Post 1048

Author: Huang Yefeng

This year, a highlight of the iPad Pro 12.9-inch update is the adoption of a mini LED backlit screen. Many experience articles describe the visual experience of mini LED as stunning. However, alongside the praise, many users have mentioned that the iPad Pro’s mini LED screen “suspected to have failed,” mainly reflected in the halo effect around displayed objects against a black background. The appearance of halos around displayed content is a technical topic worth discussing.

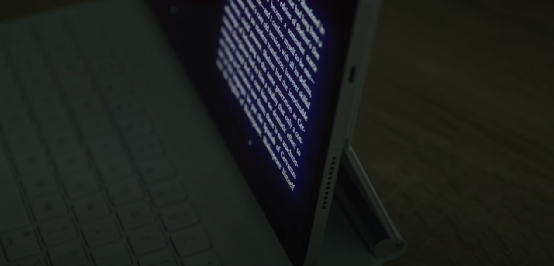

Source: The Verge

The image above is from foreign media The Verge, showing the halo effect that appears around text when reading in dark mode using the Kindle app or Apple Books. Of course, such a severe “halo” may be largely related to software optimization. However, it is indeed an exaggerated representation of the limitations of the mini LED emission principle, which is helpful for understanding the halo effect.

In this article, we will discuss the principle and characteristics of mini LED backlit panels, as well as their value and development prospects, leveraging the “halo effect” of the iPad Pro 12.9-inch. It is important to note that mini LED/micro LED is currently a top priority in the entire supply chain.

Mini LED Screen of iPad Pro

The screen used in this year’s newly launched 12.9-inch iPad Pro is called Liquid Retina XDR by Apple. Behind this marketing term is mainly the mini LED backlight technology. Before discussing mini LED technology, let’s take a look at how incredible this screen is.

First, the entire screen can achieve a brightness of 1000 nits, and when playing HDR content, the peak brightness can reach up to 1600 nits, which is basically comparable to the Apple Pro Display XDR monitor priced at 40,000-50,000 yuan, and brighter than most TVs on the market that claim to be 4K HDR. It is worth noting that other iPad Pro screens have a brightness of only 600 nits, and a brightness of 500 nits is considered good for high-end tablets and laptops.

Additionally, the contrast ratio of this screen reaches 1,000,000:1, which is also comparable to the 40,000-50,000 yuan Pro Display XDR. Many users have stated that when watching HDR content on this screen, the dark areas in the picture are noticeably darker, but more details can be presented. Although this contrast ratio is not impressive compared to the iPhone 12 screen, it is important to note that the iPhone 12 uses an OLED screen, while the iPhone 11 uses an LCD screen with a contrast ratio of 1400:1.

Some may ask, why not use an OLED screen directly? While OLED panels are indeed feasible for small screens like mobile phones, on large-sized panels, OLED technology faces two main issues: the manufacturing cost is prohibitive, and although OLED has excellent dark performance and high contrast, its lifespan due to the light-emitting materials makes it difficult to achieve the high brightness levels of LCD.

Although there are currently very few HDR content resources available for streaming in China, this screen can still outperform ordinary tablets and laptops in terms of performance for daily entertainment and office use.

Of course, Apple is not the first device manufacturer to use mini LED screens; TCL, Samsung, and LG have been promoting mini LED panels for the past two years. This year has been dubbed the “Year of Mini LED Panels” by some manufacturers, as mini LED panels are making a strong market entry.

Source: Samsung

Halo on Mini LED

Having discussed the positives, let’s talk about the negatives. As mentioned at the beginning, the mini LED screen of the iPad Pro has a “halo” effect in display. This is determined by the characteristics of mini LED backlighting. To discuss this issue, we must first understand the display principle of LCD.

The detailed principle will not be elaborated here; the core related to its light-emitting principle is that the LCD panel is a layered structure, illuminated by a backlight layer at the bottom to display the image; there is a liquid crystal layer (LC) in the middle that can control the passage of light through the deflection of liquid crystals. For example, when displaying pure white, the liquid crystal “allows” all the backlight to pass; while when displaying pure black, the liquid crystal “blocks” the backlight.

This light-emitting principle of LCD determines that ordinary LCD screens have difficulty displaying true pure black. Because even if the liquid crystal “blocks” the backlight, it cannot achieve complete blockage. Thus, the black displayed on an LCD screen is more like a shade of gray rather than pure black. In contrast, OLED can completely “turn off” the pixels when displaying black, resulting in a much purer black.

This also determines that LCD screens find it challenging to achieve high contrast ratios, so previously, LCD screens with contrast ratios of 1000:1 to 5000:1 were already considered good. This makes it more difficult for LCD to display HDR (High Dynamic Range) content. Hence, local dimming has emerged, where the backlight layer of the LCD is divided into different zones; when a specific area needs to be lit, it lights up, and when displaying black, the backlight for that area is turned off.

Source: Samsung

This technology is widely used in LCD TVs, with high-end models like the Vizio P-Series Quantum X TV having up to 480 backlight zones. Many LCD TVs have dozens of LED backlight zones. If we compare “local dimming” to OLED, OLED can be likened to having independent “backlights” for every pixel. This means that a 1080p resolution OLED panel has over 2 million “backlight zones.”

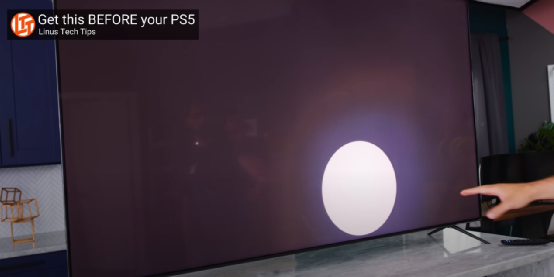

Source: Linus Tech Tips

In cases where local dimming has a coarse granularity (i.e., not many backlight zones), it is easy to observe the “halo” effect, which is caused when light from one zone leaks into adjacent zones that are not lit (or are darker). If you observe closely, you might even be able to distinguish different backlight zones with the naked eye.

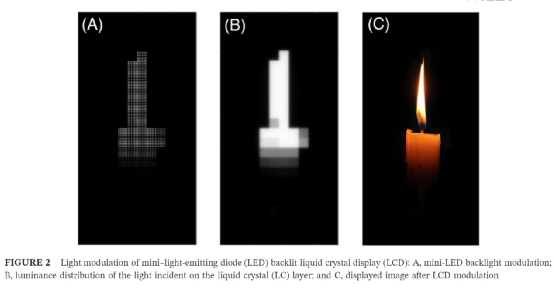

Source: Prospects and challenges of mini-LED and micro-LED displays*

The essence of Mini LED is to increase the number of backlight zones or to make each LED backlight smaller, achieving more precise backlight and image brightness control (thus mini LED is also classified as LCD). For example, in the image above, when displaying a candle, only the necessary backlight portion is lit, and there are different levels of brightness (although the precision cannot match OLED).

Mini LED TVs generally have far more backlight zones than traditional LCD TVs (depending on the size of the panel). For instance, TCL’s 8-series mini LED TV has over 25,000 mini LEDs, forming 1,000 zones.

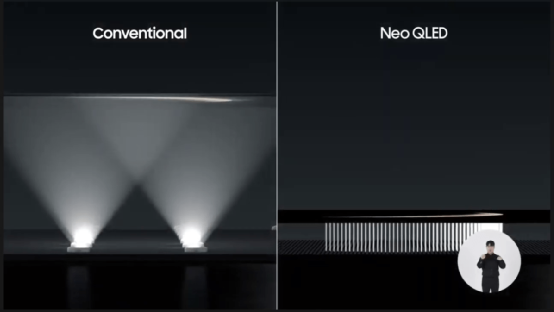

Samsung’s Neo QLED TV launched at CES 2021 boasts that each LED is 40 times smaller than traditional LEDs; it also highlights its control over halos. Although Samsung has not disclosed how many backlight zones its Neo QLED TV has, some netizens speculate that the 85-inch QN90A has around 1,320 backlight zones.

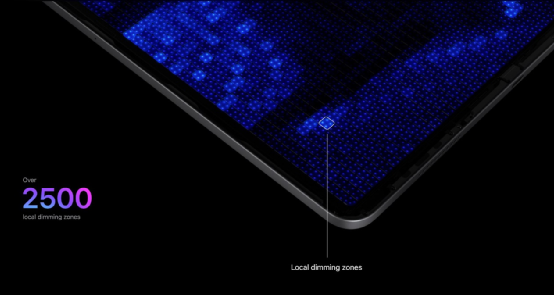

Source: Apple

This year’s iPad Pro 12.9″ has a stunning configuration for mini LED backlighting. Apple has mentioned that this tablet’s screen has over 10,000 mini LEDs, forming 2,500 zones. Note that this screen is only 12.9 inches, much smaller than those TVs. In comparison, the previous generation iPad Pro had a total of 72 LEDs for backlighting. Thus, the size of each LED in the new iPad Pro’s screen is about 120 times smaller than its predecessor.

This number of zones sounds like a significant increase over traditional LCD TV panels, but as mentioned earlier, when compared to the pixel-level precision of OLED (or micro LED), it is still lacking by more than one order of magnitude. Therefore, mini LED can alleviate the halo effect with more LEDs and zones, but it still cannot achieve pixel-level fine control, and the halo issue may still persist.

Understanding the Halo Issue in More Detail

While many consider mini LED a transitional solution to OLED, the adoption of mini LED screens in the iPad Pro shows the great potential of this type of panel, indicating its feasibility for mass production and widespread use. This technology not only allows LCDs to achieve higher contrast ratios and present darker blacks, but also brings benefits in backlight uniformity, panel thickness, and power consumption; additionally, it is more cost-effective than OLED, with peak brightness achievable at higher levels. We will not delve deeper into the value of mini LED in this article.

In the following sections, let us observe the halo issue of mini LED in more detail, as well as the more challenges that mini LED faces. A paper titled “Prospects and challenges of mini-LED and micro-LED displays” presented at SID 2019 discusses the challenges faced by mini LED in detail.

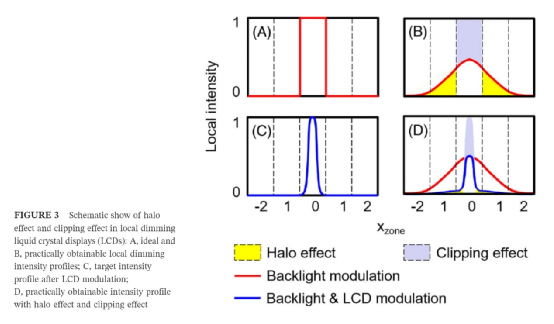

The halo effect is a significant topic under local dimming technology. As mentioned earlier, the halo effect occurs when light leaks into adjacent dark areas while displaying bright objects. Accompanying this is a phenomenon called clipping effect—here we temporarily translate it as the weakening effect, which is the phenomenon of insufficient brightness in the zones.

The image above explores the existence of these two effects. Here, the horizontal axis (Xzone) represents different backlight zones, while the vertical axis represents brightness. In this example, only the center zone has peak brightness, while the surrounding zones are in the “off” state. Ideally, it should be like graph (A). However, in reality, the brightness of each zone is not only related to the light source itself but also to the light leakage from adjacent zones. Graph (B) demonstrates this situation, where light from the center zone leaks into adjacent zones, and the brightness of that zone is weakened, resulting in both halo and clipping effects.

On the other hand, the backlight unit (BLU) of the LCD panel will further modulate the LEDs to achieve better detail representation, targeting a graph (C) scenario. Thus, with the halo and clipping effects, the final result will resemble graph (D).

There are indeed many algorithms aimed at mitigating these two effects, and various manufacturers are striving in this direction—many algorithms were proposed long before we recognized them. From a hardware perspective, higher LCD contrast or pixel-level dimming can significantly alleviate/eliminate these two effects. For LCDs, this means increasing the number of backlight zones and reducing the dark areas affected by the halo effect (the yellow area in graph B); increasing the contrast alleviates the halo effect in bright areas (the yellow portion in the central zone of graph D).

The number of backlight zones and the contrast ratio of the LCD have the most significant impact on suppressing halo and clipping effects; additionally, the optical design, such as the diffusion of LED light and the isolation of zonal light, also affects the final performance of zonal dimming—the differences in optical design may lead to fewer zones but better performance in suppressing halo effects.

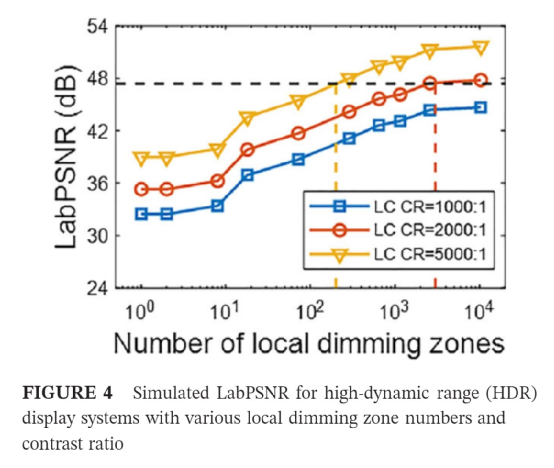

Regarding whether the halo effect is perceptible to the human eye, researchers have previously proposed using LabPSNR (Peak Signal-to-Noise Ratio in the CIE 1976 L*a*b* color space) as a measure of the halo effect. When LabPSNR > 47.7 dB, only 5% of people can distinguish whether mini LED backlighting is used.

The black dashed line in the image above indicates the critical value of LabPSNR. The different colored curves represent different LCD contrast ratios (e.g., blue for a contrast ratio of 1000:1); the horizontal axis represents the number of backlight zones. (It should be noted that this is based on a judgment for a 6.4-inch screen at a viewing distance of 25 cm. Different panel sizes may require consideration of viewing distance, but this data is still valuable for large panels.)

This graph can also be somewhat applied to this year’s iPad Pro. It is important to note that the contrast here refers to the contrast that the LCD itself can achieve, not the overall contrast after adding local dimming technology. For an LCD with a contrast ratio of 2000:1, more than 3,000 backlight zones are needed to roughly eliminate the impact of the halo effect. However, if the contrast of the LCD itself is below 1000:1, even with 10,000 zones, satisfactory results may not be achieved.

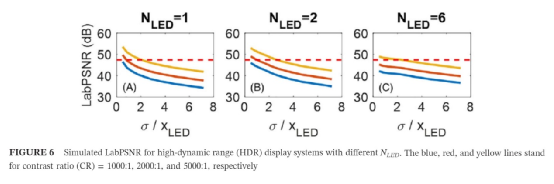

In addition, for LCD panels, light will diffuse from the mini LED backlight to the liquid crystal layer. This is related to the LED emission aperture, the distance between the mini LED and the diffuser, and the optical layers such as the brightness enhancement film (BEF). The image above illustrates how the changes in the number of LEDs in a backlight zone (NLED) affect LabPSNR due to σ/xLED variations—meaning that smaller LED emission apertures and shorter light paths can lead to higher LabPSNR.

For example, when there are 2×2 LEDs in a backlight zone, and the contrast is 2000:1, with σ/xLED=0.5, the halo effect becomes negligible (as shown in graph B).

Due to space constraints, this article will not delve deeper into more influencing factors and relationships regarding the halo effect, such as the crosstalk of adjacent backlight zones, which is also influenced by optical structures like lens collimation and isolation, making the control of backlight boundaries within zones very important. Hence, it can be seen that there is still room for improvement in mini LED technology.

Source: Samsung

Competition in the Mini LED Market is Intensifying

Overall, while the mini LED screen of the iPad Pro 12.9″ has the impact of the halo effect, its remarkable performance in brightness and contrast still far surpasses similar products, and it has made preliminary explorations for the development of mini LED technology. Although the price of mini LED is starting to show advantages, the repair cost for damage to this iPad Pro, without Apple Care+, reaches $699, significantly higher than the previous generation’s $499, indicating that the cost of mini LED is still not low.

Fortunately, this situation will soon change. Many panel manufacturers in South Korea and Taiwan are focusing on mini/micro LED panels, and supply chain-related companies in mainland China are becoming more proactive, with panel manufacturers such as BOE, TCL/Hua Xing Optoelectronics, and Tianma Microelectronics increasing their investment in R&D for these two products. In the LED supply chain, manufacturers like Sanan Optoelectronics, HC Semitek, Nationstar, and Jufei Optoelectronics have also been working on related technologies in recent years. (It is important to note that this article discusses mini LED, not micro LED. The latter is a technology that achieves pixel-level backlight control, which currently remains costly; we will explore this in another article.)

For instance, LED chip manufacturer Sanan Optoelectronics has prioritized mini/micro LED as a development strategy, announcing an investment of 1.2 billion yuan in the Ezhou Economic and Technological Development Zone in Hubei for R&D and production layout; last year, Sanan Optoelectronics and Huaxing Optoelectronics announced a collaboration to establish a joint laboratory, investing 300 million yuan to jointly develop micro LED materials, manufacturing processes, and equipment.

Additionally, companies like Nationstar have invested 1 billion yuan to expand LED packaging capacity for mini LED backlighting; Leyard and Jingyuan Optoelectronics have jointly invested hundreds of millions of yuan to produce mini/micro LED chips and modules in Wuxi, accelerating the commercialization process of new generation display solutions, and so on.

Based on the domestic investments in mini/micro LED technology in China, competition in this market is expected to intensify and accelerate the promotion and development of new technologies. The large-screen products in the market, including TVs, PCs, and tablets, will soon be affected, and a transformation in the display field is quietly underway, starting with this year’s iPad Pro.

References:

* Huang, Y, Tan, G, Gou, F, Li, M-C, Lee, S-L, Wu, S-T. Prospects and challenges of mini-LED and micro-LED displays. J Soc Inf Display. 2019; 27: 387– 401. https://doi.org/10.1002/jsid.760.