Embedded memory in automotive System-on-Chips (SoC) typically occupies a significant area on the chip. Therefore, defects in these memories can severely impact the yield of any autonomous driving device. Along with statistical process control during the ramp-up phase and mass production, collecting diagnostic information, in addition to pure test data, is a good practice in the automotive industry. Designers and technical experts must derive accurate diagnostic results from faulty devices to formulate correct maintenance strategies by identifying and correcting related issues at the source and responding to erroneous behaviors. A common approach is to generate a fault map based on the collection of all faulty bit coordinates and send it to testers one by one. More effectively, the faults encountered can be retrieved.

This paper presents a method for compressing diagnostic information during the testing of SoC embedded memory. More specifically, this method is applied to diagnose embedded FLASH memory. This strategy allows for the reconstruction of fault maps without any loss, while the compression method yields an approximate value. The proposed method utilizes only a small portion of the memory required by coordinate-based bit mapping methods and is comparable to compression methods. At the cost of moderate test time overhead, the proposed strategy allows for a significant increase in the number of devices that can be fully diagnosed without any loss in fault map reconstruction. In a real embedded FLASH production scenario, most faulty devices are diagnosed after a single transfer from the chip to the test host.

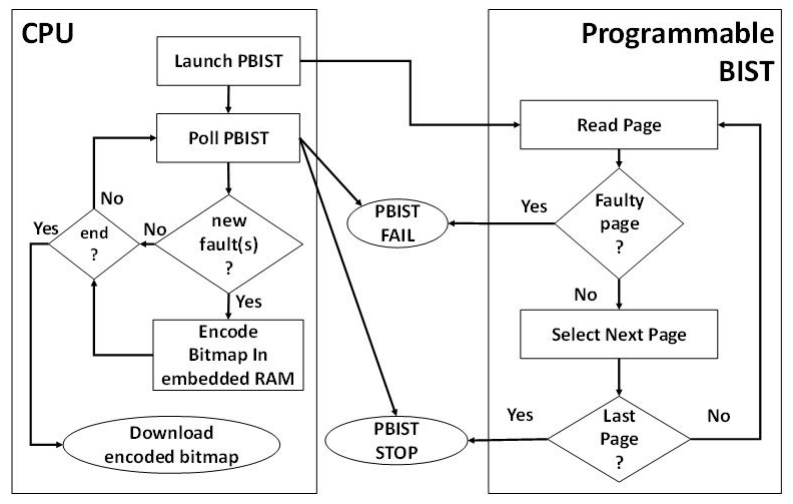

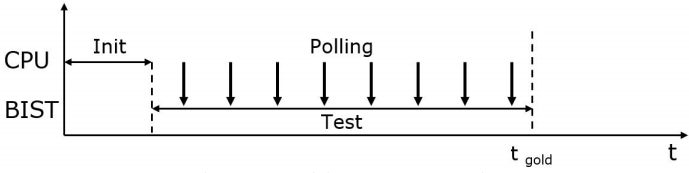

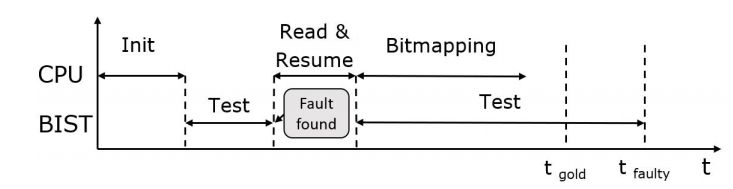

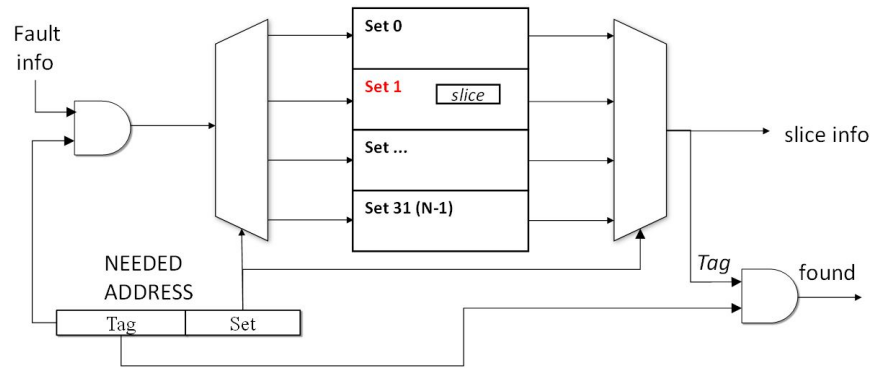

This paper is organized as follows: Section II briefly explains the BIST architecture used for eFLASH testing and analyzes the eFLASH testing process to understand the main sources of diagnostic information. Section III elaborates on the process from failure coordinates to creating the basic information structure. Section IV presents experimental results from over 1800 real case bitmaps collected during the production phase. Section V summarizes the findings.

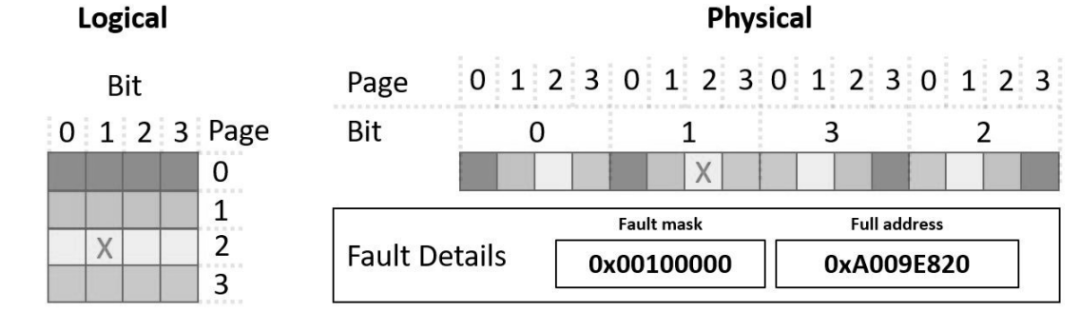

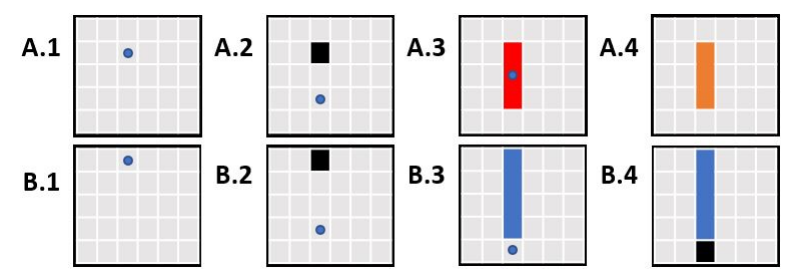

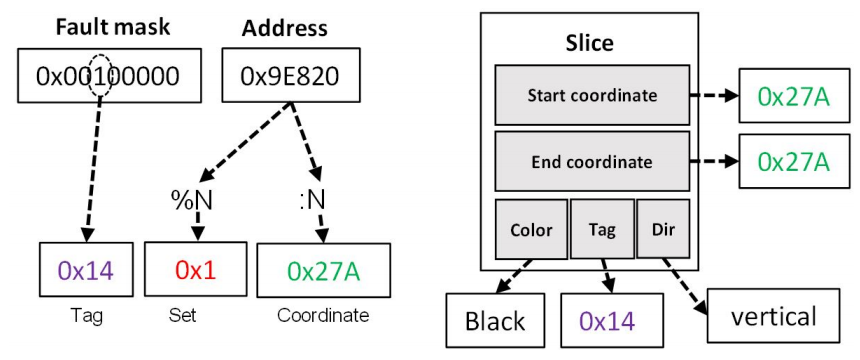

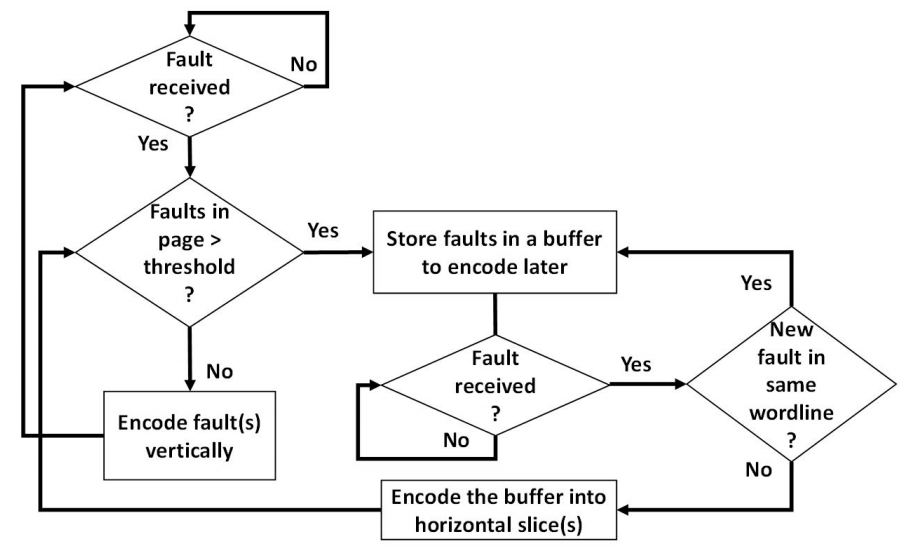

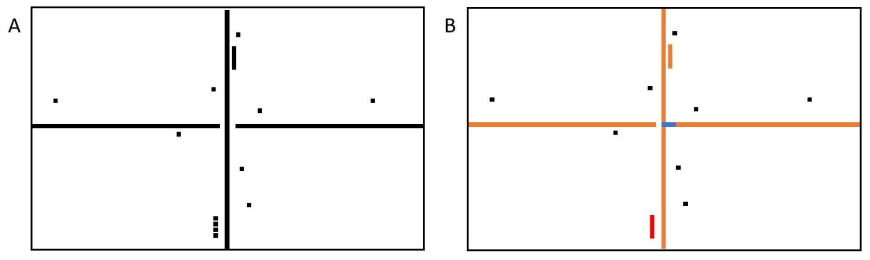

Figure 9. Flowchart for determining vertical/horizontal encoding

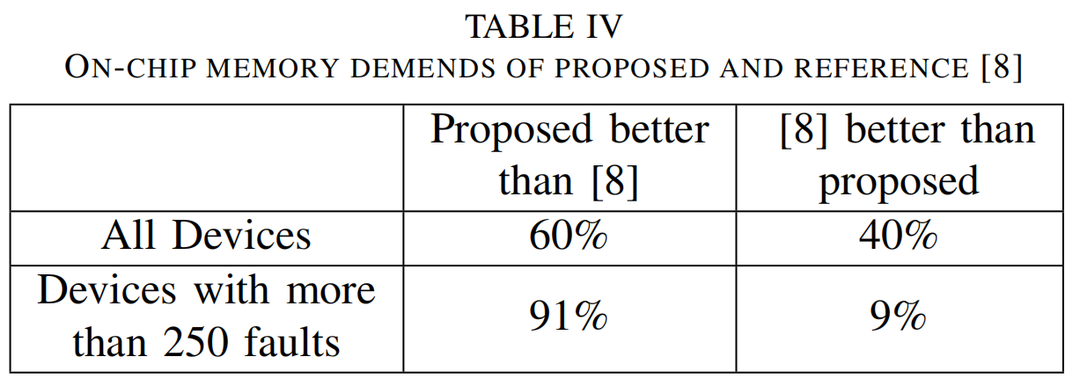

IV.Experimental Results

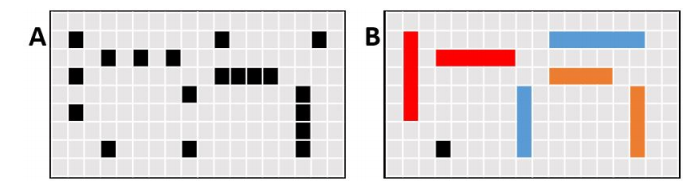

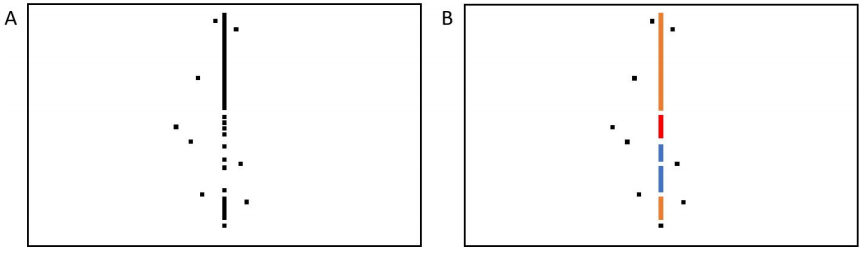

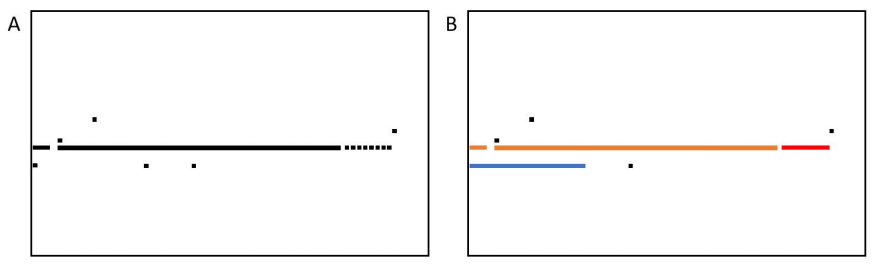

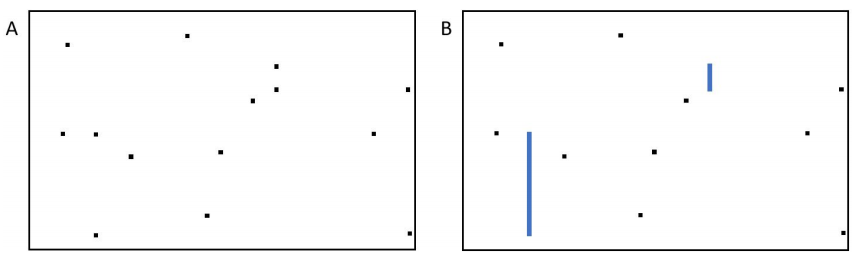

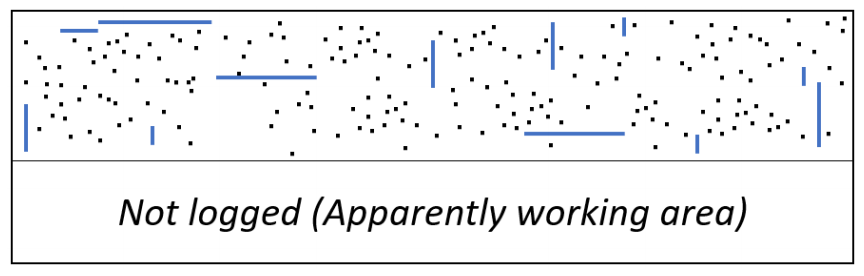

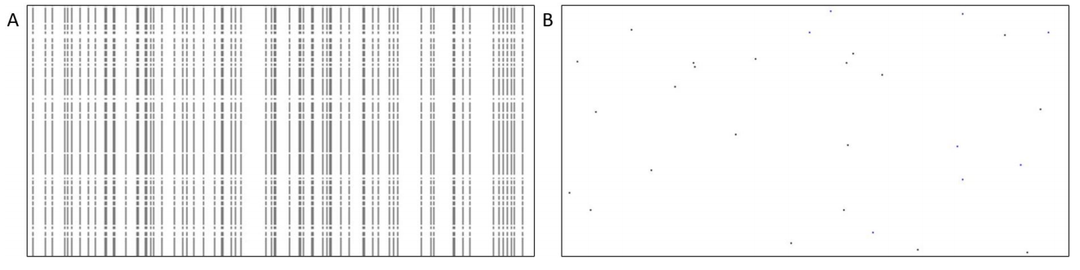

Figure 15. Comparison between the bitmap reconstructed using the method shown in [5] (A) and the bitmap compressed using the proposed method (B)

V. Conclusion

References:

[1] A. van de Goor, G. Gaydadjiev, and S. Hamdioui, “Memory testing with a RISC microcontroller” in Proc. on Design, Automation and Test in Europe, Dresden, 2010.

[2] “IEC 61508-[1-16],” Functional safety of electrical/electronic/programmable electronic safety-related systems, 2010.

[3] P. Bernardi et al. “Cumulative embedded memory failure bitmap display

& analysis” in IEEE Symposium on Design and Diagnostics of Electronic Circuits and Systems, 2010.

[4] S. Abhas, M. K. Gurram, and A. Abhijit, “Controller Architecture for

Memory BIST Algorithms” in IEEE International Students’ Conference on Electrical, Electronics and Computer Science (SCEECS), 2020.

[5] J. Chen, J. Khare, K. Walker, S. Shaik, J. Rajsky, and W. Maly, “Test response compression and bitmap encoding for embedded memories in manufacturing process monitoring” in Proceedings International Test Conference 2001.

[6] P. Bernardi et al. “An efficient algorithm for the extraction of compressed diagnostic information from embedded memory cores” in 2003 IEEE Conference on Emerging Technologies and Factory Automation.

[7] I. Schanstra et al. “Semiconductor Manufacturing Process Monitoring using Built-In Self-Test for Embedded Memories” in Proceedings International Test Conference 1998.

[8] A. L. Landzberg and R. Van Nostrand, Microelectronics Manufacturing Diagnostics Handbook, New York, USA, 1993.

[9] H. WonGi, C. JungDai, and C. Hoon, “A programmable memory BIST for embedded memory” in International SoC Design Conference, 2008.

[10] C.-H. Tsai and C.-W. Wu, “Processor-programmable memory BIST for bus-connected embedded memories” in Proc. of the Design Automation Conference, 2001.

[11] P. Bernardi et al., “A Machine Learning-based Approach to Optimize Repair and Increase Yield of Embedded Flash Memories in Automotive Systems-on-Chip” in European Test Symposium, 2019.

Sharing is hard, please give a 【👍】 and 【look at】