How to embrace Industrial IoT? First, devices need to be connected to the network, and the data and application integration based on “connection” will drive the transformation of business models, truly realizing the value of Industrial IoT.

Although it is said that sensors are the most fundamental perception devices in IoT, when people think of data collection, they often first think of sensor manufacturers. However, from a business perspective, in the practice of Industrial IoT, how to interface with controllers is the primary issue to solve. This is because there is already a lot of usable data in the controllers, which is closely related to equipment failures, status, process parameters, energy consumption parameters, etc. At the same time, in some application scenarios, commands need to be sent to the controllers (such as sending recipes, starting/stopping, modifying process parameters, etc.). Therefore, connecting to the controller is the primary consideration on the business side. Sensors are more of a first consideration only when the data dimensions on the controller side are insufficient, or for new applications or devices without controllers (either very old or purely mechanical devices).

Today, we will talk about the classification of industrial box manufacturers and my personal views on the trends of gateway products.

As mentioned earlier, the role of industrial gateways is to collect data, while also taking on the mission of automation and IT integration due to the needs of industrial cloud platforms. It can be said to be a product that connects the upper and lower levels.

Traditionally, data is collected in automation systems using SCADA software, storing it in the corresponding database. Then IT systems use the database to interface with the collected data. This approach is not only costly (especially for equipment-based operations), but also inefficient. Therefore, industrial gateways (boxes) have gained more market share.

The traditional SCADA market will gradually slow down. In terms of database and data display, IT systems have stronger configuration capabilities (high concurrency, distributed storage, H5 technology, 3D, etc.), while more flexible industrial gateways will replace at the protocol layer.

Generally speaking, industrial gateways need to have the following capabilities:

1. Capability to parse protocols from below (automation systems) (communication protocols: Modbus, PPI, MPI, CNC, etc.; bus protocols: CAN, PROFIBUS, etc.; industrial wireless protocols: WirelessHART, 433, etc.). Currently, gateways mainly focus on communication protocols, and only a few manufacturers consider bus protocols and wireless protocols from below. Traditional bus protocol conversion is also called industrial gateway, which creates confusion.

2. Capability to interface with above (IT systems) communication protocols (Ethernet, WIFI, 3G, 4G, NB-IOT, etc.).

3. Capability for secondary development of private protocols for both above and below.

4. Capability for data caching and local computing (fog computing/edge computing).

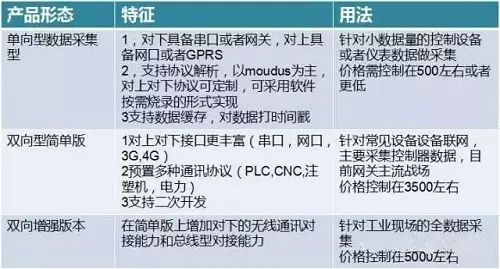

Only with such capabilities can one be considered a complete gateway. On the other hand, industrial site applications are very complex, and the cost of data access is currently very high, often causing the cost of access to account for more than half of the expenses when owners want to implement information systems. Therefore, gateway manufacturers will layout corresponding product tiers according to market size. However, currently, both domestic and foreign gateway manufacturers find it difficult to cover all applications, and the lack of unified communication protocols for interfacing with IT systems results in high access costs, greatly affecting the application of cloud and big data. Based on my years of industry experience, an ideal gateway should have the following product forms:

Currently, industrial gateways are concentrated in the second type, which is also the type with the highest demand. The first and third types are not clearly defined in the market, and while there is a strong demand in certain industries, their replicability is not as high as the second type, so fewer people are developing them.

At the same time, the first and third types have certain risks when selecting wireless communication protocols (for above or below), as they do not generally use 3G or 4G like the second type of gateway. The ideal situation is for the first type of gateway to use NB-IOT as the communication protocol for above, while the third type chooses 1-2 suitable wireless communication protocols for below (currently, process industries tend to use WirelessHART and 433; discrete industries temporarily use WIFI as a substitute, which is not very effective).

Doing all this is not enough to become an excellent industrial gateway company. Currently, the cost of interfacing gateways with the cloud remains very high, and I believe the main reasons are as follows:

1. The industrial IoT market is vast, and many gateway manufacturers are eyeing the cloud market. On one hand, many gateway companies originated from configuration and have certain software development capabilities (although I do not believe they have the capability to develop cloud solutions, the market is mixed, and any B/S software claims to be cloud). On the other hand, the cloud side currently lacks strong enterprises and corresponding standards.

2. As the main data entry point for industrial IoT, industrial gateways often encounter more demand in the early market stage. However, once data access is resolved, gateways will no longer be important, as the value of data needs to be realized through cloud data sharing (internal sharing through core relationship software and sharing through industrial cooperation ecosystems) and data mining. Simply collecting data and seeing data has very low value. Therefore, it is often said that the starting point of industrial IoT is data monitoring, while many people believe that data can be realized through B/S software. This situation leads to a high potential for replacement of industrial gateway manufacturers in the future. Additionally, due to the lack of standardized communication protocols with the cloud, gateway manufacturers often need to develop their own cloud configuration tools, resulting in high costs for each gateway manufacturer to develop their own middleware for cloud integration.

Therefore, for those who have been in the general gateway market for more than 5 years, I hope various gateway manufacturers can adopt a service-oriented mindset (customer-centered). If your gateway is positioned in a general market, then consider how to better serve downstream companies in the cloud and big data sector. This is because the general market generally adopts the strategy of minimizing total costs, so how to further reduce the costs of IoT systems from a solution perspective is a must for companies in the general market.

Finally, the market for industrial gateways (or general gateways: DTU, routers, and bus gateways, etc.) can directly reflect the current level of development of industrial IoT in China. As someone who has been involved in industrial IoT since the concept began in the domestic market, I believe that to understand the development of industrial IoT in China, one can gauge it by observing the development of domestic industrial gateways. By the way, last year, the domestic manufacturer of industrial routing equipment, YHT, achieved over 50% growth, and Advantech just spent $100 million to acquire the American general gateway supplier B+B. Undoubtedly, if 2008-2015 was the exploratory stage of industrial IoT in China, following the development of smart transportation and smart grid led by the government, since the second half of 2015, industrial IoT has been transitioning to a market led by enterprises, with industrial gateways playing a bridging role in stabilizing data collection and connecting information technology and automation. To pay attention to industrial IoT, one must first focus on industrial gateways, as the cloud and big data markets are currently relatively weak. However, there is no doubt that the future belongs to them, and gateways have their historical mission.

to hear

Dear readers, how did you find this article?

If you think it’s good, please give us a thumbs up below. Your affirmation will motivate us to keep improving;

If you think it needs improvement, please leave your valuable suggestions in the comment section below, and we will continue to improve to provide you with more valuable insights and information!

2017 International IoT Expo (Spring Exhibition)

2017 Smart Card and Financial Consumer Expo (Spring Exhibition)

March 29-31

Suzhou International Expo Center

2017 9th Shenzhen International IoT Expo

2017 Asia Smart Card and Financial Consumer Expo

Shenzhen International Smart Building Electrical & Smart Home Expo

August 16-18

Shenzhen Convention and Exhibition Center

↓↓↓ Click “Read the Original” 【For More Information】