:Click↑“Wanyiyuan Selected” Subscribe to the most reliable power supply industry self-media

:Click↑“Wanyiyuan Selected” Subscribe to the most reliable power supply industry self-media

Wanyiyuan Selected—The leading self-media in the high-reliability power supply industry

Here you can find power supply technology insights, analysis of power supply industry trends, introduction of the latest power supply products, and many power supply experts sharing their technical experiences with you. Follow us and grow together with the Chinese power supply industry!

Power Supply Design for Ship Control System Based on Modular Power Supply

Introduction

A certain ship control system uses the VME bus embedded single board computer from SBS Company as the central control console’s main control computer, which requires a power supply that is stable in voltage, has high conversion efficiency, low ripple and noise, and good heat dissipation. Furthermore, it must have a compact structure to facilitate installation within a standard 6U high chassis alongside the embedded single board computer.

This power supply design can be achieved using two methods: designing everything from the basic power conversion unit to a fully functional prototype, or using a mature power conversion functional module as a base and adding auxiliary circuits (output voltage regulation, voltage detection and alarm, etc.) to optimize and integrate into a suitable, efficient, and reliable power module. Considering that well-known companies in the domestic and international power supply field have developed a variety of modular power supplies based on market demand, adopting the second method can more flexibly and quickly complete the design and development of the power supply system, shorten the development cycle, and save manpower and design costs. Additionally, using a modular power supply reduces external wiring, solder points, or connection points, significantly increasing product reliability.

Currently, the major brands of modular power supplies from well-known companies include Vicor from the USA, Cosel from Japan, and LAMBDA, among others. The Vicor series modules have significant advantages in power density, heat management, and configuration flexibility, making them widely used in harsh environments and high-reliability applications, being the preferred power supply for computers operating in harsh conditions. This article uses Vicor modules to design the power supply for a certain embedded single board computer based on project requirements.

1 Power Supply Design and Implementation

1.1 Basic Requirements and Technical Scheme

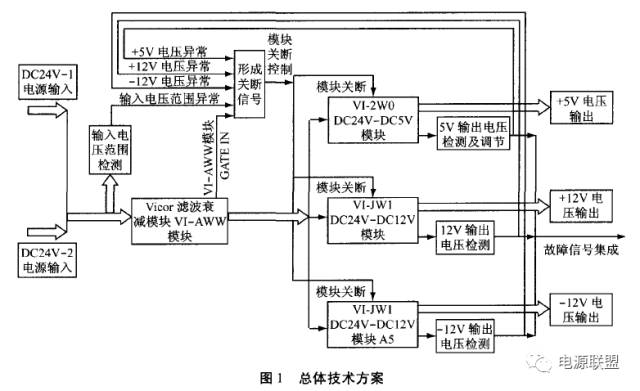

Based on the system’s power supply distribution planning, the designed power supply module can obtain two channels of DC24V input power. Therefore, the basic requirement of this power supply design is to convert the DC24V power supply into DC+5V and ±12V working power supplies that meet the requirements of the single board computer. According to the design requirements and Vicor series module specifications, the VI-IAM module (Input Attenuator Module) is selected to filter the input power supply, and then the VI-2W0 and VI-JW1 modules are used to further convert it into DC+5V and ±12V. The overall technical scheme is shown in Figure 1.

1.2 Dual Input Redundancy Design, Input Power Status Monitoring and Filtering

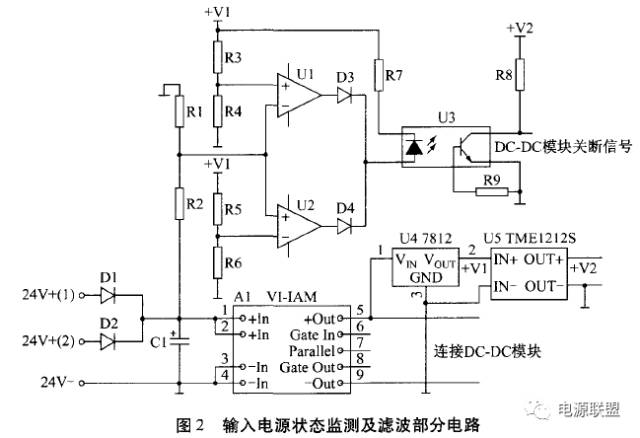

To improve system reliability, dual input redundancy power supply is used, and the dual power input and input voltage upper and lower limit monitoring and filtering circuit are shown in Figure 2. In the figure, two DC24V input power supplies are redundantly supplied through two diodes. To meet EMC technical requirements and reduce noise interference, the VI-IAM module A1 is used for filtering. The VI-IAM input attenuation module is a DC input front-end filter, which can ensure EMC technical performance when used with Vicor converter modules. To detect the input voltage range, a voltage upper and lower limit comparison circuit based on operational amplifiers is set up in the figure. When the input voltage exceeds the set upper or lower threshold, an abnormal input voltage signal is generated through an optocoupler to turn off the lower DC/DC module. The reference voltage for the input of the comparator is provided by the output of the 7812 voltage regulator, while the output of the DC/DC converter TME1212S serves as the working power supply for the optocoupler output circuit.

1.3 DC/DC Conversion Main Circuit and Regulation Circuit Design

The DC/DC conversion main circuit and regulation circuit are shown in Figure 3. The DC24V input voltage is filtered through the VI-IAM input attenuation module and then converted into +5V and ±12V DC voltage using the VI-2W0 and VI-JW1 modules. To ensure that the DC/DC converter output voltage can be adjusted within a certain deviation range, or to ensure stability at nominal values when the input voltage deviates or the load effect is significant, a voltage adjustment resistor network is connected at the output of the VI-2W0 and VI-JW1 modules according to the design and calculation methods recommended in the Vicor module application manual. Taking the adjustment of the +5V output voltage of the VI-2W0 module as an example, a potentiometer R4 with a resistance of 10 kΩ is used to adjust the output voltage, while resistors R2 and R3 limit the range of voltage adjustment. When R2 is selected as 23.63kΩ and R3 as 90KΩ, the output voltage can be adjusted within ±10%. The circuit in the dashed box in Figure 3 is used to smooth the fluctuations of the DC/DC converter input voltage. When there are significant instantaneous disturbances in the input voltage, two large-capacity electrolytic capacitors C13 and C14 will smooth the input voltage fluctuations through charging and discharging, ensuring the normal operation of the DC/DC converter.

1.4 DC/DC Conversion Module Shutdown Protection Function Circuit Design

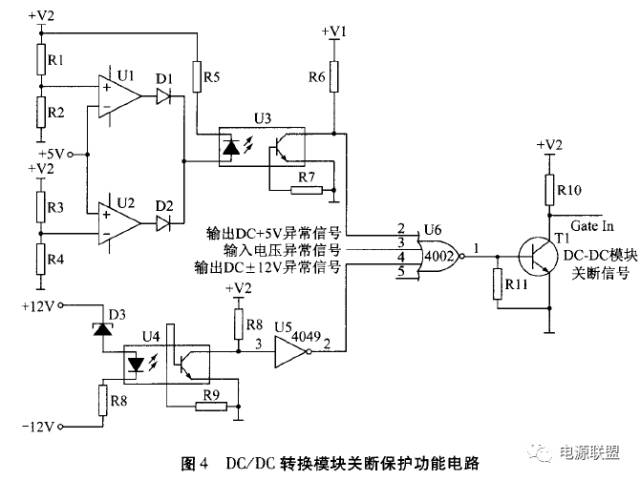

When the input voltage and output voltage of the DC/DC conversion module deviate significantly, to ensure the reliable operation of the embedded single board computer system and interface board, the power circuit should have a self-shutdown protection function: that is, automatically shut down the power supply module when there are input/output abnormalities to protect the load circuit. The DC/DC conversion module shutdown protection function circuit designed in this article is shown in Figure 4.

Since DC+5V is the most important power supply for the embedded single board computer, it should have higher power quality and better stability. The voltage upper and lower limit comparator circuit in Figure 4 detects the DC+5V output voltage. When the voltage deviates significantly from the normal value, an output voltage abnormal signal is generated through an optocoupler. The DC±12V is the power supply for the fans and other interface components in the computer, and the power quality requirement can be lower than that of DC+5V. To simplify the circuit design, a voltage regulator D3 and optocoupler U4 are used to form the DC±12V output voltage status detection circuit. When there are input/output voltage abnormalities, the shutdown signal generated by the relevant detection circuit is used as input to the NOR gate 4002 to output the overall shutdown signal. When transistor T1 is turned on, the level of the Gate In pin connected to it is pulled low, shutting down the DC/DC converter.

1.5 Other Issues

1.5.1 Heat Dissipation and Structural Design

Good heat dissipation design is crucial for improving the reliable operation of the power supply. Poor heat dissipation can easily lead to deterioration of power supply quality, and practical experience shows that power supply functional failures are often caused by thermal damage due to high temperatures. Although Vicor power modules are highly efficient (80%-90%), there is still a power loss of 10%-20%, which dissipates as heat. The power supply module designed in this article is installed in a standard 6U high chassis. Without effective heat dissipation measures, this heat will increase the temperature of the power supply itself and the internal plug-in boards of the chassis, making heat dissipation a critical issue. To address this, the power supply housing is designed with a metal shell that has good heat dissipation characteristics, and the heat dissipation surface of the Vicor power module is mounted on the metal housing. A fan is configured at the bottom of the chassis to ventilate and dissipate heat from the power supply and other circuit boards, ensuring excellent heat dissipation characteristics.

1.5.2 Electromagnetic Compatibility Design

Good electromagnetic compatibility design of the power supply is an effective way to ensure that computers and other electronic devices are electromagnetically compatible and immune to interference. The corresponding measures have already been taken in the circuit design discussed above, and are explained as follows:

1) The VI-IAM module is used together with the DC/DC converter to meet EMC technical performance requirements and reduce noise interference;

2) An X-type capacitor is connected at the input of the VI-IAM module (C1 in Figure 2), and Y-type bypass capacitors are connected between the input and output of the VI-2W0 and VI-JW1 modules and the ground plane (C2, C3, C5, C6 in Figure 3) to reduce differential-mode and common-mode interference, meeting electromagnetic compatibility requirements;

3) The power supply uses a closed metal shell to ensure good electromagnetic shielding.

1 Power Supply Design and Implementation

The power supply designed based on Vicor power modules, according to the above methods, is plugged into a standard VME bus chassis. The electrical characteristics are defined and the VME bus backplane is properly connected to supply power to the VME bus embedded single board computer and other interface devices. After laboratory trial runs and long-term continuous testing, it is shown that the power supply designed based on Vicor modules meets all performance requirements. The design and implementation methods proposed in this article have unique advantages in terms of operational reliability, power density, conversion efficiency, load characteristics, electromagnetic compatibility, and heat dissipation characteristics.

Wanyiyuan Selected—The leading self-media in the high-reliability power supply industry

Here you can find power supply technology insights, analysis of power supply industry trends, introduction of the latest power supply products, and many power supply experts sharing their technical experiences with you. Follow us and grow together with the Chinese power supply industry!

Click“Follow”to learn power supply knowledge with hundreds of thousands of engineers