To achieve the 1.5 °C temperature rise target, Direct Air Capture (DAC) is considered an indispensable negative emission technology. In recent years, hundreds of papers on new materials and processes for DAC have been published (Figure 1). Recent breakthroughs in adsorption-based DAC technology include:1) Identification of amine-functionalized porous materials as the primary DAC adsorbent, which has a strong affinity for CO2, high tolerance to moisture, and low energy requirements for regeneration;2) Development of reliable shaping methods such as granulation, hollow fibers, extrusion, 3D printing, and electrospinning, resulting in well-structured DAC adsorbents that reduce mass transfer resistance;3) With the advancement of in-situ characterization techniques and material simulation tools, the mechanisms of how extremely dilute CO2 conditions affect the adsorption process have become clearer;4) Significant improvements have been made in the thermal stability, hydrothermal stability, and chemical stability of DAC adsorbents in high-temperature, oxygen-containing, CO2-rich, or vapor environments;5) Adsorption-based DAC technology has been applied in fields such as Power-to-X, CO2 control in closed spaces, agricultural greenhouses, mineralization, and microalgae cultivation.

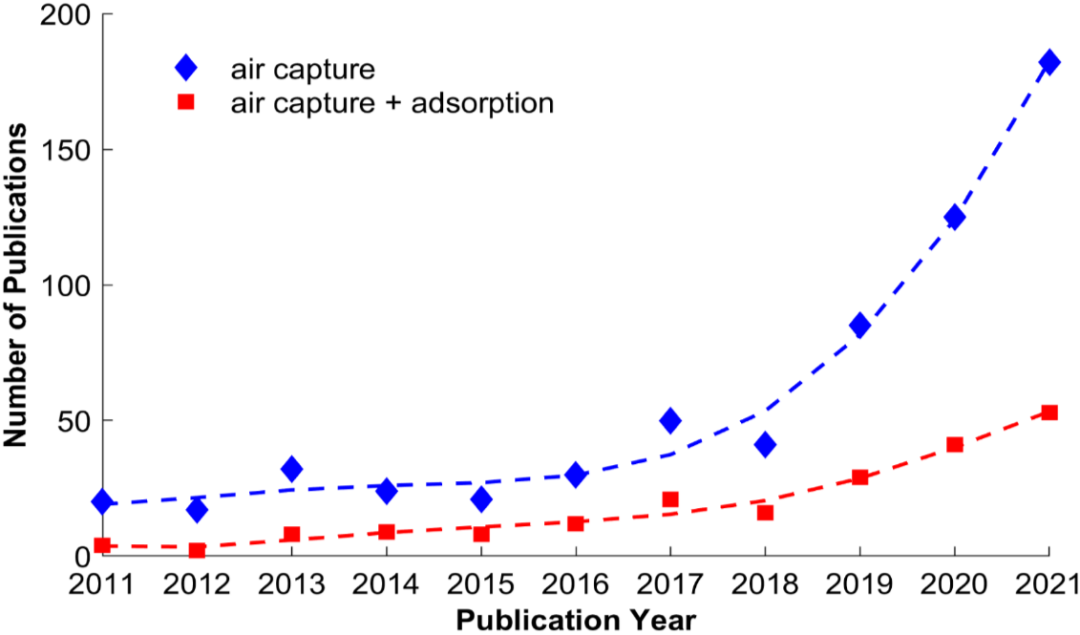

Figure 1. The number of papers with keywords (a) air capture and (b) air capture + adsorption in the Web of Science database from 2011 to 2021.

Overview of Achievements

Recently, Assistant Professor Zhu Xuancang from the School of Mechanical and Power Engineering at Shanghai Jiao Tong University, along with corresponding authors Professors Ge Tianshu and Wang Ruzhu, published a review titled Recent advances in direct air capture by adsorption in the journal Chemical Society Reviews. The article provides a detailed description of material development for adsorption-based DAC, adsorbent shaping, in-situ characterization, adsorption mechanism simulation, process design, system integration, and techno-economic analysis. This work can serve as a reference for researchers concerned with global energy and environmental issues and provide insights for further deployment of negative emission technologies.

This research work was supported by the National Natural Science Foundation of China Youth Project (52006135), Shanghai Agricultural Science and Technology Project (2022-02-08-00-12-F01176), Shanghai Science and Technology Innovation Action Plan Project (20160712800), and Shanghai Municipal Science and Technology Commission Project (21DZ1206200). This work also received guidance from Professor Dermot O’Hare from the Department of Chemistry at the University of Oxford and Associate Professor Li Jia from the Hong Kong University of Science and Technology (Guangzhou). Participating authors include Xie Wenwen from Karlsruhe Institute of Technology (currently at Bosch Group Central Research Institute), Wu Junye, Miao Yihe, Xiang Chengjie, Ge Bingyao, Gan Zhuozhen, Yang Fan, Zhang Man, and Chen Chunping from the University of Oxford.

Article Overview

This article reviews the research progress of DAC technology in material synthesis, adsorption mechanisms, system design, and applications. Adsorption-based DAC has experienced rapid development over the past decade, particularly with extensive exploration of amine-functionalized porous silica, zeolites, metal-organic frameworks (MOF), porous carbon, resins, and layered double hydroxides (LDH) as air capture materials. At the same time, a better understanding of the relationship between the structure, functionalization, and properties of the carrier is needed. To improve the technical feasibility of DAC, it is necessary to develop efficient gas-solid contactors that comprehensively consider adsorbent research and separation processes. Furthermore, there is currently a lack of techno-economic analysis for the large-scale application of adsorption-based DAC.

Key indicators for assessing the effectiveness of DAC adsorbents include:CO2 selectivity of the adsorbent in the presence of other gases, effective adsorption capacity of the adsorbent for CO2 during the adsorption-desorption cycle, adsorption and desorption kinetics, energy required for cycling or regeneration, chemical stability, mechanical strength of the adsorbent during long-term cycling, performance of the adsorbent across a wide range of temperatures and humidity, and economic feasibility based on life cycle assessment (LCA). A comprehensive analysis of the materials structure (such as particles, fibers, and monomers), possible cycling configurations (such as temperature, pressure, and concentration changes), and the structure of adsorption units (such as fixed beds, fluidized beds, and rotating beds) is required for the final assessment of the adsorbents. To meet current and future carbon capture demands, it is essential to collaboratively develop new materials, equipment, and systems.

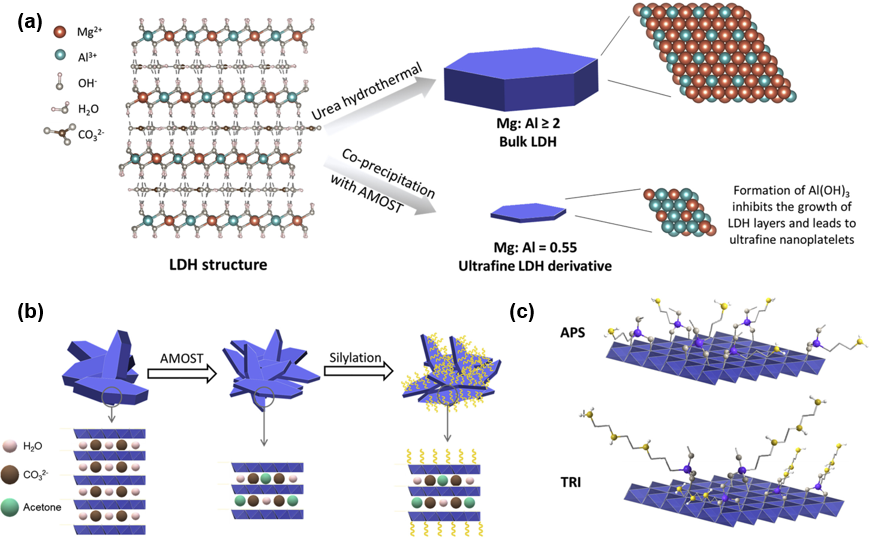

Recent work has highlighted the importance of understanding the synergistic enhancement between amines and carriers. Amine-impregnated ordered mesoporous silica remains the most promising DAC adsorbent, balancing capture performance and cost effectively. The concept of “mixed amines” has been successfully applied to amine solvent systems, which may be attractive for further improving the efficiency of amines in adsorbents. Although amine loading is considered a primary factor determining CO2 adsorption capacity, the structural characteristics and surface microstructure of the carrier also significantly affect overall CO2 capture efficiency. Amine-functionalized LDH and their derived composite oxides are a new class of DAC adsorbents that exhibit high adsorption capacity or ultra-fast kinetics under extremely dilute conditions (Figure 2). By forming slit-like mesopores through the delamination of nanosheets and generating additional porosity during calcination,LDH can create ideal diffusion pathways for CO2. Even in the absence of additives, amines can strongly adhere and disperse well on defect-rich LDH. Moreover, by altering the types and ratios of divalent and trivalent metal cations and interlayer anions, the morphology and chemical properties of LDH can be tuned, providing endless possibilities for the assembly of DAC adsorbents. More importantly, LDH can be produced and shaped on a large scale at a low cost, typically ranging from $2 to $8 per kilogram.

Figure 2. (a) Preparation process of ultrafine MgAl-LDH, (b) treatment with organic solvent washing and subsequent amine functionalization, (c) structure of amine grafted on a monolayer.

Typical polyamines are prone to oxidative degradation at high temperatures. For example, temperatures above 70 °C can lead to oxidative degradation of commercial DAC adsorbents (Lewatit VP OC 1065). Therefore, oxidative stability is an important topic worth extensive discussion. So far, DAC adsorbents loaded with TEPA have shown high CO2 adsorption amounts at different operating temperatures, but they are unstable at high temperatures. Enhancing the thermal and oxidative stability of loaded TEPA or other novel amine compounds through surface modification and additives is attractive. Balancing CO2 adsorption capacity, manufacturing costs, and antioxidant properties presents another challenge.

In addition to oxygen, the presence of water vapor in the air is also crucial for CO2 adsorption. The technical feasibility of synthesizing liquid fuels from air through co-adsorption/desorption of H2O and CO2 and subsequently solar-driven catalytic conversion relies on a deep understanding of the co-adsorption behavior of DAC adsorbents. The established co-adsorption mechanism model for Lewatit VP OC 1065 is a meaningful attempt. Further research needs to focus on high-throughput screening of the co-adsorption performance of novel amine-functionalized DAC adsorbents with H2O and CO2. The development of hydrophobic DAC adsorbents may also play a role in specific scenarios to avoid amine leaching, high regeneration energy, and structural degradation caused by H2O co-adsorption. While some ultramicroporous physical adsorbents have been shown to have lower water affinity, there is still limited research on the development of hydrophobic amine-containing DAC adsorbents.

In conventional experiments, due to the overlap of infrared spectra and loss of signals, there is still controversy regarding the chemical adsorption products of CO2 on amine polymer surfaces under extremely dilute conditions. By combining advanced in-situ spectroscopic techniques and theoretical computational methods, the CO2 adsorption mechanisms of DAC adsorbents can be understood at the molecular level. For instance, recent confirmations have established the presence of hydrated bicarbonate after the chemical adsorption of CO2. Further mechanistic studies on DAC adsorbents include the role of hydrogen bonding as a binder for CO2, the influence of surface amine density and type, inconsistencies between amine efficiency and theoretical values, adsorption enhancement upon exposure to H2O, and the detailed pathways of CO2 adsorption on amine groups.

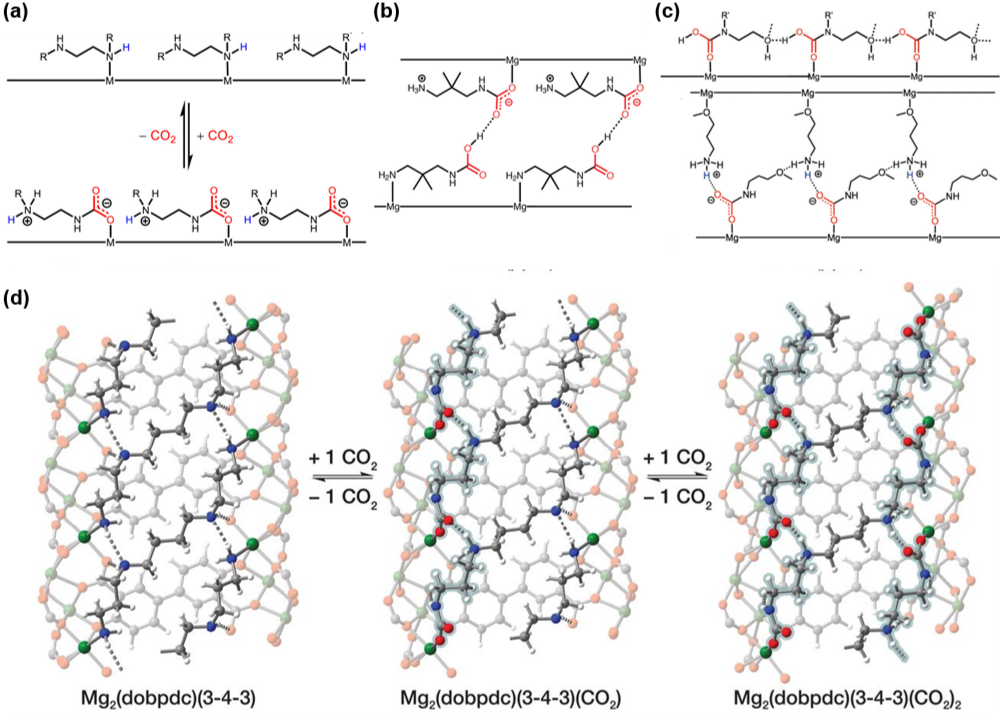

The article reviews several novel DAC adsorbents. Amine-grafted coordination unsaturatedMOF represents a series of DAC adsorbents with significant potential, although recent studies on these materials have mainly focused on higher CO2 concentrations (Figure 3). To apply them in DAC, detailed studies on adsorption/desorption kinetics under extremely dilute CO2 conditions are necessary. Although the binary amine grafted Mg2(dobpdc) material has maintained a record of 3 mmol/g CO2 adsorption at 0.4 mbar due to the synergistic insertion adsorption mechanism, many MOF-based materials are too expensive for large-scale synthesis. Inexpensive alternative carriers rich in coordination unsaturated metal sites are attractive for the large-scale synthesis of such adsorbents. LDH-derived materials with a high density of coordination unsaturated sites may be a potential choice. For example, ultrathin, ultrafine ZnAl-LDH rich in unsaturated zinc sites has been successfully employed for efficient photocatalytic CO2 reduction.

Figure 3. (a) General structure of alkyl ethylene diamine grafted M2(dobpdc) variants, (b) mixed chemical adsorption using ammonium carbamate and carbamate at a 1:1 ratio on dmpn−Mg2(dobpdc), (c) CO2 adsorption structural model of Mg2(dobpdc) functionalized with e-2-OH and 3-methoxypropyl amine, (d) predicted adsorption mechanism based on vdw corrected density functional calculations. Green, dark blue, red, gray, and white spheres represent Mg, N, O, C, and H, respectively.

The research and development of DAC should also pay particular attention to the design of gas-solid contactors that minimize pressure drops and enhance heat and mass transfer. Although wheel-based contactors meet the aforementioned requirements, they have not yet been used for DAC. Furthermore, extensive experiments are needed to verify the feasibility of scaling up structural adsorbents. Currently, research on the DAC performance of structural adsorbents is limited, necessitating a good understanding of adsorbent shaping optimization. Novel shaping techniques such as fiber spinning and 3D printing are powerful tools for early structural design, while coating and extrusion shaping are more likely to be applied in scaled manufacturing. Since 80% of the energy consumption in the DAC process comes from the regeneration stage, using renewable energy or industrial waste heat to generate steam for purge regeneration at negative pressure and lower regeneration temperatures can effectively reduce the operating costs of DAC.

Distributed DAC systems have the potential to produce significant social and environmental impacts. Fertilizing with DAC can promote plant growth, aiding in the production of food, feed, or other biochemical compounds, helping to address global hunger issues. Portable DAC systems for controlling air quality can benefit every household. For novel power systems that combine DAC with CO2 conversion, new power systems capable of outputting chemicals, power, and heat will become a new option in the transportation sector. A viable strategy is to combine DAC with dry reforming or electrochemical conversion to achieve carbon reduction and energy storage, with the stored chemical energy convertible to power and propulsion through combustion or fuel cells (Figure 4). To realize these technologies, there is an urgent need for commercialized equipment and comprehensive techno-economic analyses. The application of machine learning to the complex multivariable systems related to DAC is also worth exploring, promising to provide the most feasible or cost-effective technological pathways.

Figure 4. Potential raw material sources and downstream products for solar-driven dry reforming to produce syngas.

Integrating low-carbon or renewable energy with DAC systems is crucial to mitigating the impact of carbon dioxide on the global climate. Currently, proposals have been made for DAC systems powered by wind and photovoltaic energy, but research should continue on the thermodynamic matching between DAC and renewable energy and the establishment of demonstration systems. Other types of low-carbon energy, such as low-grade waste heat and geothermal energy, can also be considered, but careful evaluation of the carbon emissions caused by energy utilization is necessary.

DAC can be regarded as an independent air treatment system: it can remove CO2 from ambient air, similar to how widely adopted air conditioning/purification systems remove water vapor/pollutants. Since many adsorbents can effectively adsorb water vapor and pollutants, future research could focus on developing adsorption systems that can remove both CO2 and H2O. This can be achieved by developing suitable co-adsorption materials for CO2 and H2O, desorbing under similar conditions. If air conditioning systems can be used to drive carbon reduction, then DAC systems could potentially not consume additional auxiliary materials and energy. Current LCA results confirm that the adverse environmental impacts of DAC mainly stem from materials and energy, thus such coupled systems are worth investigating.

Team Overview

Zhu Xuancang, first author, Assistant Professor at the School of Mechanical and Power Engineering, Shanghai Jiao Tong University. Engaged in the synthesis of novel adsorbents, carbon capture and hydrogen production processes, and theoretical and applied research on negative emission technologies, having published more than 40 papers related to CO2 adsorption and separation in journals such as Progress in Energy and Combustion Science. He has received honors such as the Excellent Innovation Achievement of Bo Xin Personnel (2020), Shanghai Super Postdoctoral (2019), and Outstanding Doctoral Dissertation of Tsinghua University (2019).

Ge Tianshu, corresponding author, Professor at the School of Mechanical and Power Engineering, Shanghai Jiao Tong University. Specializes in refrigeration and cryogenic engineering, focusing on adsorption dehumidification and CO2 adsorption. Recipient of the NSFC Excellent Youth Science Fund, the Ministry of Education Youth Changjiang Scholars Award Program, the Global Energy Association “Global Energy Prize International Youth Program,” and the Willis Carrier Young Scholar Award from the International Institute of Refrigeration. He has also received national awards such as the Hundred Excellent Doctoral Nominations, Shanghai Outstanding Graduate Student Achievement Award, Shanghai Three-Eighth Red Banner Holder, Shanghai Qiming Star Program, and the Pujiang Program.

Wang Ruzhu, corresponding author, Chair Professor at the School of Mechanical and Power Engineering, Shanghai Jiao Tong University. An expert in refrigeration and heat pumps, focusing on adsorption technology and its applications. A globally highly cited scientist, leader of an innovative group for the National Natural Science Fund, and a national advanced worker and national-level teaching master. He has received numerous awards, including the National Natural Science Second Prize, National Technology Invention Second Prize, and National Teaching Achievement Second Prize, as well as international recognitions such as the Gustav Lorentzen Medal from the International Institute of Refrigeration, the J&E Hall International Gold Medal from the British Refrigeration Society, the Nukiyama Memorial Award from the Japan Society of Heat Transfer, the Asian Refrigeration Academic Award, the Peter Ritter von Rittinger International Heat Pump Award from the International Energy Agency, and the Georg Alefeld Memorial Award from the International Absorption and Adsorption Heat Pump Conference.

The ITEWA interdisciplinary innovation team at Shanghai Jiao Tong University (Innovative Team for Energy, Water & Air) was established by Professor Wang Ruzhu in 2018, dedicated to addressing cutting-edge fundamental scientific issues and key technologies in the fields of energy, water, and air. The aim is to achieve overall solutions at the material-device-system level through interdisciplinary collaboration, promoting breakthrough advancements in related fields. In recent years, nearly 30 papers have been published in high-level interdisciplinary journals such as Joule, Energy & Environmental Science, Advanced Material, Angewandte Chemie-International Edition, Matter, ACS Central Science, ACS Energy Letters, and Nature Communication.

Read the original article:

Zhu, X.; Xie, W.; Wu, J.; Miao, Y.; Xiang, C.; Chen, C.; Ge, B.; Gan, Z.; Yang, F.; Zhang, M.; O’Hare, D.; Li, J.; Ge, T.; Wang, R., Recent advances in direct air capture by adsorption. Chem. Soc. Rev. 2022.

DOI: 10.1039/d1cs00970b.