“PLC Permission Management: Hierarchical Authorization Tricks to Eliminate Operational Losses!”

Hello everyone! Today, let’s discuss a topic that gives engineers a headache—PLC permission management! Have you ever encountered an intern accidentally pressing the emergency stop button, causing a production line to halt for 3 hours? Or a vendor adjusting parameters during debugging, leading to equipment “striking”? Don’t panic, this will teach you how to create a permission management system that even a fool can’t mess up!

▶ A Triple Hit of Hard Lessons

A worker on the night shift at an auto parts factory accidentally deleted a formula, causing the entire production line to stop for 8 hours, resulting in a direct loss of 230,000!

An outsourced engineer at a food factory privately adjusted temperature parameters, leading to 2,000 boxes of yogurt going bad and being discarded.

The worst was a “parting gift” left by a former engineer at a chemical plant, locking the PLC with a password and causing equipment to be down for 7 days.

Do these incidents feel like installing a “self-destruct button” on the equipment? Our PLC is the nerve center of the factory!

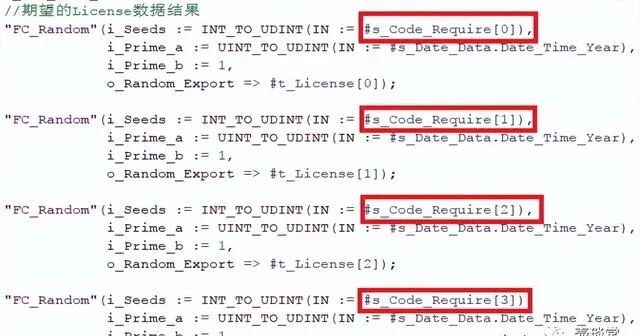

▶ Four Layers of Protection in the Permission Pyramid

① Operator Level:

Can only press the start/stop button, the parameter interface is directly locked.

The password refreshes automatically every hour, like sending a WeChat red envelope.

② Technician Level:

Formula modification permission = mobile verification code, must be confirmed within 30 seconds.

Historical operation records automatically generate a “chain of evidence”.

③ Engineer Level:

Program modifications require dual verification: facial recognition + dynamic token.

Each operation automatically generates a “time machine backup”, allowing for one-click rollback at any time.

④ Administrator Level:

Permission allocation is like dealing playing cards, each person can only take a specific suit.

Permissions of departing personnel are automatically severed, stricter than a bank account.

▶ Practical Pitfall Avoidance Guide (❗Must Read)

Common Mistake 1: Thinking that setting a password is enough.

Cracking Trick: Use a combination of “password + device fingerprint”, and make the PLC serial number part of the password factor.

Common Mistake 2: Overly complex permission settings lead to mistakes.

Ultimate Solution: Customize a “fool-proof operation package” for each position, displaying screens like a mobile app.

Common Mistake 3: Forgetting to set an “expiration date” for outsourced personnel.

Hard Lesson: A temporary worker’s permissions were not revoked for six months, leading to the implantation of malicious software.

▶ Cost-Benefit Analysis

Just do the math—this system can pay for itself in six months!

▶ Five-Step Implementation Strategy

Permission Mapping: Create a “capability boundary map” for each position.

Dynamic Passwords: Randomly refresh like a shared bike unlock code.

Operation Sandbox: Simulate key parameter adjustments before execution.

Departure Severance: Automatically trigger permission freeze upon personnel changes.

Emergency Key: Keep a set of physical encrypted dongles for emergencies.

▶ Three Soul-Searching Questions

How many levels of operational permissions does your factory currently have?

Was the last password update six months ago?

Can you immediately check all parameter modification records from last year?

If these three questions make you break out in a cold sweat, quickly type 1 in the comments! The top 3 liked friends will receive a private message with an electronic version of the “Industrial Control Permission Management Red Book”, which even includes Siemens/Mitsubishi’s ancestral secrets!

Remember: Good permission management is like putting a bulletproof vest on the PLC—it’s not felt in daily operations, but can save lives in critical moments!