In the field of testing and measurement, the development of instrument bus technology has always been a major concern for engineers and scientists. From the GPIB bus introduced in the 1960s specifically for instrument control, to the widely used USB, VXI, PXI, and the latest LXI and PXI Express, the emergence of new bus technologies has not only helped our engineers complete measurement tasks more quickly and efficiently but has also sparked widespread debate among industry experts about which bus will dominate the future of the testing and measurement field.

The Future Trend – Hybrid Bus Testing Systems

Let us first review history. Both GPIB and serial ports have been used in the testing industry for decades, yet many engineers continue to use or purchase relevant instruments. Looking at the ISA bus, which has almost exited the PC historical stage, we can still see ISA slots in some industrial computers today, and many manufacturers are still producing data acquisition cards and GPIB control cards based on the ISA bus to meet certain customers’ needs. It can be said that every bus has its unique advantages in the industry, and no single bus can perfectly replace any other.

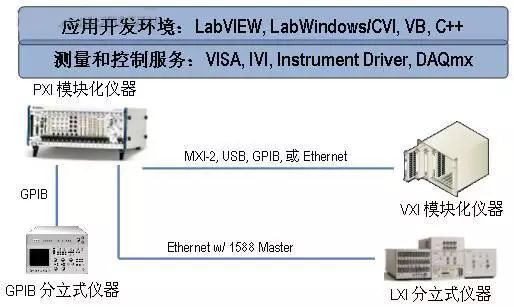

A hybrid bus testing system refers to a system that integrates different components of multiple automated testing platforms, including PXI, PCI, GPIB, VXI, USB, LAN, and LXI. From an engineer’s perspective, when designing a testing system, it is often necessary to balance various factors. Current products are becoming increasingly complex, and the demands for mixed-signal testing are also rising, which requires leveraging the advantages of different bus testing platforms to build a hybrid testing system that meets testing needs. For example, your system may require the high throughput and excellent integration provided by modular instrument buses such as PXI and PCI Express, while also needing standalone instruments based on USB or LAN (including LXI) to complete certain specific testing functions. Furthermore, using a hybrid system allows engineers to easily upgrade or add new components to existing systems without redesigning the entire system. At the same time, such hybrid systems place higher demands on software architecture, hoping to seamlessly support different bus platforms at both the driver service layer and the application software layer, meaning that a unified software architecture will become the core of the entire hybrid testing system. (See Figure 1)

Figure 1: Typical Software and Hardware Architecture of Hybrid Bus Testing Systems

Therefore, we see that these buses will coexist for a long time, and the future trend of testing systems will be based on hybrid bus testing systems. Meanwhile, software will reflect its core position in such a multi-vendor, multi-bus hybrid system.

External buses – GPIB, Serial, IEEE 1394 (FireWire), USB, LAN, and LXI primarily provide interconnectivity between traditional standalone instruments and PCs in the testing and measurement industry, so we often refer to this type of bus as standalone instrument buses. Each bus has its unique advantages for different applications. For instance, GPIB, as the most mature bus technology, offers the widest variety of instruments to choose from; using USB allows users to take full advantage of its plug-and-play features; while using LAN/LXI can meet users’ needs for distributed applications and long-distance instrument communication. Depending on different requirements for measurement functions, bandwidth, transmission delays, performance, and ease of connectivity, users can freely choose the bus connection technology that suits their applications.

GPIB, Serial, and Firewire are well-known bus technologies among engineers, so we won’t elaborate on them here. What we want to discuss are several newer standalone instrument bus technologies.

USB

Universal Serial Bus (USB) has gradually become the mainstream bus technology for instrument control due to its widespread use in PCs, ease of use with plug-and-play capabilities, and a transmission rate of up to 480 Mbits/s with USB 2.0. The increasing number of USB ports on computers has made it very convenient for engineers to connect USB-based measurement instruments to the entire system.

However, USB also has some drawbacks in terms of instrument control. For example, USB cabling lacks industrial standard specifications, which can lead to data loss in harsh environments; additionally, USB has certain limitations on cable length.

LAN and LXI

LAN, as a mature technology, has been widely used in various testing systems for several years, such as remote network analyzers and data loggers, and is particularly suitable for distributed systems and remote monitoring, filling the gap that traditional instruments originally had in this area. As part of the VXIbus specification, the VXI-11 specification defined a series of standards for network instruments to communicate between controllers and devices via TCP/IP.

The LXI (LAN eXtensions for Instrumentation) bus specification originated from the needs of the U.S. military, redefining a series of LAN-based instruments, including timing indicators based on the existing IEEE 1588 technology and optional LXI trigger buses. However, fundamentally, LXI instruments are still a type of standalone instrument based on LAN; they merely reorganize various existing technologies (such as LAN, IEEE 1588, etc.) into a new standard without significant technological innovation. Furthermore, LXI is currently primarily aimed at some high-end measurement applications for the U.S. military and has not yet gained popularity in the industrial sector, with very few LXI instruments available on the market.

Whether LAN or LXI, since they are both based on Ethernet communication methods, some inherent shortcomings of Ethernet still exist, such as the need for manual IP address configuration and how to resolve IP address conflicts; additionally, issues such as real-time data transmission, data integrity, and security need further exploration.

Here, we also want to briefly introduce the new time synchronization protocol adopted by LXI: IEEE 1588, which provides a standard method for achieving sub-microsecond-level device synchronization over a network. The protocol synchronizes the clocks of devices with the master device’s clock, ensuring that any events and timestamps in all devices use the same time reference. Synchronizing devices using IEEE 1588 requires two steps: (1) determining which device will provide the master clock based on the best master clock algorithm; (2) measuring and correcting time errors caused by clock offsets and network delays.

In practical applications, the accuracy of IEEE 1588 clock synchronization depends on many factors, such as the clock frequency of the master and slave clocks, the stability of the clocks, and the network topology. Additionally, many variables in network communication can more or less affect synchronization accuracy.

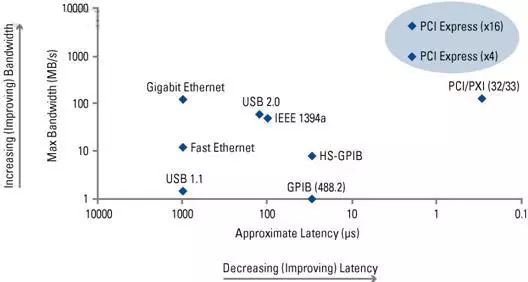

When we open the case of a modern PC, we often find that graphics cards are typically based on high-bandwidth PCI, AGP, or the latest PCI Express x16 buses, with few graphics cards based on external buses like USB or Ethernet; similarly, while a standalone instrument may provide USB, Ethernet/LAN, and RS-232 interfaces for communication with PCs, the internal data transmission still uses the PCI bus. Both examples use internal buses for massive data transmission because internal buses like PCI can provide higher bus bandwidth and lower transmission latency compared to external buses (see Figure 2). Next, let’s discuss some common internal buses.

Figure 2: Internal Buses Have Higher Bandwidth and Lower Transmission Latency Compared to External Buses

Internal Buses – VXI, PCI/PXI, PCI Express, and PXI Express

Internal buses, also known as modular instrument buses, provide developers with an open multi-vendor joint standard and flexible software to create user-defined instruments to meet different application needs. Such instruments not only have better integration and scalability but also provide superior software flexibility. As shown in the figure above, the high bandwidth characteristics of internal buses are crucial for high-speed streaming and excitation/response testing applications, while low latency determines testing time for small data transmissions, such as testing the scanning of digital multimeters + switches with high data transmission delay requirements. Common internal buses include VXI, PCI/PXI, PCI Express, and PXI Express.

VXI and PCI/PXI

VXI (VMEbus eXtensions for Instrumentation) was the first bus to introduce the modular instrument concept, successfully reducing the size of traditional instrument systems and improving system integration levels, primarily to meet the needs of high-end automated testing applications, and has been successfully applied in military aviation testing and manufacturing testing. However, due to VXI’s high cost and its reliance on outdated VME bus technology, which modern computers do not support, the market share of VXI has gradually decreased with the introduction of the PXI (PCI eXtensions for Instrumentation) bus, while PXI’s growth has been unstoppable, having surpassed VXI years ago to become the mainstream technology in modular testing and measurement. Compared to VXI, PXI, based on mature PCI bus technology, offers faster bus transmission rates (132MB/s vs 40MB/s), smaller size, and better performance-to-cost ratio. Furthermore, PXI provides nanosecond-level timing and synchronization capabilities along with robust industrial characteristics. Finally, thanks to the flexibility of software and continuously updated modular hardware, users can upgrade the entire testing system at minimal investment. Such excellent scalability and flexible software architecture make system integration based on the PXI modular instrument platform increasingly common.