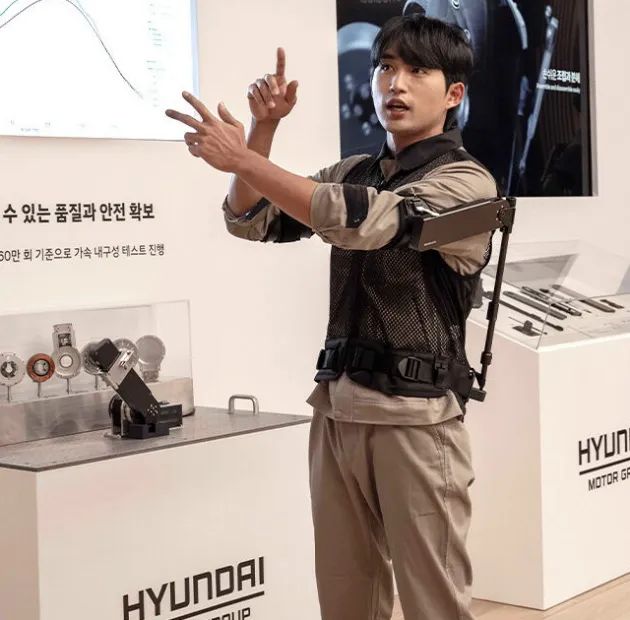

South Korean automotive manufacturer Hyundai Motor Group’s two subsidiaries—Kia Motors and Hyundai Motors—have successfully developed a mechanical exoskeleton called X-ble Shoulder, designed to enhance industrial efficiency while reducing the incidence of musculoskeletal disorders.

Operators on automotive production lines sometimes need to lift their arms high, which can place a prolonged strain on their arms and shoulders. To alleviate the impact on employees, the two companies jointly developed the X-ble Shoulder. X-ble Shoulder is lightweight due to its carbon-based composite material and does not require battery power, aiming to simplify tasks performed above head height. By optimizing the muscle strength of the upper arms, the X-ble Shoulder can reduce shoulder pressure by 60% and decrease the activity of the anterior, posterior, and lateral deltoids by 30%. It weighs approximately 1.9 kilograms and can be adjusted to fit the user’s body shape. Its length can be adjusted between 406 millimeters and 446 millimeters, ensuring complete freedom of movement for the arms from 0 to 180 degrees.

The assistive force of the X-ble Shoulder is generated by a patented multi-arm structure integrated into a muscle compensation module. Each arm of this structure can be independently adjusted to ensure optimal assistive force in different working environments. The module is designed to perform approximately 700,000 folding and unfolding operations annually in industrial settings. Its target application areas include automotive, construction, shipbuilding, aviation, and agriculture. “The X-ble Shoulder is a portable robot that fully utilizes all the technological capabilities of the robotics lab while considering real user feedback,” explained Dong Jin Hyun, Vice President and Director of the Kia and Hyundai Robotics Lab. About 300 employees and health management personnel working at Kia and Hyundai factories participated in pilot tests conducted from 2022 to 2024. Their suggestions, particularly regarding ease of operation, comfort, freedom of arm movement, assistive force adjustment, and ease of cleaning, have been incorporated into product improvements and the addition of new features.

X-ble Shoulder will first be deployed in Kia and Hyundai factories. Subsequently, starting in 2025, it will expand to 27 subsidiaries of Hyundai Motor Group and other companies within South Korea. In 2026, Kia and Hyundai plan to enter foreign markets, particularly in Europe and North America, and aim to extend sales to other fields such as construction, shipbuilding, aviation, and agriculture. The X-ble Shoulder is just the first product in the X-ble series, with X-ble being a combination of ‘X’ symbolizing infinite potential and ‘able’ as a prefix indicating capability. Previously, Kia and Hyundai released a wearable industrial robot called X-ble Waist for waist assistance in lifting heavy objects, and a wearable medical robot named X-ble MEX specifically designed to assist individuals with walking difficulties in rehabilitation training.

Disclaimer: Some articles and images in this public account are sourced from the internet, and the published articles are intended for the exchange and sharing of knowledge and market information related to composite materials, not for any commercial purposes. If any individual or organization has doubts about the copyright or the authenticity and accuracy of the content, please contact us immediately. We will address it promptly.