1What is ECU?

ECU (Electronic Control Unit), also known as “vehicle computer” or “on-board computer”, is a dedicated microcontroller for automotive applications. It consists of a microprocessor (MCU), memory (ROM, RAM), input/output interfaces (I/O), analog-to-digital converters (A/D), and large-scale integrated circuits for shaping and driving, similar to a regular computer.

It is also easily recognizable in appearance—there is a control component resembling a square box in the engine’s electronic fuel injection system, which is the ECU. The component is surrounded by many fine slots for connecting numerous input and output circuits, forming the brain and nerve center of the vehicle, constantly monitoring various input data (such as braking, gear shifting, etc.) and the operational status of the vehicle (acceleration, skidding, fuel consumption, etc.), and calculating the information sent by various sensors according to pre-designed programs. After processing, it sends various parameters to the relevant actuators to execute various predetermined control functions.

Figure 1

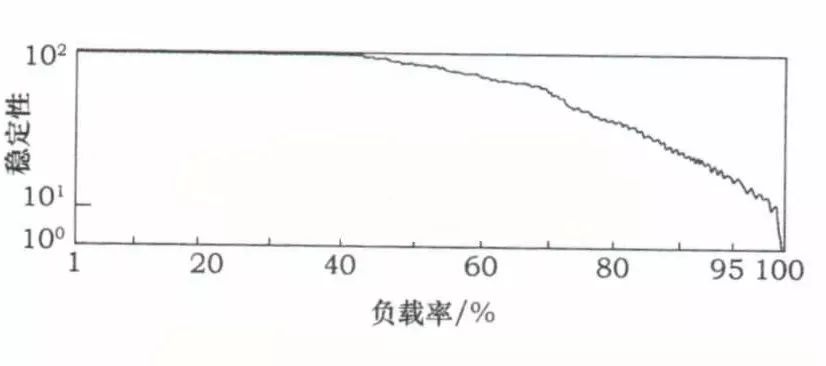

2Analysis of the Impact of Bus Load Rate on Transmission Stability

With the continuous improvement of driving performance and safety levels, the demand for precise signal acquisition and execution from various electronic control systems has increased, leading to a growing amount of information exchanged between ECUs, an increasing number of messages, and a rising load. Generally, to ensure that the transmission delay of low-priority messages remains within an acceptable time frame, the bus utilization should not exceed 30%. When the load rate exceeds 38% to 40%, stability begins to degrade; beyond 55%, there are risks affecting drivability and safety, and when it exceeds 65%, stability degradation intensifies. If it exceeds 98%, the network will be overwhelmed, as shown in Figure 2.

Figure 2

3Impact of High Load Rate on the Bus

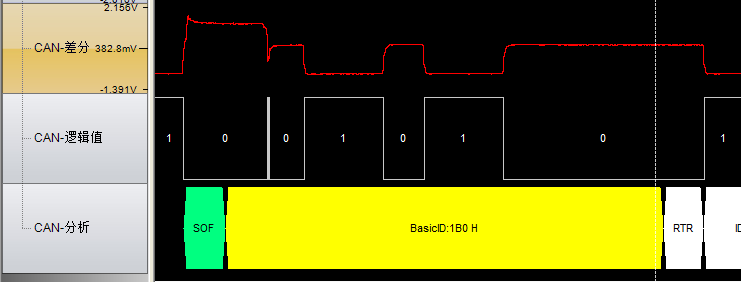

The CAN bus is essentially half-duplex communication, akin to a “one-way street”, meaning that when one node is sending, other nodes cannot send data. Although CAN message IDs have priority distinctions, if high-priority messages continuously occupy the bus, low-priority nodes cannot send data, leading to a congestion phenomenon. This phenomenon is more severe on a bus with a high load rate.

Congestion poses significant risks, leading to message competition and arbitration. At the end of arbitration, spikes can occur, posing a risk of bit flips, especially in scenarios with high capacitance, which can easily lead to bit errors. As shown in Figure 3.

Figure 3

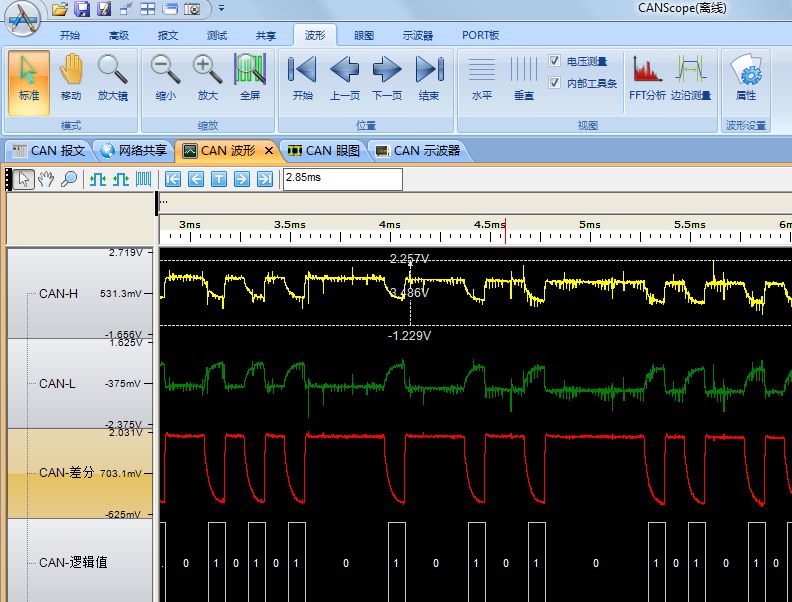

High load rates, with many bus nodes, result in a large distribution capacitance of the bus wiring, reflected in a very slow falling edge, as shown in Figure 4, where the discharge time required for the explicit level to return to the implicit level increases. For signals, this means that the implicit level time is shortened, which can easily lead to bit errors.

Figure 4

Some may ask, must the CAN bus load rate be less than 30%?

The CAN bus load rate does not necessarily have to be less than 30%. Based on experience, the load rate should be controlled within 50%. With a well-established network management strategy, the segment load rate should not exceed 70%. Of course, the lower the load rate, the better the real-time performance, but if the load rate is too low, it cannot transmit sufficient data, which is a problem with CAN; it cannot guarantee real-time performance when the data volume is large. Generally, it is said that a load rate of around 30% is optimal.

If you have any questions, you can: 1. Add Xiao Z’s WeChat: zlgmcu-888 2. Call the official technical hotline of ZLG Zhiyuan Electronics: 400-888-4005.

ZLG Zhiyuan Electronics Introduction

Guangzhou Zhiyuan Electronics Co., Ltd. is a subsidiary of Guangzhou Zhiyuan Electronics Co., Ltd., founded in 2001 by the renowned embedded systems expert Professor Zhou Ligong. It is a national high-tech certified enterprise and the Guangdong Provincial Engineering Technology Research and Development Center for high-end industrial control measurement instruments.

Vision: To become a leading enterprise in the industrial Internet ecosystem

Using the “chip + AWorks software platform” to design high value-added modules, boards, and high-end measurement instruments, connecting to the ZWS IoT cloud through wired and wireless interfaces, achieving big data processing, and forming an industrial Internet ecosystem.

Mission: To advance the process of China’s industrial Internet with leading technology

Values: Professionalism and focus achieve dreams