“The essence and core of digital transformation.”

—— Fat Head Monk

Contact the author via WeChat: 1126699

◆ ◆ ◆

Written by Kang Xiang

In the book Understanding China Manufacturing 2025, financial writer Wu Xiaobo believes that for Chinese industry, “the era of ‘cheap and good quality’ is over.”

In a sense, this ending may carry a hint of helplessness and reluctance. However, from the perspective of industrial upgrading, it is inevitable and a reality that the Chinese economy and industry must face.

Industry is the foundation of a country’s economic development and social progress. Since the beginning of the reform and opening up, China has become the world’s largest manufacturing country in 2010 due to its unwavering commitment to developing manufacturing.

Economist Robert Allen believes that China’s reclaiming of the manufacturing output crown marks the end of a 500-year cycle in economic history. Some even say that the United States should be “worried” about losing the throne it has occupied since around 1895 to China.

However, the Chinese economic community has not been blinded by victory. Many years ago, they began to ponder the dilemma of China’s manufacturing being large but not strong, such as the fact that “eight hundred million shirts can be exchanged for one airplane,” which has always been a painful reminder.

The question is, where is the way out?

Building the Starting Point of a New Type of Industry

From the experiences of traditional industrial powers like the United States, Germany, and Japan, data has become the core factor in the development of manufacturing and will drive industrial development into a new era.

With the deep integration of communication and information technology, modern industry has entered the digital age. In factories, millions of machines are running at full capacity; those who can listen to their conversations and uncover the secrets of data will become the strong players in the industrial field.

Traditional industrial machines, being “invisible” and “inaudible,” cannot communicate with each other or with humans, which is clearly not a future we can rely on, and intelligent manufacturing is even more out of reach.

The good news is that we have the Internet of Things (IoT). In the simplest terms, the IoT can connect any object to the network for information exchange and communication, enabling intelligent identification, positioning, tracking, monitoring, production, and management.

In this vision, traditional machines can also be equipped with “eyes and ears” without completely overturning past industrial facilities and platforms, which also protects the wealth of human society—after all, the previous asset consumption was enormous, and complete devaluation would inevitably harm all parties.

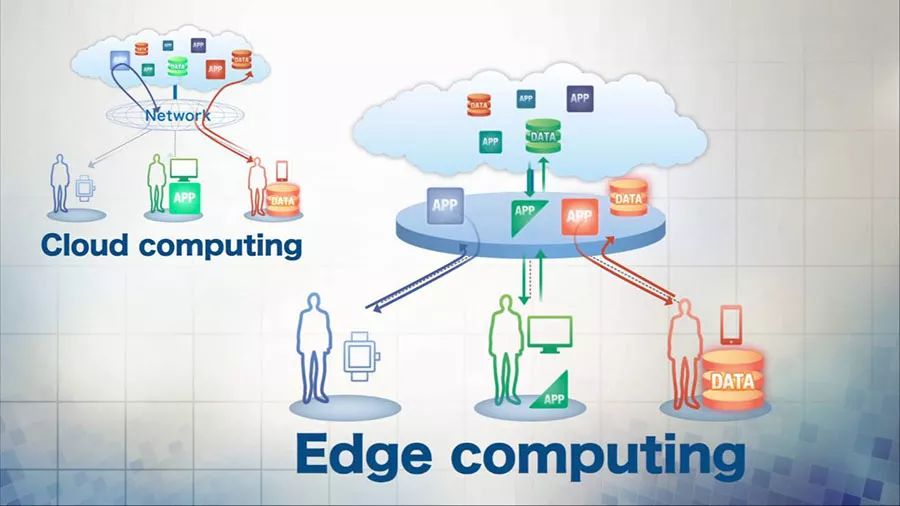

However, even with data collection through the IoT, processing becomes a tricky issue. In the past centralized computing model, all data had to be processed at the center, leading to some unavoidable problems.

For example, in industrial application scenarios, many remote data require timely processing and feedback, but often by the time data is transmitted to the center, processed, and returned to the front-end unit, it has already depreciated or even “spoiled,” losing all meaning.

If one insists on sending this data back, the central computation is not a big problem, but the transmission process will inevitably consume more bandwidth, unnecessarily increasing the overall costs for enterprises, which is a significant concern for many companies pursuing digital transformation and efficiency.

Edge Computing has emerged as a bright spot.

In this new computing model, all data that needs to be processed in real-time locally no longer needs to be sent to the center but is computed and analyzed locally, ensuring the value of the data and making the prospects for intelligent manufacturing incredibly clear.

Of course, edge computing does not isolate access to historical data from central computing nodes—usually cloud computing platforms. This access may only be a form of “post-event” verification, rather than issuing operational commands from the center to the edge as in the past.

Clearly, edge computing will build the starting point of a new type of industry and will connect the entirety of the new industrial era.

The Emergence of the Edge Computing Alliance

It may sound easy to say, but edge computing is indeed significant.

As a bridge connecting the physical and digital worlds, edge computing is the fusion point of the ICT and OT industries, requiring solutions to cross-industry technical integration and collaboration challenges. This demands that various manufacturers and organizations in the industry chain unite in unprecedented ways to promote overall industrial development.

On November 30 last year, six organizations, including Huawei, the Shenyang Institute of Automation of the Chinese Academy of Sciences, the China Academy of Information and Communications Technology, Intel, ARM, and Softcom Power, officially established the Edge Computing Consortium (ECC).

The official founding ceremony of ECC last year

At the founding ceremony, a senior official from the Ministry of Industry and Information Technology stated that during the process of upgrading traditional manufacturing to intelligent manufacturing, it is particularly necessary to use edge computing technology to intelligently connect production equipment in workshops, improve efficiency, and promote innovation.

Edge computing is an open platform that integrates network, computing, storage, and application core capabilities, providing the nearest intelligent services—applications initiated from the edge side generate faster network service responses, thus meeting the basic needs of industries in real-time business, application intelligence, security, and privacy protection.

In this model, machine tools, robots, peripheral devices, and sensors in automated systems are connected and can provide advanced data analysis, improving production quality, efficiency, flexibility, and equipment reliability during the production process, thereby enhancing Overall Equipment Effectiveness (OEE) and promoting production profit increases.

Through the resources and capabilities of edge computing, virtual space and physical entities can be closely integrated. It can be said that in the field of industrial manufacturing, achieving digital manufacturing, networked collaboration, and intelligent transformation cannot be separated from the IoT, big data, and cloud computing, and even more so from edge computing.

To some extent, edge computing is like a supplement and extension of cloud computing; the two cannot replace each other but rather strengthen one another. The essence of enterprise digital transformation is based on the processing and mining of massive data, and without cloud computing and edge computing, the so-called transformation would only be a heavy blow to cotton.

The establishment of the Edge Computing Alliance has achieved the goal of spanning multiple fields, including OT, IT, and CT. Since its establishment nearly a year ago, the alliance has grown to over 130 members, including many internationally renowned companies such as Mitsubishi, Bosch, Schindler, Schneider, Infosys, McAfee, ABB, and Fault Tolerance in the United States.

In a very short time, the alliance has begun to set agendas such as technical architecture formulation, conducted extensive work in promoting horizontal decoupling and platformization, and built a number of testbeds related to industrial manufacturing, making positive attempts in areas such as predictive maintenance for industrial robots and IoT for machine tools.

The Layout of Giants Has Already Begun

More and more technology and industrial companies are beginning to realize the enormous potential of edge computing. From various perspectives, the application scenarios of edge computing are rich, and its industrial value is prominent, capable of helping manufacturing achieve a transition from product-based to service-based business models.

Companies such as Cisco, HPE, GE, Mitsubishi, and SAP have all begun to explore edge computing in the field of industrial manufacturing, with competition revolving around ecosystems. Each manufacturer lays out based on its strengths, and edge computing has become a key node connecting the upper and lower streams.

However, the terminology used by manufacturers may vary. For example, terms like micro-cloud and fog computing are essentially no different from edge computing; they all provide computing close to the application end on-site.

Edge computing has provided the strongest impetus for the IoT. For many years, the IoT could be said to be calm, with more significance than substance, while the emergence of edge computing has directly brought the IoT into an application explosion period, heralding a new industrial landscape.

The establishment of the Edge Computing Alliance has connected the strongest manufacturers in various fields, including OT, IT, and CT, with research and institutions in automation and transmission protocols. Each draws on the strengths of others to jointly promote the practical application of edge computing in the industrial field.

From the perspective of integrating the industrial value chain, the alliance has proposed CROSS, which aims to achieve Real-time Business, Data Optimization, Smart Applications, and Security and Privacy Protection based on Agile Connection.

At the same time, bringing value and opportunities to users at the network edge is also a core focus for alliance members.

Alliance members have also abandoned “narrow-mindedness” and actively collaborated with heavyweight players in the industrial field. For example, at this year’s largest industrial exhibition, the Hannover Messe, ECC founding member Huawei partnered with leading industrial internet software company GE Digital to jointly release an industrial predictive maintenance solution based on industrial cloud, which has attracted significant attention in the industry.

The new solution seamlessly integrates Huawei’s edge computing IoT EC-IoT solution with GE’s industrial internet cloud platform Predix, quickly achieving end-to-end connectivity from industrial equipment to cloud applications, real-time monitoring of equipment status, data analysis and insights, and intelligent decision-making for maintenance.

Understanding China Manufacturing 2025 is certainly important, but injecting a catalyst for the development of Chinese manufacturing and even global industry through edge computing is a more substantial enhancement.

The establishment of the Edge Computing Alliance is approaching its first anniversary, and at the upcoming alliance’s new industrial summit on November 29, we can expect to hear more valuable information.

(✰ Meeting is not as good as a chance encounter. Today’s two articles happen to be related to GE, so interested friends may want to check them out.)

Editor: Ayou