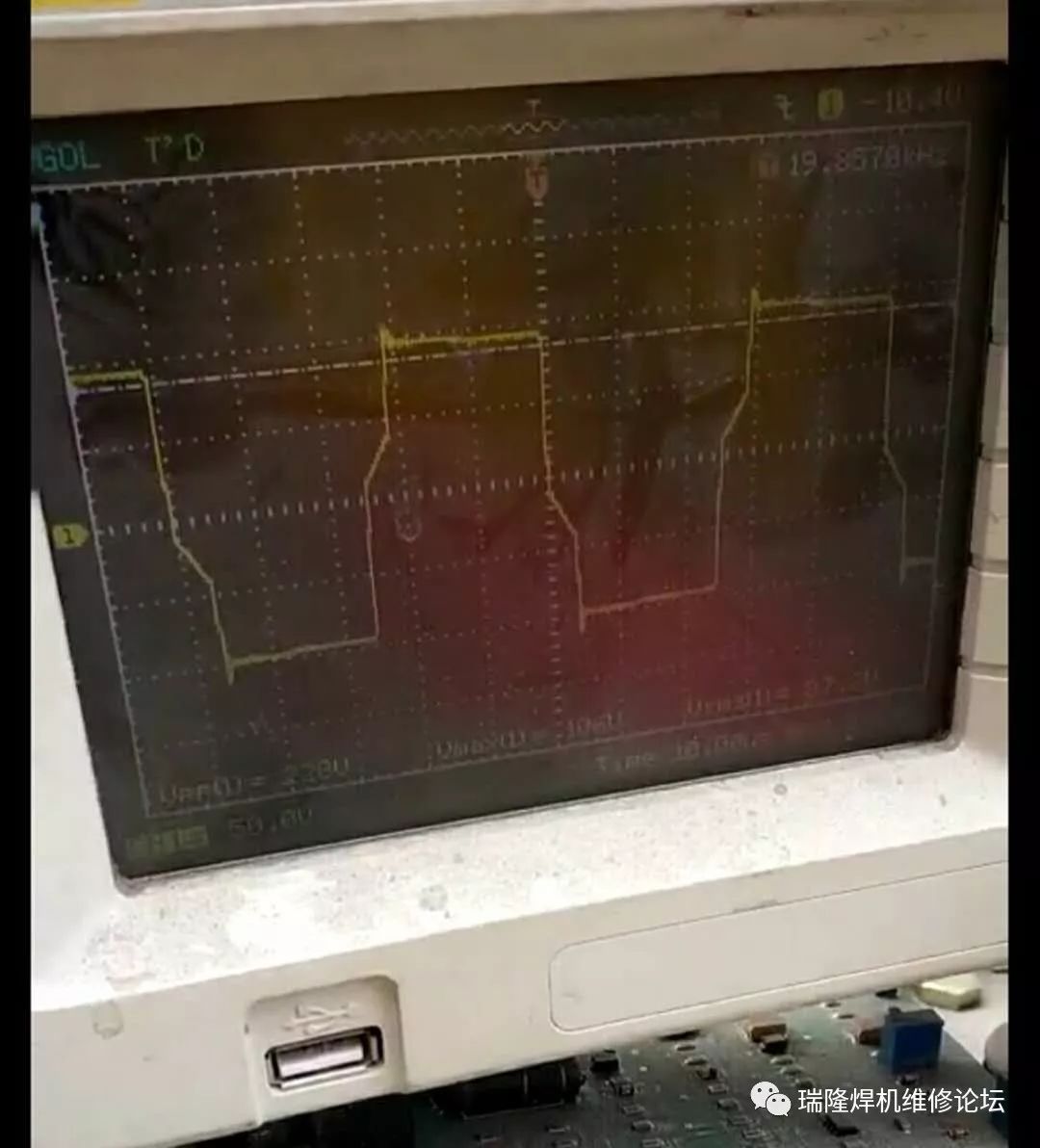

(1) The drive waveform of soft switch welding machines rises and falls at an angle, as shown in the figure below.

The waveform of hard switch machines is like a single tube wave, rising and falling straight. Issues with absorption can cause spikes in the waveform. During maintenance, some waveforms may be unfamiliar; if the four sets of waveforms are consistent, there is generally no problem. The mutual inductance coil connected in series with the primary of the main transformer must be checked before powering on; if it is faulty, it can cause the main transformer to make a buzzing sound and may also damage the IGBT module.

(2) The single-board machine represents intensified competition in the welding machine industry, where users seek cheaper products. Apart from repairing those sold in their own stores, relying on repairing other users’ single-board machines can lead to financial difficulties, as they are hard to charge for and require significant labor, often resulting in blown tubes when the casing is opened.

(3) For well-equipped welding machine maintenance, in addition to an oscilloscope, a voltage regulator and a resistance box are also needed. During maintenance, apply pressure using the voltage regulator, connect the output to the resistance box, and use the oscilloscope to detect the primary waveform of the main transformer. Gradually increase the pressure; if the waveform does not narrow, immediately shut down and check. If the loaded waveform does not narrow, it can blow tubes. With a voltage regulator, you can check whether the conversion between 220 and 380 is normal. For dual power welding machines, when connected to 380 high voltage, the voltage at the bottom plate is 380v × 1.45 × 2=1102 volts, while the voltage rating of the electrolytic capacitor at the bottom plate is generally 450 volts. When two capacitors are in series, the voltage rating is only 900 volts.IGBT has a maximum voltage rating of 1200 volts. Once the voltage doubles, both the electrolytic capacitor and the tubes cannot withstand it, and they will explode like firecrackers. Do not position your face towards the electrolytic capacitor or other easily explosive components while powered on. When maintaining dual power welding machines, if we are unsure whether 380 is normal, before testing, remove the high-voltage connection from the bottom plate to the inverter board (the red line circled in the figure below).

Set the multimeter to the DC 1000 volt range, insert the two probes into both sides of the high-voltage connection, and while powered on, closely monitor the voltage reading on the multimeter. If the voltage immediately exceeds 700 volts, quickly shut down, indicating that 380 has doubled the voltage. Testing in this manner is safe. Some technicians are more cautious and will disconnect the rectifier bridge connection at the bottom plate when testing with 380 to observe whether the voltage doubling relay operates.

(4) The K3878 and 2611 field effect transistors (with a voltage rating of 900 volts) are used in 380 volt or dual power welding machines; the 2837, 2698, and 23n50e (with a voltage rating of 500 volts) are used in 220 volt welding machines.

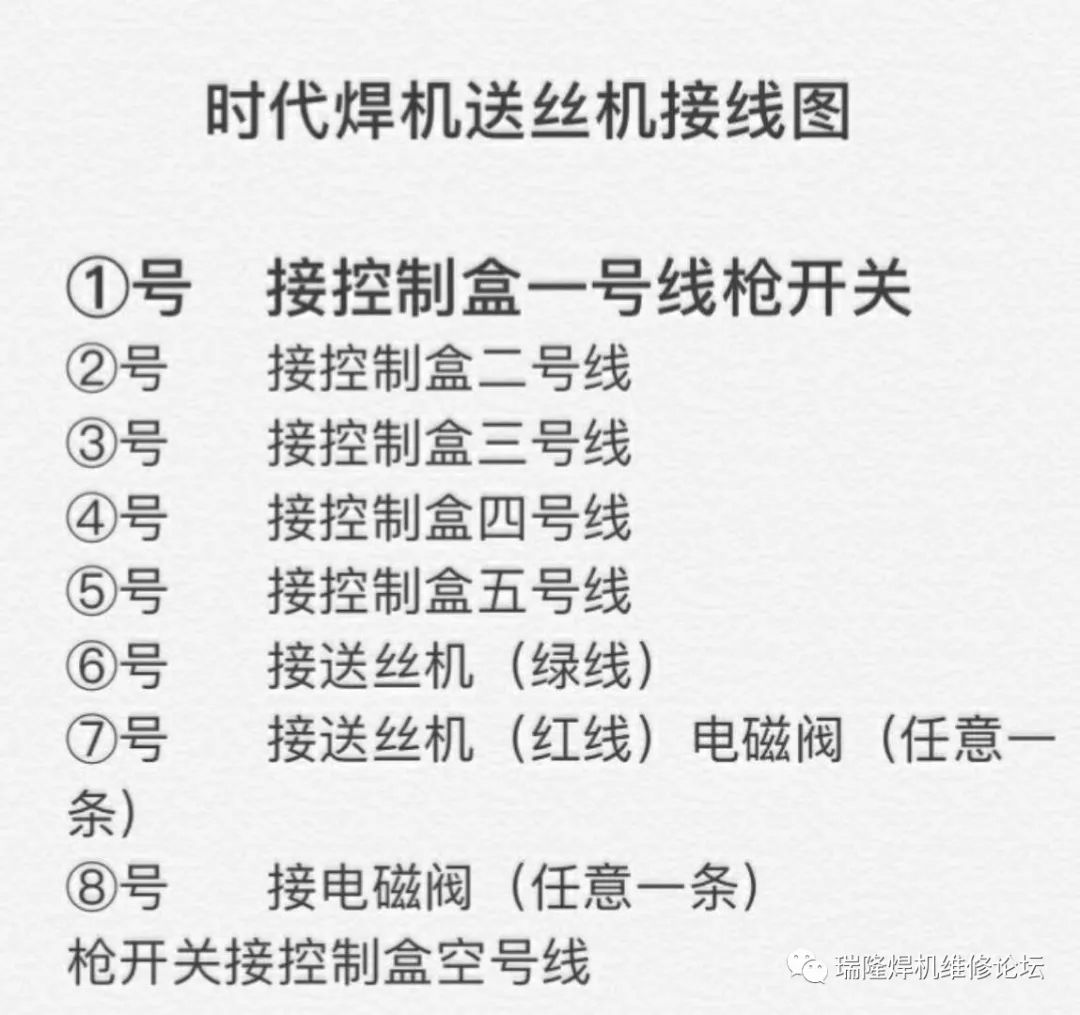

(5) The gas shielded welding control line of the era is eight-core, as shown in the figure below.

(6)The transformer is a device that changes AC voltage using the principle of electromagnetic induction, with the main components being the primary coil, secondary coil, and core (magnetic core). Its main functions include: voltage transformation and current transformation. Most transformers in welding machines are step-down transformers, converting high voltage from the primary to low voltage in the secondary. Since the input power of the transformer equals the output power, power = voltage × current, the current in the secondary must be greater than that in the primary, thus the copper wire wound on the secondary must be thicker than that on the primary (the part circled in the figure below is the copper wire).

Based on this knowledge, we can determine which side is the primary and which is the secondary of the transformer. Common step-up transformers are only used in high-frequency transformers on argon arc welding and plasma welding machines, known as high-voltage packs.

If you find this article useful, feel free to share it with your friends.