The national standard of China (GB7665-2005) defines a sensor as: “a device or apparatus that can sense the measured quantity and convert it into a usable output signal according to certain rules.” Sensors, as an important means of information acquisition, along with communication technology and computer technology, constitute the three pillars of information technology.

Below, we will mainly introduce the seven major types of sensors.

Sensor 1: Physical Sensors

Physical sensors

Physical sensors are devices that detect physical quantities. They utilize certain physical effects to convert the measured physical quantity into a signal in a form that is easy to process. The output signal has a definite relationship with the input signal.

<Main Physical Sensors>

Photoelectric sensors, piezoelectric sensors, piezoresistive sensors, electromagnetic sensors, thermoelectric sensors, fiber optic sensors, etc.

<Classification Methods of Physical Sensors>

Classified by their application

Pressure sensitive sensors, position sensors, liquid level sensors, energy consumption sensors, speed sensors, acceleration sensors, radiation sensors, thermal sensors, 24GHz radar sensors.

Classified by their principles

Vibration sensors, humidity sensors, magnetic sensors, gas sensors, vacuum sensors, biosensors, etc.

Classified by their output signals

Analog sensors – convert non-electrical quantities into analog electrical signals.

Digital sensors – convert non-electrical quantities into digital output signals (including direct and indirect conversions).

Switch sensors – output a set low or high signal when a measured signal reaches a certain threshold.

Classified by their materials

All materials respond accordingly and characteristically under external influences. Those materials that are most sensitive to external actions, i.e., those with functional characteristics, are used to create the sensitive elements of sensors. From the perspective of the materials used, sensors can be divided into the following categories:

(1) By the type of materials used: metal polymers, ceramic mixtures.

(2) By physical properties of the materials: conductors, insulators, semiconductors, magnetic materials.

(3) By the crystal structure of the materials: single crystal, polycrystalline, amorphous materials.

The development of sensors closely related to the use of new materials can be summarized in the following three directions: (1) Exploring new phenomena, effects, and responses within known materials and then applying them in sensor technology.

(2) Exploring new materials and applying known phenomena, effects, and responses to improve sensor technology.

(3) Exploring new phenomena, effects, and responses based on the research of new materials and implementing them in sensor technology.

The progress of modern sensor manufacturing depends on the intensity of developing new materials and sensitive elements for sensor technology. The basic trend in sensor development is closely related to the application of semiconductor and dielectric materials.

<Case>

Common photoelectric sensors. This type of sensor converts light signals into electrical signals, directly detecting radiation information from objects and can also convert other physical quantities into light signals. The principle of photoelectric sensors is the photoelectric effect: when light strikes a substance, the electrical effect on the substance changes, which includes electron emission, conductivity, and potential current. Clearly, devices that can easily produce such effects become the main components of photoelectric sensors, such as light-sensitive resistors.

Thus, we understand that the main workflow of photoelectric sensors is to receive corresponding light irradiation, convert light energy into electrical energy through devices like light-sensitive resistors, and then obtain the required output electrical signal through amplification and noise reduction processing. The output electrical signal has a certain relationship with the original light signal, usually close to linear, making it not very complicated to calculate the original light signal. The principles of other physical sensors can be analogized to those of photoelectric sensors.

The application range of physical sensors is very broad. Looking at the application of physical sensors from the perspective of biomedicine, it is not difficult to speculate that physical sensors have important applications in other areas as well.

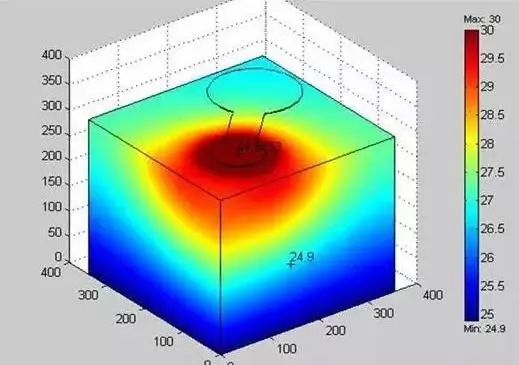

For example, blood pressure measurement is one of the most routine medical measurements. Our usual blood pressure measurement is indirect, determining the blood pressure value in blood vessels by detecting the relationship between blood flow and pressure on the body surface. The sensors needed to measure blood pressure typically include an elastic diaphragm, which converts the pressure signal into the deformation of the diaphragm, and then converts it into the corresponding electrical signal based on the strain or displacement of the diaphragm. At the peak of the electrical signal, we can detect systolic pressure, and after passing through an inverter and peak detector, we can obtain diastolic pressure. By integrating, we can get the average pressure.

Other applications such as respiratory measurement technology and body surface temperature measurement also rely on the application of physical sensors.

As an important means of data acquisition, sensor measurement is an indispensable component in industrial production and even in household life, and physical sensors are the most common family of sensors. Flexibly using physical sensors can undoubtedly create more products and better benefits.

Sensor 2: Fiber Optic Sensors

Fiber optic sensors

<Concept>

The basic working principle of fiber optic sensors is to send light signals from a light source through optical fibers to a modulator, where the parameters to be measured interact with the incoming light in the modulation zone, causing changes in the optical properties of the light (such as intensity, wavelength, frequency, phase, polarization state, etc.), becoming a modulated signal source. After passing through the optical fiber to the light detector and demodulating, the measured parameters are obtained.

Sensors are developing towards sensitivity, precision, adaptability, compactness, and intelligence. In this process, fiber optic sensors, as a new member of the sensor family, are highly favored. Fiber optics have many excellent properties, such as resistance to electromagnetic interference and atomic radiation, fine diameter, soft texture, light weight, insulation, non-induction electrical properties, chemical properties such as water resistance, high-temperature resistance, and corrosion resistance, enabling them to act as human eyes and ears in places unreachable by humans (such as high temperature zones) or in areas harmful to humans (such as nuclear radiation zones). They can also surpass human physiological limits to receive external information that human senses cannot perceive.

Fiber optic sensors can measure various physical quantities, such as sound fields, electric fields, pressure, temperature, angular velocity, acceleration, etc., and can accomplish measurement tasks that existing measurement technologies find difficult. In confined spaces, under strong electromagnetic interference and high voltage environments, fiber optic sensors demonstrate unique capabilities. Currently, there are over 70 types of fiber optic sensors, generally divided into self-sensing fiber optic sensors and fiber-utilizing sensors.

<Self-Sensing Fiber Optic Sensors>

Self-sensing fiber optic sensors directly receive external measured quantities. External measured physical quantities can cause changes in the length, refractive index, and diameter of the measuring arm, resulting in changes in the light transmitted within the fiber in terms of amplitude, phase, frequency, and polarization. The light transmitted by the measuring arm interferes (compares) with the reference light from the reference arm, causing changes in the phase (or amplitude) of the output light. Based on this change, the measured variation can be detected. The sensitivity of the phase transmitted in the fiber to external influences is very high, and utilizing interference technology can detect minute phase changes corresponding to physical quantities at the level of 10^-4 radians. By leveraging the flexibility and low loss of optical fibers, very long fibers can be coiled into small diameters to increase utilization length and achieve higher sensitivity.

The fiber optic acoustic sensor is a type of self-sensing fiber optic sensor. When the fiber optic is subjected to a very slight external force, it will produce slight bending, causing significant changes in its light transmission capability. Sound is a mechanical wave, and its effect on the fiber optic is to exert force and cause bending, allowing the sound intensity to be obtained through bending. The fiber optic gyro is also a type of self-sensing fiber optic sensor. Compared to laser gyros, fiber optic gyros have higher sensitivity, smaller size, and lower cost, making them suitable for high-performance inertial navigation systems in aircraft, ships, missiles, etc.

<Fiber-Utilizing Sensors>

Another major category of fiber optic sensors is fiber-utilizing sensors. Their structure is roughly as follows: the sensor is located at the end of the fiber, and the fiber serves merely as a light transmission line, converting the measured physical quantity into changes in the amplitude, phase, or amplitude variations of light. In this sensor system, traditional sensors are combined with optical fibers. The introduction of optical fibers enables the possibility of remote measurement with probe-like characteristics. This type of fiber transmission sensor has a wide range of applications and is easy to use, but its precision is slightly lower than that of the first type of sensors.

Fiber optics have emerged as a latecomer in the sensor family, gaining widespread application due to their excellent performance, and are a noteworthy type of sensor in production practice.

Fiber optic sensors can be applied in various areas: temperature detection, pressure detection, liquid level, flow, and flow speed detection.

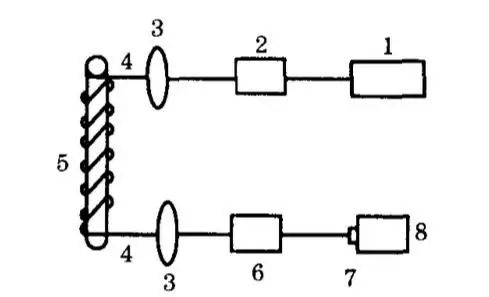

Attached diagrams: Principles of several fiber optic sensors

Fiber Optic Current Sensor

Full Internal Reflection Fiber Optic Sensor

Sensor 3: Bionic Sensors

Bionic Sensors

<Concept>

Bionic sensors are a new type of sensor that employs new detection principles, utilizing immobilized cells, enzymes, or other biologically active substances in conjunction with transducers to form sensors. This type of sensor has developed in recent years as a result of the interplay between biomedical, electronic, and engineering fields. The characteristics of this sensor include high functionality and long lifespan. Among bionic sensors, the most common are biosimulated sensors.

Bionic sensors can be classified based on the medium used: enzyme sensors, microbial sensors, organelle sensors, tissue sensors, etc. Bionic sensors are closely related to various aspects of biological theory and are a direct result of the development of biological theory. Among the biosimulated sensors, urea sensors are a recently developed type. Below, we will use the urea sensor as an example to introduce the application of bionic sensors.

<Case: Urea Sensor>

This sensor primarily consists of two parts: a biological membrane and its ion channels. The biological membrane can sense external stimulus influences, while the ion channel can receive information from the biological membrane, amplifying and transmitting it. When the sensing part of the membrane is affected by external stimulus substances, the permeability of the membrane changes, allowing a large number of ions to flow into the cell, forming information transmission. The key role is played by the membrane proteins that make up the biological membrane, which can produce conformational network changes, altering the permeability of the membrane to transmit and amplify information. The ion channels of the biological membrane, formed by polymerized amino acids, can be replaced by easily synthesized polyamines in organic chemistry (L-glutamic acid, PLG), which have better chemical stability than enzymes.

PLG is water-soluble and not suitable for electrical modification, but it can be synthesized with polymers to form the sensing membrane used in sensors. The principle of the ion channels of the biological membrane is basically the same as that of the biological membrane itself. After fixing the block copolymer membrane on the electrode, if substances that induce changes in the PLG conformational network are added, the permeability of the membrane will change, resulting in changes in current. The change in current can be used to detect the presence of stimulus substances. The urea sensor has been proven to be a stable biosimulated sensor, with a detection limit in the order of 10^-3 and can detect stimulus substances, but is currently not suitable for biological measurements.

Currently, despite the successful development of many bionic sensors, the stability, reproducibility, and batch production capabilities of bionic sensors are clearly insufficient, so bionic sensing technology is still in its infancy. Therefore, in the future, in addition to continuing to develop new series of bionic sensors and improving existing series, the immobilization technology of bioactive membranes and the solidification of bionic sensors warrant further research.

In the near future, bionic sensors simulating the functions of smell, taste, hearing, and touch may appear, potentially surpassing the sensitivity of human senses, enhancing the capabilities of current robots in vision, taste, touch, and manipulation of target objects. We can see the broad prospects for the application of bionic sensors, but all of this requires further development in biotechnology, and we await the arrival of that day.

Sensor 4: Infrared Sensors

Infrared Sensors

<Concept: Infrared Sensors>

Photodetectors that convert infrared radiation energy into electrical energy are known as infrared sensors. Infrared sensors, also referred to as infrared detectors, utilize the characteristic of objects to produce infrared radiation to achieve automatic detection. In physics, we know that visible light, invisible light, infrared light, and radio waves are all electromagnetic waves, among which infrared light is also called infrared radiation. It possesses properties such as reflection, refraction, scattering, interference, and absorption. Any material that has a temperature above absolute zero can emit infrared radiation. Infrared sensors measure without direct contact with the measured object, thus eliminating friction, and have advantages such as high sensitivity and fast response.

Infrared technology has developed into an emerging technology in recent decades. It is commonly used for non-contact temperature measurement, gas composition analysis, and non-destructive testing, and has found widespread applications in medicine, military, space technology, and environmental engineering.

Infrared technology has become well-known today, with broad applications in modern science and technology, national defense, and various fields of agriculture and industry.

<Classification>

There are many types of infrared sensors, and they can be classified into different categories based on different mechanisms:

1. By function:

(1) Radiometers for measuring radiation and spectra;

(2) Search and tracking systems for locating and tracking infrared targets, determining their spatial positions and tracking their movements;

(3) Thermal imaging systems that can produce images of the distribution of infrared radiation across an entire target;

(4) Infrared ranging and communication systems;

(5) Hybrid systems, which refer to combinations of two or more systems from various categories.

2. By working principle:

(1) Some infrared radiation is converted into heat, extracting changes in resistance and electromotive force as output signals (thermal type); (2) Quantum type, which utilizes the phenomenon of semiconductor migration to absorb energy differences through the photoelectric effect and utilizes the photomotive effect caused by PN junctions.

Sensor 5: Electromagnetic Sensors

Electromagnetic Sensors

Magnetic sensors are the oldest sensors, with the compass being the earliest application of magnetic sensors. However, as modern sensors, magnetic sensors need to convert magnetic signals into electrical signals for ease of signal processing. The earliest applications were magnetic-electric sensors manufactured based on the principle of electromagnetic induction. These magnetic-electric sensors made outstanding contributions in the field of industrial control but have now been replaced by new types of magnetic sensors primarily based on high-performance magnetic-sensitive materials.

Among the electromagnetic effect sensors currently used, magnetic rotary sensors are an important type. Magnetic rotary sensors mainly consist of semiconductor magnetoresistive elements, permanent magnets, fixtures, and casings. A typical structure involves mounting a pair of magnetoresistive elements on a permanent magnet stimulus, connecting the input and output terminals of the elements to the fixture, and then sealing it in a metal box with engineering plastics to form a closed structure, which provides good reliability.

Magnetic rotary sensors possess many advantages in terms of shape that cannot be matched by many semiconductor magnetoresistive elements. In addition to having high sensitivity and large output signals, they also have a strong rotational speed detection range, a result of advancements in electronic technology. Moreover, these sensors can operate over a wide temperature range, have a long service life, and exhibit strong resistance to dust, water, and oil, making them suitable for various environmental conditions and external noise. Therefore, these sensors are widely valued in industrial applications.

Magnetic rotary sensors have broad applications in factory automation systems due to their satisfactory characteristics and maintenance-free operation. Their main applications include detecting the rotation of servo motors in machine tools, positioning robotic arms in factory automation, detecting hydraulic stroke, and detecting positions of equipment related to factory automation, as well as detection units for rotary encoders and various rotary detection units. Modern magnetic rotary sensors include four-phase sensors and single-phase sensors. In operation, four-phase differential rotary sensors use one pair of detection units for differential detection while another pair performs reverse differential detection. Thus, the detection capability of four-phase sensors is four times that of single units. The two-element single-phase rotary sensor also has its advantages, namely compact reliability, large output signals, the ability to detect low-speed motion, strong resistance to environmental influences, and low noise, making it cost-effective. Therefore, single-phase sensors also have great market potential.

Magnetic rotary sensors also have significant application potential in household appliances. In cassette recorders, magnetoresistive elements can be used to detect the endpoint of magnetic tapes. Many household video recorders have variable-speed and high-speed playback capabilities, which can also utilize magnetic rotary sensors to detect spindle speed and control it for high-quality images. The forward and reverse rotation and high and low-speed rotation functions of motors in washing machines can also be achieved through the detection and control of servo rotary sensors. These switches can sense metallic objects entering their inspection areas, controlling the opening or closing of their internal circuits. The switches generate their own magnetic fields, and when a metallic object enters the magnetic field, it causes changes in that field. These changes can be transformed into electrical signals through the internal circuitry of the switch.

Furthermore, electromagnetic sensors represent a widely applicable high-tech field, with both domestic and international research efforts being invested in their study. The applications of these sensors are permeating various sectors of the national economy, national defense construction, and daily life. With the advent of the information society, their status and role are bound to increase.

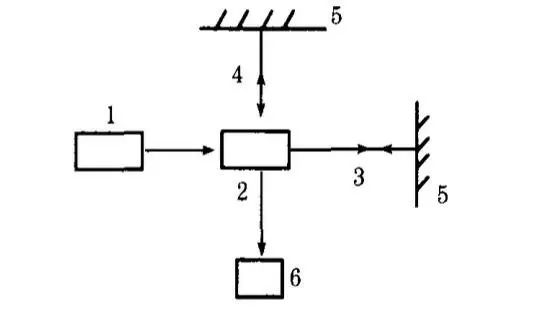

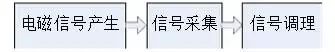

The path information of intelligent tracking vehicles based on electromagnetic signals is generated by alternating magnetic fields produced by powered wires. The design of sensors based on alternating magnetic fields includes two parts: signal acquisition and signal conditioning. Below, we will gradually introduce the entire sensor module through the principles of electromagnetic signals, sensor selection, and signal conditioning, as shown in Figure 1:

Figure: Electromagnetic Sensor Module

Sensor 6: Magneto-Optic Effect Sensors

Magneto-Optic Effect Sensors

Modern electrical measurement technology is becoming increasingly mature. Due to its high precision and ease of connection to microcomputers for automatic real-time processing, it has been widely applied in the measurement of electrical and non-electrical quantities. However, electrical measurement methods are easily disturbed, and during AC measurements, the frequency response is not wide enough and there are certain requirements for withstand voltage and insulation. With the rapid development of laser technology today, these issues have been resolved.

Magneto-optic effect sensors are high-performance sensors developed using laser technology. Lasers, which rapidly developed in the early 1960s, signify that humanity has entered a new phase of mastering and utilizing light waves. Previously, the low monochromaticity of ordinary light sources limited many important applications, but the emergence of lasers has propelled radio and optical technologies forward, leading to mutual penetration and supplementation. Nowadays, many sensors have been created using lasers, solving many technical challenges that were previously insurmountable, making them suitable for hazardous and flammable environments such as coal mines, oil, and natural gas storage.

For example, laser-made fiber optic sensors can measure parameters like crude oil injection and the cracking conditions of large oil tanks. In measurement locations, there is no need for power supply, which is particularly suitable for petrochemical equipment that requires strict safety and explosion-proof measures. It can also be used to achieve optical remote measurement of chemical technologies in certain links of large steel plants.

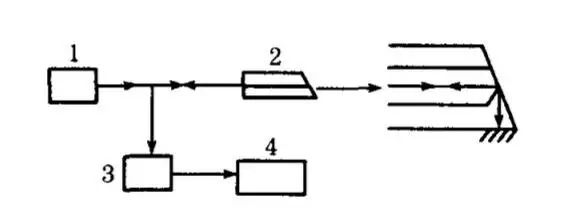

The principle of magneto-optic effect sensors mainly utilizes the polarization state of light to achieve sensor functionality. When a beam of polarized light passes through a medium, if there is an external magnetic field in the direction of light propagation, the light will rotate an angle through the polarization plane, which is the magneto-optic effect. The angle of rotation can be used to measure the applied magnetic field. Under specific experimental setups, the deflected angle is proportional to the output light intensity, and by illuminating a laser diode (LD) with the output light, digitalized light intensity can be obtained for measuring specific physical quantities.

In the use of magneto-optic effect sensors, the selection of magneto-optic media and lasers is crucial, as different devices exhibit varying capabilities in sensitivity and working range. With the emergence of high-performance lasers and new types of magneto-optic media in recent decades, the performance of magneto-optic effect sensors has strengthened, and their applications have become increasingly widespread. As a specific-purpose sensor, the magneto-optic effect sensor can perform its functions in specific environments and is a very important industrial sensor.

Sensor 7: Pressure Sensors

Pressure Sensors

Pressure sensors are the most commonly used type of sensor in industrial practice. The pressure sensors we typically use are primarily manufactured using the piezoelectric effect, and such sensors are also referred to as piezoelectric sensors.

We know that crystals are anisotropic, while amorphous materials are isotropic. Certain crystalline media, when subjected to mechanical force in a specific direction, exhibit polarization effects; once the mechanical force is removed, they return to a non-charged state. This means that when subjected to pressure, certain crystals may produce electrical effects, known as the polarization effect. Scientists have developed pressure sensors based on this effect.

The piezoelectric materials primarily used in piezoelectric sensors include quartz, potassium sodium tartrate, and diammonium phosphate. Quartz (silicon dioxide) is a natural crystal where the piezoelectric effect was first discovered. Within a certain temperature range, the piezoelectric properties persist, but they completely disappear when the temperature exceeds this range (this high temperature is known as the “Curie point”). Due to the small changes in electric field with stress (indicating a relatively low piezoelectric coefficient), quartz has gradually been replaced by other piezoelectric crystals. Potassium sodium tartrate has high piezoelectric sensitivity and piezoelectric coefficients, but it can only be used in environments with room temperature and low humidity. Diammonium phosphate is a synthetic crystal that can withstand high temperatures and considerable humidity, thus it has gained widespread applications. Nowadays, the piezoelectric effect is also applied in polycrystalline materials, such as piezoelectric ceramics, including barium titanate piezoelectric ceramics, PZT, niobate piezoelectric ceramics, lead magnesium niobate piezoelectric ceramics, etc.

The piezoelectric effect is the primary working principle of piezoelectric sensors. Piezoelectric sensors cannot be used for static measurements because the charge generated by external forces can only be preserved if the circuit has infinite input impedance. This is not the case in reality, which determines that piezoelectric sensors can only measure dynamic stress.

Piezoelectric sensors are mainly used to measure acceleration, pressure, and force. Piezoelectric accelerometers are a commonly used type of accelerometer. They possess excellent characteristics such as simple structure, small size, light weight, and long service life. Piezoelectric accelerometers have been widely used in measuring vibrations and impacts in aircraft, automobiles, ships, bridges, and buildings. Particularly, the shape of piezoelectric sensors holds a special status in aerospace and aeronautical fields. They can also be used to measure combustion pressures within engines and vacuum levels. They can also be used in military applications, such as measuring the pressure changes in the chamber at the moment a bullet is fired and the pressure of shock waves at the muzzle.

They can measure both large and small pressures. Piezoelectric sensors are also widely used in biomedical measurements, such as the ventricular catheter microphone made from piezoelectric sensors, as measuring dynamic pressure is so common that the applications of piezoelectric sensors are very extensive. In addition to piezoelectric sensors, there are also piezoresistive sensors made using the piezoresistive effect and strain gauges that utilize strain effects; these different pressure sensors use various effects and materials to fulfill their unique purposes in different contexts.

Source: Jie Ge Kan Internet of Things

Long press the image below, recognize the QR code in the image, and follow the WeChat public account of Science and Technology Fengsui