Whether for smartphones or ultra-high-definition television screens, High Dynamic Range (HDR) cameras are no longer limited to delivering popular visual effects. An increasing number of high-performance cameras support Advanced Driver Assistance Systems (ADAS) and Autonomous Vehicle (AV) applications. For example, Waymo’s fifth-generation self-driving car is equipped with at least 29 cameras, in addition to 5 LiDARs and 6 radars.

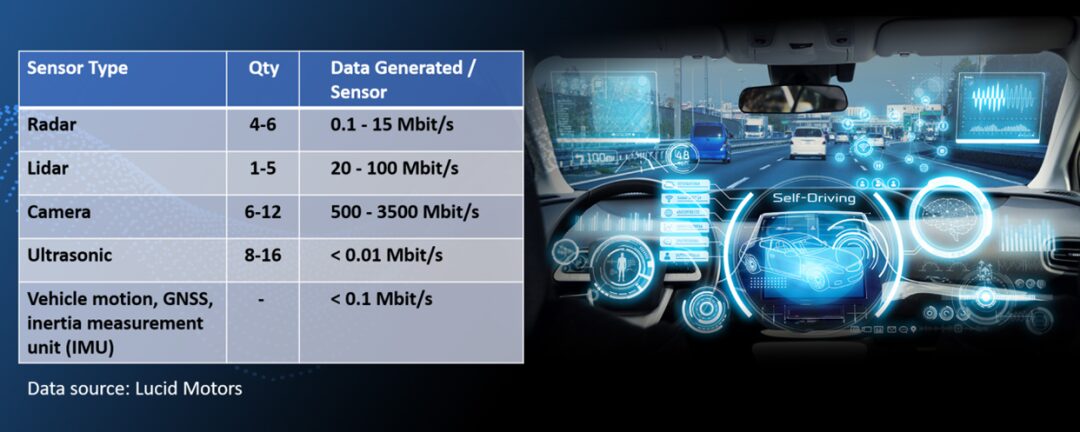

Future autonomous vehicles will need to support a total bandwidth of 3 to 40 GBit/s (approximately 1.4 to 19 TB/h), with cameras generating the most data.

Figure 1: The data generated by cameras is the largest among ADAS and AV sensors. Data source: Lucid Motors

In-Vehicle Network – Domain Architecture

In-Vehicle Network – Domain Architecture

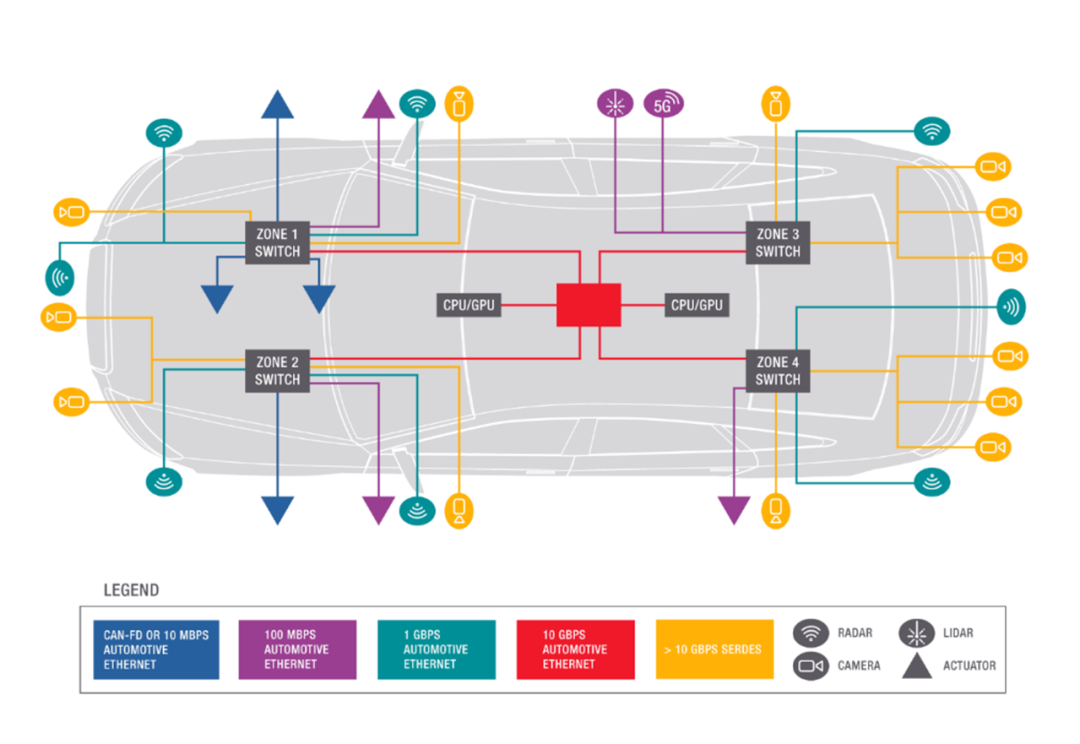

These different types of sensors use different data rates in the platform, and one of the challenges faced by automotive engineers is how to reduce the complexity of in-vehicle networks through domain architecture.

Figure 2: Conceptual diagram of a domain-based in-vehicle network architecture

Figure 2 is a simplified representation of the partitioned architecture: different types of sensors are aggregated into different partitions, with automotive Ethernet serving as the interconnection between the partitions or domains.

The Role of Automotive SerDes is Becoming Increasingly Important

ADAS camera sensors require high data rates and transmission speeds to operate as designed. Developers are increasingly turning to Serializer/Deserializer (SerDes) connections to link these cameras to the vehicle’s image processing Electronic Control Unit (ECU), as shown in the light orange interconnect in Figure 2. This SerDes connection converts parallel data to serial data (and vice versa), enabling faster communication between devices using lower-cost cables and connectors.

Currently, SerDes solutions are delivered by various vendors using closed proprietary standards, but this is about to change. The industry recognizes that transparent and unified standards and testing requirements will drive chip vendors, Tier 1 automotive suppliers, and automakers to accelerate development cycles, reduce costs, and enhance interoperability with other commercial devices.

The industry is already addressing some urgent challenges faced by SerDes in vehicle networking, such as validation:

• Interoperability between different Media Dependent Interface (MDI) cables and connectors

• Integrity of transmitter, interconnect, and receiver performance

• Robustness of the system against various Electromagnetic Interference (EMI)

• Network security from the physical layer to the entire protocol stack

Interoperability is a real issue. Transceivers are sensitive devices that must be carefully tested to ensure they can operate in harsh automotive environments, including high temperatures, vibrations, electrostatic discharge, and electromagnetic interference. Let’s look at some examples of transceiver testing.

Transmitter Testing

Transmitter Testing

For transmitters, it is essential to ensure that the characteristics of the transmitted signal are good.

Figure 3: A rearview ADAS safety camera with packet loss

Figure 3 is an example of a car’s rear camera view with horizontal lines. These lines are caused by packet loss due to transmission gaps. The driver may still be able to see an image with a few lost packets, but if a child suddenly appears behind the reversing vehicle, the transmission will flicker black, which would be catastrophic!

Multiple vendors are involved in the implementation of this safety feature: camera manufacturers, cable suppliers, switch suppliers sending signals, as well as GPUs or ECUs processing the data, and finally the brakes used for parking. We can see why overall interoperability is crucial.

Channel Testing

Channel Testing

Link or channel testing is crucial for ensuring signal integrity between the transmitter and receiver. Given the cable lengths used in harsh automotive environments, examining the relationship between impedance and frequency is also an essential aspect of predicting channel performance within the vehicle.

The link portion includes cables and inline connectors, as well as matching connectors at both ends. Ultimately, the wiring harness is responsible for transmitting control and payload data, as well as providing DC power for remote sensors.

The channel characteristics of a SerDes link include time-domain and frequency-domain analysis. This requires examining the wiring system, Media Dependent Interface (MDI), as well as fixture and testing setup requirements.

Figure 4: Example of a Media Dependent Interface (MDI) connector with H-MTD and SMA

The actual MDI connectors are not standardized, but there are strict specifications that help ensure minimal unnecessary interaction between the MDI and cables. For example, Figure 4 provides an example of the H-MTD connector for multi-Gig automotive Ethernet, which can also be used for emerging SerDes standards.

In channel testing, we need to look for errors such as:

• Impedance mismatch

• Crosstalk between cables

Receiver Testing

The receiver is responsible for understanding the data sent through the link and then passing it to the ECU or display device for further processing. Bit errors in the receiver will lead to data loss or corruption from safety-critical sensors such as cameras, radars, and LiDARs.

The true functionality of receivers is becoming increasingly difficult, especially when sending through long channels exposed to multiple simultaneous noise sources. To describe the capability of a receiver, it is necessary to measure the error levels present when multiple noise sources are involved, including:

• Narrowband interference

• Large current injection

• Instantaneous transients

• Crosstalk from foreign cable bundles

Measurement devices may include noise sources, amplifiers, and coupling circuits that inject precise levels of noise into the active SerDes link. The signal quality registers of the Device Under Test (DUT) are then queried to verify whether the receiver can correctly interpret signals in the presence of noise. The focus of receiver testing is to stress the receiver to ensure it can still maintain a low bit error rate.

In-Vehicle Network Testing is Becoming Crucial

In-Vehicle Network Testing is Becoming Crucial

According to MarketsandMarkets, the global automotive camera market, along with integrated radar and camera markets, is expected to grow from $6.1 billion in 2021 to $10.1 billion by 2026.

As the need for more cameras and other sensors increases to ensure greater safety and drive autonomous driving, in-vehicle network testing has become an indispensable part, only ensuring interoperability and meeting performance standards for critical mission functions can better promote autonomous driving.

-

Is Neuromorphic Computing the Ultimate Solution for Autonomous Driving?

-

The Era of Smart Cockpits is Coming: What Other Concerns Will There Be?

-

Analysis of Smart Car Functions – Vehicle Blind Spot Monitoring System

-

Autonomous Driving Industry Weekly Report (10.18)

-

Focusing on the Cybersecurity of Intelligent Connected Vehicles: Pilot Zone Officially Launches Unmanned City Road Testing

-

Collaborating to Solve Problems: Exploring the Path to Vehicle-Route Coordination Applications

-

Data Analysis of the Advantages and Disadvantages of China’s LiDAR Industry

-

What Will the Future of Automotive Seats Look Like?

-

Recommendations for the Development of the Unmanned Delivery Industry

-

Which Country is Strongest in Autonomous Driving? A Review of the Autonomous Driving Maturity Index by Country and Region