👆If you wish to meet regularly,

Welcome to star 🌟 and bookmark it~

With the rapid development of the electronic information industry, issues of electromagnetic leakage and high-temperature infrared radiation have become increasingly prominent. Particularly in the field of military protection, they can easily lead to information leakage and infrared exposure. Therefore, the design and manufacture of compatible low-reflectivity electromagnetic interference (EMI) shielding and high-temperature infrared stealth materials hold significant importance in the military domain. However, how to synergistically design and manufacture compatible composites with low-reflectivity EMI shielding and infrared stealth performance has gradually become a major challenge in the metallized polymer nonwoven fabric system.

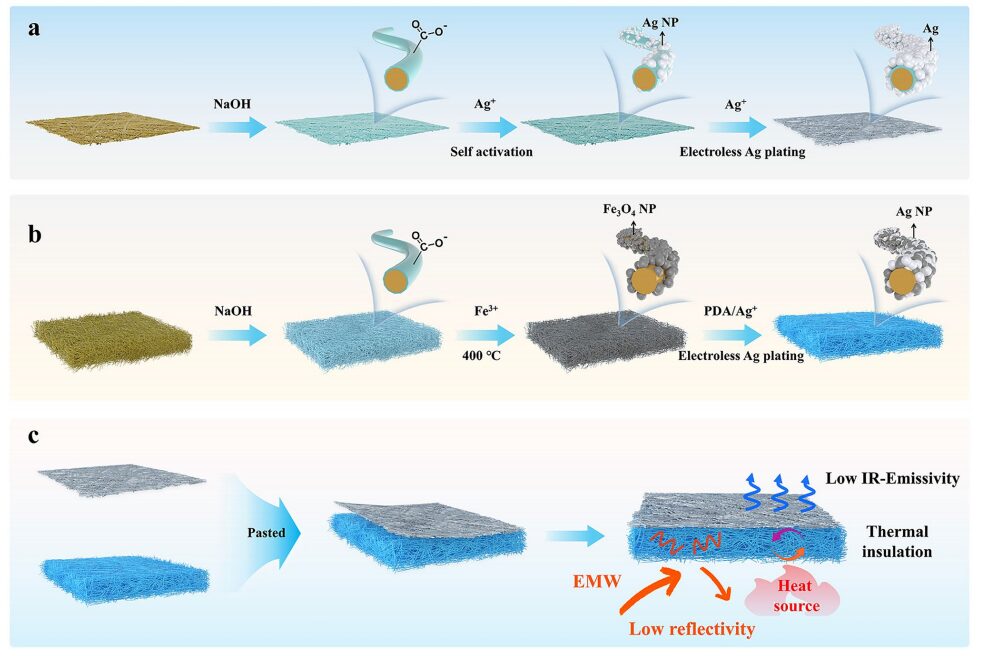

To address the aforementioned challenges, Professor Liu Tianxi and Associate Professor Wang Zicheng from Jiangnan University prepared hierarchical polyimide (PI) fiber composites through alkali treatment, in-situ growth of magnetic particles, and a “self-activating” chemical plating process for silver. In particular, by systematically assembling Fe3O4/ Ag-loaded PI nonwoven fabric (PFA) and pure Ag-coated PI nonwoven fabric (PA), layered impedance matching can be constructed, resulting in ultralow reflectivity EMI shielding performance. Additionally, the thermal insulation of the fluffy three-dimensional (3D) spatial structure of PFA and the low infrared emissivity derived from the silver plating of PA provide excellent infrared stealth performance. More importantly, the strong bonding interactions between Fe3O4, Ag, and PI fibers enhance the thermal stability and high-temperature infrared stealth performance of the EMI shielding. This outstanding comprehensive performance suggests broad application prospects for military tents in protecting internal equipment from electromagnetic interference from adjacent devices and/or enemies and suppressing external infrared detection.

The related research content titled “Hierarchical Polyimide Nonwoven Fabric with Ultralow-Reflectivity Electromagnetic Interference Shielding and High-Temperature Resistant Infrared Stealth Performance” was published in the journal Nano-Micro Letters.

In this study, PI nanofiber materials were first prepared using electrospinning equipment (Yongkang Leye ET series). Then, through alkali treatment, in-situ growth of magnetic particles, and a “self-activating” chemical plating process, hierarchical PI fiber composites with ultralow reflectivity EMI shielding and high-temperature infrared stealth performance were successfully obtained.

The developed hierarchical polyimide fiber composites exhibit ultralow reflectivity and EMI shielding capabilities, with various potential applications in military environments. For instance, the material’s low reflectivity and high electromagnetic wave absorption capabilities make it suitable for stealth technology. The EMI shielding performance can protect sensitive electronic devices and communication systems from electromagnetic interference. Additionally, it can be used in soldiers’ protective clothing. The material can be designed with specific optical properties to achieve camouflage effects, helping personnel and equipment blend into the surrounding environment.

Scheme 1 Schematic diagram of the preparation process of PFA/PA nonwoven fabric.

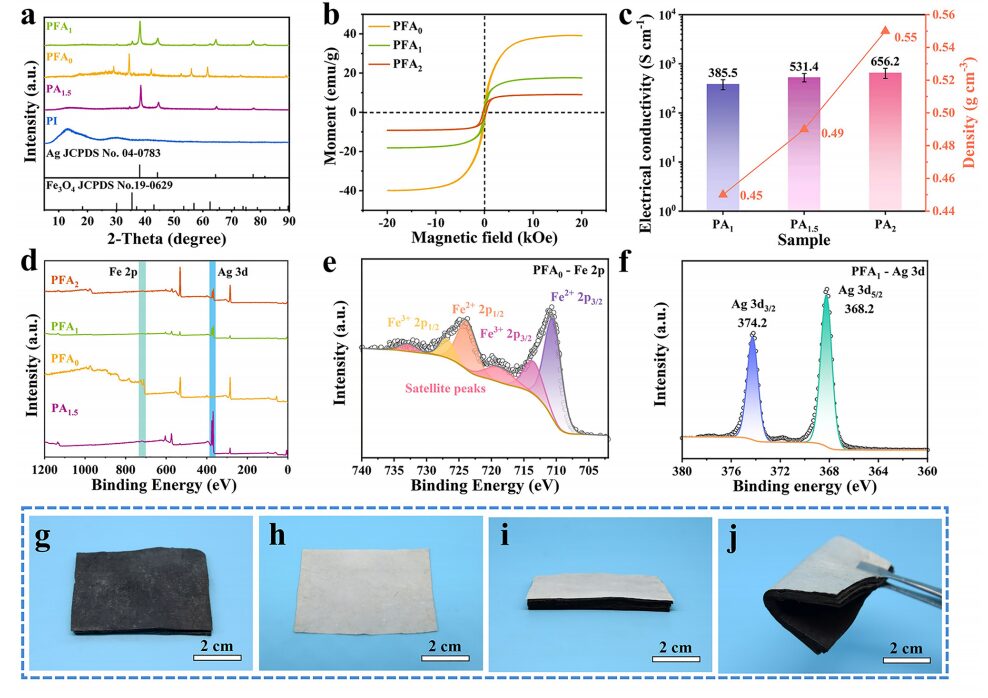

Figure 2 XRD spectra of PI, PA1.5, PFA0, and PFA1. b Hysteresis loops of PFA0, PFA1, and PFA2. c Conductivity and density of PA1, PA1.5, and PA2. d XPS spectra of PA1.5, PFA0, PFA1, and PFA2. e High-resolution XPS spectra of Fe 2p for PFA0 and f Ag 3d for PFA1. g Optical photos of 4*PFA1, h PA1.5, and i, j 4*PFA1/PA1.5.

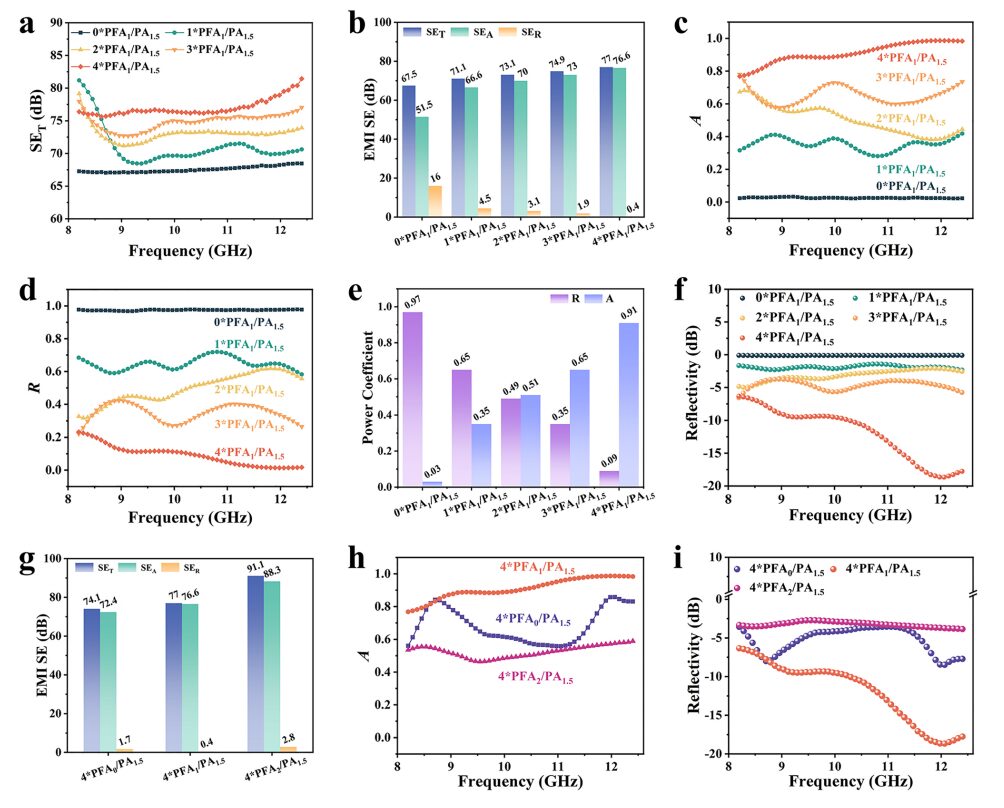

Figure 3 a SET, b EMI SE, c A, d R, e Power coefficient, f Reflection diagram of N*PFA1/PA1.5, g EMI SE, h A, i Reflection diagram of 4*PFA1/PA1.5.

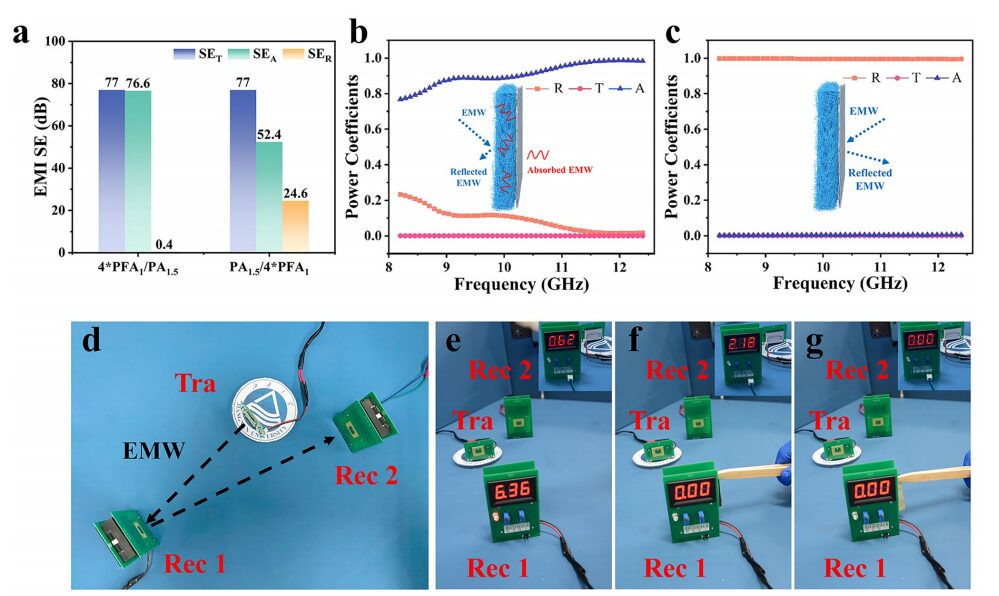

Figure 4. Electromagnetic shielding performance of 4*PFA1/PA1.5 and PA1.5/4*PFA1 under different incident directions: (a) electromagnetic shielding performance and its corresponding (b, c) power coefficient diagrams; (d) Demonstration of electromagnetic shielding performance: between the transmitter and receiver (e) without sample, (f) PA1.5/4*PFA1, (g) change of the electromagnetic shielding system when inserting 4*PFA1/PA1.5.

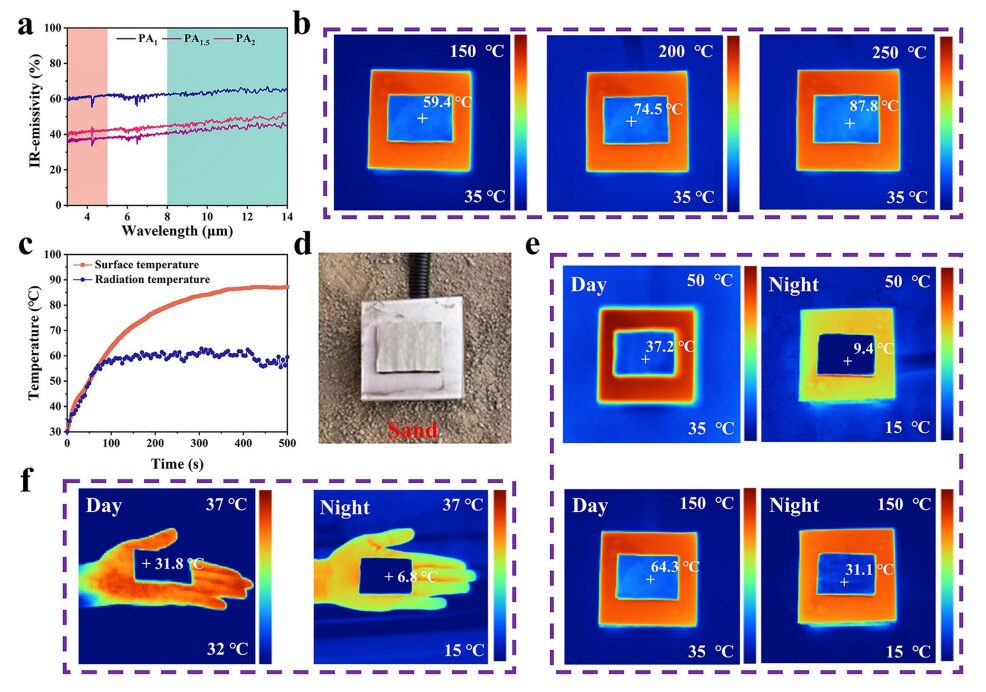

Figure 5. (a) Infrared emissivity curve of PAx; (b) Infrared imaging of 4*PFA1/PA1.5 at thermal stages of 150, 200, 250 ℃; (c) Actual surface temperature and infrared radiation temperature curve of 4*PFA1/PA1.5 at 150 ℃; (d) Schematic diagram of simulated desert environment; (e) Infrared imaging of 4*PFA1/PA1.5 at different heat source temperatures; (f) Infrared imaging of 4*PFA1/PA1.5 on the palm under day and night conditions.

Figure 6. (a) Electromagnetic shielding performance of 4*PFA1/PA1.5 at 8.2 – 40 GHz, (b) Power coefficient, (c) Reflection rate; (d) Schematic diagram of the low-reflective electromagnetic shielding mechanism of 4*PFA1/PA1.5; (e – h) Demonstration of the electromagnetic shielding and infrared stealth compatibility performance of 4*PFA1/PA1.5.

Figure 7. Schematic diagram of possible application scenarios for 4*PFA1/PA1.5 compatible low-reflective electromagnetic shielding and infrared stealth performance.

Original link:

https://doi.org/10.1007/s40820-024-01590-3

[End]

Breaking News

Yisibang Electrospinning Laboratory, industry-leading collaboration, full technical support, cutting-edge equipment one-stop experience. Facing technical challenges and innovation bottlenecks? We provide one-on-one answers and invite you to explore the new realm of “electrospinning technology” together!

Click to view image details