Once mobile devices can connect to the Industrial Internet of Things (IIoT) and access real-time production data, they can assist decision-makers when they need this information and improve factory operations.

Data collection is a crucial step in making decisions for the Industrial Internet of Things. By collecting the right data, mobile HMI solutions help bridge the gap between control systems and mobile devices that need to access this information. Once mobile devices can connect to the IIoT and access real-time production data, they can assist decision-makers when they need this information and effectively improve factory operations.

Remote HMI Applications

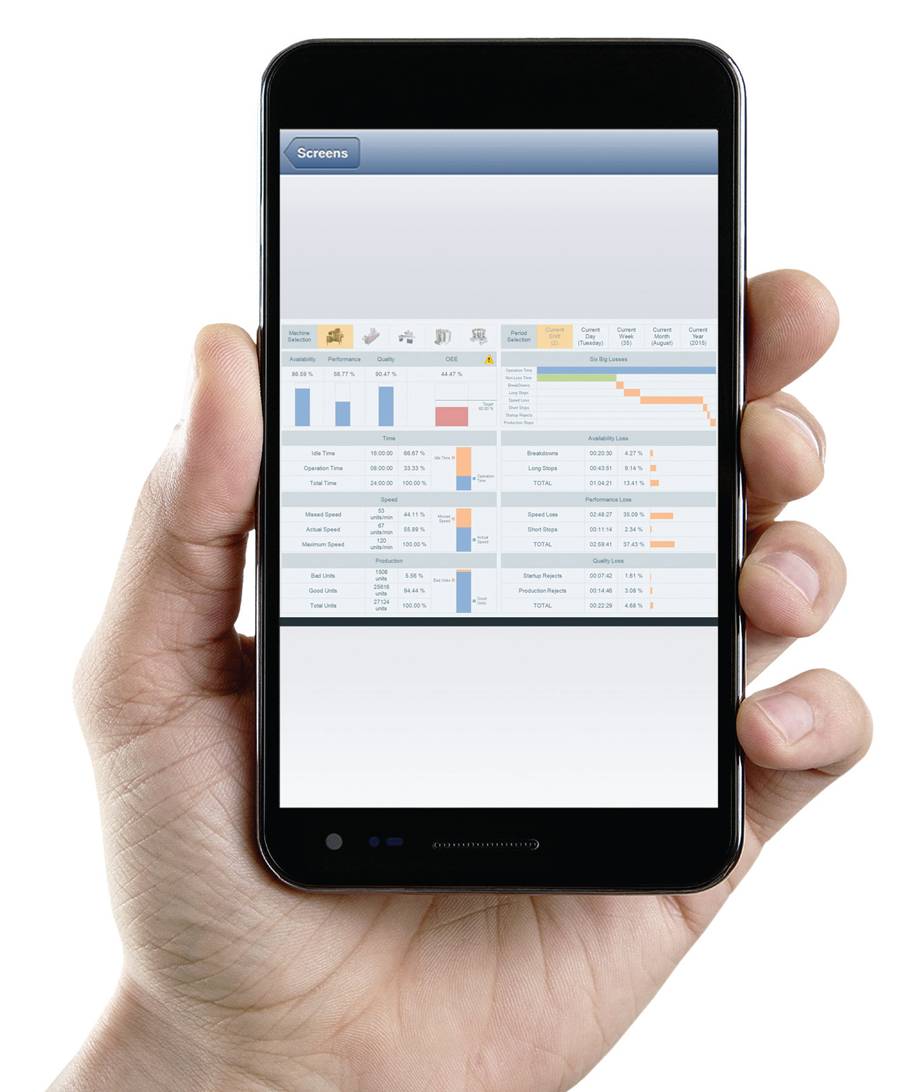

For manufacturing users, mobile HMI helps bridge the gap between control systems and mobile devices (as shown in Figure 1). Users typically need flexible and convenient access to HMI and data from mobile devices.

In the past, HMI solutions were usually developed on Microsoft Windows platforms connected to local networks, even for actual operation. However, Windows is no longer the only option; HMI can run on different operating systems and hardware platforms, leveraging their unique advantages.

Figure 1: HMI devices using software such as InduSoft Web Studio can provide real-time information to workers moving continuously within the workshop. To facilitate connection and integration with other systems, HMI can use built-in templates. Image source: InduSoft

Real-time HMI applications can be hosted in different areas, and users need to be able to download each application to different operating systems. Common operating systems for hosting real-time applications include Windows desktop operating systems, servers, and embedded versions. Frequently used platforms also include Linux, Wind River VxWorks, and others. To adapt applications to operating systems, one only needs to purchase, configure, and maintain the functionalities required for each application to obtain the most cost-effective solution. For mobile devices, it is necessary to operate on Google’s Android system, as well as Apple’s iOS and OS X, and also to run on Windows-based laptops.

Because applications can be developed on Windows PCs and then downloaded for real-time operation on different platforms and devices without modifying graphics, templates, symbols, or trends, modern HMI offers significant flexibility. This feature greatly simplifies the implementation of mobile HMI real-time applications. Mobile devices use HTML5 standards to automatically adjust HMI screens based on the screen size of the target platform. Now, real-time HMI deployed on Windows systems can be quickly accessed via mobile devices, but first, you need the right data.

Starting with Data Collection

So far, for many applications, the data required to implement a complete IIoT solution has not been provided to decision-makers. First, we need to collect data from field devices, and then pass the correct data to those who need it.

For example, an IoT application called “EcoNet Home Wi-Fi Module” allows users to track various functions of selected Rheem electric water heaters on their smartphones, such as leak detection, service diagnostics, and system status. It can serve as a remote control for Rheem water heaters. This application connects to the internet via Wi-Fi and can directly provide alerts and notifications to mobile devices, such as leak detection. Utilizing vacation mode and remote temperature adjustment features, it can also save costs. If connected to a network platform, it can also collect usage data over time.

In many cases, due to 24/7 operational requirements, network security issues, and other factors, the deployment of IIoT applications progresses much slower than similar commercial IoT applications. However, some companies have begun to offer data collection and storage services.

For instance, GE’s smart grid services integrate the functionality of collecting data using power generation and distribution system infrastructure. Theoretically, the collected data can be used to improve productivity, promote renewable energy utilization, reduce carbon emissions, enhance production efficiency, and prevent overloads and power outages. Applications like these smart grids aim to highlight the importance of real-time and historical data, thereby improving reliability and optimizing equipment, systems, and businesses.

In other manufacturing applications, data typically comes from field devices connected to industrial controllers. These controllers then connect to HMIs, which provide the data to mobile devices.

Correctly Transmitting Data

At any time and place, it is essential to transmit the correct process and equipment data to decision-makers. At this point, many mobile device users need to pay attention to the measurements or statistics of machines or processes. Using mobile devices to directly control machines is also an option, but this is typically limited to local users, such as factory operators or technicians.

Specific software and other human-machine interface software platforms offer various ways to access the data and graphics displayed on the factory floor or control room HMIs. Real-time HMI applications can be installed on office PCs, providing the same user experience, but this is often redundant. When an application, such as a secure electronic reader, is installed on a PC or connected to the local factory network and capable of hosting an internet browser, a better choice for these remote HMI applications is on-site real-time applications or thin clients. Since the factory network is already in place and has good security, this solution is highly cost-effective.

If HMI is for remote devices and deployed outside the factory, then web-based thin clients can be used. While very similar to secure reader thin clients, web-based thin clients access HMIs through a web browser using secure socket layer (SSL) and other security methods such as encryption. For obvious reasons, control functionalities of these applications should be minimized, but full browsing access is usually required.

To further extend remote information access, mobile thin clients can be used. Using HTML 5 browsers on mobile devices is a smart, cost-effective way to provide decision-makers with the information they need.

Data Management of Mobile HMI

HMI data is stored in many different locations and can be accessed remotely via mobile devices. HMI systems can store text files, spreadsheet formats, or various databases and historical databases on-site. HMI can connect to the company’s databases, or on-site historical databases, or even cloud-hosted databases for data storage and access. Then, mobile devices can connect to the data storage areas. Engineering implementation, operations, scheduling, and management personnel can view and utilize this data (see Figure 2). Other connections allow field engineers and factory floor personnel to access data via mobile devices, thin clients, or computers.

Figure 2: Mobile data visualization and access through software like Wonderware Online help make informed decisions faster.

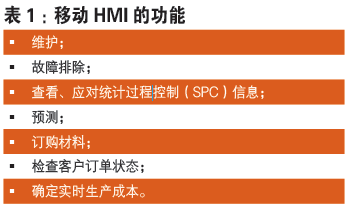

The data collected from field devices and viewed on mobile devices has many different uses (see Table 1). Some can be achieved by viewing field device data, such as maintenance and troubleshooting.

For example, statistical process control software can be installed on the same PC as HMI and can interpret field device data, providing actionable process and quality assurance information to mobile devices. SPC algorithms can help adjust real-time control parameters or alert before machines/processes start producing defects. It can also work in conjunction with data analysis and aggregation software to achieve predictive capabilities, providing this information to mobile users so they can identify and resolve issues before they arise. Other uses of data include predictive maintenance and identifying process bottlenecks.

The production data recorded in mobile HMI can be combined with inventory information obtained from enterprise resource planning (ERP) or data from manufacturing execution systems (MES) to remind mobile users of material usage, order requirements, customer order status, and real-time production costs.

Making Better Decisions

Each configured mobile HMI device can display only the data that specific users need. By only transmitting and displaying the required data, this simplifies and speeds up the response to the received information. It also provides a certain level of security, enhancing operational safety. For example, local operators can view and control permissions, while sales personnel can only access customer order information status.

Mobile HMI devices allow users to see the real-time operational status of equipment or processes, and they can focus only on the parts of interest. For example, data or process status trend charts provide a quick overview while allowing advanced users to view more detailed information when anomalies are detected.

To successfully implement IIoT systems within manufacturing enterprises, it is essential to collect the correct data and then present it appropriately to business decision-makers to improve operational activities. As more data becomes available, mobile HMI devices can provide users with clearer real-time information about equipment and processes, helping users make better production and business decisions.

This article is an original translation by CONTROL ENGINEERING China, all rights reserved; please cite the source when reposting on WeChat or online.