Abstract: Objective: To optimize the wet spinning process of Bletilla striata polysaccharide (BSP)/polyvinyl alcohol (PVA) using the Box-Behnken response surface method, to prepare composite fibers, and to evaluate their structural and performance characteristics.Method: The overall evaluation value of three mechanical properties, including fiber tensile strength, breaking strength, and elongation at break, was used as the evaluation index. Five factors, including the mass fraction of BSP, mass fraction of PVA, BSP/PVA volume mixing ratio, coagulation time, and spinning speed, were investigated through single-factor experiments. Based on the results of single-factor experiments, response surface design was applied to optimize the spinning process of BSP/PVA composite fibers, focusing on the mass fraction of BSP, BSP/PVA volume mixing ratio, and coagulation time. The morphology, structure, thermal properties, and moisture absorption of the fibers were characterized and analyzed using scanning electron microscopy, infrared spectroscopy, differential scanning calorimetry, and moisture absorption tests. Berberine hydrochloride (BH) was used as a model drug to evaluate the drug loading capacity and antibacterial activity of the composite fibers.Results: The optimal spinning process was determined to be a BSP mass fraction of 7.5%, a BSP/PVA volume mixing ratio of 1:1, and a coagulation time of 3 minutes. The composite fibers exhibited a dense surface and a three-dimensional network structure internally, resulting in enhanced thermal/mechanical properties and excellent moisture absorption. The drug encapsulation rate of the composite fibers reached 70.2%, and the drug-loaded fibers formed significant inhibition zones in antibacterial tests against Escherichia coli and Staphylococcus aureus.Conclusion: The optimized spinning process is feasible and cost-effective, and the prepared BSP/PVA composite fibers possess good physical properties and a certain drug loading capacity, making them worthy of further research in the field of biomedical textiles.

Bletilla striata polysaccharide (BSP) is a neutral polysaccharide extracted from the tubers of the orchid plant Bletilla striata (Thunb.) Reichb. f., composed of mannose and glucose in a ratio of 2.4:1, and exhibits biological activities such as anti-inflammatory, promoting coagulation, enhancing macrophage immune capacity, and antioxidant properties.[1-2] BSP is a key hemostatic agent in traditional Chinese medicine, first recorded in the “Shennong Bencao Jing” and included in various editions of the “Chinese Pharmacopoeia,” known for its astringent hemostatic, swelling, and tissue regeneration effects, used for symptoms such as hematemesis, hemoptysis, abscesses, and traumatic bleeding.[3-4]

BSP, as the main hemostatic component of Bletilla, possesses good biocompatibility, adhesion, self-degradability, and non-toxic side effects. In recent years, there have been numerous reports on the research of BSP in drug delivery systems and new biomaterials, such as its development into liposomes, micelles, nanoparticles, microspheres, microneedles, hydrogels, and films; and its preparation into hemostatic sponges, wound dressings, and tissue scaffolds, demonstrating a wide range of application prospects in drug formulation and wound dressing fields.

BSP can be prepared into fibers through wet spinning, but its application has been limited due to poor mechanical properties, thus there are fewer studies reported. Polyvinyl alcohol (PVA) is a hydrophilic polymer containing multiple hydroxyl groups, known for its biodegradability and biocompatibility, making it an excellent biomedical polymer material. PVA can be used to improve the mechanical properties of BSP fiber products, expanding the application range of BSP.

This experiment aims to optimize the wet spinning process of BSP/PVA based on single-factor investigations and response surface design, and to study the morphology, structure, and properties of the composite fibers. At the same time, the composite fibers will be used as drug carriers, with berberine hydrochloride (BH) as the model drug to prepare drug-loaded fibers and evaluate their antibacterial activity. It is expected that based on the theory of “drug-excipient integration” in traditional Chinese medicine formulation design, a new environmentally friendly and stable spinning preparation process will be developed to produce a novel BSP-based composite fiber.

1 Instruments and Materials

MP-01 wet small spinning machine, single-channel, injection flow rate 1-50 mL, speed 0.01-12.50 mm/min, thrust > 50 N, Functional Fiber Research Laboratory, College of Light Textile and Food, Sichuan University; YM061 electronic single yarn strength tester, Laizhou Yuanmao Instrument Co., Ltd.; JSM-7500F field emission scanning electron microscope (SEM), JEOL Ltd., Japan; ESJ200-4 type analytical balance, Shenyang Longteng Electronics Co., Ltd.; UV 2400 ultraviolet spectrophotometer, Beijing Purification General Instrument Co., Ltd.

BSP, self-prepared in the laboratory, preparation methods refer to literature reports; BH, batch number B139120, mass fraction ≥ 98%, Aladdin Reagent Company; PVA1799 type, beef extract, peptone, sodium chloride, and agar are all analytical grade, Chengdu Hengli Reagent Company.

2 Methods and Results

2.1 Preparation of Spinning Solution and Composite Fibers

2.1.1 Preparation of Spinning Solution: Dissolve BSP powder in hot water, stir at 70°C with a magnetic stirrer for 1 hour until completely dissolved, to obtain a series of BSP spinning solutions with different mass fractions; dissolve PVA in hot water, stir at 95°C with a magnetic stirrer for 2 hours until completely dissolved, to obtain a series of PVA spinning solutions. Blend BSP and PVA solutions in a specific volume ratio to prepare composite spinning solutions, and allow to stand and degas before use.

2.1.2 Wet Spinning Process: Using wet spinning equipment, under constant thrust, the degassed spinning solution is injected into a spinning needle with an inner diameter of 0.55 mm, followed by drawing into an ethanol coagulation bath, and then processed through a guide roller, drying roller, and winding roller to obtain the fibers.

2.1.3 Fiber Preparation: According to the above wet spinning process, take a BSP spinning solution with a mass fraction of 7.5% to prepare BSP fibers (BF); blend BSP spinning solution with PVA spinning solution in a specified ratio to prepare composite fibers (BP); add BH powder to the composite spinning solution to prepare drug-loaded fibers (B-BP) with a mass fraction of 1%.

2.2 Single-Factor Experiments

Initial conditions: BSP mass fraction 5%, PVA mass fraction 15%, BSP/PVA volume mixing ratio 3:1, spinning speed 1.5 mm/min, coagulation time 2 min.

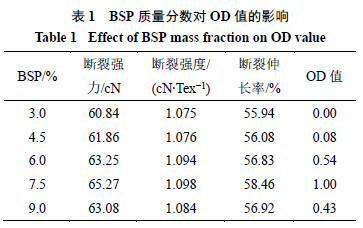

2.2.1 Effect of BSP Mass Fraction on Overall Evaluation Value (OD): During the wet spinning process, keeping the other conditions constant, prepare composite spinning solutions with BSP mass fractions of 3.0%, 4.5%, 6.0%, 7.5%, and 9.0%, to investigate the influence of different BSP mass fractions on the OD values of the tensile strength, breaking strength, and elongation at break data of the composite fibers. The method for testing the mechanical properties mentioned above can be found in section “2.4.3”. The OD value is calculated using Hassan’s method to standardize the content of each indicator component, expressed as a normalized value (d) from 0 to 1, where di = (Yi – Ymin)/(Ymax – Ymin). Here, Yi is the measured value, Ymin and Ymax refer to the minimum and maximum values measured for each indicator across different trials. Based on the formula OD = (d1d2d3…dk)1/k (where k is the number of indicators), the OD value was obtained.

From Table 1, it can be seen that the OD value increases with the increase in BSP mass fraction, and after reaching a BSP mass fraction of 7.5%, the OD value begins to decrease. Therefore, in the Box-Behnken experimental optimization design, the selected range for BSP mass fraction is 6.0% to 9.0%.

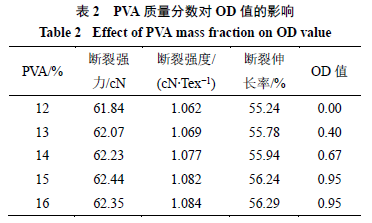

2.2.2 Effect of PVA Mass Fraction on OD Value: In the wet spinning process, keeping the other conditions constant, prepare composite spinning solutions with PVA mass fractions of 12%, 13%, 14%, 15%, and 16%, to investigate the influence of different PVA mass fractions on the OD values of the tensile strength, breaking strength, and elongation at break data of the composite fibers. From Table 2, it can be seen that the OD value increases with the increase in PVA mass fraction, reaching the maximum at PVA mass fractions of 15% and 16%. Considering the minimal difference in impact on OD values between PVA mass fractions of 15% and 16%, the PVA mass fraction was determined to be 15%.

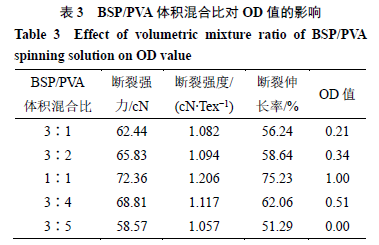

2.2.3 Effect of BSP/PVA Volume Mixing Ratio on OD Value: Keeping the other conditions constant, blend BSP spinning solution and PVA spinning solution at volume ratios of 3:1, 3:2, 1:1, 3:4, and 3:5, degas and then conduct wet spinning to investigate the influence of BSP/PVA volume mixing ratio on the OD values of the tensile strength, breaking strength, and elongation at break data of the composite fibers. From Table 3, it can be seen that the OD value increases with the increase of PVA proportion in the BSP/PVA spinning solution, reaching the maximum at a BSP/PVA volume mixing ratio of 1:1, then decreasing. Therefore, the levels selected for the volume mixing ratio in subsequent Box-Behnken experiments are 3:2, 1:1, and 3:4.

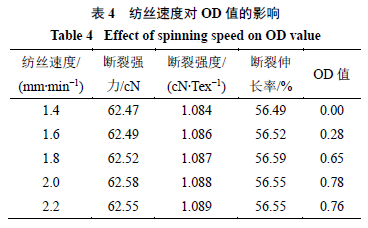

2.2.4 Effect of Spinning Speed on OD Value: In the wet spinning process, keeping the spinning solution constant and other conditions fixed, investigate the influence of different spinning speeds of 1.4, 1.6, 1.8, 2.0, and 2.2 mm/min on the OD values of the tensile strength, breaking strength, and elongation at break data of the composite fibers. From Table 4, it can be seen that the OD value increases with the increase in spinning speed, reaching the maximum at 2.0 mm/min. The subsequent changes have little effect on the OD value, thus the spinning speed was determined to be 2.0 mm/min.

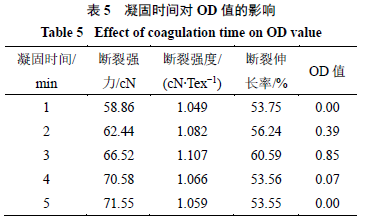

2.2.5 Effect of Coagulation Time on OD Value: In the wet spinning process, keeping the spinning solution constant and other conditions fixed, adjust the coagulation time in the coagulation bath to investigate the influence of different coagulation times of 1, 2, 3, 4, and 5 minutes on the OD values of the tensile strength, breaking strength, and elongation at break data of the composite fibers. From Table 5, it can be seen that the OD value increases with the increase in coagulation time, and after 3 minutes of coagulation, the OD value begins to decrease. Therefore, in the further Box-Behnken experimental optimization design, the selected levels for coagulation time are 2, 3, and 4 minutes.

2.3 Box-Behnken Response Surface Method Optimization Experimental Design

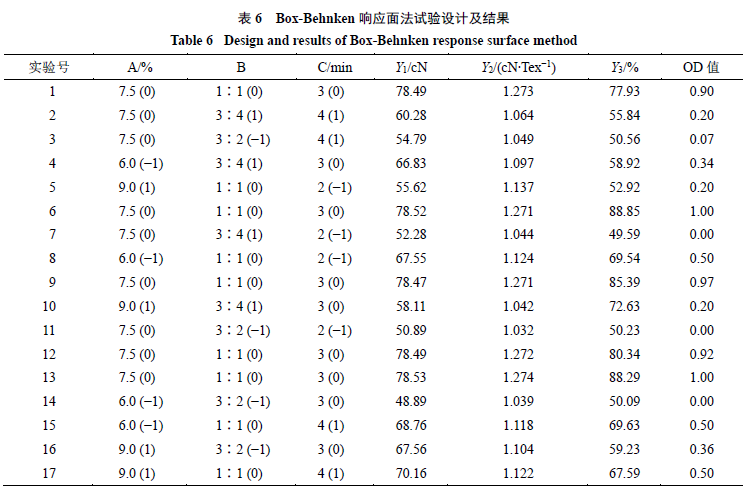

2.3.1 Experimental Design and Results: Based on the single-factor experiments, select BSP mass fraction (A), BSP/PVA volume mixing ratio (B), and coagulation time (C) as the factors to investigate, using the OD values of fiber tensile strength (Y1), breaking strength (Y2), and elongation at break (Y3) as evaluation indicators for Box-Behnken experimental design.[15] The levels of each factor are shown in Table 6. The Box-Behnken experimental design scheme and OD value data are shown in Table 6.

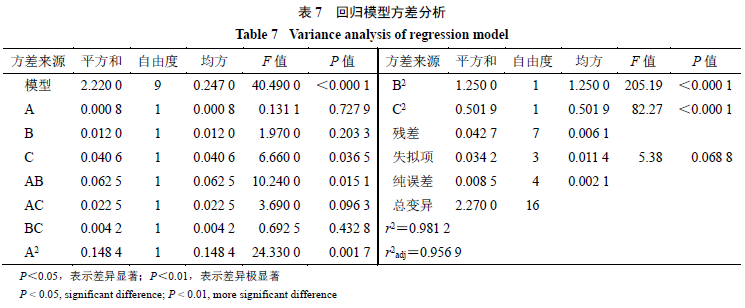

2.3.2 Model Fitting and Significance Analysis: Using Design Expert 10.0 software, the OD value data from Table 6 for each group of indicator components were subjected to multiple regression fitting and two-term analysis to establish a second-order regression model equation for the preparation process OD value of composite fibers based on BSP mass fraction (A), BSP/PVA volume mixing ratio (B), and coagulation time (C): OD = 0.9580 – 0.01A + 0.0388B + 0.0713C – 0.125AB + 0.075AC + 0.0325BC – 0.1878A2 – 0.5453B2 – 0.3453C2.

The variance analysis results of the regression model are shown in Table 7. From Table 7, it can be seen that the P value of the fitted model is less than 0.01, indicating that the model is highly significant. The P value of the lack of fit is greater than 0.05, indicating that the model fits well, and the residuals of the model may be due to random errors. The adjusted coefficient of determination r2adj = 0.9569 indicates that 95.69% of the variation in the OD value of composite fiber mechanical properties is attributed to the variations among BSP mass fraction (A), BSP/PVA volume mixing ratio (B), and coagulation time (C). This model allows for the analysis and prediction of the wet spinning process of composite fibers. Through variance analysis, among the first-order terms, the order of influence of the three factors on the mechanical properties of the composite fibers’ OD value is C > B > A, i.e., coagulation time > BSP/PVA volume mixing ratio > BSP mass fraction; in the second-order terms, A2, B2, and C2 are significant, indicating that the influences of BSP mass fraction, BSP/PVA volume mixing ratio, and coagulation time on the response value are nonlinear; among the interaction terms, AB is significant, while AC and BC are not significant, indicating a very significant interaction between BSP mass fraction and BSP/PVA volume mixing ratio.

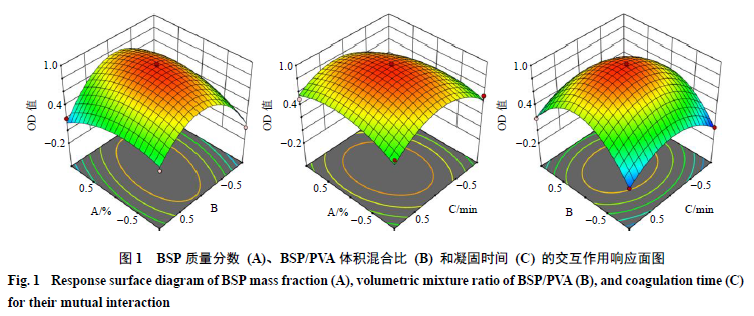

2.3.3 Optimal Spinning Process Prediction and Experimental Verification Comparison: Using Design Expert 10.0 software to analyze the interactions of the three factors, BSP mass fraction (A), BSP/PVA volume mixing ratio (B), and coagulation time (C) on the OD value as shown in Figure 1.

Based on the analysis results from the software, calculating and predicting the second-order regression equation, the optimal preparation process for composite fibers was determined to be a BSP mass fraction of 7.47%, a BSP/PVA volume mixing ratio of 1:1.04, and a coagulation time of 3.10 minutes. At this point, the predicted tensile strength of the composite fibers is 78.82 cN, breaking strength 1.271 cN/Tex, and elongation at break 84.38%.

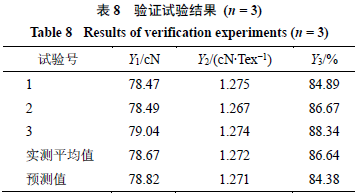

For practical operation, the optimal process parameters were revised to a BSP mass fraction of 7.5%, a BSP/PVA volume mixing ratio of 1:1, and a coagulation time of 3 minutes. Under these optimal conditions, three parallel preparations of composite fibers were conducted for process verification. The results are shown in Table 8.

The results show that under the optimized process conditions, the average values of the composite fibers’ Y1 is 78.67 cN, Y2 is 1.272 cN/Tex, and Y3 is 86.64%, with deviation rates from the predicted values of 0.19%, 0.08%, and 2.70%, respectively. The measured data is consistent with the predicted values, indicating that the fitted mathematical regression model of this experiment is reliable.

2.4 Characterization and Analysis of Fiber Properties

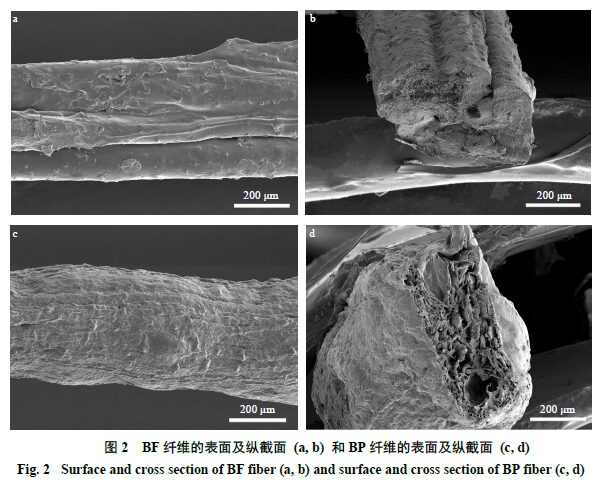

2.4.1 Analysis of Fiber Morphology and Structure: SEM was used to observe the surface and cross-sectional micro-morphology of BF and BP fibers. The samples were first subjected to liquid nitrogen fracture and gold spraying for 30 seconds, and the results are shown in Figure 2. SEM observations revealed multiple grooves on the surface of BF fibers.[12] The grooves were caused by the random and uneven phase transformation occurring during the “double diffusion” movement of the solvent water and non-solvent ethanol. With the addition of PVA, the surface of BP fibers tends to become denser compared to BF fibers, and the cross-section shows that a three-dimensional network pore structure is formed internally.

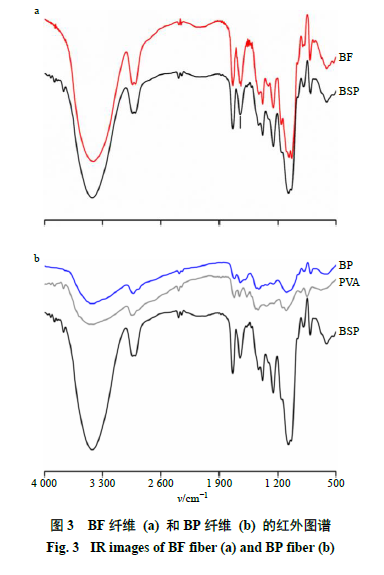

2.4.2 FTIR Analysis of Fibers: FTIR spectrometer was used for the infrared characterization of the fibers. Testing conditions: 2 mg of dried sample, KBr pellet, FTIR spectral scanning in the range of 500-4000 cm−1, recording the infrared spectrum, as shown in Figure 3. In the infrared spectra of BSP and BF fiber samples, a strong broad peak at 3430.74 cm−1 corresponds to the stretching vibration of -OH, which is the most obvious hydroxyl absorption peak of polysaccharides; at 2937.93 cm−1 and 1743.47 cm−1, stretching vibrations of C-H and weak absorption peaks of uronic acids were observed, respectively; while the absorption peak at 1648.84 cm−1 confirms the presence of asymmetric stretching vibrations of C=O; the peak at 1078.86 cm−1 indicates the presence of furanoside; simultaneously, signals at 883.77 cm−1 and 811.06 cm−1 represent mannose residues.[11] No new absorption peaks were observed in the BF fiber samples, indicating that there is no change in the chemical structure of BSP and BF fibers during the spinning process. In the infrared spectrum of BP fibers, the characteristic absorption peak of β-1,4 glycosidic bonds in BSP was observed at 883.77 cm−1[1], confirming the presence of BSP in the composite fibers, and the -OH stretching vibration peak broadened, with a peak shift to a higher wavenumber, indicating that intermolecular hydrogen bonding may have occurred due to the blending of BSP and PVA, making the fiber structure more stable.

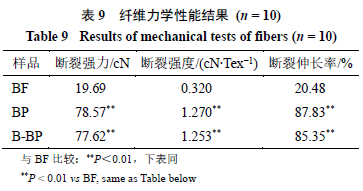

2.4.3 Mechanical Performance Testing: Using an electronic balance, 100 cm long fibers were accurately weighed to calculate the fiber linear density. Then, the mechanical performance of the fibers was measured using an electronic single yarn strength tester, with a stretching speed of 0 mm/min and a gauge length of 5 cm, recording the values of tensile strength, breaking strength, and elongation at break, with each sample tested in 10 groups to obtain the average values. The test results of the breaking strength, breaking strength, and elongation at break of BF, BP, and B-BP fibers are shown in Table 9. The results indicate that the tensile properties of the fibers were enhanced due to the addition of PVA, resulting in significant improvement in mechanical performance. Since BH is in a dispersed state within the fiber, it affects the binding force between the fiber macromolecular chains, leading to a slight decrease in the mechanical performance of B-BP fibers compared to BP fibers.

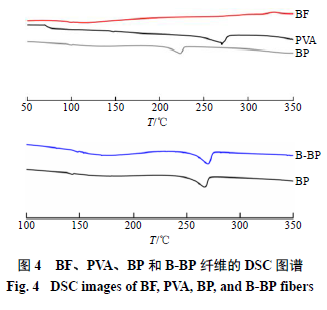

2.4.4 Differential Scanning Calorimetry Testing: Set the N2 flow rate to 50 mL/min. The temperature control program was set to a range of 25-350 °C, with a heating rate of 20 °C/min. The DSC test spectra of BF, PVA, BP, and B-BP fibers are shown in Figure 4. The results show that during the heating process, BSP exhibits one endothermic peak around 330 °C; BP fibers have only one glass transition temperature (Tg), indicating good compatibility due to intermolecular interactions between BSP and PVA.[16] The crystallization temperature of B-BP fibers increases because BH, as a small molecule, has strong crystallinity and is uniformly dispersed in the fibers, acting as a “nucleating agent,” accelerating the crystallization rate, increasing crystallinity, and promoting the orderly arrangement and stacking of fiber molecular chains, thus reflecting an increase in melting temperature (Tm)[17-18], enhancing the thermal properties of the fibers.

2.4.5 Moisture Absorption Testing: Weigh the fiber of a fixed length and record its mass as m1; place the fiber in deionized water for a certain period, then take it out, absorb the surface moisture with filter paper, and weigh it again, recording its mass as m2; the fiber moisture absorption rate = (m2 – m1)/m1.

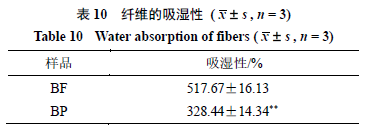

The fibers prepared by the wet spinning process have numerous micropores, and many hydrophilic groups, such as hydroxyl (-OH), exist in the fibers, which can form hydrogen bonds with water molecules, retaining them within the fibers. These characteristics are highly favorable for the diffusion and absorption of water molecules, and the more free hydrophilic groups present in the fibers, the stronger the moisture absorption capacity.[19] As shown in Table 10, the moisture absorption rate of BF fibers reached over 500%, demonstrating excellent swelling ability. The blending of BSP with PVA forms intermolecular interactions, reducing the free hydrophilic groups, resulting in BP fibers having lower moisture absorption capacity than BF fibers, yet still maintaining high moisture absorption performance. An ideal wound dressing adheres to the wound surface, quickly absorbing the secretion fluid from the wound, and maintains a moist healing environment, thus high moisture absorption and retention performance contribute to promoting wound healing.

2.5 Analysis of Drug Loading Performance of Drug-Loaded Fibers

2.5.1 Preparation of Buffer Solution and Drawing of Standard Curve: First, a certain amount of NaCl, KCl, Na2HPO4•12H2O, KH2PO4 were added to pure water, and then the pH value was adjusted to 7.4 using dilute phosphoric acid and dilute sodium hydroxide solution to prepare PBS buffer solution. Next, a certain amount of BH was dissolved in PBS solution, creating a series of BH concentration solutions, and the absorbance (A) at the maximum absorption wavelength of BH was measured using a visible light spectrophotometer, and a standard curve was drawn.

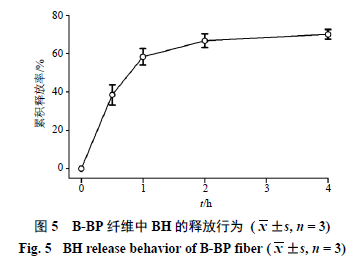

2.5.2 In Vitro Release and Drug Encapsulation Rate Determination of Drug-Loaded Fibers: Take three parallel samples of B-BP fibers, add equal amounts of PBS buffer solution, and place them in a constant temperature shaking incubator at 37 °C. At 0.5, 1, 2, and 4 hours, take 2 mL of buffer solution, then add equal amounts of PBS buffer solution to the sample bottle to continue drug release, and measure the A value of the taken buffer solution. According to the drug standard curve equation, calculate the drug concentration and release amount, draw the cumulative drug release rate curve, and calculate the encapsulation rate of B-BP fibers.

Encapsulation Rate = w1BH/wBH

wBH and w1BH represent the amount of BH added to B-BP fibers and the actual mass of BH, respectively.

The release curve of B-BP fibers is shown in Figure 5. In the early stage of drug release, the drug attached to the fiber surface is released first, with a rapid release rate. As the fibers gradually absorb moisture and water molecules enter the fiber interior, the drug distributed within the fibers begins to release gradually. After sufficient swelling, the release rate tends to stabilize until the drug is completely released. Previous studies have found that the release of BH is pH-dependent.[17] Under weak alkaline conditions, the release of BH is faster compared to weak acidic and neutral environments. Therefore, PBS buffer solution with a pH of 7.4 was selected as the release medium, with the regression equation being A = 0.8193C + 1.6793, r2 = 0.9995. The release amount of the drug was calculated based on the regression equation, and the encapsulation rate of the fibers was found to be approximately 70.2%.

During the various processes of preparing drug-loaded fibers through wet spinning, such as entering the coagulation bath and stretching medium process, the drug may precipitate from the spinning solution or fiber, leading to a loss of the drug, resulting in the drug content in the drug-loaded fibers being lower than that in the spinning solution. Based on the mild wet spinning conditions, the drug is not destroyed during the spinning process, and considering the structure and performance of the fibers, wet-spun fibers show excellent application prospects as a drug delivery system.[20]

2.6 In Vitro Antibacterial Activity Analysis of Drug-Loaded Fibers

2.6.1 Preparation of Solid Culture Medium: Weigh a certain amount of beef extract, peptone, sodium chloride, and agar, add to pure water, boil, adjust the pH value to 7.2-7.4, and sterilize using an autoclave for later use.

2.6.2 Culture Medium Plating: Add the sterilized culture medium to petri dishes and allow it to solidify for use.

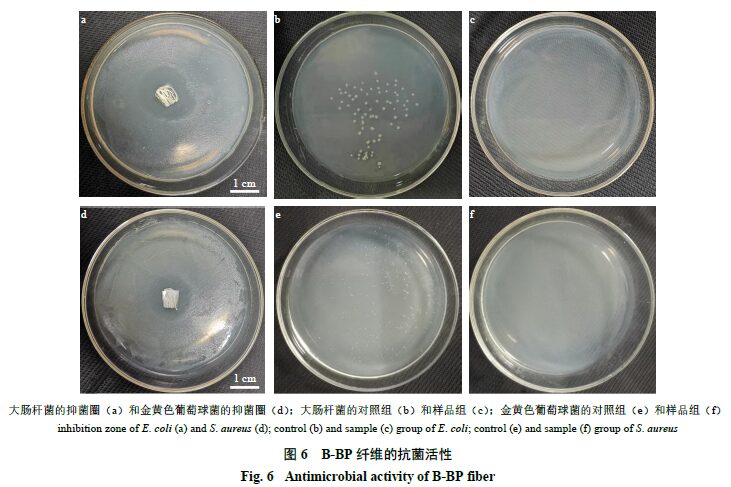

2.6.3 Qualitative Test (Inhibition Zone Method): In the petri dish, add 100 μL of 1×108 cfu/mL of Escherichia coli and Staphylococcus aureus evenly using a spreader, take 10 mg of B-BP fiber sample, cut it into 1 cm × 1 cm, irradiate with UV for 30 minutes, then place it on the culture medium, and incubate the petri dish in a 37 °C constant temperature incubator for 24 hours to observe the size of the inhibition zone (outer diameter minus inner diameter).

2.6.4 Quantitative Test (Inhibition Rate Method): Take an EP tube to dilute the bacterial solution stepwise, using a dilution concentration with a bacterial colony count below 200 as the experimental bacterial solution concentration. Take 10 mg of B-BP fiber and incubate it with the bacterial solution in a well plate for 4 hours, then take 100 μL to evenly spread in the petri dish, and incubate the petri dish in a 37 °C constant temperature incubator for 24 hours. Afterward, observe and record the number of viable bacteria n2, using the bacterial count n1 from the control group without fiber samples as a reference to calculate the inhibition rate.

Inhibition Rate = (n1 – n2)/n1

The experimental results shown in Figure 6 indicate that the sample diameter is known to be 1 cm, and the inhibition effects of B-BP fibers can be visually observed through the inhibition zones, with an inhibition zone diameter of 20 mm against Escherichia coli and 14 mm against Staphylococcus aureus; compared to the control group, the quantitative test shows an inhibition rate of 100% against both Escherichia coli and Staphylococcus aureus, demonstrating strong antibacterial capacity. Staphylococcus aureus is a Gram-positive bacterium with a thick cell wall and strong survival ability, and the antibacterial effect of the drug-loaded fibers against it is slightly lower than that against Escherichia coli.[21]

Antibacterial materials play a crucial role in effectively inhibiting bacteria, preventing further infection and deterioration of wounds, and are essential in the wound healing process. In the context of bacterial resistance, selecting natural antibacterial agents such as BH encapsulated in composite fibers, experimental results indicate that this drug fiber exhibits good antibacterial performance. Additionally, based on previous research, BSP, as a hemostatic material, contains a rich structure of mannose, which can bind to the mannose receptors (CD206) on macrophage membranes and activate macrophages; inducing the proliferation of endothelial cells (EGF) and the expression of vascular endothelial growth factor (VEGF); promoting the proliferation of fibroblasts and collagen deposition, playing a role in the inflammation, proliferation, and remodeling phases of wound healing, thus accelerating wound healing speed.[10] This indicates that the fiber loaded with BH has potential applications as a medical antibacterial dressing.

3 Discussion

BSP, also known as Bletilla gum, in previous studies, based on the theory of “drug-excipient integration” in traditional Chinese medicine formulation design, exhibits properties of water retention, thickening, suspension, gelation, and film formation, with rapid floating and sustained release performance, making it an excellent gastric retention floating sustained-release formulation excipient, reflecting the “excipient as drug” from a formulation perspective; multiple β-1,4-mannose residues in BSP form a helical structure conducive to drug encapsulation, forming a structure that encapsulates the contents, improving the physicochemical properties of the guest molecules, reflecting the “excipient as drug” from a therapeutic perspective. The BSP/PVA composite system, based on the physiological activity and water-absorbing swelling properties of BSP, can be prepared into multifunctional wet-spun fibers.

At the same time, the preparation of BSP/PVA composite fibers is influenced by various factors. Based on single-factor experiments, the interaction between influencing factors was investigated using response surface methodology to establish predictive models, and significant and lack-of-fit terms were examined to diagnose the reliability of the model, ultimately deriving the optimal process conditions.[24-25] Using the environmentally friendly and low-cost wet spinning method, BSP/PVA was used as the spinning solution, and ethanol as the coagulation bath, successfully producing BP fibers. The optimized spinning process is feasible and cost-effective, and BP fibers exhibit better tensile performance compared to BSP fibers due to the addition of PVA while maintaining high moisture absorption capacity. The B-BP fibers after loading BH demonstrate good antibacterial ability, indicating that BP fibers have a certain drug loading capacity, and further research on the drug release performance of BP fibers will be conducted.

References (Omitted)

Source: Yang Kai, Ma Zihao, Li Yuan, Gao Yuanping, Yang Xiao, Zeng Rui, Zhang Jizhong, He Xin, Wang Yihan. Optimization of Wet Spinning Process for Bletilla Striata Polysaccharide/Polyvinyl Alcohol Fibers Using Box-Behnken Response Surface Method and Evaluation of Fiber Performance [J]. Chinese Herbal Medicines, 2020, 51(14): 3645-3654.