The term “Internet of Things” (IoT), also known as a sensor network, refers to the connection of various information sensing devices, such as Radio Frequency Identification (RFID) devices, infrared sensors, Global Positioning Systems (GPS), laser scanners, and other devices to the internet, forming a network that enables intelligent identification and management.

According to data from the Qianzhan Industry Research Institute, in 2016, the scale of China’s IoT industry exceeded 900 billion RMB, with a year-on-year growth rate consistently exceeding 20%. As an emerging application in the communications industry, the market size of IoT will continue to expand under the trend of ubiquitous connectivity. With the improvement of industry standards, continuous technological advancements, and government policy support, China’s IoT industry will maintain a good development momentum, providing new impetus for sustained and stable economic growth. The wave of expanding mobile interconnectivity to ubiquitous connectivity will create a larger market space and industrial opportunities compared to the internet.

IoT utilizes technologies such as Radio Frequency Identification (RFID), GPS, cameras, sensors, and sensor networks to perceive, capture, and measure information, enabling the collection and acquisition of information about objects anytime and anywhere, thus achieving intelligent decision-making and control. Therefore, in the application of IoT in the industrial sector, IoT-related technologies and products are at the core of smart industry.

The industrial sector is a significant area for IoT applications. Various terminals with environmental sensing capabilities, pervasive computing models, and mobile communications are continuously integrated into all aspects of industrial production, significantly improving manufacturing efficiency, enhancing product quality, and reducing product costs and resource consumption, thus accelerating the transformation of traditional industries towards intelligence.

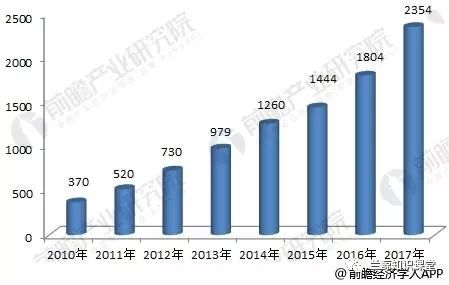

According to the “Market Demand and Investment Forecast Analysis Report for IoT Industry Applications” released by the Qianzhan Industry Research Institute, in 2014, the domestic demand scale of IoT in the industrial sector was 126 billion RMB; in 2016, it was 180.4 billion RMB. In 2017, the domestic demand scale of IoT in the industrial sector was approximately 235.4 billion RMB.

Domestic IoT Demand Scale in the Industrial Sector (2010-2017, unit: billion RMB)

Data source: Compiled by Qianzhan Industry Research Institute

Analysis of IoT Application Issues in the Industrial Sector

1. IT Security Issues

Unlike previous industrial revolutions brought about by new hardware and technologies, Industry 4.0 is the fourth industrial revolution driven by the internet. Consequently, 66% of respondents believe that IT security is a significant challenge. When a company’s IT system connects to the network, there may be unknown threats emerging at any time within the warehouse management system, machinery, or supply chain.

2. Manufacturing System Management Issues

Industry 4.0 not only brings production efficiency but also changes the mindset of traditional manufacturing. Once intelligent production is truly implemented, it will bring significant changes to manufacturing management systems, which will inevitably become more complex, including overall production logistics, human-machine collaboration, etc., making employee training even more important.

3. Communication Infrastructure Construction Issues

Communication networks are crucial for achieving Industry 4.0. However, to establish a network that all organizations can cooperate with, a consistent interface, communication standards, and specifications must be in place. Currently, many standards have yet to be established, such as industrial communication, engineering, IT security, digital factories, and equipment integration have not yet been incorporated into the overall reference framework.

Prospects and Development Trend Predictions for IoT Applications in the Industrial Sector

In recent years, the Chinese government has been vigorously promoting the deep penetration of IoT technology into traditional industries through the strategy of integrating industrialization and informatization. The “Special Action Plan for Deep Integration of Industrialization and Informatization (2013-2018)” released by the Ministry of Industry and Information Technology in September 2013 emphasizes that the pilot work for the integration of the internet and industry has entered a comprehensive implementation stage.

A new type of networked intelligent production mode characterized by IoT integration and innovation is shaping the core competitiveness of future manufacturing, promoting the formation of new industrial organizational methods, new relationships between enterprises and users, new service models, and new business formats, pushing traditional industrial sectors such as automobiles, aircraft, engineering equipment, and home appliances towards networking, intelligence, flexibility, and service orientation, and nurturing and promoting the development of a new global industrial revolution.

General Electric, a manufacturing giant in the United States, has fully utilized IoT technology and launched more than twenty industrial internet/IOT application products, covering various fields including oil and gas platform monitoring and management, railway locomotive efficiency analysis, enhancing the power output of wind turbines, optimizing power company distribution systems, and medical cloud imaging. AT&T has developed M2M solutions based on GE’s software platform Predix, and an increasing number of industrial machines will connect to the network via M2M.

For example, IoT applications in smart factories have a broad application prospect, with significant economic and social benefits. Smart factories that introduce IoT can achieve at least the following five functions: electronic work orders, transparency of the production process, controllability of the production process, precise capacity statistics, and electronic dashboards in the workshop. Through these five functions, not only can the information of the manufacturing process be visualized, but it will also have many implications for production management and decision-making. According to the contribution ratio of IoT to smart industry output value, by 2023, the domestic demand scale of IoT in the industrial sector is expected to be around 782.1 billion RMB.

Forecast of Domestic IoT Demand Scale in the Industrial Sector (2018-2023, unit: billion RMB)

Data source: Compiled by Qianzhan Industry Research Institute

The above materials have been authorized for use. For reprints, please contact this public account or the author; other materials are compiled from the internet. If there are any infringements, please contact me in the background, and I will delete them immediately.

Long press the QR code below to follow us