Author: Snail of the Automotive Industry

Author: Snail of the Automotive Industry

The ASC (Active Short Circuit) of motor controllers is a safety protection mechanism for motors.

Working Principle:

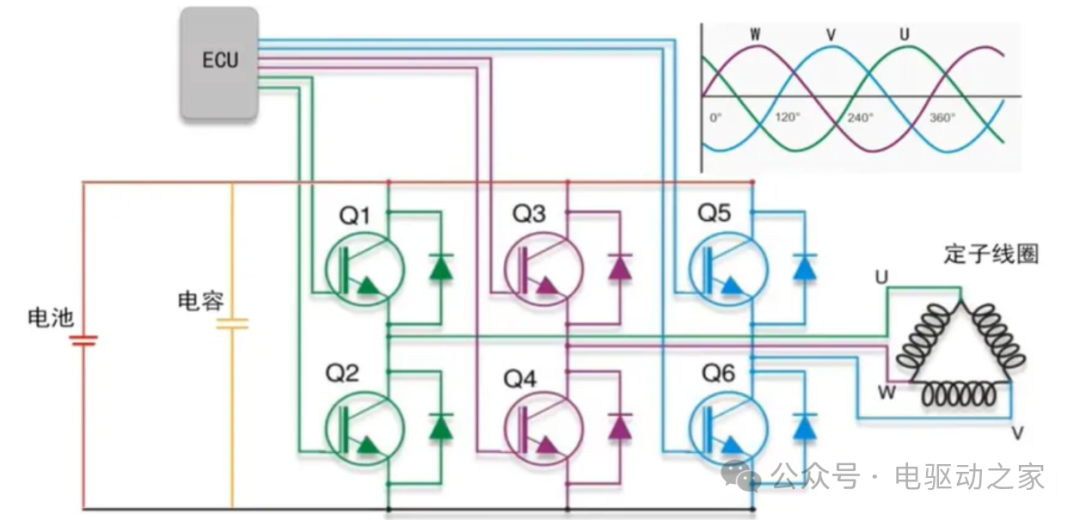

By simultaneously turning on the upper or lower three bridges of the IGBT, a closed loop is formed in the motor stator windings, thereby achieving active short circuit protection. Generally, there are two forms: upper ASC and lower ASC. Upper ASC turns off the three IGBTs in the lower bridge arm while turning on the three IGBTs in the upper bridge arm; lower ASC turns on the three IGBTs in the lower bridge arm while turning off the three IGBTs in the upper bridge arm.

Conditions for Entering ASC:

- External Controller Faults: Such as over/under voltage caused by main connection disconnection, collisions, etc.

- Sensor-Related Faults: Such as bus voltage detection, Hall sensor disconnection, temperature detection, resolver faults, etc.

- Actuator-Related Faults: Such as open circuit in IGBT, short circuit in IGBT, three-phase overcurrent (three-phase imbalance), motor overspeed, etc.

- Algorithm-Related Faults: Such as watchdog, abnormal torque monitoring, excessive voltage vector deviation, etc.

- External Power Supply Faults: Such as high voltage over/under voltage, 12V over/under voltage, 12V disconnection, etc.

- Other Hardware Faults: Such as RAM anomalies, Flash anomalies, power supply for drivers, etc.

- Specific Operating Condition Requirements: When the vehicle is out of control, implementing ASC can generate reverse torque, allowing the vehicle to decelerate safely; in case of power battery faults, implementing ASC can isolate the motor, motor controller, and power battery, ensuring high voltage safety; during vehicle operation, if the driving motor speed is too high or abnormal, implementing ASC can prevent excessive back EMF from damaging the power battery, bus capacitors, and other high-voltage components.

Design for Entering and Exiting ASC:

- Entry Design: When the above fault conditions are detected and certain conditions are met, such as motor speed, bus voltage, etc., reaching set thresholds, the motor controller will quickly respond, controlling the IGBT’s upper and lower bridge arms to enter the ASC state. During the moment of entering ASC, a large current surge may occur, so thresholds need to be set reasonably to avoid damage to components like IGBT.

- Exit Design: When faults are cleared or related parameters return to normal ranges, such as motor speed decreasing to low speed, bus voltage returning to normal, the control system will automatically exit the ASC state based on preset logic and strategies, restoring normal operating mode or entering other safe states, such as FreeWheeling state.

What Happens When Entering ASC:

- Generation of Reverse Torque: This will create braking force on the vehicle, causing it to decelerate. In low-speed areas, ASC is generally not used to avoid excessive braking torque affecting driving comfort; however, in high-speed areas, due to high back EMF, using ASC can prevent excessive back EMF from impacting components on the bus.

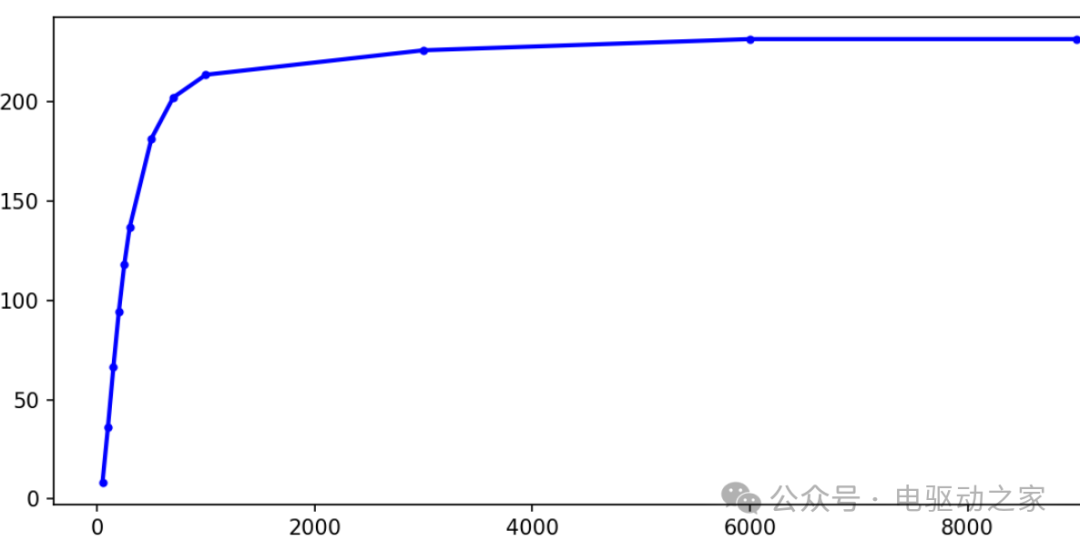

Motor current testing after entering ASC

Motor current testing after entering ASC- Internal Heating of the Motor: Due to the closed loop formed in the motor stator windings, current flowing through the windings generates heat, causing the motor temperature to rise, but it will not affect the controller.

- Limiting Back EMF: Short-circuiting the three-phase lines of the motor can decouple the motor from the controller’s DC bus, meaning that even if the motor speed is high, the generated voltage cannot exceed a certain value, preventing excessive back EMF from damaging the power battery, bus capacitors, and other high-voltage components.

- Increased System Safety: Implementing ASC can isolate the motor, motor controller, and power battery, ensuring high voltage safety for the entire vehicle, preventing damage to the controller system, avoiding unintended large torque outputs, and protecting the controller and motor.

Recent Featured Articles:

-

Tool for querying electric vehicle drive and battery parameters (with database)

-

Xiaomi unveils two new types of axial flux motors for vehicles

-

Lei Jun admits: Xiaomi will struggle to catch up with Tesla’s energy consumption in three to five years—what does Tesla rely on?

-

What is the infinitely variable transmission of Geely’s Thunder God EM-i super electric hybrid system?

-

Great Wall’s ‘stubborn’ approach—reflections on the second-generation HI-4 hybrid system

-

What high-tech highlights does BYD’s super e-platform have?

-

The genius who invented the Hi-4 hybrid architecture is—Wei Jianjun, a detailed explanation of Great Wall’s hybrid evolution

-

Does multi-speed hybrid still have a future?—When ‘top students’ fail against ‘lazy people’s gospel’

-

Xiaomi SU7 Ultra’s terrifying experience at the Nürburgring, sensor issues caused the electric drive system to stall

-

Porsche: Is the claim that the motor heating can be reduced to 1/4 from 400V to 800V true?

-

How to calculate the DC-link bus capacitor for motor controllers?

-

Code animation: How does the motor resolver obtain rotor position?

-

Groundbreaking innovation: Where does the Hyundai Kia EV9 Dual-Stage Motor lead?

-

MATLAB programming to achieve optimal engine working curve calculation (OOL)

-

Sharing: Can engineers of motor controllers handle high-power rear-wheel drive cars slipping on open roads?

- What is BYD’s current charging? Why was it glossed over in the press conference? Is it really a trick!

-

Understanding the changes in GB/T 18488-2024 “Drive Motor Systems for Electric Vehicles” in one image

-

Great Wall Motor Chairman Wei Jianjun: Is the statement ‘the motor has no torque when it slows down’ true?

- Lei Jun’s marketing, ordinary car companies need to learn for ten thousand years!

- Highlights of Xiaomi’s super electric motor

- Electric vehicle performance calculation tool (updated V1.2)

- Average efficiency calculation tool for automotive motors under certain conditions V1.0

- Automotive motor efficiency MAP interpolation, efficiency MAP format conversion, and high-efficiency area ratio calculation, all in one go

- How does the Leopard 5 consume 18L of fuel per 100 kilometers? Looking at the vehicle’s high-speed energy consumption calculation V1.0

- How much is reasonable for motor PDIV testing? Tool sharing

- Tool: Motor model naming tool V1.0, needed by every motor manufacturer and OEM

- Tool: Quickly estimate the performance of derived motors based on existing motors V1.0

- Tool: CAN-DBC to Excel tool V1.0, includes Model 3 CAN_DBC

- One-click drawing of efficiency contour maps and high-efficiency area ratios (III)

- Do you know how to process the hollow shaft of an oil-cooled motor?

- Discussing electric vehicle motor PDIV testing again

- Dual-gun charging? Boost charging? Pulse heating? All of these, how does BYD have so many tricks?

- Is Xiaomi’s 871V voltage using a 1200V module considered aggressive?

- Xiaomi SU7 motor controller failures, Infineon is not to blame

- What black technology does Haopu Quark electric drive have?

- Electric vehicle CLTC, WLTC condition generation tool V1.1

- How to calculate rotor dynamic balance, should we take G2.5 or G1?