With the development of computer technology, storage logic has begun to enter the industrial control field. The Programmable Logic Controller (PLC), as a general-purpose industrial control computer, is a representative achievement of storage logic in industrial applications.Since the first PLC was successfully developed in 1969 and applied to the automotive manufacturing assembly line, PLCs have continuously evolved. Especially in the last two decades, PLC technology has developed rapidly, becoming increasingly powerful, and is widely used in production processes, playing an increasingly important role in the economic field as one of the three pillars of industrial automation technology.PLC is a new type of general-purpose industrial automatic control device based on traditional sequential controllers, integrating computer technology, microelectronics technology, automatic control technology, digital technology, and communication network technology. It is an important pillar of modern industrial control. This section mainly introduces the applications, characteristics, classifications, and performance indicators of PLCs.

Applications of PLC

In recent decades, as the prices of microprocessor chips and related components have significantly decreased, the price of PLCs has also dropped, while their functions have greatly enhanced, enabling them to solve complex computation and communication problems. Therefore, the application scope of PLCs has become increasingly broad.Currently, PLCs are widely used in industries such as steel, mining, cement, petroleum, chemical, power, machinery manufacturing, automotive, loading and unloading, papermaking, textiles, environmental protection, and entertainment.The application scope of PLCs can generally be divided into the following five categories.

1) Sequential Control

Sequential control is the most widely used field of PLC applications and is also the area where PLCs excel. PLC sequential control is used to replace traditional relay sequential control.PLCs are applied in scenarios such as single-machine control, multi-level group control, and production line control, for example, injection molding machines, printing machines, stapling machines, packaging machines, paper cutting machines, combination machine tools, grinding machines, assembly lines, electroplating lines, and elevator control.

2) Motion Control

PLC manufacturers currently provide single-axis or multi-axis position control modules for stepper motors or servo motors. In most cases, the PLC sends data describing the target position to the control module, which moves one or more axes to reach the target position. Each axis movement is controlled by the position control module, maintaining appropriate speed and acceleration to ensure smooth motion.Relatively speaking, position control modules are smaller, cheaper, faster, and easier to operate than Computer Numerical Control (CNC) devices.

3) Process Control

PLCs can also monitor a large number of physical parameters, such as temperature, pressure, flow, liquid level, and speed. The Proportional-Integral-Derivative (PID) module enables PLCs to have closed-loop control capabilities, meaning a PLC with PID control capabilities can be used for process control. When a variable in process control deviates, the PID control algorithm calculates the correct control amount to maintain the output at the set value.

4) Data Processing

In machining, PLCs serve as the main control and management system in CNC systems, capable of completing a large amount of data processing work.

5) Communication Network

PLC communication includes communication between the host and remote I/O, communication between multiple PLCs, and communication between PLCs and other intelligent control devices (such as computers, frequency converters, CNC devices, etc.). Together with other intelligent control devices, PLCs can form a distributed control system with “centralized management and decentralized control.”

Characteristics of PLC

1) High Reliability and Strong Anti-Interference Ability

To meet the safety and reliability requirements of control devices in industrial production, PLCs adopt microelectronics technology, where a large number of switching actions are completed by contactless semiconductor circuits. The design fully considers the impacts of temperature, humidity, dust, and vibration in the industrial production environment: isolation, filtering, shielding, and grounding anti-interference measures are adopted in hardware; fault diagnosis and data protection measures are implemented in software. These technologies give PLCs a high anti-interference capability.Currently, PLCs produced by various manufacturers have an average mean time between failures far exceeding the 100,000 hours stipulated by the International Electrotechnical Commission (IEC), with some even reaching hundreds of thousands of hours.

2) General Purpose and Flexibility

PLC products have been serialized in production, with various structural forms, providing great flexibility in model selection. Additionally, there are many types of PLCs and peripheral modules, allowing users to flexibly combine different components based on different task requirements to form control devices with different hardware structures.More importantly, the main functions of the PLC control system are realized through programming. Therefore, when changes to the control functions of the equipment are needed, only minor modifications to the program and wiring are necessary, resulting in a minimal workload, something that is difficult to achieve with conventional relay control systems.

3) Simple and Convenient Programming

The programming of PLC application programs is very convenient. Programming can be done using ladder diagram language, which is very similar to relay contactor control circuits. This programming language is intuitive and easy to master, even for those without computer knowledge. The Sequential Function Chart (SFC) is a structured block control flow chart that makes programming even simpler and more convenient.

4) Complete Functions and Strong Expansion Capability

PLC’s input/output system has complete functions and reliable performance, capable of adapting to various forms and types of digital and analog input/output.The functional units of PLCs can easily realize D/A, A/D conversion, and PID calculations, achieving process control, digital control, and other functions. It can also work together with other computer systems and control devices to form distributed or decentralized control systems, effectively meeting various control needs.

5) Short Design, Construction, and Debugging Cycles, Easy Maintenance

The intermediate relays, time relays, counters, and other electrical components in relay contactor control systems appear in PLC control systems as “soft components” and are replaced by programs instead of hard wiring, thus reducing installation and wiring workload; workers can also program in advance according to specific control requirements before the PLC arrives, significantly shortening the construction period.PLCs are compact and lightweight, making them easy to install. They have complete self-diagnosis and monitoring functions, displaying their internal working state, communication state, I/O point state, abnormal state, and power state. Workers can quickly identify the cause of faults, facilitating rapid resolution.Due to these characteristics, PLCs are widely applied; it can be said that wherever there are factories and control requirements, there will be applications of PLCs.

Classification of PLC

PLCs are developed to meet the needs of modern production, and their classification must also conform to the demands of modern production. Generally, PLCs can be classified from three perspectives: control scale, control performance, and structural characteristics.

1. Classification by Control Scale

PLCs can be classified into small PLCs, medium PLCs, and large PLCs based on control scale.

1) Small PLC

Small PLCs generally refer to those with an input/output point number (I/O points) of less than 256 points, using a single CPU (8-bit or 16-bit), and with a user program memory capacity of less than 4KB, primarily for digital control.Due to the limitation on the number of control points, their control functions have certain limitations. However, small PLCs are compact and flexible, making them suitable for direct installation in electrical control cabinets, ideal for single machine control or small system control.Examples include Siemens’ S7-200 and S7-1200 series, and Mitsubishi’s FX series.

2) Medium PLC

Medium PLCs generally refer to those with I/O points ranging from 256 to 2048, using dual CPUs or multiple CPUs, and with user program memory capacities of 2 to 8KB or larger, having both digital and analog control functions as well as stronger digital computation capabilities.Due to their greater number of control points, medium PLCs have strong control functions and can be used for direct control of equipment as well as monitoring multiple subordinate PLCs, suitable for medium to large control systems.Examples include Siemens’ S7-300 series, OMRON’s C200H series, and some models in Mitsubishi’s Q series.

3) Large PLC

Large PLCs generally refer to those with I/O points greater than 2048, using dual CPUs or multiple CPUs (16-bit or 32-bit), and with user program memory capacities of 8 to 16KB or larger. Due to their high number of control points, large PLCs have strong control functions, high computational capabilities, and fast operating speeds, capable of performing complex arithmetic calculations and matrix operations.Large PLCs can not only be used for direct control of equipment but also for monitoring multiple subordinate PLCs, forming a distributed production process control system. They are suitable for equipment automation processes, process automation control, and process monitoring systems.Examples include Siemens’ S7-400 series, OMRON’s CVM1 and CS1 series, and some models in Mitsubishi’s Q series.

2. Classification by Control Performance

PLCs can be classified into low-end, mid-range, and high-end machines based on control performance.

1) Low-end Machines

This type of PLC has basic control functions and general computational capabilities, operates at relatively low speeds, and supports a limited number and types of input and output modules.This type of PLC is suitable for small-scale simple control and is generally used as a slave station in networks. For example, Siemens’ S7-200 series belongs to this category.

2) Mid-range Machines

This type of PLC has strong control functions and computational capabilities, capable of performing general logic operations as well as more complex trigonometric, exponential, and PID operations, operating at relatively high speeds, and supporting a greater number and variety of input and output modules.This type of PLC can handle both small-scale and larger control tasks, and can function as both a slave and a master station in networks. For example, Siemens’ S7-300 series belongs to this category.

3) High-end Machines

This type of PLC has powerful control functions and computational capabilities, capable of performing logic operations, trigonometric operations, exponential operations, PID operations, and complex matrix calculations, operating at high speeds, and able to support a large number and variety of input and output modules.This type of PLC can handle both medium-scale and very large control tasks and is generally used as a master station in networks. For example, Siemens’ S7-400 series belongs to this category.PLCs can also be classified into integrated and modular types based on structure.

3. Classification by Structure

1) Integrated Type

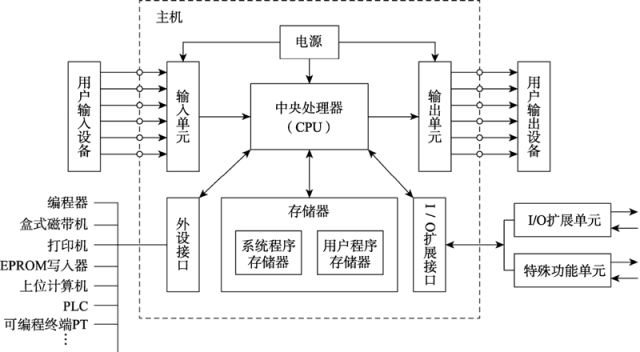

Integrated structure PLCs compactly install the power supply, CPU, memory, and I/O system in a standard casing, forming the basic unit of the PLC.A basic unit is a complete PLC capable of implementing various controls. When the number of control points does not meet requirements, expansion units can be connected, which do not include a CPU. Basic units and several expansion units can form larger systems.The advantages of integrated structures are compactness, small size, low cost, and easy installation, while the disadvantage is that the number of input and output points is limited. Most small PLCs are of integrated structure, such as Siemens’ S7-200 series and Mitsubishi’s FX series PLCs.The composition of an integrated PLC is shown in the figure below:

Figure 1: Composition Diagram of Integrated PLC

Figure 1: Composition Diagram of Integrated PLC

2) Modular Type

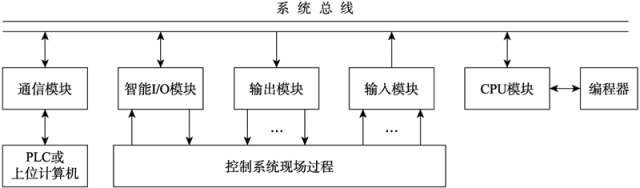

Modular structure PLCs divide the various components of the PLC system into several modules based on functionality, such as CPU modules, input modules, output modules, power supply modules, etc. These modules can be plugged into a frame or baseboard to form a complete control system. Although each module has a relatively singular function, the variety of modules is increasing.For example, some PLCs, in addition to basic I/O modules, also have special function modules, such as temperature detection modules, position detection modules, PID control modules, communication modules, etc. Modular structure PLCs adopt a building block approach, allowing users to assemble systems by inserting the required modules onto a baseboard.The characteristics of modular structure PLCs are that the CPU, input, and output are all independent modules, with uniform module sizes, easy installation, and flexible selection of I/O modules (by point count), making installation, debugging, expansion, and maintenance convenient.Most medium and large machines are of modular structure, such as Siemens’ S7-300 series, S7-400 series, and Mitsubishi’s Q series PLCs.The composition of a modular PLC is shown in the figure below, with modules interconnected via buses on the baseboard. The CPU and each expansion module are typically connected via cables, with a maximum distance of 10m.

Figure 2: Composition Diagram of Modular PLC

Figure 2: Composition Diagram of Modular PLC

Technical Indicators of PLC

The technical indicators of PLCs include hardware indicators and software indicators.

1. Hardware Indicators

Hardware indicators include general indicators, input characteristics, and output characteristics.General indicators are mainly reflected in performance metrics such as environmental temperature, environmental humidity, vibration resistance, impact resistance, noise resistance, anti-interference, and withstand voltage.Input characteristics are mainly reflected in the degree of isolation of the input circuit, input sensitivity, response time, and required power supply.Output characteristics are mainly reflected in circuit composition (referring to relay output, transistor output, or thyristor output), circuit isolation, maximum load, minimum load, response time, and external power supply.

2. Software Indicators

Software indicators mainly include program capacity, programming language, communication functions, operating speed, instruction types, and the types and numbers of components.Program capacity refers to the size of the PLC’s internal and external memory, generally ranging from a few kilobytes to several megabytes. The types of memory are usually RAM, EPROM, and EEPROM.Programming language refers to the languages used by PLCs to compile user programs. PLCs can use many programming languages, including ladder diagrams, statement lists, sequential function charts, and function block diagrams. The availability of more programming languages makes compiling user programs faster and more convenient.Communication functions refer to whether the PLC has communication capabilities and what types of communication capabilities it has. Generally, it can be divided into remote I/O communication, computer communication, point-to-point communication, high-speed buses, MAP networks, etc. Currently, communication capability is a major indicator for assessing PLC performance.Operating speed refers to the duration of operation processing time, which can be measured by the execution time of basic instructions; the shorter the time, the better, generally below the microsecond level. The stronger the instruction functionality, the better the PLC’s performance.The types and quantities of components reflect the performance of the PLC and indicate its scale. The number of I/O components indicates the input and output capability of the PLC; the variety of I/O components (DC, AC, analog, high-speed counting, positioning, PID) indicates the performance level of the PLC.

3. Introduction to Major Performance Indicators

1) Storage Capacity

Here, storage capacity refers to the capacity of the user program memory. Storage capacity determines the size of user programs that the PLC can accommodate, generally calculated in bytes. Every 1024 bytes equals 1KB. The storage capacity of medium and small PLCs is generally below 8KB, while large PLCs can reach 256KB to 2MB. Some PLCs express capacity by the number of stored user program instructions, typically around 2000 instructions for medium and small PLCs.

2) Input/Output (I/O) Point Count

I/O point count refers to the sum of input points and output points. The more I/O points, the more external input and output devices can be connected, leading to a larger control scale; thus, I/O point count is an indicator of PLC scale. Internationally, PLCs with a total I/O point count of 64 points or less are referred to as micro PLCs; 64 to 256 points are called small PLCs; 256 to 2048 points are medium PLCs; and more than 2048 points are large PLCs.

3) Scan Speed

Scan speed refers to the speed at which the PLC executes programs. It is generally measured by the time taken to execute 1KB. The execution speed of different functional instructions varies significantly, and some brands of PLCs provide execution times for various instructions in their user manuals, allowing comparisons of PLC speeds based on similar operations.

4) Instruction Functionality and Quantity

The strength of instruction functionality and the number of instructions reflect the PLC’s capabilities. Generally, the more types and numbers of programming instructions, the stronger the processing and control capabilities, making it easier to compile user programs.

5) Types and Quantity of Internal Components

During program compilation, a large number of internal components are needed to store variables, intermediate results, timing and counting information, module setting parameters, and various flags. The greater the variety and number of these components, the stronger the PLC’s information processing capability.

6) Number of Intelligent Units

To complete certain special control tasks, PLC manufacturers design dedicated intelligent units for their products, such as analog control units, positioning control units, speed control units, and communication working units. The variety and functionality of intelligent units are important indicators for assessing the quality of PLC products.

7) Expansion Capability

The expansion capability of PLCs includes the expansion of I/O points, storage capacity, networking functions, and the connection of various modules. Most PLCs can expand I/O points using I/O expansion units; some PLCs can use various functional modules for expansion. However, the expansion capabilities of PLCs are always limited.Understanding the various indicators of PLCs allows for selecting suitable products from numerous PLCs based on specific control engineering requirements.

Editor—Mu Yun

All articles, images, audio and video files, and other materials reproduced on this website are owned by the copyright holders. The non-original articles and images used by this site cannot all be confirmed with the copyright holders. If the authors and editors of the selected content believe that their works should not be publicly disseminated or should not be used without compensation, please promptly notify us via email or phone so that appropriate measures can be taken to avoid unnecessary economic losses to both parties.