Introduction

The “Edge Computing Standard Component Plan” aims to form an industrial closed loop of “technology research and development, standard formulation, product testing, application demonstration, and large-scale commercialization,” promoting the development of edge computing in China to a new stage. As the most authoritative and influential edge computing product testing activity in the country, the test results showcase the optimization and iteration capabilities of edge computing vendors’ products and provide reliable and accurate selection references for enterprise users, facilitating the large-scale deployment of edge computing in China.

After centralized testing by the China Academy of Information and Communications Technology, the industrial-grade node-type edge computing module S20, independently developed by Sothis Cloud Intelligent Control Technology (Shanghai) Co., Ltd., successfully passed the product testing of the “Edge Computing Standard Component Plan” and has been deployed and operated stably in various industry sectors, helping various industries bridge the IT and OT connection and empowering the digital transformation of enterprises.

The Sothis S20 industrial-grade node-type edge computing module integrates technologies from multiple fields such as edge computing, 5G, and AI, aiming to provide comprehensive digital solutions for enterprises in the industrial sector. This product is suitable for various industrial scenarios and can achieve cloud collaboration and device interconnection in manufacturing factories of different scales. The S20 is based on data-driven principles, focusing on automation and intelligence, while emphasizing flexibility, reliability, and customizability, dedicated to helping enterprises enhance operational efficiency and promote the intelligent upgrade of industrial production. By processing and analyzing data at the edge, it can effectively reduce data transmission latency and bandwidth pressure, empowering real-time decision-making and predictive maintenance applications. Its integrated AI capabilities support localized intelligent analysis, such as visual inspection and equipment fault diagnosis, further optimizing production processes and resource allocation. The support of 5G communication technology ensures high-speed and stable data transmission, providing a guarantee for building a more resilient industrial IoT infrastructure.

Sothis Industrial Grade Node Type Edge Computing Module S20

Sothis Industrial Grade Node Type Edge Computing Module S20

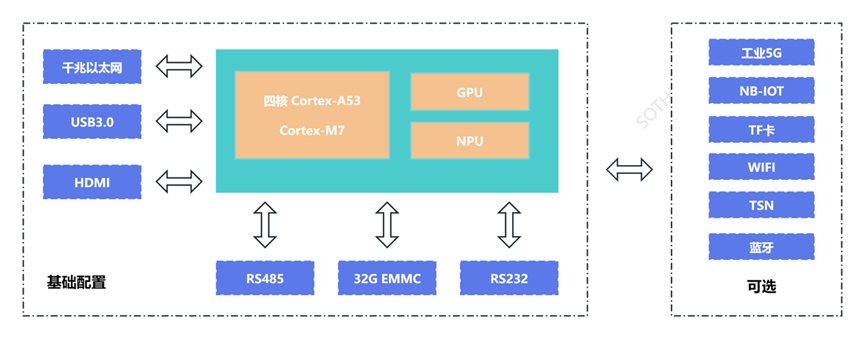

S20 Industrial Grade Node Type Edge Computing Module System Architecture Diagram

🔹 Heterogeneous computing power collaboration, supporting various processing methods such as CPU, GPU, and NPU to meet the needs of complex data processing and real-time computing;

🔹 Adopts a hardware-software integrated architecture, achieving dynamic reconstruction and intelligent allocation of hardware resource pools through software-defined methods, ensuring efficient resource utilization;

🔹 Supports standard unification of multiple protocols, facilitating seamless connection with different devices and systems, simplifying data collection, forwarding, and other operational processes, and improving system integration efficiency;

🔹 Equipped with device-side control functions, enabling intelligent management of connected devices, enhancing the overall operational efficiency of the system;

🔹 Supports direct cloud connection, facilitating centralized management and analysis of data, promoting efficient integration of edge computing and cloud computing;

🔹 Equipped with rich programmable interfaces, flexibly adapting to various industrial application requirements, supporting the expansion of various peripherals and systems, enhancing system flexibility and customizability;

🔹 Fanless passive cooling, stable and reliable.

Typical Cases

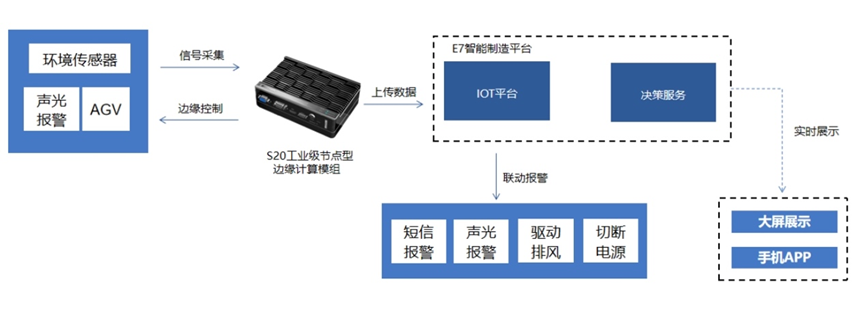

Case 1:Environmental Perception System

The environmental perception system monitors changes in the surrounding environment through various sensors, capable of real-time capturing information such as flames, smoke, and temperature, enhancing the safety and decision-making efficiency of modern industry and smart buildings. Combined with edge computing technology, the performance of these systems and the application of inspection AGVs have been significantly improved. Firstly, the environmental perception system can quickly identify potential fire risks by integrating various sensors, such as flame and smoke detectors. When the AGV is conducting inspections, the built-in visual recognition system can monitor the environment through cameras, and once flames or smoke are detected, the system will immediately respond. This rapid recognition capability is crucial for ensuring the safety of personnel and equipment.

Utilizing the Sothis S20 node-type edge computing module, the environmental perception system enhances data processing efficiency. Traditional cloud computing models may experience delays when processing real-time data, while edge computing moves data processing closer to the data source. After detecting a fire, the edge computing device can instantly analyze and respond, for example, sending alerts to the control center or initiating firefighting procedures, significantly reducing response time and enhancing system safety.

The environmental perception system also optimizes resource usage. The data volume generated during AGV inspections is enormous, especially during flame and smoke detection. Edge computing filters data locally, uploading only critical information to the cloud, effectively alleviating bandwidth pressure on the cloud. The system evaluates environmental safety locally, sending relevant data to the cloud for in-depth analysis only when anomalies such as fires are detected, greatly enhancing data transmission efficiency.

Additionally, the environmental perception system is closely integrated with the intelligent lighting system. By integrating ambient light sensors, the intelligent lighting system can automatically adjust the lighting intensity based on environmental light conditions, reducing energy consumption.

Environmental Perception System Architecture

Environmental Perception System Architecture

5G Ecosystem Laboratory On-site Image

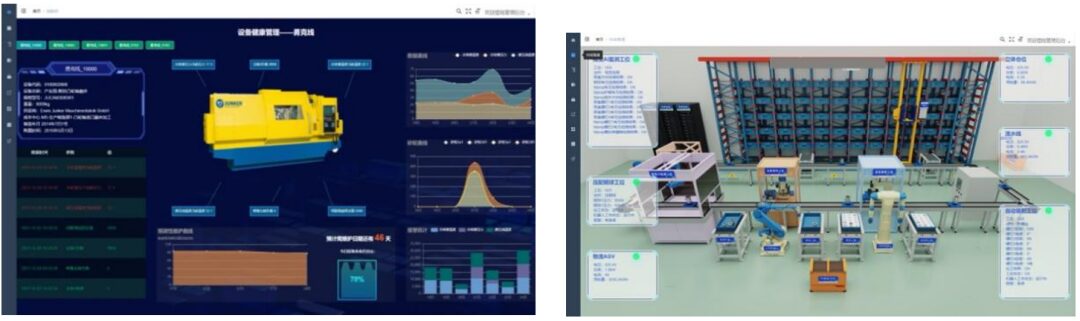

Case 2:Equipment Health Management System

This all-in-one machine can achieve hardware-software integration, addressing basic IT issues and device IoT problems for SMEs through a plug-and-play operation mode, providing a one-stop IoT solution for SMEs.

Company Profile

Contact Person: Liu Haifeng

Contact Information: 13764404221

Related News:

Supporting Equipment Updates in the Industrial Sector: The Sixth Batch of the “Edge Computing Standard Component Plan” Testing Collection Has Officially Started!

Supporting Industrial Equipment Updates | The Fifth Batch of the “Edge Computing Standard Component Plan” Testing Results Released. The China Academy of Information and Communications Technology has launched the first batch of “Edge Computing Standard Component Plan” product testing for 2024. The China Academy of Information and Communications Technology has launched the testing collection for the “Edge Computing Standard Component Plan” product testing for the first half of 2024.

Recommended Reading