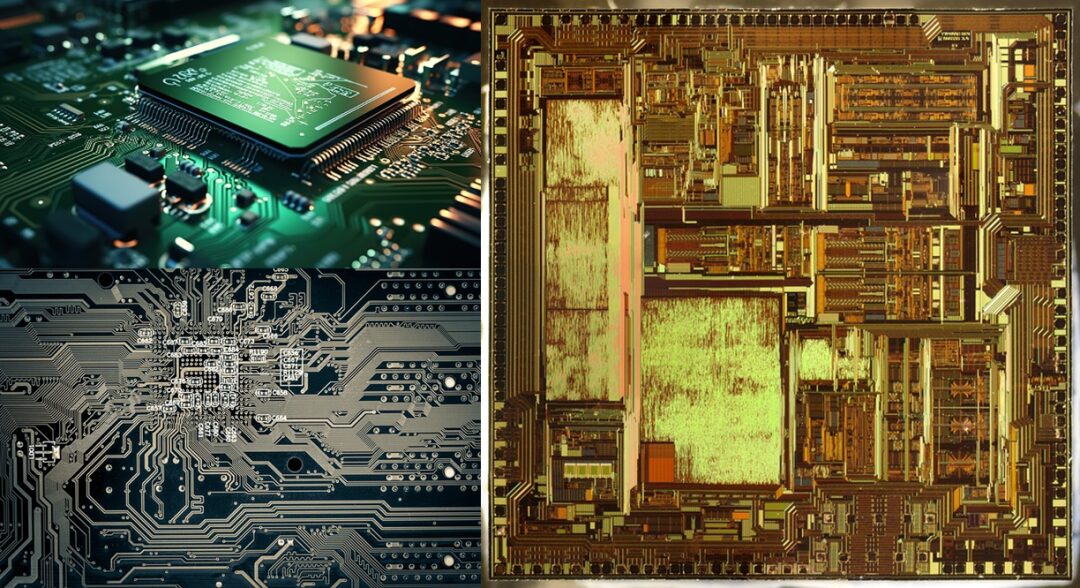

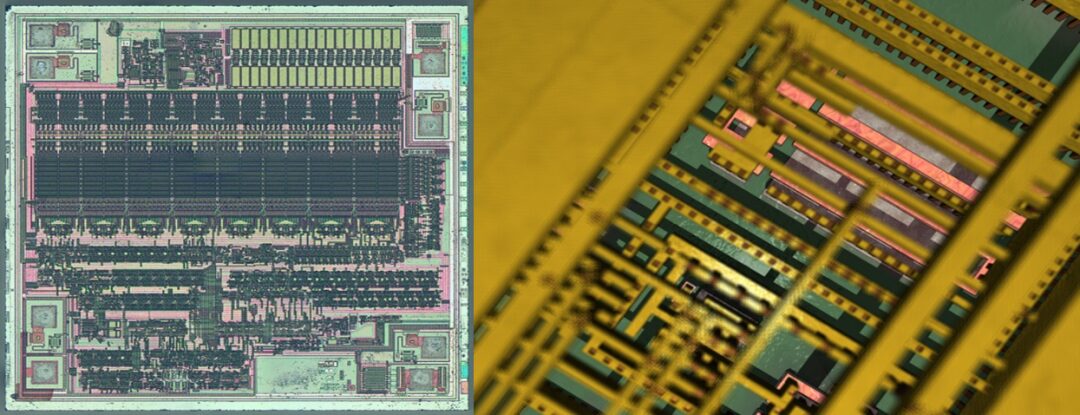

The “multi-layer” approach to chip manufacturing

What limits the internal size of chips?

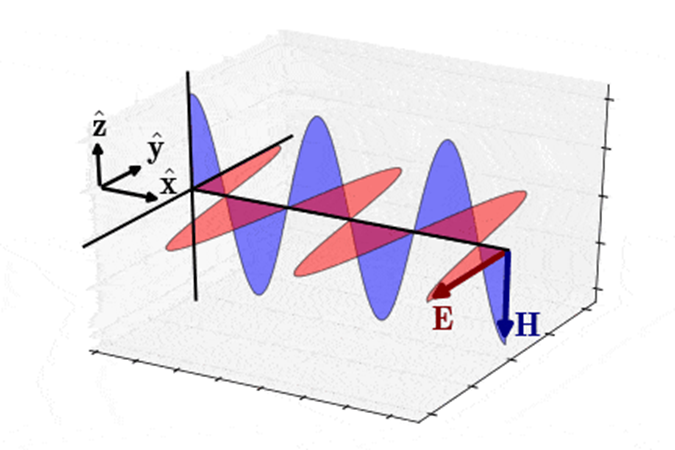

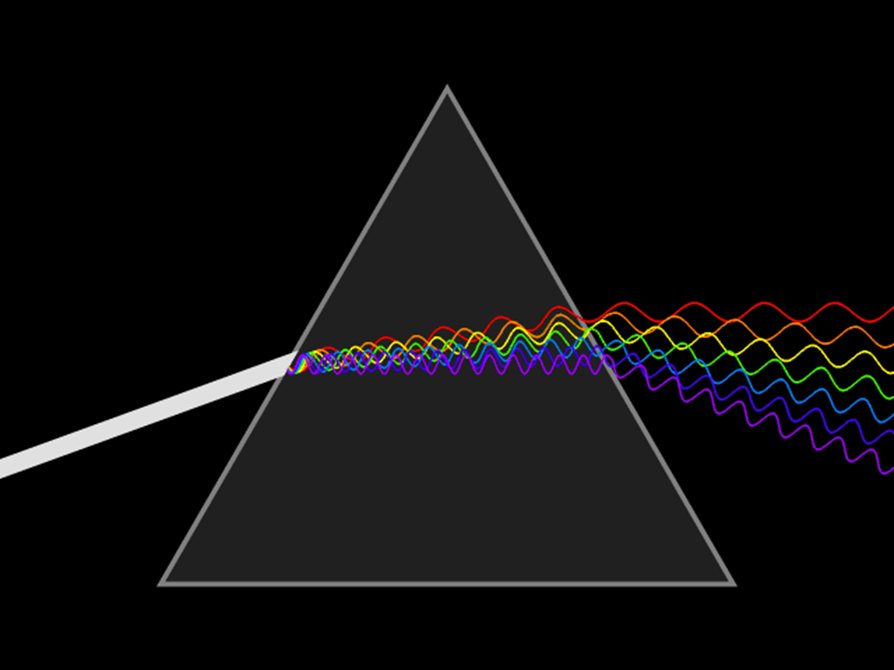

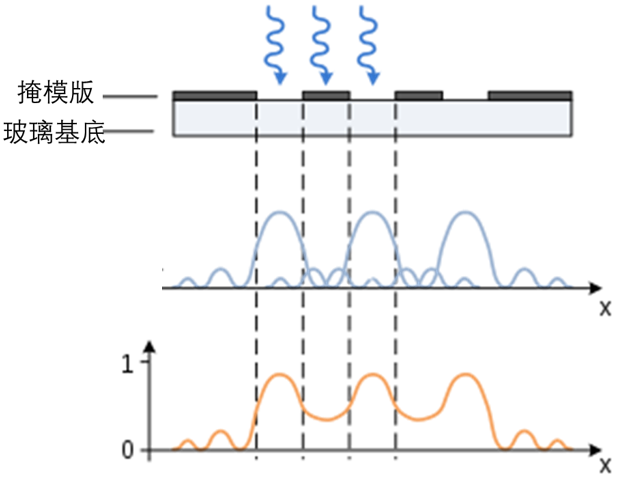

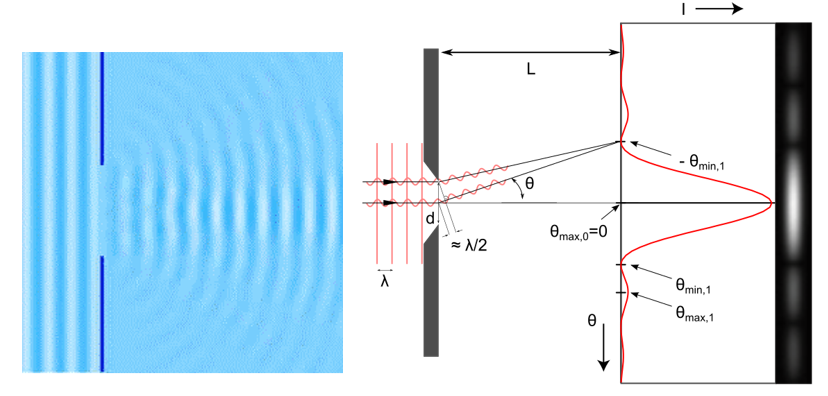

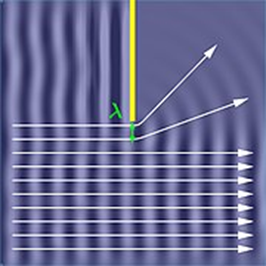

Diffraction

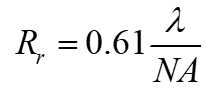

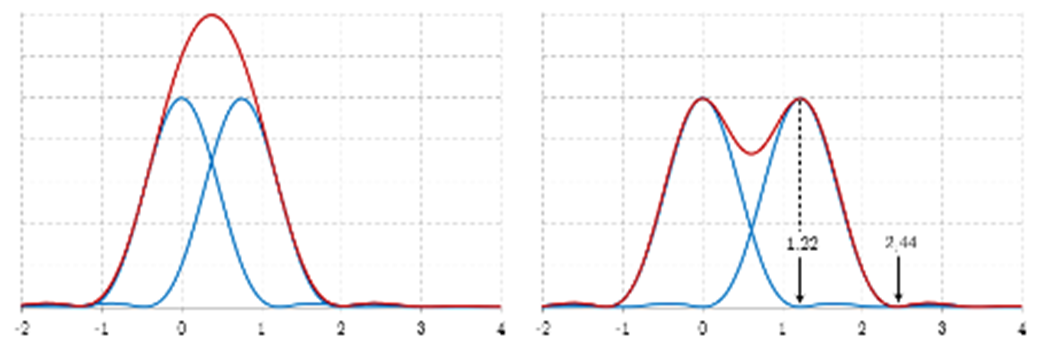

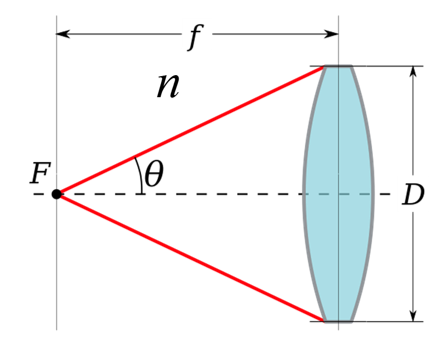

Resolution

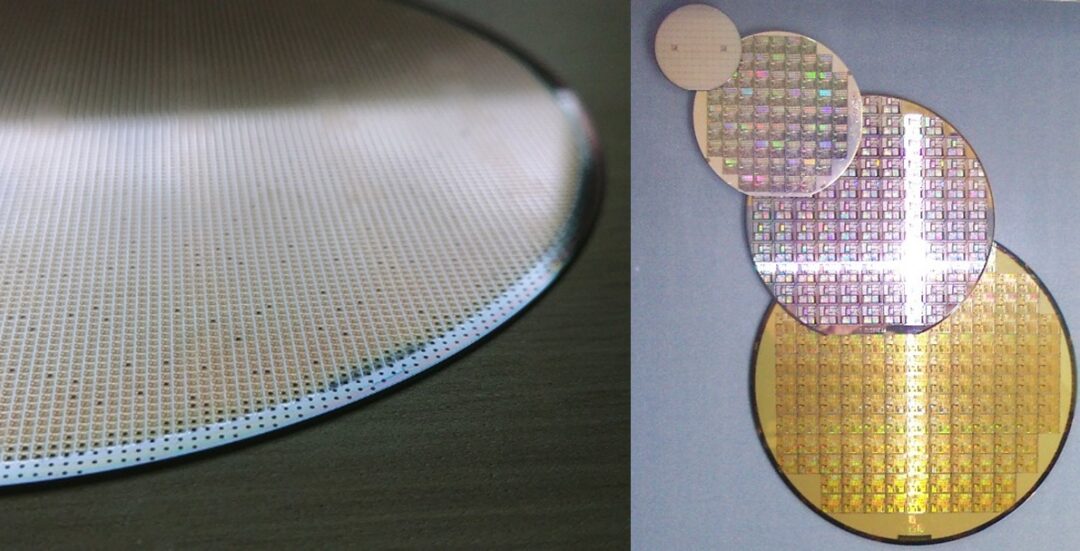

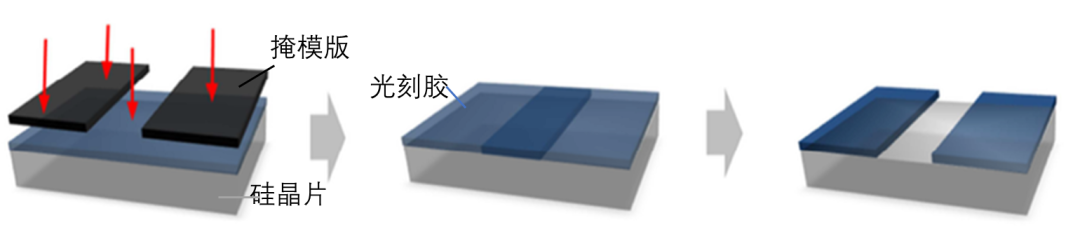

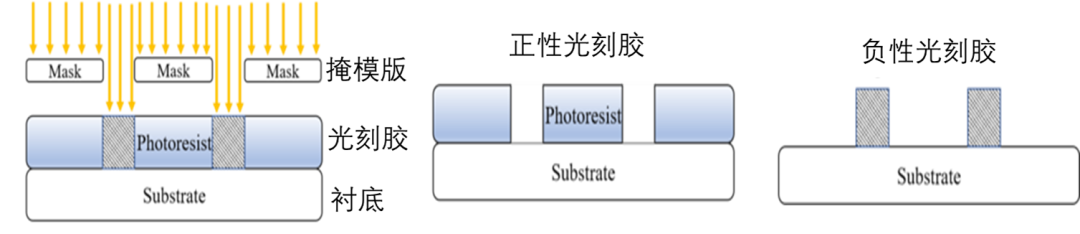

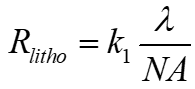

Photolithography

How to sharpen the light as a carving knife?

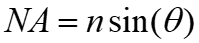

Increase the numerical aperture of the photolithography system

Shorten the wavelength

Reduce the process factor