☞ This is the 13237th article published by Metal Processing (mw1950pub).

☞ This is the 13237th article published by Metal Processing (mw1950pub).

Editor’s Note

Academician of the Chinese Academy of Engineering, and head of the 04 Special Project Group, Lu Bingheng, emphasized sternly at the Fifth World Intelligence Conference: “Producing machine tools like producing cars is absolutely wrong!” He also stated that there is still a certain gap in the processing efficiency, dynamic accuracy, and advanced levels of high-end CNC machine tools, and this area needs to strengthen basic research, including the deep development of machine tool dynamics, electromechanical control, servo systems, and intelligent control systems. He noted that intelligent control is an important means to solve these problems and is the main route, which will be our future focus.“

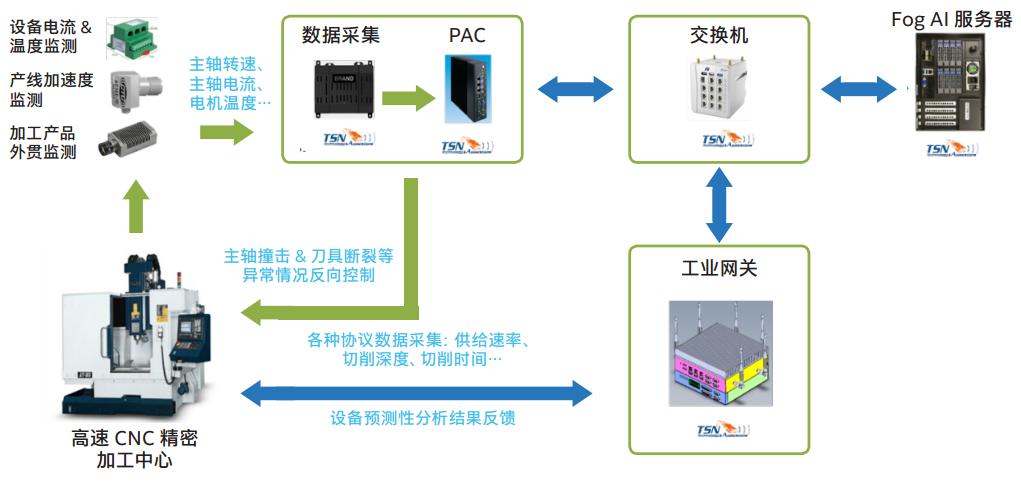

1) TSN networks, as an open protocol standard (IEEE 802.1), can eliminate compatibility issues between devices from different manufacturers, making industrial IoT connectivity more convenient and also providing advantages in data transmission bandwidth.

2) TSN networks break the boundaries between control systems and analysis systems in traditional manufacturing production lines, making it easier to deploy AI applications on the production front lines. At the same time, the priority control and data security mechanisms provided by hardware devices can ensure the high reliability required by the production line.

1、2Data sources are from internal tests, evaluations, and validations of Industrial Fulian. For details, please consult Industrial Fulian at https://www.fii-foxconn.com. Intel does not control or audit third-party data. Please review this content, consult other sources, and verify the accuracy of the mentioned data.

About Zhuoxin Chuangchi

Shenzhen Zhuoxin Chuangchi Technology Co., Ltd. (under the brand: Future Robotics) is committed to providing reliable, convenient, and cost-effective hardware and system solutions in the fields of smart manufacturing and artificial intelligence. With rich project experience and superb R&D capabilities in industrial computers, machine vision, motion control, and other fields, it is market-driven, providing a wealth of embedded products for global enterprises and individual users, applied in industrial automation, robotics, machine vision, medical applications, intelligent transportation, finance, education, and IoT fields.

About Intel

Intel (NASDAQ: INTC) as an industry leader creates technologies that change the world, driving global progress and enriching lives. Inspired by Moore’s Law, we are constantly committed to advancing semiconductor design and manufacturing, helping our customers tackle the most significant challenges. By embedding intelligence into cloud, network, edge, and various computing devices, we unlock the potential of data, making business and society better. For more information on Intel’s innovations, please visit Intel China News Center newsroom.intel.cn and the official website intel.cn.