In modern manufacturing enterprises, the automation systems of production lines generally use PLC as the main node of the control and communication network, with the most common being fieldbus protocols; at the same time, the management and operation systems of enterprises generally adopt computer-based communication networks, primarily using TCP/IP protocols. How to achieve data communication between different application systems, bridging the data pathways between different communication protocols, and performing functions such as data analysis, storage, and forwarding—such as quickly issuing production instructions and rapidly releasing production status—has become an objective requirement for the emergence and development of data gateway technology.

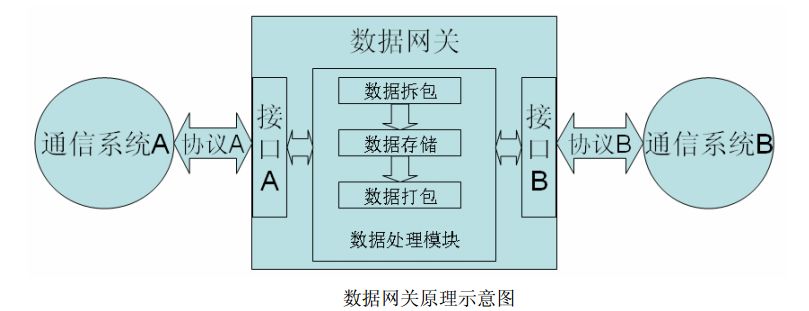

Basic Principles of Data Gateways

The role of a data gateway is to connect different communication systems and achieve data interoperability. Therefore, the first step is to establish a physical connection between different systems. Based on this physical connection, software connections are made according to the communication protocols of different systems, utilizing the interfaces allowed by the protocols to forward data through the processes of receiving, extracting, and sending data.

Implementation Methods of Data Gateways

From the basic principles of data gateways described above, we can understand the two essential elements required by data gateways: interfaces and data processing. The rich choice of interfaces and powerful computing capabilities brought about by the development of modern computer technology provide the necessary conditions for this. A computer equipped with the appropriate interfaces and installed with the corresponding data processing software is a data gateway.

The most typical representative among existing implementation methods is the industrial control computer (commonly referred to as the IPC). Manufacturers modularize various interfaces (cards) and combine them with general-purpose computer host modules to achieve the goal of connecting general-purpose computers to specific communication systems. Customers can easily build a hardware platform for data gateways by selecting interface modules (cards) and general-purpose computer hosts that meet processing capabilities according to their needs. On this basis, dedicated data processing software can be developed to achieve powerful functions such as data analysis, storage, and forwarding.

Applications of Data Gateways

The fundamental function of a data gateway is to perform the translation and conversion of content between different communication protocols. However, how to process the data during this process or how to use this data determines the applications of the data gateway. Based on different data processing methods, data gateways can be divided into general data gateways and dedicated data gateways.

1. General Data Gateways

This type of data gateway primarily focuses on data transmission functions and only performs simple processing on the transmitted data, such as validity filtering, storage, and reorganization. The most typical application is the operation upper-level machine system in control systems, which connects to the control system via industrial Ethernet, fieldbus, or other means, sending the collected data via Ethernet (generally TCP/IP protocol) to the operator’s upper-level machine, displaying the corresponding status on the control screen, while also sending the operation instructions issued by the upper-level machine to on-site PLCs and other controllers, achieving data connectivity between the on-site equipment communication system and the manual operation communication system. In this typical case, it is difficult to find a specific data gateway; in fact, the operation upper-level machine integrates the function of data conversion, acting as a data gateway. In addition, advanced management systems such as ERP, MES, and ASP, which have been widely used since the beginning of this century, achieve information interoperability with production line control systems, requiring a large amount of data organization, storage, and forwarding, thus necessitating the use of data gateways as the primary information bridge and transit station.

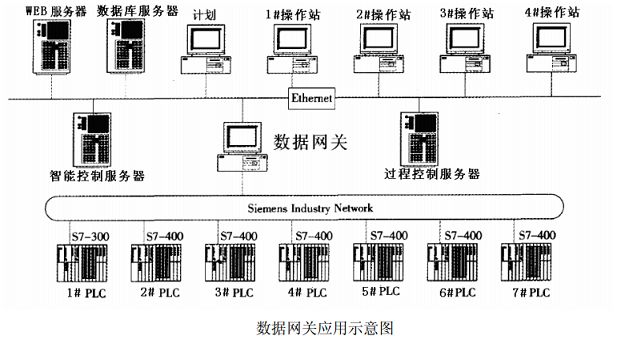

The above image shows a comprehensive production control system where the data gateway connects the production line control system and the production command system, serving as the data hub. With the data gateway configured, the entire system has the following functions:

(1) Real-time storage of production data and status. Through the database, long-term historical data can be saved, facilitating production process analysis and quality traceability.

(2) Real-time reporting and publishing of production status. Managers can efficiently formulate production plans based on real-time data; marketing personnel can track order production in a timely manner and provide feedback to customers.

(3) Rapid issuance of production instructions. Production planning information from MES, ERP, etc., can be quickly dispatched to the production line, achieving rapid order response and shortening delivery times.

(4) Enhanced system stability. All operation stations are networked, allowing each operation station to understand the production situation of the entire line, and they can serve as backups for each other, substituting for one another when necessary.

(5) Improved production automation levels. It facilitates the addition of specialized computing devices for process control, intelligent control, etc., compensating for the lack of intelligent computing and large data volume computing capabilities of ordinary PLCs, making production more refined and improving product quality.

2. Dedicated Data Gateways

Compared to general types, this type not only has the basic functions of data storage, forwarding, etc., but its greatest feature is that it integrates other advanced functions, forming dedicated devices based on data gateway technology. Currently, there are several main types:

(1) Information publishing data gateways integrate web publishing functions, directly connecting to the internet via wired or wireless interfaces, allowing users to obtain real-time production information from anywhere. To ensure that normal production is not disturbed, data isolation can be implemented through hardware or software, ensuring that the data flow is unidirectional; for example, using hardware isolation technology can achieve complete isolation.

(2) Process control data gateways, in addition to the basic functions of data gateways, primarily focus on data computation, mainly implemented through software, providing advanced control for production systems, especially single complex devices, compensating for the difficulties faced by PLCs and other on-site controllers in data processing, historical data retrieval, and complex algorithm realization, thus improving the level of production automation.

(3) Information storage data gateways mainly focus on data storage, establishing a local database to perform long-term storage of received data and providing various organization and query interfaces to facilitate production process optimization and quality traceability.

Integration of Data Gateways with the Latest Information Technologies

The emergence of the latest information technologies such as cloud technology and IoT technology is largely based on the development of internet technology, and the characteristics of data gateways in connecting different communication networks provide support for the application of these new technologies in traditional industries.

1. Data Gateways and Cloud Computing

Through data gateways, production data can be sent to the enterprise’s R&D and quality centers, or even specialized data analysis centers, utilizing the powerful computing capabilities and information resources of the “external brain” to conduct comprehensive and in-depth analysis of production data, thereby obtaining more efficient guidance for production process parameters, enhancing product quality, and optimizing production processes. With only a small investment in hardware, this capability for professional massive data analysis and computation can be achieved, realizing a balance between low cost and high efficiency.

2. Data Gateways and Mobile Internet Terminals

Through data gateways, production data is sent in real-time to the mobile internet terminals of enterprise decision-makers, allowing them to formulate production strategies at any time based on market changes, maximizing benefits; production data is also sent in real-time to remote sales managers’ mobile internet terminals, enabling them to track order status and provide feedback to customers, as well as relay new customer demands to the production line, optimizing order plans in a timely manner, thereby reducing production costs and shortening delivery cycles.

3. Data Gateways and IoT Technologies

Through data gateways, the production line status is integrated with logistics information such as raw materials, auxiliary materials, and finished products, allowing for a comprehensive analysis of various processes to determine the optimal scheduling scheme, achieving efficient resource utilization, immediate production, reducing intermediate links, lowering inventory, and saving logistics costs.

Smart Gateways in the Internet of Things

The Internet of Things is a fusion application of intelligent sensing, radio frequency identification technology, ubiquitous computing, and pervasive networks, regarded as the third wave of world information industry development following computers and the internet. The main purpose of the Internet of Things is to enable new sensing devices with radio frequency technology, infrared sensing technology, or other sensing capabilities to seamlessly integrate into the internet, achieving information exchange among them and further intelligent identification and monitoring management.

In the field of information perception in the Internet of Things, due to the special application scenarios of wireless sensor network technology, it is generally applied within localized areas, where networks cannot communicate with each other and are not suitable for achieving remote data transmission. This results in sensor device nodes forming isolated information islands, making it impossible to achieve true comprehensive interconnectivity and collaborative sensing. In addition, the diverse types of sensing technologies used in IoT applications adopt different communication protocols, making interconnectivity impossible.

The IoT gateway, as a new term, will play a very important role in the future IoT era. It will become the link connecting wireless sensor networks with traditional communication networks, completing protocol conversion between wireless sensor networks, traditional communication networks, and other different types of networks, achieving data interconnectivity in local and wide area networks. Moreover, IoT gateways also need to have device management functions, allowing operators to manage the underlying sensing nodes, understand the relevant information of each node, and achieve remote control.

Functionally, the IoT gateway or smart gateway primarily achieves the following three functions:

-

Capability of accessing sensing networks.

The IoT gateway must first possess the functionality to acquire information about the properties and states of various nodes, meaning it can perceive the real-time status of each node. Secondly, it must have the ability to remotely control, wake up, and diagnose nodes, enabling automated management of the nodes.

-

Capability of interoperating heterogeneous networks.

The IoT gateway must meet the requirements for cross-domain communication, necessitating a complete addressing technology to ensure that all node information can be accurately, efficiently, and securely located and queried. With the development of IoT applications, the number of node addresses will gradually increase, and their coding structure will differ from the domain name structure in DNS, thus requiring a set of addressing technology different from the internet to meet this demand.

-

Standardization of communication and data formats.

The gateway must achieve protocol conversion from sensing networks to traditional communication networks, unifying the standard format data transmitted by the protocol adaptation layer, and unpacking the data issued by the wide-area access layer into standard format data, parsing commands, and converting them into signals and control instructions recognizable by the sensing layer protocol.

In simple terms, the IoT gateway primarily completes three tasks: first, it collects data from sensor nodes; second, it executes data protocol conversion; and finally, it quickly and effectively sends the converted data to the public network. In addition, the IoT gateway also possesses corresponding management and control capabilities.

1. Access to Sensing Networks

The IoT smart gateway needs to have the capability to access sensing networks. Sensing networks are primarily composed of various sensor networks with different functions, including cameras, card readers, tags, sound-sensitive sensors, pressure-sensitive sensors, temperature-sensitive sensors, etc. The methods for acquiring these sensor perception information are varied, and there is currently no unified standard. The main access methods can be divided into wired and wireless access. The mainstream wired access methods include CAN, RS232/485, Ethernet, etc. CAN is often used in automotive computer control systems, while RS232/485 is mainly used for some older equipment control and low-speed data transmission. Ethernet is very reliable and effective for long-distance, large-volume sensor data transmission.

The mainstream wireless access methods include Zigbee, Bluetooth, IrDA, and Wi-Fi, all of which fall under the category of short-range communication. Zigbee is characterized by low power consumption and flexible networking, generally used for low-speed short-distance wireless transmission and control. Bluetooth is primarily used in systems requiring high real-time performance, such as mice, keyboards, and headsets. IrDA uses infrared for point-to-point transmission, with the characteristics of small size, low power consumption, and low cost. However, since infrared transmission can only occur in point-to-point unobstructed conditions, it is somewhat limited by the application environment.

Wi-Fi, as the fastest advancing wireless access technology, has undergone more than a dozen iterations of versions and is now widely used in mobile phones, laptops, and various smart products, featuring easy networking, wide coverage, and fast transmission rates, though it also has drawbacks such as high power consumption and complex protocols.

2. Interoperability of Heterogeneous Networks

The IoT smart gateway needs to have the capability for interoperability among heterogeneous networks. Due to different sensor networks using different protocol encapsulations for perception information, this results in a soft isolation of data between networks. On one hand, physically interconnected sensing networks cannot communicate; on the other hand, sensing networks cannot communicate with core switching networks, preventing perception data from being accessed remotely. Thus, protocol gateways need to be set up to resolve this issue.

In traditional RS-232/485 communication sensor networks, there are many bus standards and protocols, with Modbus, Profibus, and Interbus being the most commonly used protocols, among which Modbus is widely applied in intelligent transportation, smart agriculture, and intelligent buildings.

As the internet and sensor networks accessed via Ethernet and Wi-Fi are all based on the TCP/IP protocol stack, if a remote user needs to access and control devices using the Modbus protocol, the Modbus messages must be encapsulated according to the TCP/IP protocol at the application layer or undergo protocol conversion.

Additionally, as the IPv4 address space is nearing exhaustion, the next generation of IPv6 protocol will gradually replace IPv4, and the transition phase from IPv4 to IPv6 will be a long process, during which IPv4 and IPv6 networks will coexist, requiring the IoT gateway to address interoperability between IPv4 and IPv6 networks.

3. Standardization of Communication and Data Formats

The IoT smart gateway needs to have monitoring and control management capabilities, as well as the ability to accommodate new nodes. The monitoring and control management includes centralized monitoring of the status and perception information of the connected sensors, control and management of both the sensors and the gateway itself. On one hand, the functional modules within the gateway should be flexibly controlled, with configuration methods being simple, diverse, and user-friendly; on the other hand, control should be possible both through local networks and serial ports as well as remotely across different network segments.

Moreover, the types of IoT nodes are extremely diverse. The content of monitoring and control management should include the status and functionality of the gateway node itself, as well as the status and information of the connected sensor networks. To achieve these functionalities, all smart gateway nodes must use standardized communication methods to ensure that the entire IoT system has high maintainability.

In summary, on one hand, with the vigorous development of computer technology, sensing technology, and embedded technology, household electronic appliances will become increasingly intelligent; on the other hand, with the improvement of people’s living standards and quality, smart homes are gaining more attention, and at the same time, smart gateways will see greater development and are on the path to maturity.

The future of manufacturing is intelligent, and the foundation of intelligence is sensors; the direction of the internet is the Internet of Things, and the cornerstone of the Internet of Things is also sensors;

【Clickthe blue title, to get the article】

1、Understand MEMS Sensors in One Article

2、Understand Proximity Sensors in One Article

3、Understand Magnetic Sensors in One Article

4、Understand Flow Sensors in One Article

5、Understand the Principles and Classifications of Pressure Sensors in One Article

6、Understand Acceleration Sensors in One Article

7、Understand Ultrasonic Sensors in One Article

8、Understand Displacement Sensors in One Article

9、Understand Photoelectric Sensors in One Article

10、Understand Fiber Optic Sensors in One Article

11、Understand Temperature and Humidity Sensors in One Article

12、Understand Image Sensors in One Article

13、Understand Biological Sensors in One Article

14、Understand Hall Sensors in One Article

15、Understand Distance Sensors in One Article

16、Understand Oxygen Sensors in One Article

17、Understand Wind Direction and Speed Sensors in One Article

18、Understand Nano Sensors in One Article

19、Understand Infrared Sensors in One Article

21、Understand Gas Sensors in One Article

23、Today’s Discussion on Automotive Sensors

24、Understand Mobile Phone Sensors in One Article

25、Understand Medical Sensors in One Article

26、Understand Chemical Sensors in One Article

27、Understand Angular Velocity Sensors (Gyroscopes) in One Article

28、Understand Transducers in One Article

29、Understand Rotary Encoders in One Article

30、Understand Gearboxes in One Article

31、Understand Vibration Sensors in One Article

32、Understand Capacitive Sensors in One Article

33、Understand Eddy Current Sensors in One Article

34、Understand Inductive Sensors in One Article

35、Understand Grating Sensors in One Article

36、Understand Piezoelectric Sensors in One Article

37、Understand Smoke Sensors in One Article

38、Understand Resistive Sensors in One Article

39、Wireless Network Sensors Explained in One Article

40、Market Status and Major Manufacturers of MEMS Sensors

41、Market Status and Major Manufacturers of Image Sensors

42、Market Status and Major Manufacturers of Gas Sensors

43、Market Status and Major Manufacturers of Fingerprint Sensors

44、Market Status and Major Manufacturers of Automotive MEMS Sensors

This public account is looking for long-term column authors with high salaries. If you have excellent writing abilities as a technology professional or enthusiast, please contact Sensor Editor: YG18511751369 (WeChat ID)

Looking forward to the next article with over 100,000 views from your pen!

Disclaimer: The copyright of this article belongs to the original author. If the videos, images, or texts used in this article involve copyright issues, please inform us as soon as possible, and we will confirm the copyright based on the proof materials you provide and pay remuneration according to national standards or immediately delete the content! The content of this article reflects the views of the original author and does not represent the views of this public account or its responsibility for its authenticity.

To publish your products, please click “Read the Original”