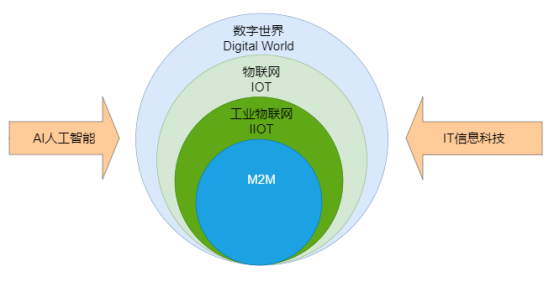

In today’s rapidly advancing technology landscape, the terms Internet of Things (IoT) and Industrial Internet of Things (IIoT) frequently appear in our discussions. They sound quite similar, like a pair of “twin brothers,” but in reality, they each possess unique “personalities” and “missions.” Today, let us clear the fog and delve into the mysteries of these two concepts.

Concept Origins: The Evolution from Connectivity to Intelligence

The Internet of Things, simply put, is a network that connects any object to the internet through various information sensing devices, such as sensors, Radio Frequency Identification (RFID), and Global Positioning Systems (GPS), enabling information exchange and communication for intelligent identification, location, tracking, monitoring, and management. Its emergence has made our lives more convenient. Imagine, in the morning, smart curtains automatically open with the sunlight, smart speakers play your favorite music, and smart air conditioners adjust according to indoor temperature—these are vivid manifestations of IoT in our daily lives. It is based on the internet, with “perception” at its core, tightly connecting people with objects and objects with each other, making our interaction with the surrounding world easier and more natural.

The Industrial Internet of Things, on the other hand, is a deeper application of IoT technology in the industrial sector, a subset of the “internet,” and a key player in “industrial management.” It connects all industrial assets, including machines, control systems, information systems, and business processes, aiming to achieve intelligent collaboration among vast industrial entities. If IoT enhances our lives, then IIoT equips industrial production with a “smart brain,” transforming the nature of industrial production and realizing the intelligent development of industrial entities, which is an inevitable requirement for smart manufacturing.

Conceptual Differences: Competitors on Different Tracks

1. Service Type: Human-Centric vs. Production-Centric

The IoT primarily revolves around human life, centering on people. The interaction between “things” is aimed at enhancing human perception and response to the surrounding environment, facilitating daily life. Common communication methods include machine-to-user communication and client-server interaction. For example, remotely controlling a smart camera at home via a mobile app is a typical case of machine-to-user communication; similarly, a smart watch uploads our health data to a cloud server for us to analyze at any time, which falls under client-server interaction.

The communication in IIoT, however, is machine-oriented, spanning various industrial markets and application scenarios. It focuses on optimizing industrial production processes, such as real-time monitoring of factory production processes, collecting operational data from equipment through numerous sensors, promptly identifying anomalies, and making adjustments; it also involves creating automated industrial factories to achieve automation and intelligence in production processes, reducing human intervention, and improving production efficiency and product quality.

2. Connected Devices: Diverse and Flexible vs. Professional and Stable

The devices connected by IoT are rich and varied, covering consumer electronics, smart homes, wearable devices, etc., emphasizing a flexible and user-friendly approach to integrating new devices into the internet ecosystem. The network structure of these devices is relatively flexible, supporting temporary mobile networks like Bluetooth and WiFi, with lower real-time requirements (except in special scenarios like medical applications). For instance, a smart bracelet connects to a smartphone via Bluetooth to transmit exercise data, allowing for relatively free connection within a certain range.

In contrast, IIoT primarily connects fixed industrial devices, such as sensors, Programmable Logic Controllers (PLCs), and industrial robots. These devices require connection through highly reliable, low-latency networks, such as 5G and industrial Ethernet, to ensure real-time and stable data transmission. In industrial production, any delay or interruption in data transmission can lead to production accidents or significant economic losses.

3. Data Volume and Processing: Moderate Scale vs. Massive Complexity

The data generated by IoT is relatively moderate, mainly used for user behavior analysis, environmental monitoring, etc. For example, a smart trash can counts the daily amount of garbage disposed of, providing a reference for waste collection; smart streetlights automatically adjust brightness based on ambient light, generating limited data with relatively simple processing.

In contrast, IIoT generates massive amounts of data during operation, as industrial production involves numerous links and devices, each continuously producing data. This data needs to be processed deeply using big data analysis and artificial intelligence technologies to optimize industrial decision-making, such as equipment fault prediction and energy efficiency management. For instance, equipment in a large factory generates a vast amount of data daily, and through data analysis, potential equipment failures can be predicted, allowing for maintenance to avoid losses caused by downtime.

Architecture Unveiled: The “Skeletal Framework” of IIoT

The architecture of IIoT can be interpreted from different perspectives, with various levels of classification, but all closely revolve around industrial production needs. The architecture based on system concepts is divided into physical, communication, and application layers. The physical layer consists of physical entities such as sensors, actuators, and manufacturing equipment, acting as the “tentacles” of industrial production, collecting environmental data like temperature, pressure, and vibration in real-time and executing control commands. The communication layer integrates various communication technologies, serving as the “highway” for data transmission, ensuring efficient data transfer and protocol adaptation. The application layer encompasses industrial applications such as smart factories and supply chain management, providing production decision support through data analysis and algorithm optimization.

Additionally, there are service-oriented IoT architectures and cloud-based IIoT infrastructures, which provide support for the operation and development of IIoT from different dimensions, addressing issues like device interoperability, data management, and service deployment.

Application Value: Moving Towards a Smart New Era

The Industrial Internet of Things has extensive applications across various fields, including energy, transportation, mining, food supply chains, and health services. In smart grids, it aids in monitoring electricity production, transmission, and distribution, optimizing power resource allocation; in transportation and logistics, it enables real-time monitoring and intelligent scheduling of goods transport; in mining safety, it ensures miner safety by monitoring disaster signals; in food supply chains, it tracks the entire process of food to ensure safety. As technology continues to advance, both IoT and IIoT will further integrate with technologies such as artificial intelligence, blockchain, and digital twins. In the future, IoT will make our lives smarter and more convenient, while IIoT will drive industrial production towards a more efficient, safe, and sustainable direction, collectively creating more value for human society and opening the door to a smart new era.