The following is a complete implementation plan for integrating industrial gateways with RFID technology to achieve IoT data collection, covering hardware selection, software architecture, implementation steps, and typical cases, applicable to scenarios such as smart manufacturing, warehousing logistics, and asset tracking:

1. Core Architecture and Technology Selection

1. System Architecture Diagram

graph TD

A[Industrial Gateway] --> B[RFID Reader]

B --> C[Electronic Tag (RFID Tag)]

A --> D[Edge Computing Module]

D --> E[Data Cleaning/Deduplication]

A --> F[Cloud Platform (e.g., Alibaba Cloud IoT)]

F --> G[Data Storage (Time Series Database/Graph Database)]

F --> H[Visualization Dashboard (Asset Location/Status Monitoring)]

C --> B

2. Hardware Selection Guide

| Component | Selection Points | Typical Products | Cost Range |

|---|---|---|---|

| Industrial Gateway | Supports RFID protocols (ISO 18000-6C/7), multiple communication interfaces (RS485/Ethernet/4G), edge computing capabilities | Advantech UNO-2483G (supports Modbus to MQTT) | 80,000-150,000 CNY |

| RFID Reader | Frequency band selection (UHF for bulk reading, HF for high precision), reading distance (0.1-10 meters) | Zebra Technologies RFD900 (UHF, reading distance 8 meters) | 100,000-300,000 CNY |

| Electronic Tag | Material compatibility (anti-metal tags, flexible tags), lifespan (active tags 3-5 years, passive tags 10+ years) | Impinj Monza R6 (passive UHF tag) | 0.5-5 CNY/tag |

| Antenna | Directional/omnidirectional antenna selection (directional for warehouse shelves, omnidirectional for open spaces) | Avery Dennison 9662 antenna (gain 8dBi) | 2,000-5,000 CNY |

2. Key Technology Implementation

1. Protocol Parsing and Data Collection

-

RFID Protocol AdaptationThe industrial gateway connects to the RFID reader via TCP/UDP, parsing raw data (such as EPC code, signal strength RSSI), supporting mainstream protocols:

# Pseudocode: Modbus RTU to JSON data def parse_rfid_data(raw_data): epc = raw_data[4:12] # Extract EPC code (8 bytes) rssi = int.from_bytes(raw_data[12:14], byteorder='big', signed=True) # Signal strength timestamp = datetime.now().isoformat() return { "device_id": "Reader_01", "tag_epc": epc, "rssi": rssi, "timestamp": timestamp } -

Anti-Collision AlgorithmUses ALOHA or binary tree algorithms to handle multi-tag recognition conflicts, improving batch reading efficiency (a single reader with a single antenna can read 50+ tags simultaneously).

2. Edge Computing and Data Preprocessing

-

Data DeduplicationReduces invalid data by using EPC code + time window (e.g., filtering duplicate data within 5 seconds), lowering cloud transmission pressure:

# In-memory deduplication cache class DataDeduplicator: def __init__(self, window=5): self.cache = set() self.window = window # Time window (seconds) def process(self, epc, timestamp): now = time.time() # Clear expired data self.cache = {item for item in self.cache if now - item[1] < self.window} if epc not in [item[0] for item in self.cache]: self.cache.add((epc, now)) return True # New data return False # Duplicate data -

Status JudgmentDetermines tag status based on RSSI value (e.g., triggering an alarm when an asset leaves a predefined area):

<span>if rssi < -70 dBm: send "Tag Lost" event</span>

3. Cloud Integration and Application Development

-

Data Upload ProtocolSupports MQTT/HTTP protocols to upload cleaned data to the cloud, example MQTT message body:

{ "device": "gateway_001", "tag_info": { "epc": "3012A80004123456", "location": "Warehouse_A_007", // Generated by positioning algorithm "status": "normal", "read_time": "2024-10-01T14:30:00Z" } } -

Visualization DashboardUses ECharts/Grafana to implement asset location heat maps, real-time read/write log monitoring, supporting drill-down queries (clicking on a tag to view historical trajectory).

3. Implementation Steps and Key Points

1. On-Site Survey and Deployment Planning

-

Environmental Assessment

- Metal Environment: Use anti-metal tags (e.g., Avery Dennison 9D31), keep the reader antenna at least 10cm away from metal surfaces.

- High Humidity Environment: Choose IP67 rated waterproof readers (e.g., Datalogic FM3000).

-

Layout Design

- Warehouse Shelves: Install one directional antenna every 2 meters, covering 3-5 layers of shelves, ensuring a tag reading rate of ≥99%.

- Production Line Workstations: Deploy fixed readers at assembly nodes, combined with PLC systems to achieve production progress tracking.

2. Gateway Configuration and Joint Debugging

-

Parameter Settings

- Reader Power: Adjust according to the scenario (warehouse 8dBm, production line 5dBm to avoid adjacent interference).

- Reading Interval: Set to 500ms for high-frequency scenarios (e.g., assembly line), 10 seconds for low-frequency scenarios (e.g., inventory counting).

-

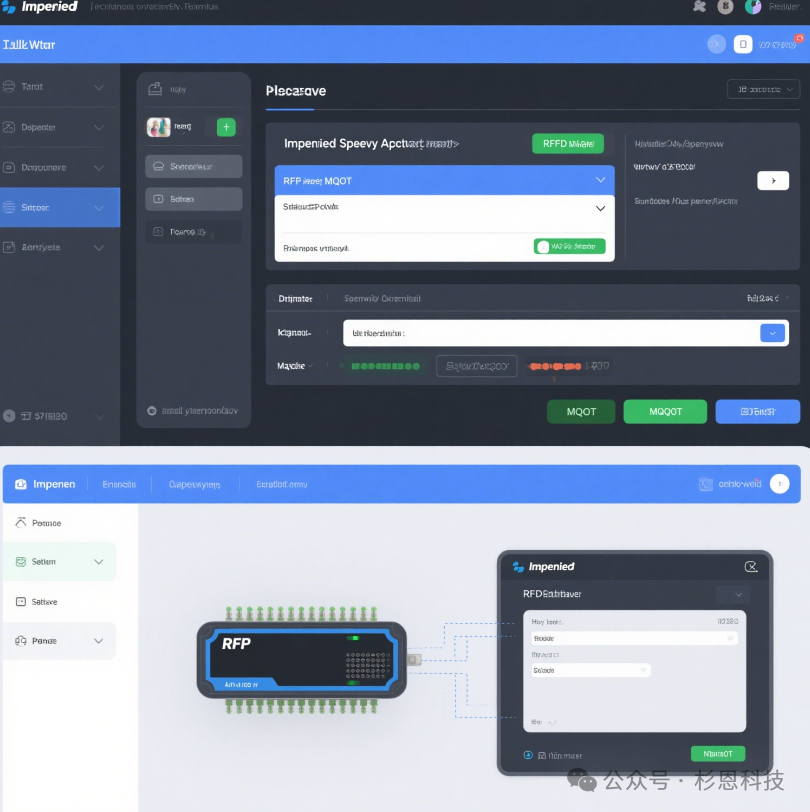

Protocol ConversionConvert the private protocol of the RFID reader (e.g., Impinj Speedway protocol) to standard MQTT protocol through the industrial gateway, example configuration interface:

3. Data Security and Reliability

-

Device AuthenticationUse digital certificates for mutual authentication of gateways and readers to prevent unauthorized device access:

# Generate device certificate (Openssl example) openssl req -new -x509 -keyout device.key -out device.crt -days 365 -

Data EncryptionUse TLS 1.3 encryption for the transport layer, and AES-256 encryption for sensitive data (e.g., EPC and asset association).

4. Typical Application Scenarios

1. Smart Warehouse Management

-

Inbound ProcessWhen a forklift passes through the inbound gate, the gateway reads the goods’ tags in bulk (reading 50+ tags at once), automatically generating an inbound order, improving efficiency by 60%.

-

Inventory OptimizationHandheld terminals (integrated RFID module + industrial gateway) scan shelves, completing inventory of 1,000+ goods within 10 minutes, reducing the error rate from 3% in manual inventory to 0.1%.

2. Production Manufacturing Traceability

-

Production Line MonitoringDeploy readers in the SMT placement process to track PCB board flow in real-time, binding and storing process parameters (e.g., soldering temperature) with product IDs in the MES system.

-

Quality TraceabilityWhen a product fails inspection, trace back through the knowledge graph (e.g., Neo4j):

<span>Product ID → Production Station → Operator → Raw Material Batch → Quality Inspection Record</span>

3. Asset Tracking Management

-

Medical Equipment ManagementAttach active tags (3-year battery life) to MRI machines, monitoring location in real-time (accuracy 3 meters) through the gateway, solving the problem of locating equipment and reducing manual inspection costs by 30%.

-

Logistics Container MonitoringInstall RFID sensors on container door locks, triggering the gateway to send alarm information when opened, combined with GPS positioning for full anti-theft tracking.

5. Risk Control and Optimization

1. Common Problem Solutions

| Problem | Cause | Solution |

|---|---|---|

| High Tag Miss Rate | Improper antenna layout | Use RFID simulation software (e.g., EMPro) to optimize antenna positions, increase redundant readers |

| Data Delay Exceeds 5 Seconds | High load on gateway edge computing | Upgrade gateway hardware (e.g., add NPU chip), optimize deduplication algorithm |

| Duplicate Tag IDs Across Gateways | Lack of global ID allocation rules | Use “Gateway ID + Tag EPC” combination to generate globally unique identifiers |

2. Performance Optimization Metrics

- Reading Efficiency: A single gateway with a single reader supports real-time collection of 200+ tags/second (UHF scenarios).

- Data Accuracy: Through anti-collision algorithms + deduplication strategies, effective data ratio ≥98%.

- Response Time: Tag status change to cloud alarm ≤2 seconds (4G network environment).

6. Cost Budget and Cycle

1. Cost Composition (Example for 10,000 Square Meter Warehouse)

| Item | Cost | Proportion |

|---|---|---|

| Hardware Equipment (Gateway + Reader + Tags) | 500,000-800,000 CNY | 60% |

| Software Development (Gateway Configuration + Cloud Platform) | 200,000-300,000 CNY | 25% |

| Implementation and Training | 100,000-150,000 CNY | 15% |

2. Implementation Cycle

- Requirement Analysis: 2-4 weeks

- Solution Design: 3-5 weeks

- Hardware Deployment: 4-6 weeks

- Joint Debugging and Optimization: 2-3 weeks

- Acceptance and Delivery: 1-2 weeks

7. Conclusion

The integration plan of industrial gateways and RFID achieves efficient connection between the physical and digital worlds through the “edge collection + cloud application” model, with core values in:

- Efficiency Improvement: Automation of data collection, reducing manual intervention (e.g., warehouse inventory time shortened by 70%).

- Precise Traceability: Full-link asset tracking, supporting rapid location of quality issues (traceability time reduced from hours to minutes).

- Decision Support: Real-time data drives inventory management and production scheduling optimization, reducing stagnant inventory costs by 30%.

Through standardized hardware selection, modular software design, and scenario-based implementation strategies, this plan can be quickly replicated across different industrial scenarios, becoming the core infrastructure for enterprise digital transformation.