This article’s images are sourced from: Beckhoff

Author | Song Huazhen

The demand for control and intelligence in agricultural machinery is not any less than that in industrial applications. As agriculture moves towards automation, high-performance control systems are essential.

In China, when discussing agriculture, many people instinctively feel that automation has little place in agricultural equipment. This is because, as described in the Zhejiang and Fujian regions, “seven mountains, two waters, and one part of farmland”. Due to the limited per capita land and the small plots of land cultivated by households, machinery cannot fully demonstrate its capabilities.

However, several factors indicate that agricultural machinery still has significant development potential:

1). Agricultural machinery is not solely for personal purchase: As a service tool, agricultural machinery can also undertake large-scale operations like other engineering machinery. Villagers can pre-arrange unified operations with equipment, allowing them to work on larger plots of land.

2). Consolidation of land: Due to a lack of labor, many lands have been leased to companies investing in agriculture, allowing for relatively larger land consolidation for large-scale farming. Even in the Loess Plateau of Shaanxi, such intensive farming scenes can be observed.

3). Xinjiang Agricultural Reclamation and Northeast Plain: These are currently the main areas for large-scale agricultural equipment. In fact, regions like the Guanzhong Plain, Sichuan Basin, Hubei’s Jianghan Plain, and the North China Plain are also suitable for large-scale farming.

4). Labor costs are rising due to increasing labor costs in manufacturing, leading young labor to shift towards manufacturing. This will inevitably increase the cost of hiring temporary labor in rural areas, ultimately pushing agricultural operations towards scaling up in the future.

Based on this, large-scale joint operations and more intelligent agricultural machinery will find their place, and automation will have room to play.

01

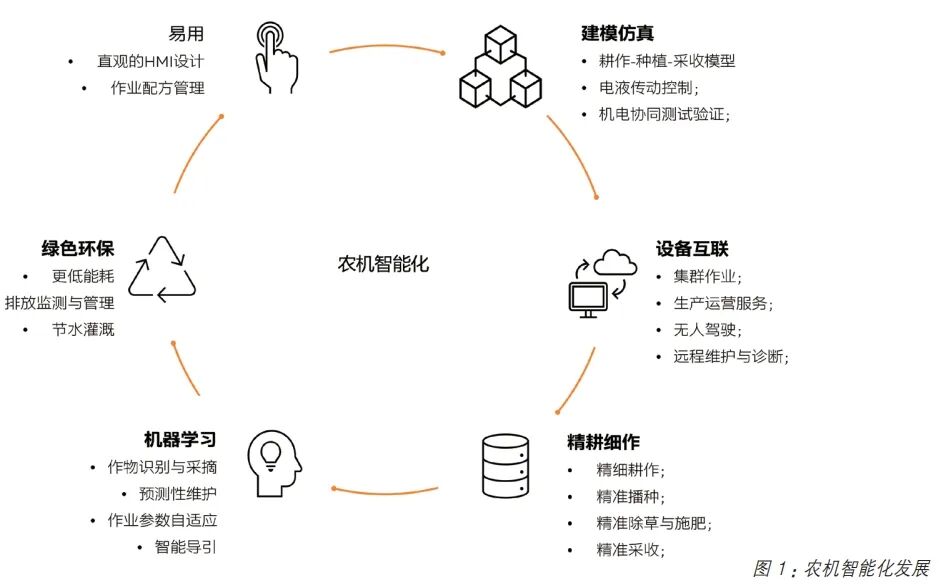

Smart agriculture demands high standards for intelligent control

In fact, the demand for control and intelligence in agricultural machinery is not any less than that in industrial applications. Agricultural intelligence involves managing the entire lifecycle of “tilling – planting – managing – harvesting”. The upstream connects resource ends (seeds, fertilizers, irrigation, pesticides), the midstream involves land tilling, sowing, fertilizing, weeding, harvesting, and the downstream includes agricultural product processing and logistics. As a part of this chain, agricultural machinery must be able to produce efficiently. Most agricultural operations have a “window period”, which often requires efficient execution. Figure 1 shows several development directions for agricultural machinery intelligence, which also needs to leverage digital capabilities for enhancement.

1). Modeling and simulation: Agricultural machinery also has an urgent need for intelligence. Take planting operations as an example. Soil moisture, humidity, required tilling depth, sowing spacing, and fertilization amounts need to be configured, and parameters such as engine horsepower output and working angles of the equipment also need to be matched; otherwise, it will not achieve tilling results with low energy consumption.

During the harvesting phase, similar considerations apply regarding crop spacing, height, crop types, and maturity stages, requiring appropriate parameter and power output matching, including direct counting, classification, and packaging.

All these aspects of agricultural machinery’s power transmission, hydraulic drive systems, sensors, and mechanical structures need to be designed accordingly, which also requires physical modeling and virtual testing and validation to design efficient working machines. Agricultural machinery is not just brute force work; it requires a clever, efficient, and energy-saving approach to operations.

2). Equipment interconnectivity: Since agriculture has adopted a leasing service model, it is necessary to effectively schedule and allocate the use of agricultural machinery based on production needs and monitor operational progress in real-time to achieve minimal time granularity in production scheduling. At the same time, these production operation data will also be linked to agricultural product acquisition and processing to achieve rapid intensive processing.

3). Demand for precision farming: After modeling the machinery, real-time sampling will occur on-site, providing decision support to operators, such as adjusting working depth and parameters based on feedback data. Fertilization will also be better measured and precisely targeted to the required parts of the crops, avoiding waste and ineffective application of fertilizers. Precision harvesting requires matching appropriate harvesting parameters based on the specifications of different production areas to achieve accurate collection.

4). Machine learning: For crops like cotton and fruits, it is necessary to directly locate the crops and learn their maturity (for example, the maturity of apples and peaches determines whether they should be harvested) and can directly classify them online (images can determine the quality of apples; larger apples have higher prices). All these require machine learning methods for judgment and decision-making.

5). Energy conservation and environmental protection: Appropriate operations will be more energy-efficient—achieving operational efficiency with lower fuel consumption. Irrigation will also save water—based on production conditions for water scheduling and distribution—this also requires digital support.

6). Usability: Agricultural machinery operators do not need to master complex professional knowledge but should be able to operate the machines more simply. The machines need to be easy to learn, easy to operate, and capable of providing intuitive alarm prompts and operational support.

In terms of fine tillage, intelligent facilities, intelligent processing of agricultural products, and intelligent information services, there is a need to improve the level of agricultural automation. This requires not only automated control but also data-based collaboration, scheduling, and services for the entire data chain from tillage to final sales, maximizing the development of agricultural economic output.

02

Harsh working conditions for agricultural equipment

The control requirements for agricultural machinery differ significantly from industrial ones, primarily due to the complexity and harshness of their working conditions. In northern winters, temperatures can drop to -30°C, while summers often reach 40°C. In the south, high temperatures are accompanied by high humidity. Coastal areas are also subject to potential salt mist corrosion. The harsh environments faced by these controllers include vibration, condensation, impact, oil contamination, and water. Therefore, the control systems must have a very high tolerance.

However, this does not affect the operation of Beckhoff’s X90 embedded controller. Various complex conditions that ordinary controllers cannot handle are precisely what the X90 is designed for. It must withstand the vibrations, dust, and other harsh environments found in agricultural settings.

It is a controller designed for machines in environments such as engineering, mining, and agriculture: it has 48 I/O channels, which are interchangeable, and both input and output can be configured; it comes standard with three CAN ports, using the SAE J 1939 protocol, and also supports ISOBUS in agricultural machinery; it uses an ARM processor, capable of supporting millisecond-level tasks; it features USB ports, fast Ethernet, and POWERLINK real-time Ethernet interfaces. It is also integrated with Beckhoff’s Automation Studio for programming, allowing algorithms and logic tasks to be written in high-level languages, hydraulic libraries to be called, and intelligent algorithms specifically designed for agricultural machinery to be developed.

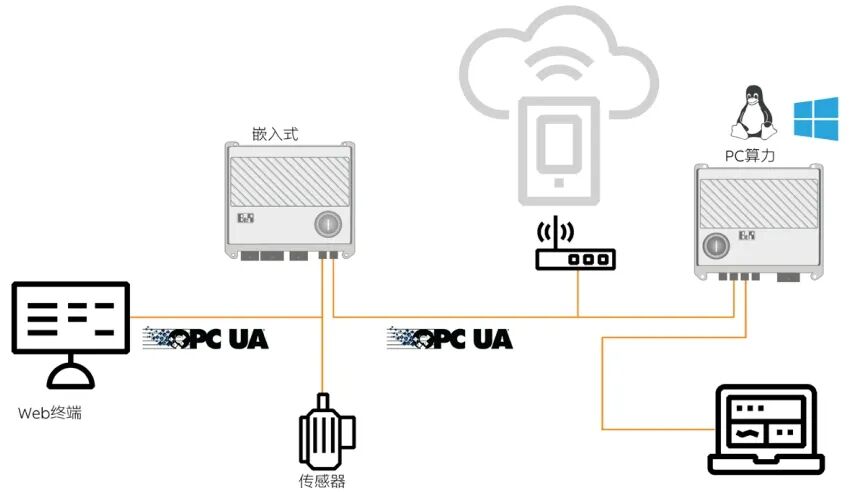

In 2022, Beckhoff also launched the Automation PC Mobile 3100 (referred to as APC Mobile 3100), which is based on the Intel Core i7 processor. As shown in Figure 2, the controller has a clock speed of up to 2.8GHz. Unlike the X90, it is a controller that uses hypervisor technology, supporting both Linux/Windows open operating systems and real-time operating systems (RTOS) to run simultaneously. This means it can handle tasks with greater computational demands, such as model execution, graphics processing, and intelligent analysis.

▲Figure 2: Automation PC Mobile 3100 Controller

03

Control and interconnectivity of agricultural machinery

In Figure 3, we can see that using controllers like the X90 or Mobile PC 3100, it can connect to operators, display terminals, hydraulic mechanisms, engines, speed/vibration, wind direction, temperature, and other sensors, forming a complete operational equipment or joint equipment. At the same time, through wireless networks, these operational data will be aggregated into production management systems, serving as the basis for production scheduling and collaboration.

▲Figure 3: Beckhoff Agricultural Machinery Controller Architecture

Using web technology terminals for HMI interaction can also be designed as stylish as your smartphone (Figure 4). In fact, whether it is stylish or not is not important; what matters most for agricultural machinery is “ease of operation” and “sufficient brightness”. Beckhoff’s Power Panel T series utilizes web technology to achieve the “intuitive graphical display” required for agricultural machinery, using IT controls to express machine interactions intuitively. Additionally, agricultural machinery typically operates under direct sunlight, so the screen needs to be bright enough to be visible even in strong light. This HMI also has a significant appeal for agricultural machinery as it can operate normally at -30°C, meaning it can work in extremely cold regions like the Northeast and Northwest.

▲Figure 4: Beckhoff T50 Series HMI

04

Protocols Developed Specifically for Agricultural Machinery

ISOBUS is a protocol based on CAN communication that allows machines from different manufacturers to exchange data. As a member of the Agricultural Electronics Foundation (AEF), Beckhoff provides connectivity for the industry through the new ISOBUS protocol.

The ISOBUS protocol covers connections between terminals, auxiliary controls, task controllers (geolocation), task controller partition control, and the ECU of basic tractors. Beckhoff is also a member of AEF, CiA, AEM, and VDMA alliances, which aim to establish communication protocols between agricultural machinery.

As agriculture moves towards intelligence, it requires high-performance control systems to support this transition.

Key Concepts:

■ The demand for control and intelligence in agricultural machinery is not any less than that in industrial applications.

■ The development of agricultural machinery intelligence also requires leveraging digital capabilities for enhancement.

Consider this:

What key development directions should be prioritized for agricultural machinery intelligence?

– END –

▲This article is from the September 2023 issue of CONTROL ENGINEERING China magazine, focusing on automation: Moving Towards Smart Agriculture, High-Performance Agricultural Machinery Control

✦

Recommended Reading

✦