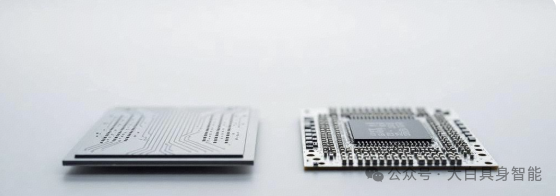

In motor control systems,FPGA (Field Programmable Gate Array) and DSP (Digital Signal Processor) are two commonly used chip solutions, each with unique advantages and limitations. The following is a comparative analysis of them:

1. Advantages and Disadvantages of FPGA

Advantages:

Parallel Processing Capability

The hardware architecture of FPGA supports multi-task parallel execution, such as simultaneously processingPWM generation, current sampling, position feedback, and multiple closed-loop controls (speed loop, current loop, etc.), making it particularly suitable for scenarios requiring coordinated control of multiple motors or high real-time performance.

Ultra-Low Latency and Determinism

Real-time response capability based on hardware logic (nanosecond-level latency) with extremely high timing control accuracy, suitable for high-speed motors (such as brushless DC motors, servo motors) or applications requiring strict synchronization (such as industrial robots).

Highly Customizable

Hardware logic can be flexibly configured according to needs, such as integrating dedicated encoder interfaces, custom communication protocols (such as EtherCAT), or implementing hardware acceleration modules (such as SVPWM, FOC algorithms), enhancing system efficiency.

Strong Anti-Interference Capability

The control logic is directly implemented in hardware circuits, reducing the risk of software runaway, making it suitable for harsh electromagnetic environments.

Disadvantages:

High Development Complexity

Requires the use of VHDL or Verilog and other hardware description languages ( HDL) for development, which requires a high level of hardware design capability from engineers; debugging cycles are long, and verification processes are complex.

Higher Cost

High-performance FPGA chips and supporting development tools (such as Xilinx Vivado) are significantly more expensive than DSP, especially after large-scale mass production, which may not be economically viable.

Limited Algorithm Flexibility

Complex mathematical operations (such as floating-point operations, advanced filters) require custom hardware module design, resulting in lower development efficiency compared to DSP software library calls.

2. Advantages and Disadvantages of DSP

Advantages:

High Algorithm Processing Efficiency

Optimized for mathematical operations (such as single-cycle multiply-accumulate instructions MAC), with built-in floating-point units (such as TI C2000 series), suitable for implementing complex algorithms like vector control and sliding mode observers.

Convenient Development

Based on C/C++ programming, combined with mature IDE (such as Code Composer Studio) and motor control libraries (such as TI MotorWare), allowing for rapid algorithm framework setup and shortened development cycles.

Rich Peripheral Integration

Typically includes dedicated motor control modules (such as high-resolution PWM, high-precision ADC, encoder interfaces), simplifying hardware design and reducing costs.

Power Consumption and Cost Advantages

Mid-range DSP chips are affordable, and their static power consumption is low, making them suitable for consumer-level or cost-sensitive applications (such as home appliances, drones).

Disadvantages:

Sequential Execution Bottleneck

CPU cores process tasks sequentially, and multi-loop control relies on interrupt priority scheduling, which may cause timing jitter under high dynamic loads, affecting the performance of high-speed motors.

Limited Expandability

Peripheral functions and interfaces are fixed, making it difficult to customize as flexibly as FPGA, requiring external chips for complex protocols or special sensor interfaces.

Real-Time Limitations

Microsecond-level response delays can meet most scenarios, but may be insufficient for ultra-high-speed motors (such as 100,000 RPM or above) or nanosecond-level synchronization control (such as lithography machines).

3. Comparison of Typical Application Scenarios

| Scenario | Recommended Solution | Reason |

| Multi-Axis Servo Systems | FPGA | Parallel control of multiple motors, custom communication protocols (such as EtherCAT), hard real-time synchronization |

| High-Speed Motors (>50k RPM | FPGA | Nanosecond-level PWM response, precise dead-time control |

| Appliance Motors (Fans, Compressors) | DSP | Low cost, rapid development, meeting basic FOC requirements |

| Complex Algorithms (Adaptive Control) | DSP + FPGA Collaboration | DSP handles advanced algorithms, FPGA is responsible for real-time closed-loop and signal acquisition |

| High-Reliability Industrial Equipment | FPGA | Hardware redundancy design, strong anti-interference capability |

4. Hybrid Solutions and Trends

SoC FPGA (such as Xilinx Zynq): integrates ARM cores with FPGA logic, balancing software flexibility and hardware real-time performance, suitable for high-end servo drivers.

DSP+FPGA Collaboration: DSP processes upper-level algorithms, FPGA implements lower-level control, balancing performance and development costs.

Dedicated ASIC: customizable motor control chips for mass production scenarios, but with high initial investment, suitable only for ultra-large-scale applications.

To find out what happens next, please stay tuned for the next installment.