This article mainly introduces key technology applications in smart factories, including IoT application technology, complex system simulation technology, and production management technology.

Author: Li Fangyuan

Source: Control Network, Automation Expo

Author Introduction:

Li Fangyuan (1973-), male, from Zhoushan, Zhejiang, associate professor, senior engineer, master’s degree, graduated from the Control Engineering major of Zhejiang University of Technology, currently working at Zhejiang Business Vocational and Technical College, engaged in the application and research of new technologies in intelligent manufacturing for a long time.

Lecture 1: IoT Application Technology in Smart Factories

Abstract: Smart factories utilize IoT technology and monitoring technology to enhance information management services. Through the IoT platform, the controllability of the production process can be improved, and manual intervention in the production line can be reduced. This article mainly introduces the three levels of the IoT platform: the sensing network layer, the transmission network layer, and the application network layer, as well as three common wireless network technologies: ZigBee, Wi-Fi, and Lora.

Keywords: Smart Factory; IoT; Zigbee Technology; Wi-Fi Technology; Lora Technology

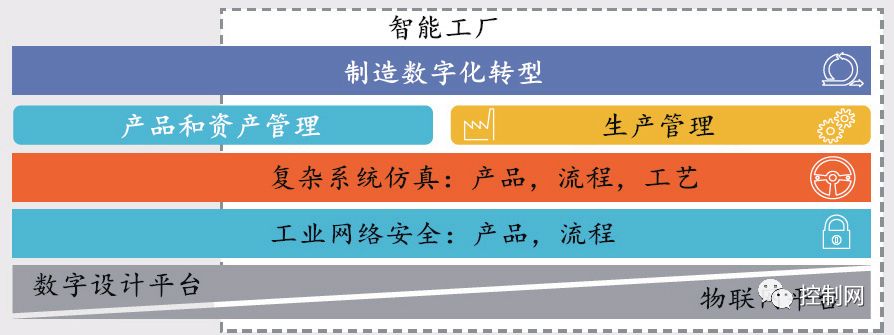

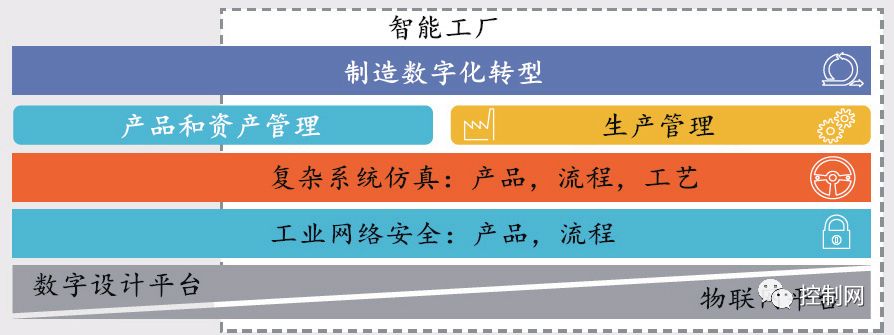

Figure 1 shows the model of a smart factory, where an open IoT platform and an advanced digital design platform serve as the foundation, integrating product and asset management, production management, and utilizing big data analysis, cloud computing, and sensing technology to achieve digital transformation in manufacturing.In a smart factory, the industrial IoT encompasses a wide, multi-level, and deep integration from production to service, from the device layer to the network layer, and from manufacturing resources to information fusion. In smart factories, by fully utilizing new generation information technology innovations such as cloud computing, big data, and digital virtualization through the IoT platform, goals such as improving productivity and work efficiency, reducing costs, and minimizing resource usage can be achieved.

Figure 1: Smart Factory Model

2. IoT Platform of Smart Factories

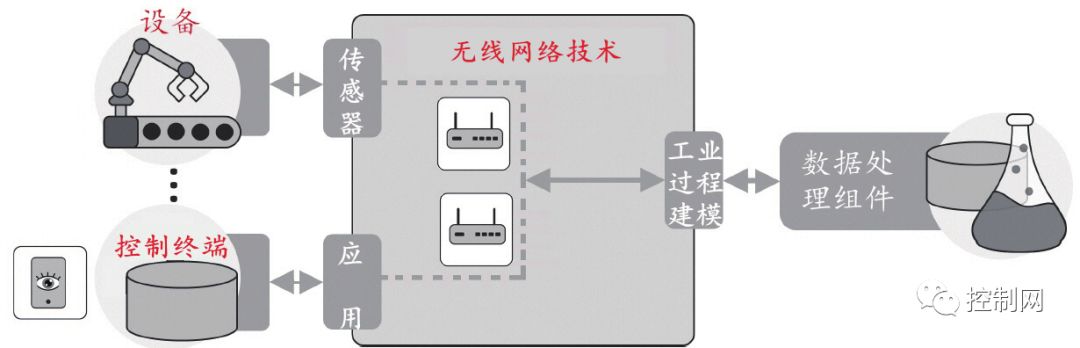

Based on the direction of data flow and data processing methods within the IoT network, the IoT platform of smart factories can be divided into three levels, as shown in Figure 2.

Figure 2: IoT Platform of Smart Factories

(1) Sensing Network Layer: Primarily using QR codes, RFID, and sensors, this layer mainly identifies industrial equipment such as processing equipment and assembly lines in the manufacturing industry and collects data from the perceived signals. Industrial sensors, as a type of detection device, can measure or sense the status of manufacturing equipment or products, temperature changes, concentration levels, flow trends, etc., converting corresponding physical quantities in discrete or process manufacturing into electrical signals, communication codes, or other forms of information that can be transmitted, processed, and digitally stored. This is a prerequisite for achieving intelligent detection and control in manufacturing, monitoring the production process through reading various effective parameter signals.

(2) Transmission Network Layer: This layer utilizes wireless network technologies such as Zigbee, Wi-Fi, Lora, broadcasting networks, and mobile communication networks to achieve data transmission and computation. In smart factories, the wireless network is a mesh network consisting of a large number of randomly distributed sensor nodes, with a self-organizing capability, while exhibiting characteristics of ubiquitous collaboration and heterogeneous interconnection for signal transmission.

(3) Application Network Layer: This layer includes various input and output control terminals, such as computers, touch screens, tablets, and smartphones. The various applications displayed on smart terminals are industrial process models constructed after data processing and expressed in a certain tangible way.

In the IoT platform of smart factories, two standardization issues also need to be addressed:

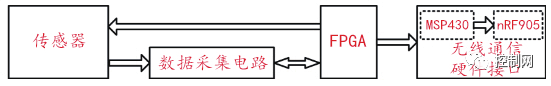

(1) Standardization of Hardware Interfaces. Consistent rules for hardware interfaces ensure that different IoT sensor device manufacturers can guarantee the effectiveness of data transmission when connecting to wireless networks. For example, in the wireless communication interface of a certain sensor shown in Figure 3, the FPGA can generate driving pulses to the sensor body and also transmit signals to the data acquisition circuit, which includes the MSP430 microcontroller and the nRF905 radio frequency chip.

Figure 3: Example of Hardware Interface Standardization

(2) Standardization of Data Protocols. Data protocols refer to the horizontal and vertical data flow exchange protocols of the three layers of the IoT platform, which can be divided into control data flow and management data flow.

3. Three Wireless Network Technologies of IoT

ZigBee technology is a cost-effective, energy-efficient, and highly stable short-range wireless networking communication technology. The wireless data transmission module of ZigBee networks can include up to 65,000 nodes and has self-organizing capabilities..Within the entire network coverage, each ZigBee node can serve as a signal collection and control monitoring object; within its own signal coverage, it can connect with multiple isolated sub-nodes that do not bear the task of relaying network information, automatically relaying data information from other network nodes.

As an open wireless LAN standard based on the IEEE802.15.4 protocol, ZigBee is particularly suitable for low-rate data transmission between bottom-level devices in factories. It can use three frequency bands, including the ISM band of 2.4GHz, which is commonly used domestically, characterized by being application-free and free of charge, with 16 channels available; the 868MHz band in Europe, which has 1 channel available; and the 915MHz band in the United States, which has 10 channels available.

According to the OSI model, ZigBee networks are divided into four layers: physical layer (PHI), media access layer (MAC), network layer or security layer (NWK), and application layer (APL), distributed from bottom to top as shown in Figure 4. In the network layering, the physical layer provides data and management services to the media access layer, proceeding sequentially from bottom to top. In the adoption of protocol standards, the lowest PHI and MAC layers use the IEEE802.15.4 protocol standard, while the NWK and APL layers are standardized by the ZigBee Alliance.

|

|

|

|

Network Layer/Security Layer (NWK)

|

|

|

|

|

|

Figure 4: ZigBee Network Layering

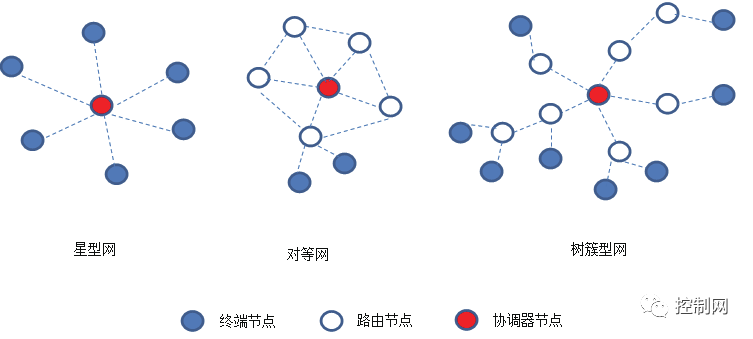

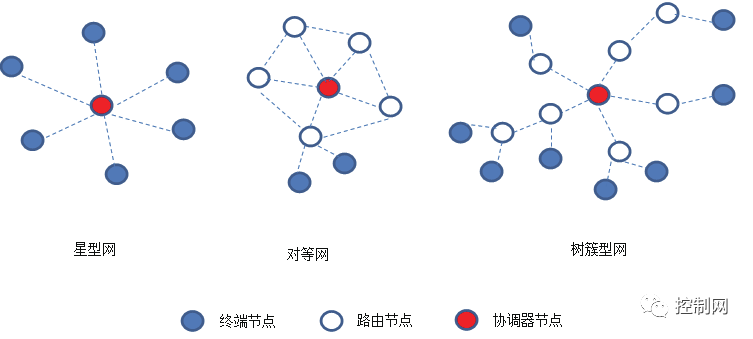

Star, tree-cluster, and peer-to-peer topologies are the three types supported by ZigBee, as shown in Figure 5. In the figure, routing nodes complete the relevant data routing, and the information of terminal nodes generally needs to be forwarded through routing nodes before reaching the coordinator node, which is responsible for network management. The star network is the simplest type, where nodes do not communicate directly with each other; all data information must be forwarded through the coordinator node. In a peer-to-peer network, nodes are interconnected, and data forwarding is generally done in a multi-hop manner, with each node having forwarding capabilities. The tree-cluster network is the most complex structure, consisting of coordinator nodes, routing nodes, and terminal nodes. Generally, large-scale equipment monitoring in factories is completed through peer-to-peer networks, while star and tree-cluster networks operate on a one-to-many basis.

Figure 5: Zigbee Topology Structure

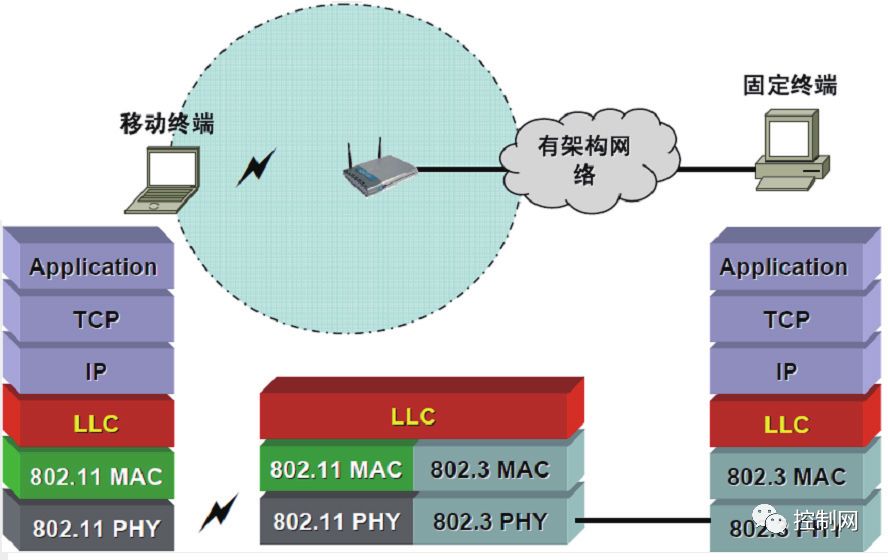

Wi-Fi stands for Wireless Fidelity, which adopts an 11Mbps wireless standard – the 802.11b standard. The greatest advantage of Wi-Fi is its high transmission speed and long effective distance, reaching 11Mbps transmission speed and approximately 300m transmission distance for commercial devices. Figure 6 shows the protocol stack of Wi-Fi networks, and Figure 7 shows the structure of Wi-Fi networks.

Figure 7: Wi-Fi Network Structure

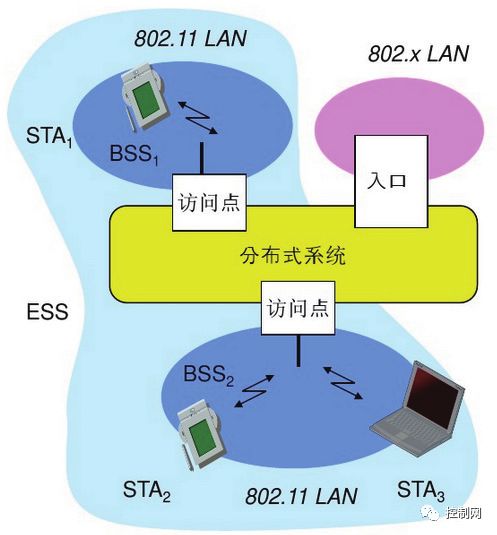

In a Wi-Fi network, the station (STA) refers to various terminal devices with Wi-Fi communication capabilities, such as mobile phones, tablets, touch screens, etc., that are connected to the wireless network. BSS is the Basic Service Set, which can consist of an access point and several stations, or several stations (at least two). A BSS with an access point is known as a infrastructure basic service set; a BSS without an access point is known as an independent basic service set, or AdHoc Network. ESS is the Extended Service Set, which is a distributed system formed by one or more BSS basic service sets connected together. Through the extended service set, the coverage area of the Wi-Fi wireless network can be extended to cover the entire group of devices in the manufacturing factory.

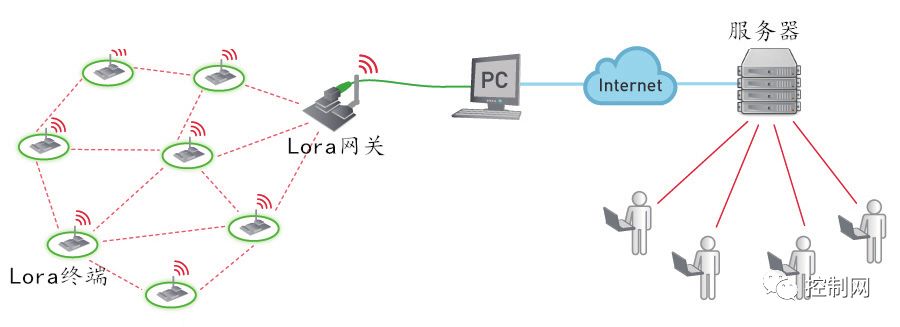

Lora is an LPWAN communication technology first launched by the American company Semtech and widely implemented worldwide. It employs spread spectrum communication, offering advantages such as long-distance transmission, low power consumption, and multi-node networking. Currently, the working frequency bands of LoRa mainly include 915MHz, 868MHz, and 433MHz, all of which belong to free frequency bands.

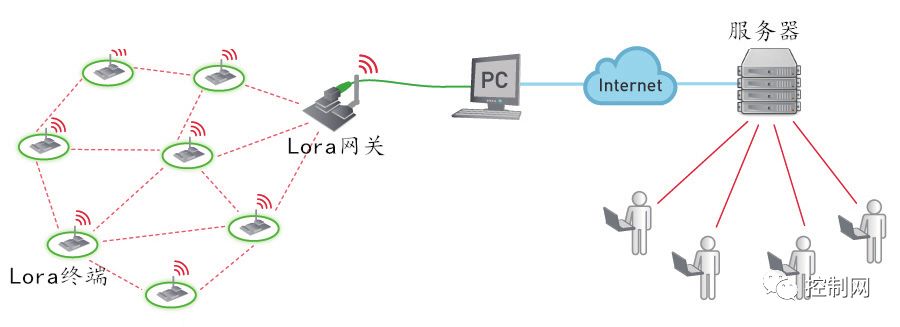

Figure 8 shows the LoRa network, which mainly consists of LoRa terminals (which can have built-in LoRa modules), LoRa gateways (or base stations), and servers including network servers and application servers, forming a typical star topology. In this structure, the LoRa gateway acts as a transparent relay to connect the LoRa terminal devices in the field with the relevant remote servers, transmitting various data bidirectionally from devices, processes, and remote servers, such as sensor data, standard processing data for modeling, and processed data sent to the application layer.

Figure 5: Zigbee Topology Structure

Wi-Fi stands for Wireless Fidelity, which adopts an 11Mbps wireless standard – the 802.11b standard. The greatest advantage of Wi-Fi is its high transmission speed and long effective distance, reaching 11Mbps transmission speed and approximately 300m transmission distance for commercial devices. Figure 6 shows the protocol stack of Wi-Fi networks, and Figure 7 shows the structure of Wi-Fi networks.

Figure 7: Wi-Fi Network Structure

In a Wi-Fi network, the station (STA) refers to various terminal devices with Wi-Fi communication capabilities, such as mobile phones, tablets, touch screens, etc., that are connected to the wireless network. BSS is the Basic Service Set, which can consist of an access point and several stations, or several stations (at least two). A BSS with an access point is known as a infrastructure basic service set; a BSS without an access point is known as an independent basic service set, or AdHoc Network. ESS is the Extended Service Set, which is a distributed system formed by one or more BSS basic service sets connected together. Through the extended service set, the coverage area of the Wi-Fi wireless network can be extended to cover the entire group of devices in the manufacturing factory.

Lora is an LPWAN communication technology first launched by the American company Semtech and widely implemented worldwide. It employs spread spectrum communication, offering advantages such as long-distance transmission, low power consumption, and multi-node networking. Currently, the working frequency bands of LoRa mainly include 915MHz, 868MHz, and 433MHz, all of which belong to free frequency bands.

Figure 8 shows the LoRa network, which mainly consists of LoRa terminals (which can have built-in LoRa modules), LoRa gateways (or base stations), and servers including network servers and application servers, forming a typical star topology. In this structure, the LoRa gateway acts as a transparent relay to connect the LoRa terminal devices in the field with the relevant remote servers, transmitting various data bidirectionally from devices, processes, and remote servers, such as sensor data, standard processing data for modeling, and processed data sent to the application layer.

In the construction of smart factories, analyzing the data collected through the IoT can help industrial enterprises analyze the status of various equipment or products, achieve early warning or alarms for abnormal states, thereby enabling predictive maintenance and avoiding unplanned downtime; at the same time, it also helps enterprises improve product performance, reduce energy consumption, ensure safety, and promote improvements in capacity, emissions reduction, and efficiency in manufacturing enterprises.

In the construction of smart factories, analyzing the data collected through the IoT can help industrial enterprises analyze the status of various equipment or products, achieve early warning or alarms for abnormal states, thereby enabling predictive maintenance and avoiding unplanned downtime; at the same time, it also helps enterprises improve product performance, reduce energy consumption, ensure safety, and promote improvements in capacity, emissions reduction, and efficiency in manufacturing enterprises.

This article is excerpted from the August 2018 issue of Automation Expo

Lecture 2: Complex System Simulation Technology in Smart Factories

Abstract: The simulation of complex systems is a simulation model technology that reflects the system behavior or processes of smart factories through simulation experiments using simulation hardware and software, assisted by numerical computation and problem-solving. This article mainly introduces two major types of simulation technologies in smart factories: simulation technology for discrete manufacturing and simulation technology for process manufacturing.

Keywords: Smart Factory; Simulation Technology; Complex Systems

1. Introduction

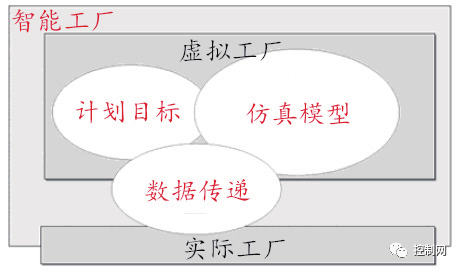

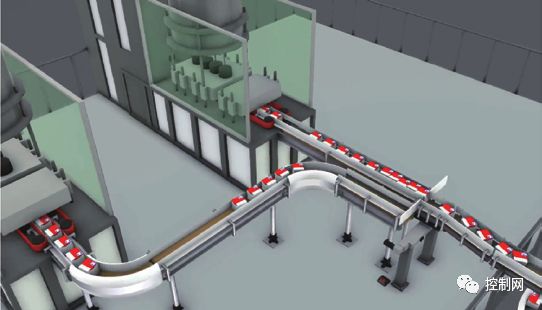

Figure 1 shows the model of a smart factory, where the simulation of complex systems is an important part encompassing product and asset management, production management. It is a simulation model technology that reflects the system behavior or processes of smart factories through simulation experiments using simulation hardware and software, assisted by numerical computation and problem-solving.

Figure 1: Smart Factory Model

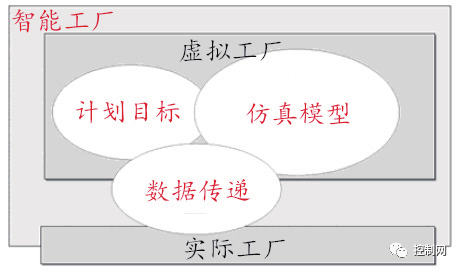

With the rapid development of information processing technology and network technology, in smart factories, the data information transmitted by actual factories and the computer integrated simulation system form a virtual factory simulation environment, linking factory operators and product R&D personnel through the IoT platform to jointly research and plan goals, promptly discover and resolve product, process, and technology issues, as shown in Figure 2.

Figure 2: Simulation Environment of Smart Factories

The simulation technology of smart factories is mainly divided into two major categories based on the differences in simulation models and simulation experiment methods: simulation technology for discrete manufacturing and simulation technology for process manufacturing.

2. Simulation Technology for Discrete Manufacturing in Smart Factories

In smart factories, the simulation method for discrete event systems is mainly applied in discrete manufacturing industries such as injection molding, stamping, and sheet metal processing, mainly integrating the following processes: product development, testing and optimization, production process development and optimization, and factory design and improvement.

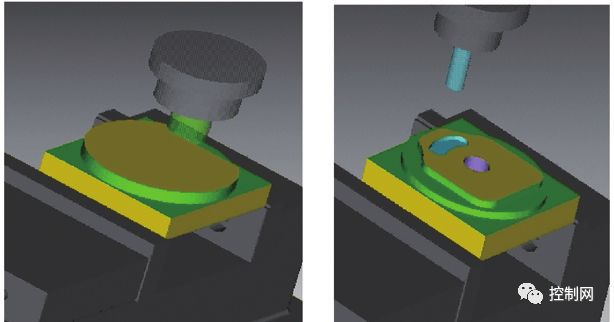

Through virtual machine tool processing systems, processing technology can be optimized, processing quality can be predicted and inspected, and cutting parameters and tool paths can be optimized, improving the utilization and production efficiency of machine tool equipment. Common CNC machine tools mainly consist of components such as the bed, column, motion axis, and workbench, along with tools, fixtures, and auxiliary components.Virtual machine tools are mainly categorized into three types based on structural characteristics: general modules, auxiliary modules, and specialized modules. Among these, general modules refer to various machine tool components shared by the bed, column, workbench, etc.; auxiliary modules refer to machine tool tools such as cutters and fixtures; specialized modules are established for the special components of special machine tools.

The modeling process of virtual machine tools using Vericut simulation software is as follows:

(1) Preparation. Clarify the model of the machine tool control system, the structural form and dimensions of the machine tool, the working principle of the machine tool, spindle stroke, coordinate system, as well as the blank, tools, and fixtures.

(2) Machine Tool Construction. The software provides several common machine tool models for use, but they generally do not meet requirements. At this point, users need to construct the machine tool themselves.

(3) Machine Tool Control System Setup. Users can select the control system from VERICUT according to the actual machine tool being used. If the control system does not exist, it can also be customized according to IEC61131-3 rules.

(4) Establish Machine Tool Tool Library.

(5) Set Machine Tool System Parameters.

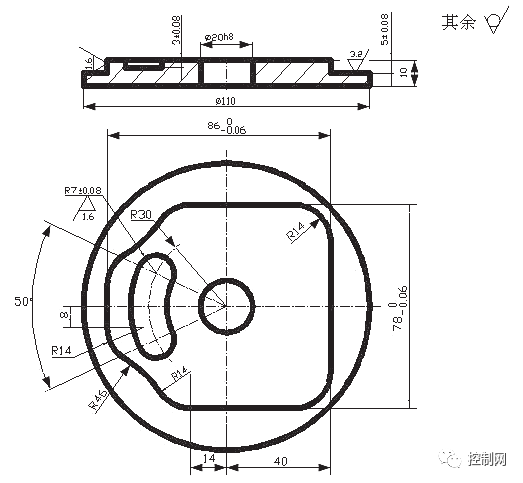

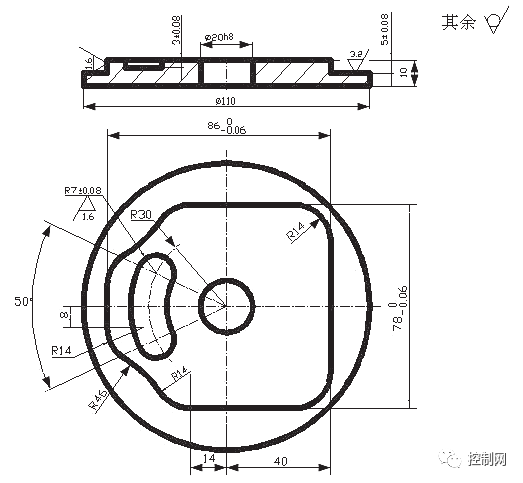

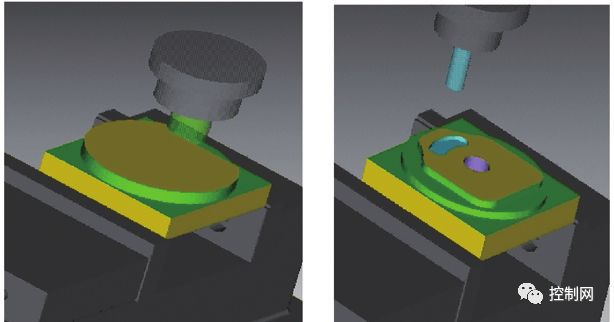

A certain product processing, such as the part shown in Figure 3, currently uses the three-axis milling machine sample provided by Vericut software, and the simulation results are shown in Figure 4.

Figure 3: Processed Parts

(a) Simulation Result One (b) Simulation Result Two

Figure 4: Three-Axis Milling Virtual Machine

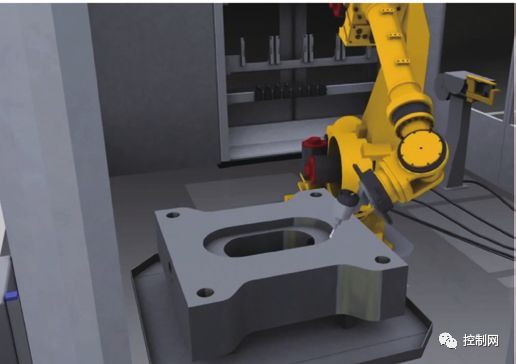

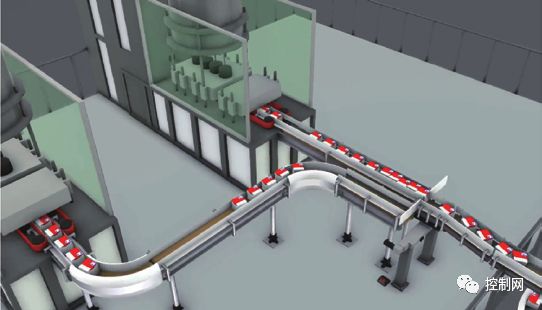

The design and simulation of mechanical products can make the planning of manufacturing workshops more efficient, allowing project-related personnel to quickly understand the plan, thereby avoiding potential errors, reducing many failure costs, and ensuring that the entire manufacturing workshop’s automation system and personnel operation engineering can be smoothly mass-produced.

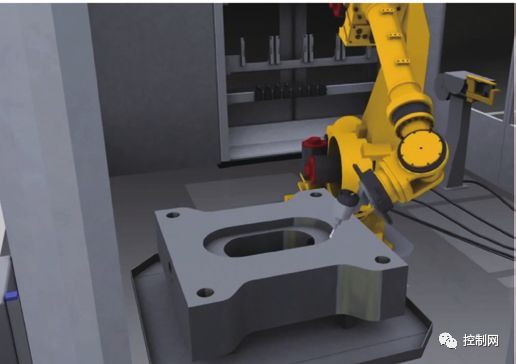

Figure 5: Intelligent Model

In addition to mechanical processing, discrete manufacturing simulation software should also have numerous intelligent models, as shown in Figure 5, including a vast database of 3D models for industrial robots, mechanisms, and logistics systems, enabling rapid factory planning and design. Finally, after integrating practical application experience, it can accurately predict manufacturing activities, ensuring the benefits of implementing the manufacturing factory.

Figure 6 shows the application of Visual Components virtual simulation software on the production line, which features a quick function that can be used on demand, significantly improving the efficiency of robot simulation and logistics simulation, while integrating the functions of PLC and robot simulation, allowing for offline programming of robots or PLCs.

Figure 6: Application of Visual Components Software

3. Simulation Technology for Process Manufacturing in Smart Factories

Process manufacturing refers to industries such as paper making, steel, chemical, and textile, where the processed objects continuously pass through production equipment, undergoing chemical or physical changes through a series of flow boxes, blast furnaces, reaction kettles, and winding machines, ultimately producing products such as paper, steel, polyethylene, and long fibers.Due to the strong variability of materials and numerous constraints in the process of process manufacturing, significant differences arise between its production processes and those of discrete manufacturing industries.

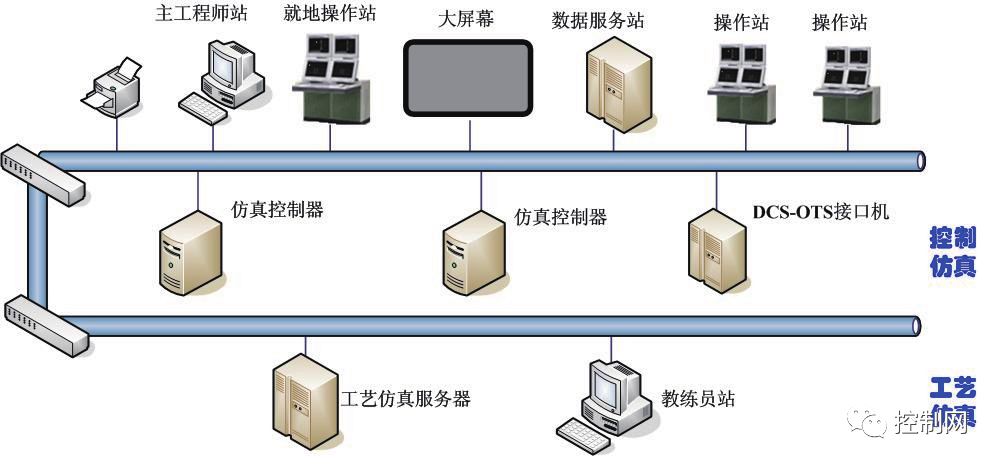

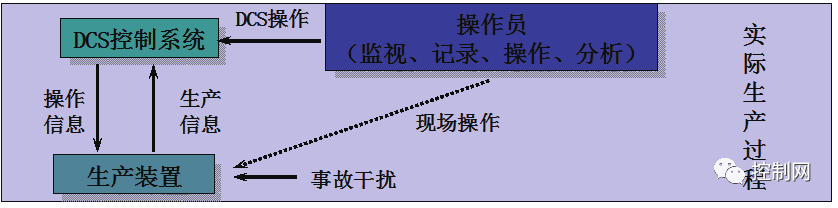

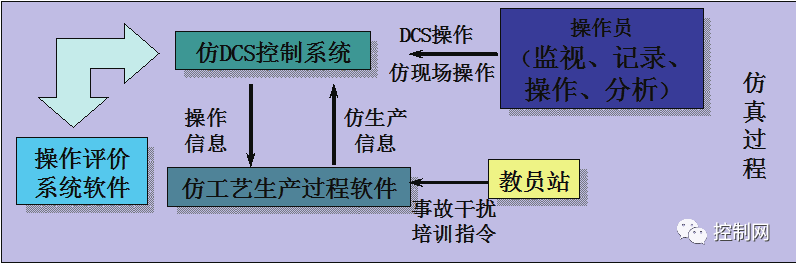

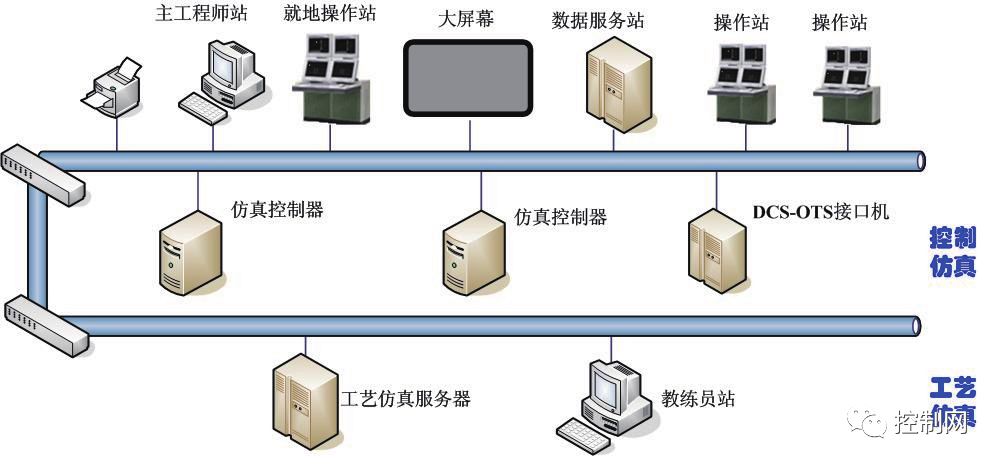

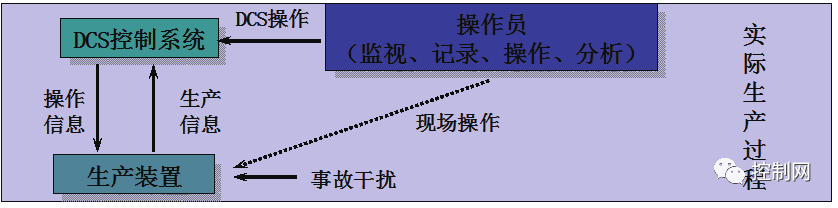

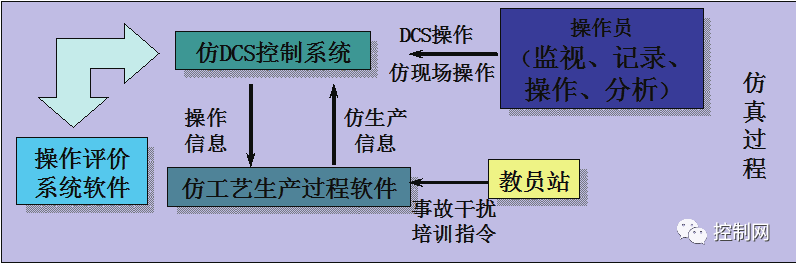

Figure 7 shows the actual production process and simulation process of process manufacturing. Process manufacturing often operates through DCS, PLC, and other control systems, facilitating bidirectional data transmission of operational and production information with production devices. The simulation system based on virtual DCS mainly consists of process simulation and control simulation. The process simulation, as shown in Figure 8, refers to simulating the actual device on-site through dynamic process mathematical models, achieved by software that implements the simulated production process consisting of a process simulation server and process mathematical models; control simulation refers to simulating DCS control systems, including simulating configuration control logic and virtual DPU technology.

(a) Actual Production Process

(b) Simulation Process

(b) Simulation Process

Figure 7: Actual Production Process and Simulation Process

Figure 8: Control Simulation and Process Simulation

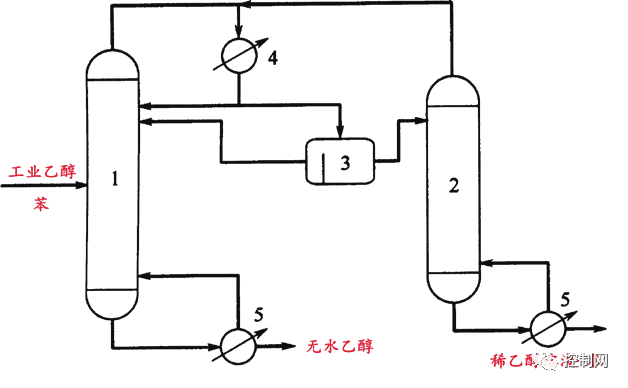

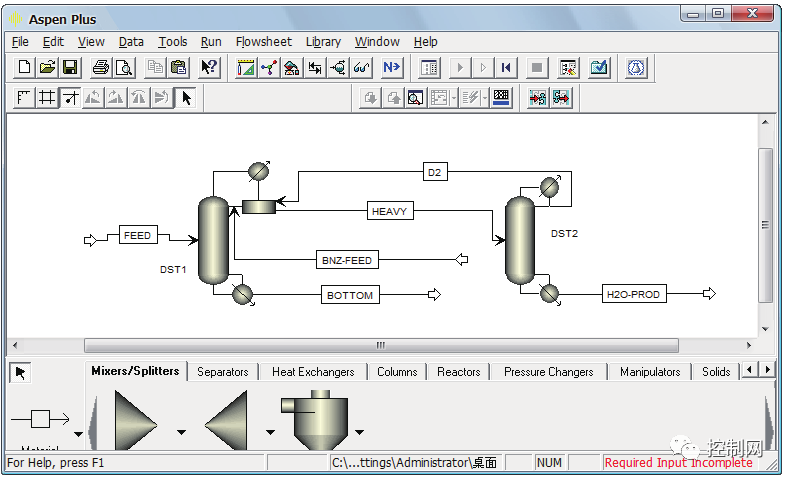

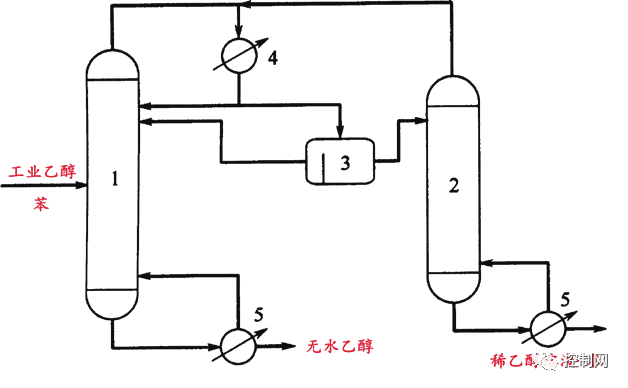

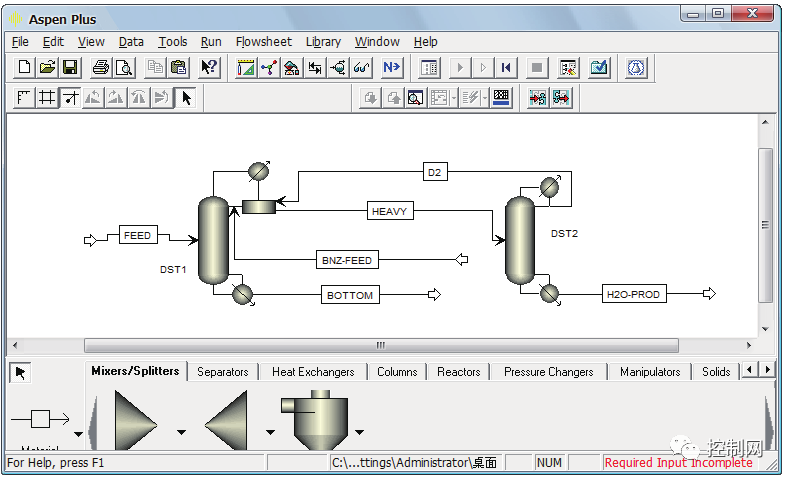

The software running on process simulation can be selected based on the actual production process, such as the large-scale general process simulation system AspenPlus. The simulation flowchart of constant boiling distillation of anhydrous ethanol is shown in Figure 9. In Figure 9 (a), industrial ethanol and benzene enter the constant boiling distillation tower, forming a ternary constant boiling mixture of ethanol-water-benzene, which is vaporized from the top of the tower. Since this constant boiling mixture contains a large amount of water, the bottom of the tower extracts almost pure ethanol. The vapor at the top of the tower enters the condenser, with part of it refluxing and another part entering the separator. The light phase of the separator returns to the constant boiling tower to replenish the reflux, while the heavy phase enters the benzene recovery tower. The vapor at the top of the recovery tower enters the condenser, and the bottom product of the tower is dilute ethanol. Sometimes, the bottom product of the recovery tower is sent to an ethanol recovery tower, with the bottom product ultimately yielding almost pure water. Since benzene is recycled in the process, only a small amount of benzene needs to be supplemented periodically to maintain the operation of the constant boiling tower. In Figure 9 (b), a “RadFrac” module with a decanter simulates the constant boiling tower: the input information for the constant boiling tower feed (FEED) includes pressure, vaporization rate (or temperature), and component flow (or flow and composition); in the “Components” project of “Specifications,” ethanol, water, and benzene are searched by English name or molecular formula and added to the component list; in Properties→Global→Basemethod, the thermodynamic calculation method NRTL is specified; in Blocks→DISTl, the equipment parameters of the constant boiling tower are entered, setting the number of tower plates, condenser type, effective phase as gas-liquid-liquid, and the convergence algorithm as constant boiling algorithm.

(a) Constant Boiling Distillation Process of Anhydrous Ethanol

1:Constant boiling distillation tower;2:Recovery tower;3:Separator;4:Condenser;5:Reboiler

(b) Simulation Flowchart of Constant Boiling Distillation of Anhydrous Ethanol

Figure 9: Actual and Simulated Flowchart of Constant Boiling Distillation of Anhydrous Ethanol

Table 1 shows the logistics output information calculated by AspenPlus based on the input information.

In the simulation system of process manufacturing, process model modeling is completed in the simulation software based on process diagrams and in graphical modeling form. Simulation software generally has a mature process model library, allowing for rapid modeling while completing dynamic and static debugging. For the information collection part, it is necessary to plan reasonably during the early modeling stage, leaving interfaces for each system to realize the correlation with other operational parameters.

4. Conclusion

By using virtual simulation software tools, more discrete manufacturing or process manufacturing production sites can be simulated in a short time. At the design stage, the effectiveness of production equipment can be planned and verified, and during operation, it can be used for training or process monitoring. At the same time, by including the method of establishing mathematical models into simulation software, the virtual system can be made closer to the real system and contribute to the prediction of production processes.

This article is excerpted from the September 2018 issue of Automation Expo

Lecture 3: Production Management Technology in Smart Factories

Abstract: Production management is a comprehensive management activity that plans, organizes, and controls production activities. By implementing workflow technology in smart factories, various resources of enterprises, such as people, information, application tools, and business processes, can be effectively organized together, improving the reusability of manufacturing execution system software.

Keywords: Smart Factory; Production Management Technology; Manufacturing Execution System; Industrial Control System

Figure 1 shows the model of a smart factory, where production management is a comprehensive management activity that plans, organizes, and controls production activities. By reasonably organizing the production process, effectively utilizing production resources, and conducting production activities economically and rationally, the expected production goals can be achieved.

Figure 1: Smart Factory Model

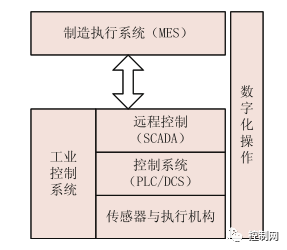

The production management technology of smart factories is mainly divided into two levels (as shown in Figure 2), namely the Manufacturing Execution System (MES) and the Industrial Control System, where MES connects the enterprise’s production planning with the industrial control system of workshop operations, while the industrial control system includes sensors and actuators (including data collectors, barcodes, various measuring and detection instruments, robotic arms, etc.), control systems (PLC/DCS), and remote control (SCADA). Additionally, digital operations are the most important manifestation of human-machine coordination in smart factories, including the latest technologies such as mobile/remote operations, augmented/virtual operations, and health/safety operations.

Figure 2: Production Management Levels

2. Manufacturing Execution System of Smart Factories

In traditional manufacturing processes, workers must report to the person in charge after completing each operation, who then assigns the next operation, leading to certain waiting times and significantly reducing production efficiency due to delays in waiting times.In smart factories, with the introduction of the Manufacturing Execution System (MES), it can intelligently navigate the manufacturing process based on the workflow and the abstract, generalized description of the business rules between its various operational steps, providing on-site operators with intuitive information on batch tasks to be executed or processed, and then managing the executed tasks through a task item list manager, ultimately allowing for the addition of new task items to the workflow task list and the deletion of completed task items based on feedback from on-site operators, a process referred to as “workflow technology.”.

The workflow technology of the Manufacturing Execution System is a technique that effectively controls and coordinates the execution of complex activities, enabling interaction between on-site operators and management application software such as ERP. By adopting workflow technology, the business logic of MES can be separated from specific business implementations. This method has significant advantages in practical enterprise applications, namely, it can change system functions or improve system performance by modifying or redefining process models without modifying hardware environments, operating systems, database systems, programming languages, application development tools, user interfaces, or other specific functional module implementation methods.

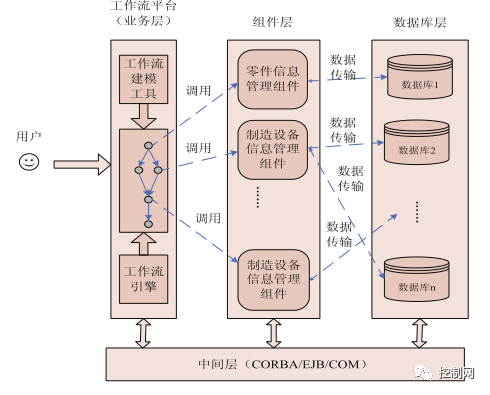

As shown in Figure 3, the MES development process based on workflow separates the business process logic of MES from specific business implementations, extracts atomic-level enterprise business activities, and uses components to implement these atomic activities, driven by business process models to run these activities, achieving comprehensive integration of enterprise business and software implementation.

Figure 3: MES Development Process Based on Workflow

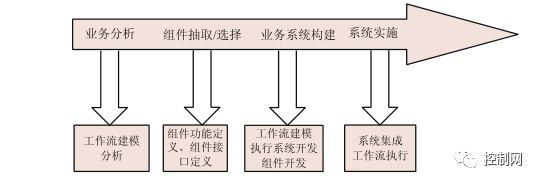

In the MES system, workflow technology can be used to design and establish a workflow environment to support the analysis of business processes in factory production management, extraction of business components, construction of business systems, and execution of business systems, as shown in Figure 4.

Figure 4: Establishment Process of MES Based on Workflow

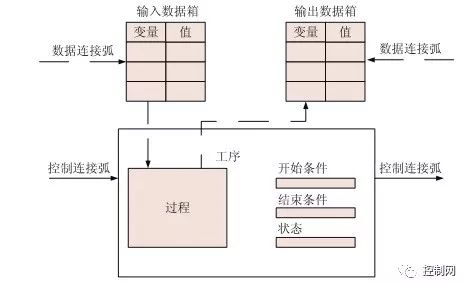

The basic unit of the MES workflow is the process, where each process’s data includes start conditions, end conditions, status, and processing data. For the information transfer between processes, control connection arcs and data connection arcs are used. Figure 5 shows the internal structure diagram of the MES process.

Figure 5: Internal Structure Diagram of the Manufacturing Execution System

In actual workshop processing, when on-site operators log into the Manufacturing Execution System, the workflow engine first reads the corresponding task list for the equipment from the task list and displays it on the equipment’s display screen, which also includes the processing data required for the operation to guide workers in processing. When a process is completed, based on the process definitions and workflow-related data, the task list obtains relevant information from the operators to update the task items in the task list and uses the workflow engine to obtain the next process and its assigned equipment for the relevant workers, refreshing the operator’s client task list in real-time to notify the operator to process and provide the necessary process documentation and processing data.

3. Industrial Control System of Smart Factories

Smart factories are based on the core of traditional industrial control systems, especially upgraded and transformed from PLC/DCS.PLC/DCS has powerful industrial control programming capabilities, and with the emergence of fieldbus technology, independent PLC/DCS systems are no longer information islands. With the development of technology, real-time Ethernet technology has gradually become an option for industrial control systems, and even within real-time Ethernet products, support for fieldbuses such as CANOpen has been achieved. At the same time, due to the continuous improvement of the computing power of industrial control systems, the capabilities and demands for data exchange are also continuously increasing.

With the emergence of IoT platforms in smart factories, the boundaries between the control layer where industrial control systems (especially PLCs) reside and the management layer of MES systems are no longer so distinct. In this data-driven era, industrial information or product data is the greatest wealth of enterprises; technological innovation cannot solely rely on customer satisfaction; more feedback must come from data, such as whether program execution is smooth and the impact of application scenarios on equipment.

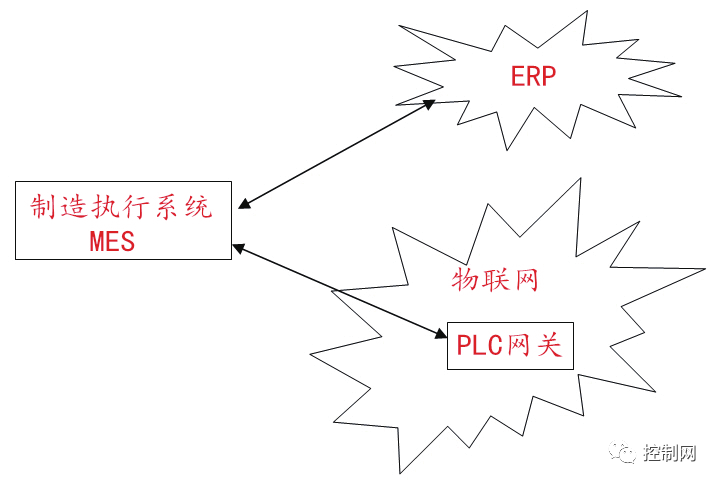

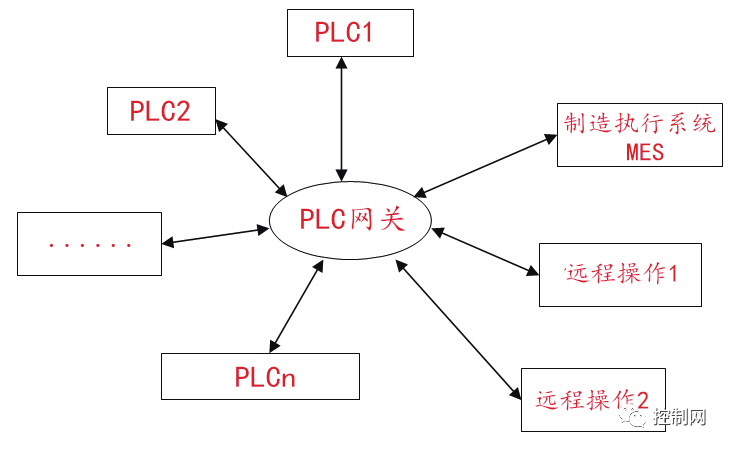

Figure 6 shows the topology diagram of industrial control systems. In addition to automatically running according to device application programs, PLCs and other control systems can also aggregate data with IoT platforms through PLC gateways and exchange data with MES systems, transmitting basic parameters such as equipment operating time and product quantity in real-time to the MES system, establishing a star topology connection with management application software such as ERP through the MES system, as shown in Figure 7.

Figure 6: Topology Diagram of Industrial Control Systems

Figure 7: PLC Gateway Topology Diagram

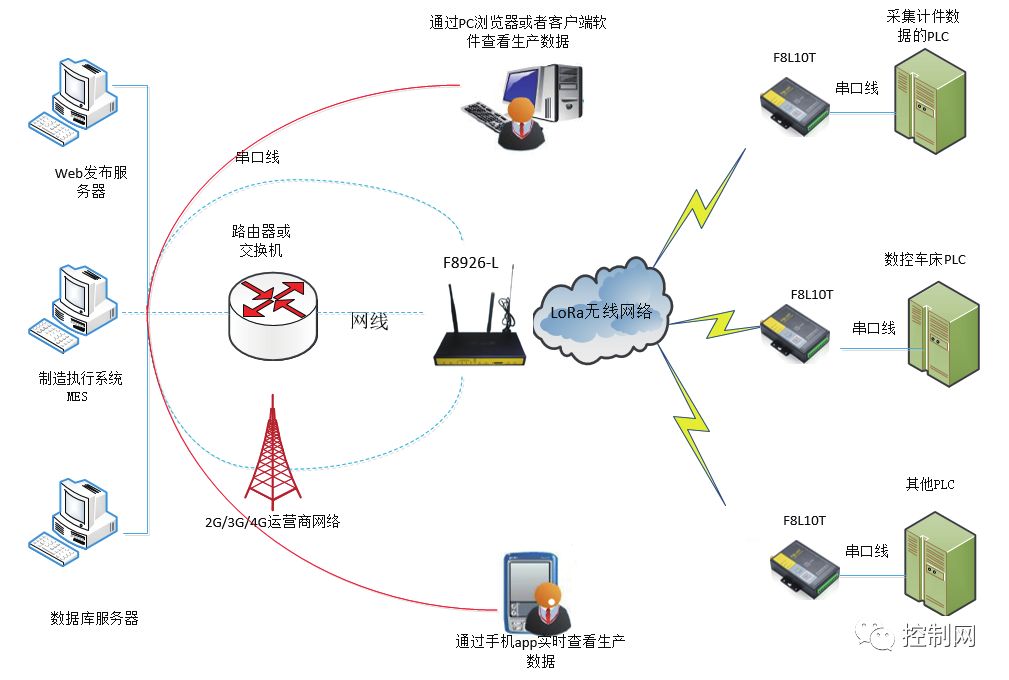

Figure 8 is the solution topology diagram for intelligent piece management and production line equipment monitoring in factory workshops, enabling intelligent management of multiple production workshops. When production data is aggregated into the Manufacturing Execution System (MES), it can be viewed in real-time on the local server and corresponding mobile apps and web servers can be developed, allowing personnel to manage remotely, even when away from the site.

The system’s working process is as follows: The LoRa module, as the core device of the IoT platform, collects counting data from PLCs, CNC lathe PLCs, and other PLCs, establishing a wireless connection with the LoRa IoT network through F8L10T. The LoRa IoT aggregates production-related data into the Manufacturing Execution System (MES) via the F8926-L gateway through 3G/4G networks and other means using TCP/IP protocols. The web platform is deployed on the server, allowing managers to log in to the server via a browser to view production data, monitor production capacity in real-time, and manage scientifically; at the same time, corresponding mobile apps can be developed to connect to the server, downloading production data from the server, allowing for convenient and quick office work anytime and anywhere.

Figure 8: Solution Topology Diagram

By implementing workflow technology in smart factories, various resources of enterprises, such as people, information, application tools, and business processes, can be effectively organized together, improving the reusability of manufacturing execution system software. The workflow-based MES system can also flexibly collect various on-site data from industrial control systems through the IoT platform and process the data by redefining processes and building systems, maximizing the efficiency of smart factories.

(b) Simulation Process

(b) Simulation Process