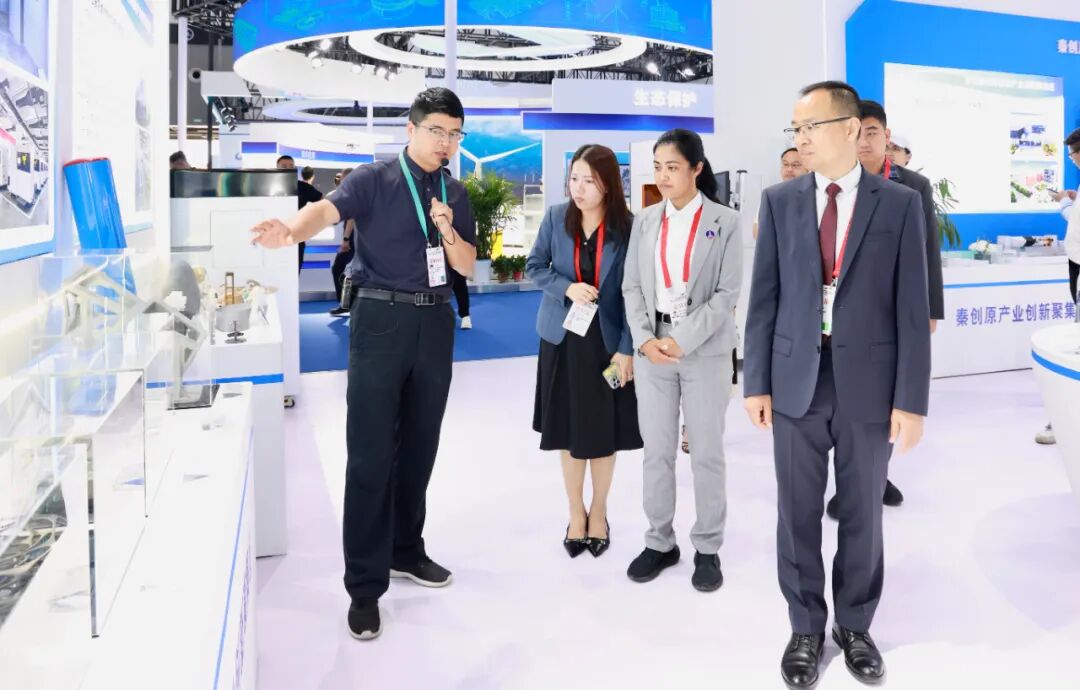

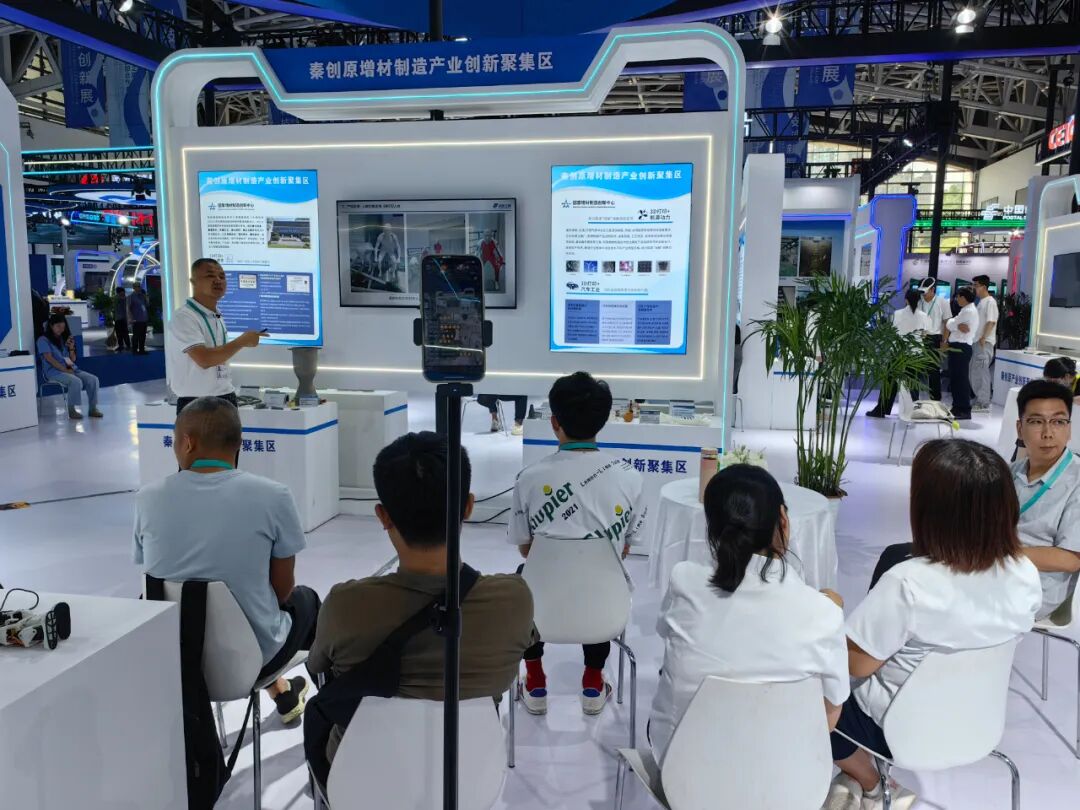

The Qin Chuang Yuan Additive Manufacturing Industry Innovation Cluster Area, centered on Weinan High-tech Zone, with the Weinan High-tech Zone 3D Printing Industry Cultivation Base as an important carrier, adheres to the concept of “resource aggregation, innovation-driven, co-construction and sharing, serving the whole province, and radiating and driving”. We closely follow the strategic requirements of “1235” and consistently uphold the main line of “deep integration of technological innovation and industrial innovation,” implementing a dual-wheel drive of “technological research and development and application scenario innovation,” promoting the three major fields of “characteristic, intensive, and chain-clustered development of the additive manufacturing industry,” and focusing on the construction of five major platform tasks: high-level innovation platforms, high-energy industry platforms, high-efficiency transformation platforms, high-standard operation platforms, and high-level scientific and technological innovation ecological platforms, achieving phased results.First, we focus on building high-level innovation platforms. Around the development needs of the industrial chain, on one hand, we collaborate with leading enterprises to plan and implement the Shaanxi Province Aerospace Metal Additive Manufacturing Innovation Consortium and the Shaanxi Province Medical-Engineering Integration Additive Manufacturing Common Technology R&D Platform project, which has been approved for construction by the end of 2024, with self-raised funds and 5 million provincial matching funds already in place, accelerating the implementation of key innovation tasks. On the other hand, the Western Technology Center for Hot Isostatic Pressing, in cooperation with China Steel Research Group, has been fully completed and put into use, and a “Hot Isostatic Pressing Technology Research Center” has been established in collaboration with Xi’an University of Technology to conduct research on hot isostatic pressing technology for lightweight high-entropy alloy composite materials for vehicles, effectively filling the gap in hot treatment technology and processing services for additive manufacturing in the western region.Second, we continuously enhance industry cultivation capabilities. With the high-energy industry platform as the focus, we deeply implement the four major projects of “climbing, upgrading, advancing, and listing” for technology-based enterprises, carry out gradient cultivation of enterprises, and establish and implement policies and services for “precise drip irrigation.” We conduct precise investment promotion for the industrial chain, compile and use industrial chain and innovation chain maps, actively carry out various investment promotion activities, and promote the establishment of out-of-province enterprises such as Tianqi Industrial and Tongke Lianying. The production expansion projects of key enterprises such as Weinan Plitex, Zhitou, Jugao, Yixin Weichuang, and Micro-arc Reinforcement have all reached production capacity, with 30 new registered enterprises, a total of 69 recognized technology-based SMEs, 39 high-tech enterprises, 13 large-scale industrial enterprises, and 4 specialized and innovative enterprises. The total operating income reached 610 million yuan, contributing to a 17.7% growth in the additive manufacturing industry chain output value in the province. Third, we vigorously implement the transfer and transformation of achievements. Focusing on the construction tasks of the high-efficiency transformation platform, we successfully planned and implemented the Shaanxi Province Additive Manufacturing Industry Chain Supply and Demand Matching Activity (automotive industry application) and the 9th Silk Expo Additive Manufacturing Industry Chain Special Roadshow and the Shaanxi Province Science and Technology Achievement Transformation “Three Reforms” Weinan Action. We strengthen cooperation with institutions such as the Xi’an Jiaotong University Technology Transfer Center, release technology demand lists, establish project tracking service systems, and accelerate the transfer and transformation of scientific and technological achievements from China Communications First Public Institute, Shaanxi Steel Group, Xi’an University of Arts and Sciences, etc. We support Shaanxi Yixin Weichuang Company in applying for the provincial-level comprehensive thermal management technology concept verification center and successfully obtaining approval, leading the organization of over 20 enterprises to apply for 16 provincial science and technology department “four-chain integration” projects and 9 key technology core tackling projects. Focusing on the needs of industries such as fine chemicals and engineering machinery in Weinan, we organize enterprises like Plitex and Lingzhi 3D to carry out additive manufacturing technology scenario matching activities, accelerating market application cooperation with universities and enterprises in Weinan such as Weinan Normal University, Shenwei Management, and Shaanxi Coal Qicheng.Fourth, we steadily enhance the service capabilities of the park. Taking the construction of a high-standard operation platform as our responsibility, as one of the co-construction units of the additive manufacturing industry innovation cluster area, Torch Company was elected as a new executive council member of the Shaanxi Province Additive Manufacturing Industry Technology Innovation Alliance, and was newly selected as an investor in the Shaanxi Additive Manufacturing Venture Capital Fund (Phase II) and the Weinan High-tech Zone Angel Investment Fund. As the operating entity of the Weinan 3D Printing Industry Cultivation Base, we organized the application for the provincial-level high-energy scientific and technological innovation incubator for additive manufacturing and successfully obtained approval. After self-raised funds and provincial matching funds are in place, we accelerate the enhancement of “industry + incubation, investment + incubation” service capabilities. At the same time, we plan and implement a public service platform for innovation in the additive manufacturing industry, applying for provincial-level “four-chain integration” projects, focusing on testing services for the performance, quality, and reliability of specialized materials, devices, equipment, printed products, and software for additive manufacturing.Fifth, we explore the construction of a high-level scientific and technological innovation ecological platform. We strengthen diversified technological financial supply, actively promote the market operation of the second phase fund for additive manufacturing venture capital and angel investment funds, jointly develop products such as intellectual property and equity pledge loans with financial institutions like SPD Bank, and explore the “technology + fund + industry” model, successfully facilitating key domestic enterprises in the industrial chain such as Shanghai Yingpu, Suzhou Boli, Jiangsu Weilai, Tianqi Industrial, and Shaanxi Dingyi to reach intentions for project landing in Weinan High-tech Zone, further extending the industrial chain. We lead the establishment of the Weinan City Technology Manager Association, introduce and cultivate a team of compound technology brokers, and carry out customized exclusive scientific and technological innovation services such as technology achievement excavation, docking, landing, tracking services, and entrepreneurial incubation. We plan to hold a release conference for the achievements of the additive manufacturing industry innovation cluster area and a technology project signing event in July.

Third, we vigorously implement the transfer and transformation of achievements. Focusing on the construction tasks of the high-efficiency transformation platform, we successfully planned and implemented the Shaanxi Province Additive Manufacturing Industry Chain Supply and Demand Matching Activity (automotive industry application) and the 9th Silk Expo Additive Manufacturing Industry Chain Special Roadshow and the Shaanxi Province Science and Technology Achievement Transformation “Three Reforms” Weinan Action. We strengthen cooperation with institutions such as the Xi’an Jiaotong University Technology Transfer Center, release technology demand lists, establish project tracking service systems, and accelerate the transfer and transformation of scientific and technological achievements from China Communications First Public Institute, Shaanxi Steel Group, Xi’an University of Arts and Sciences, etc. We support Shaanxi Yixin Weichuang Company in applying for the provincial-level comprehensive thermal management technology concept verification center and successfully obtaining approval, leading the organization of over 20 enterprises to apply for 16 provincial science and technology department “four-chain integration” projects and 9 key technology core tackling projects. Focusing on the needs of industries such as fine chemicals and engineering machinery in Weinan, we organize enterprises like Plitex and Lingzhi 3D to carry out additive manufacturing technology scenario matching activities, accelerating market application cooperation with universities and enterprises in Weinan such as Weinan Normal University, Shenwei Management, and Shaanxi Coal Qicheng.Fourth, we steadily enhance the service capabilities of the park. Taking the construction of a high-standard operation platform as our responsibility, as one of the co-construction units of the additive manufacturing industry innovation cluster area, Torch Company was elected as a new executive council member of the Shaanxi Province Additive Manufacturing Industry Technology Innovation Alliance, and was newly selected as an investor in the Shaanxi Additive Manufacturing Venture Capital Fund (Phase II) and the Weinan High-tech Zone Angel Investment Fund. As the operating entity of the Weinan 3D Printing Industry Cultivation Base, we organized the application for the provincial-level high-energy scientific and technological innovation incubator for additive manufacturing and successfully obtained approval. After self-raised funds and provincial matching funds are in place, we accelerate the enhancement of “industry + incubation, investment + incubation” service capabilities. At the same time, we plan and implement a public service platform for innovation in the additive manufacturing industry, applying for provincial-level “four-chain integration” projects, focusing on testing services for the performance, quality, and reliability of specialized materials, devices, equipment, printed products, and software for additive manufacturing.Fifth, we explore the construction of a high-level scientific and technological innovation ecological platform. We strengthen diversified technological financial supply, actively promote the market operation of the second phase fund for additive manufacturing venture capital and angel investment funds, jointly develop products such as intellectual property and equity pledge loans with financial institutions like SPD Bank, and explore the “technology + fund + industry” model, successfully facilitating key domestic enterprises in the industrial chain such as Shanghai Yingpu, Suzhou Boli, Jiangsu Weilai, Tianqi Industrial, and Shaanxi Dingyi to reach intentions for project landing in Weinan High-tech Zone, further extending the industrial chain. We lead the establishment of the Weinan City Technology Manager Association, introduce and cultivate a team of compound technology brokers, and carry out customized exclusive scientific and technological innovation services such as technology achievement excavation, docking, landing, tracking services, and entrepreneurial incubation. We plan to hold a release conference for the achievements of the additive manufacturing industry innovation cluster area and a technology project signing event in July.

The 3D Printing Innovation Base Selected as a Typical Case by the Ministry of Industry and Information Technology

Receiving this national honor is a support, affirmation, and recognition from the competent authorities for the park’s adherence to cultivating and developing new productive forces. Prior to this, the park was twice recognized by the Ministry of Industry and Information Technology as a national industrial base, namely the national new industrialization industry demonstration base recognized in 2018 and the national small and micro enterprise innovation and entrepreneurship base recognized in 2022.

The typical case project of the Ministry of Industry and Information Technology was applied for by our park in July last year, and after provincial and municipal recommendations, formal reviews, expert evaluations, and defense procedures, it was officially approved in October last year. A total of nearly 200 application materials were collected nationwide for the typical case project, and finally, 66 typical cases were selected, with 5 units and 8 cases from Shaanxi Province selected, ranking second in the country. Among them, the park is the only industrial park in Weinan City selected as a typical case, and we elaborated on typical practices in the case materials around “technological innovation,” which were ultimately included in the “2024 Collection of Typical Cases for Promoting New Industrialization in Industrial Parks” by the Information Center of the Ministry of Industry and Information Technology for nationwide promotion and publicity.

Writing a New Chapter for the High-Quality Development of the 3D Printing Industry

Focusing on the Layout and Construction of Innovation Industry Platforms. Effectively leveraging the half-hour economic circle effect of Xi’an, seizing the opportunity of the province’s deepening “three reforms,” and taking the opportunity of the new three-year action plan policy of Qin Chuang Yuan, we efficiently utilize the rich advantages of provincial scientific and educational resources, increase cooperation with universities and research institutes inside and outside the province, and synergize with the National Additive Manufacturing Innovation Center, leading enterprises in the industry such as Xi’an Plitex, Sailong Metal, and Shaanxi Zhitou to build the Additive Manufacturing Shaanxi Laboratory, creating a key innovation platform in the field of additive manufacturing nationwide. At the same time, we encourage enterprises to increase R&D investment, jointly build industrial technology research institutes, enterprise technology centers, engineering technology research centers, and expert academician workstations with universities and research institutes, facilitating enterprises to precisely undertake the transformation of scientific research achievements, achieving breakthroughs in new technologies, new product development, and new scenario applications, forming core competitiveness in the industrial chain.

Focusing on Extending and Expanding the Upstream and Downstream Industrial Chains. Adhering to the principle of “emphasizing both introduction and cultivation,” focusing on the four industrial development directions of additive manufacturing: “materials, equipment, process software, and application services,” with “additive manufacturing + application” as the main breakthrough point, actively building a digital platform for the additive manufacturing industry, breaking down information barriers in the industrial chain, closely monitoring key links in the additive manufacturing industry chain, and carrying out chain-based investment promotion, technology investment promotion, and fund investment promotion to accurately introduce supporting enterprises in the upstream and downstream of the industrial chain. At the same time, we tailor a full lifecycle “step-by-step cultivation” plan for existing enterprises, guiding them to develop in the direction of “specialized, refined, characteristic, and innovative.” We encourage research teams to explore technology R&D and concept experiments in multiple directions and diversify, nurturing more achievement transformation enterprises.

Focusing on Efficient Services for the Industry. Striving to build a high-efficiency operation team, continuously optimizing and enhancing the park’s operational management capabilities and levels, forming a professional technical manager team and entrepreneurial mentor team, and carrying out customized exclusive scientific and technological innovation services such as technology achievement excavation, docking, landing, tracking services, and entrepreneurial incubation. Regularly hold activities such as additive manufacturing summits, supply-demand matching, innovation and entrepreneurship competitions, project roadshows, and application scenario promotions, creating nationally influential promotional brand activities for additive manufacturing. Additionally, we will solve the funding difficulties faced by enterprises through multiple channels, strengthen diversified technological financial supply, utilize industrial investment funds to leverage social capital to invest in technology achievement transformation projects, start-up enterprises, and industrialization projects, and jointly develop new financial products such as intellectual property pledge financing, intellectual property securitization, financing leasing, and technology insurance with financial institutions, striving to build a financial service team with strong business capabilities, high quality, and high standards, and establish a complete industrial service system to contribute greater strength to the development of the additive manufacturing industry in the province.

Editor: Wang XinReview: Wang XiaohongFinal Review: Zhou XinhongSupervised by: Li Ying