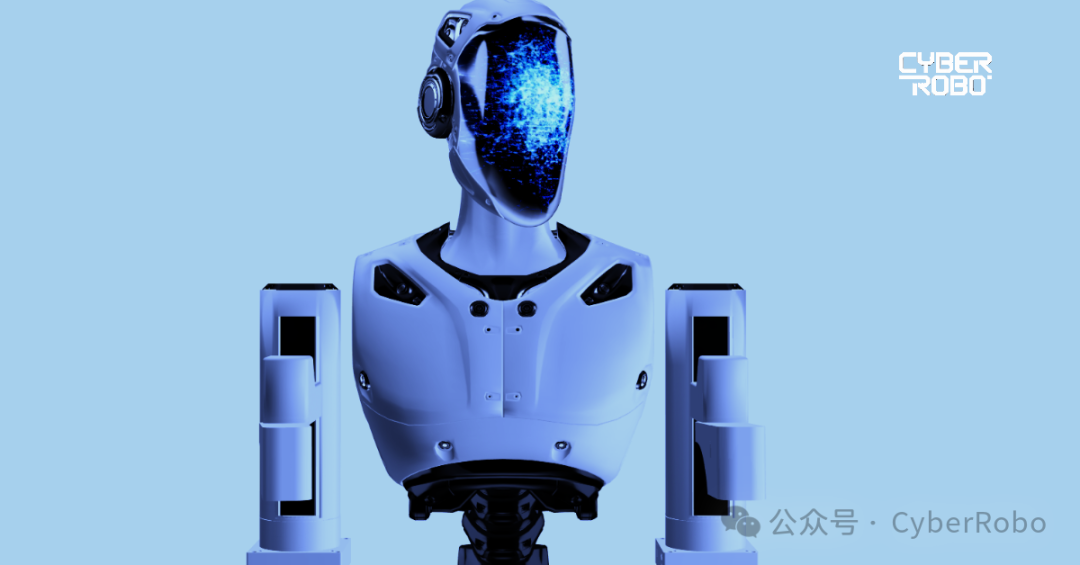

Cover: Borg 01

CyberRobo:

Note: Electromechanical integration refers to the engineering technology field that combines mechanical, electronic, computer control, and system integration technologies. By merging mechanical systems, electronic systems, and information systems, it enables devices to automatically and intelligently perform complex tasks. It is widely applied in manufacturing, automation, and robotics.

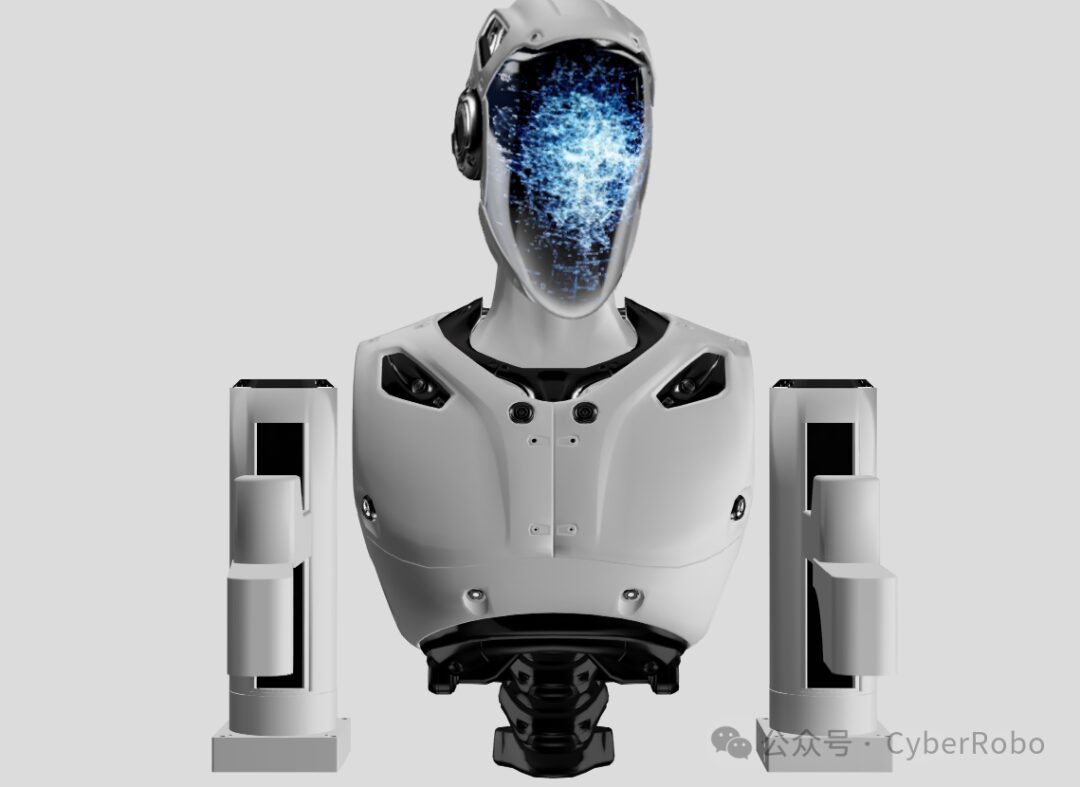

Argon One: A Half-Body AI Humanoid Robot

Argon SCARA: Collaborative Robotic Arm

One more thing

Recommended ReadingYour Humanoid Robot Encyclopedia

Finding the body, suppliers, industry belts, checking financing trends, open-source projects, all here:

-

185+ humanoid robots covering countries worldwide, multiple types and application fields

-

230+ core component manufacturers of humanoid robots globally, world models, and robotic system providers

-

49+ humanoid robot industry belts

-

85+ humanoid robot financing records (23/24 years)

-

90+ open-source humanoid robot projects

Welcome to join CyberRobo to unlock more