In many tech products, heat sinks may be overlooked as less important accessories. However, in NVIDIA Jetson embedded products, the importance of heat sinks cannot be ignored. This article will discuss a heat sink failure case we experienced.

A year ago, a middleman who purchased a batch of NVIDIA Jetson Xavier NX module heat sinks from us reported that two heat sinks had failed:

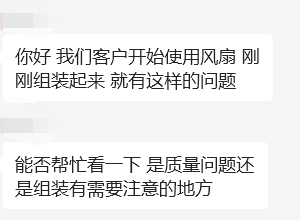

The middleman hoped for:

Our first reaction was: out of hundreds of supplied heat sinks, only two failed, and this batch was delivered a year ago. We really can’t take the blame for this.

However, we also understood the middleman’s situation, as customer satisfaction is paramount.

So we proposed some possible causes and troubleshooting methods online, including the installation direction of the spring clips and whether the wires underneath interfered with the blades, etc. The middleman actively fed back to the end user, but the end user wanted these two heat sinks returned to the factory for detailed analysis:

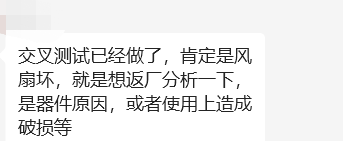

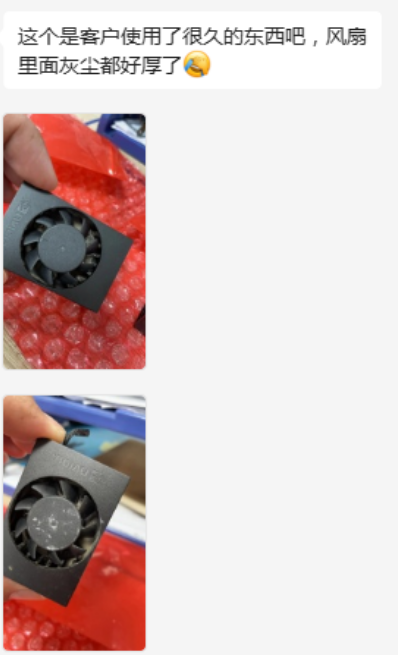

To reassure the middleman, we eventually expedited these two problematic heat sinks to the factory. The factory engineer’s first reaction upon receiving the heat sinks was:

Thus, from another perspective, it also indicates that the middleman’s claim that “the customer encountered this issue right after assembly” is not valid.

This conclusion was conveyed back to the end user, who responded:

Alright, let’s get started:

After a week of testing, the engineers provided a detailed analysis report:

The report included:

This analysis team, led by the quality manager, included the R&D manager, production supervisor, PE manager, PE engineer, and CQE engineer.

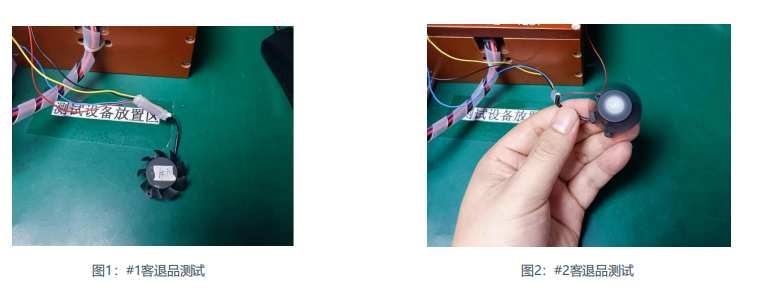

First, an appearance inspection was conducted with no deformation or damage observed.

Next, individual re-evaluation:

The conclusion was: #1 powering on found it not spinning, consistent with the customer’s feedback of failure.

#2 powering on can operate normally.

Then the engineers performed a fan disassembly analysis:

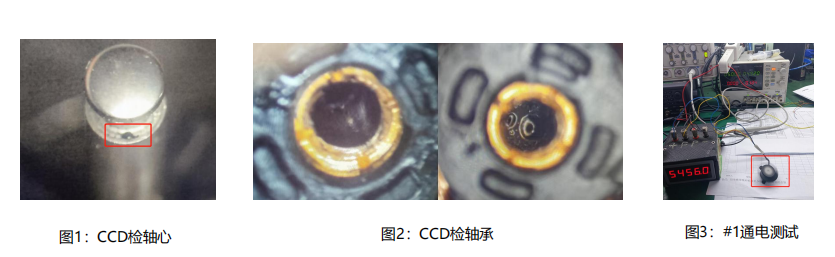

– The returned items were disassembled for CCD observation of the stator surface & axis surface, revealing black substances at the axis ball head position (Figure 1)

– CCD observation of the internal bearing found black substances on the inner surface of the bearing (Figure 2)

– Wiped the internal bearing & root of the axis with a lint-free cloth, reinserted the fan into the bearing, powered it on for testing, and the fan operated normally (Figure 3)

– Through the above investigation, it can be concluded that the fan not spinning is related to the black substances.

Next, an analysis of the black substances was conducted:

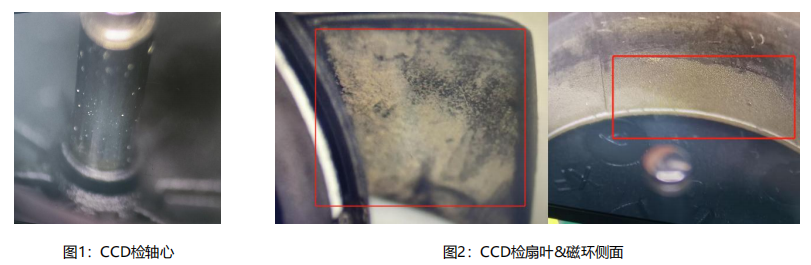

– After cleaning the axis, CCD detection showed no friction marks, ruling out that the black substances were caused by friction between the axis and bearing (Figure 1)

– CCD observation of the fan blades and magnetic ring showed a large amount of dust particles (Figure 2)

– Pressing the black substances with hand revealed a noticeable graininess and stickiness.

– Through the above investigation, it was initially suspected that foreign objects entered during the fan’s operation and mixed with oil, creating sludge that caused the fan not to spin.

Final conclusion:

Foreign objects and oil contaminants entered the fan, and after cleaning these, it could operate normally!

The middleman was very satisfied with the inspection report provided by the factory, and the end user had no further feedback.

Through this case, we want to particularly emphasize the role of professional suppliers.

Professional suppliers can provide high-quality heat sinks and offer users comprehensive manufacturing and service support. Users should pay attention to the supplier’s reputation and quality assurance when purchasing and installing heat sinks, and follow the correct installation steps.

Seemingly low-tech accessories also play a crucial role in the stability and performance of the system. Choosing a professional supplier and following the correct installation and maintenance steps can ensure users safely use heat sinks and improve the reliability and performance of embedded systems.