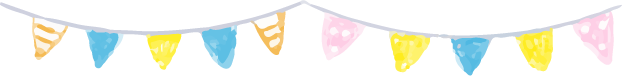

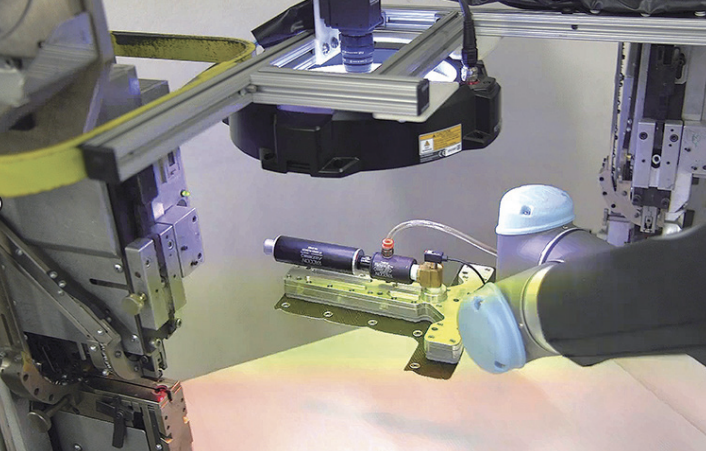

Image Source: Universal Robots

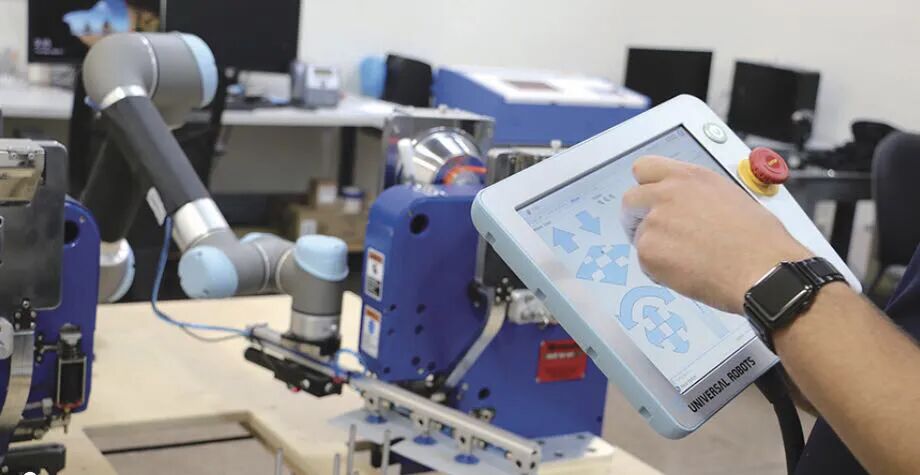

Image Source: Universal Robots

Author | Joe Campbell

“

A manufacturing company engaged in wire and cable management and protection has doubled its production output while achieving a zero defect rate by applying collaborative robots. The installation, integration, and use of collaborative robots have become a DIY project.

”

Zippertubing Company, a family-owned business, integrated collaborative robots into a vision-guided application that required a clip fastener to wrap cable sheaths, despite having no prior experience with robotic technology.

Collaborative robots can help companies achieve zero defects in production while doubling output. By implementing a higher degree of automation, Zippertubing has saved 32% in labor costs, effectively reducing expenses.

The company’s operations manager, Tim Mead, is often asked at trade shows by robot manufacturers, “What type of integrator are you using?”

“But we want something we can integrate ourselves. This will save a lot of money and bring the installation costs down to a reasonable level,” Mead said. His company is facing a significant increase in demand for sheathing, primarily from the automotive and aerospace sectors for protective hoses, pipes, and cables. On Zippertubing’s production line, workers struggle to keep up with the fast-paced, precise, and repetitive task of correctly inserting cable sheaths into the clip machine. The company hopes to use user-friendly collaborative robots to assist.

For several reasons, Zippertubing ultimately chose a 5 kg payload collaborative robot. “After a quick demo phase, we realized this was a collaborative robot we could integrate ourselves,” said the company’s engineering manager, Matt Hesselbacher. “Considering the monthly changes in production line products, we are also looking into its versatility. Since operators will be working around the robot, safety is another concern we need to consider.”

▎Universal Robots’ distributor, In-Position Technology, provided a simple demonstration for the customer, while the online Robot University offers free training. Zippertubing needed to install a safety scanner that slows the robot down when someone enters the work area.

Mead said, “The biggest benefit we’ve gained is: product quality has greatly improved; the robot has been running for 8 months, and we have transitioned from having some products returned to now producing zero defects. With the collaborative robot, our specified part tolerances are 300% better than manual operations.” Zippertubing’s customers have also noticed this improvement.

This Arizona-based company programmed its collaborative robot to pick up pre-cut fabric materials, then move them through a socket machine, inserting 5 male snaps before moving to a second machine to add 5 female snaps. After the collaborative robot presents the parts to a vision camera, which checks if the snaps were added correctly, the 25-second cycle ends. Based on the inspection results, the collaborative robot places the completed workpieces in either the “qualified” pile or the “scrap” pile.

Higher Manufacturing Capacity

Zippertubing is developing a more compact collaborative robot device that can reduce cycle times while increasing the number of parts produced after hours by integrating a turntable for fabric transport.

“We can have the robot run all night, doubling output. It can also handle 2-3 other parts, covering more products,” Mead detailed how the collaborative robot has reduced the company’s workforce by 32% in these applications. “We can reallocate the freed-up labor to more customized, high-skill, high-demand departments on the production line, where operators can utilize their skills more effectively.”

▎Zippertubing’s operations manager, Mead, stated that after achieving automation, the collaborative robot saved 32% in labor. “We manufacture many different parts, which are not produced in large batches but are more customized. By utilizing those surplus employees, we can have them produce these custom parts in other business departments, thus improving overall efficiency while keeping the total number of employees unchanged.”

Mead’s background is in chemical engineering, not robotic programming, so he was initially reluctant to build the robotic device from scratch.

The collaborative robot distributor created a demo interface, “It looked very simple, and there are many cool training materials on the manufacturer’s website,” Mead said. “The distributor’s trainers came over to provide us with some programming tips, and then we could operate it ourselves.”

The first challenge Zippertubing faced was figuring out how to get the robot to pick up the fabric, which was ultimately resolved through the built-in wizard in the collaborative robot programming interface.

“The second step was breaking, which was very simple; we connected a latch rod to the relay,” Mead said. “Without using a foot pedal, we only used the robot’s digital I/O.” His team iterated on the correct positioning of the snaps.

▎Zippertubing, which is engaged in wire and cable management and protection, designed a wrap-around Velcro sleeve for the robot arm to secure the air lines and electrical systems used for the arm in place. Tim Mead mentioned that when they commercialized products for other Universal Robots users, they said, “With the changes in I/O, we can remove and replace it when changing products.”

The Robot is the Brain of the Unit

The next step was to utilize a vision system for quality inspection. The challenge was: how to make the robot communicate with the camera, and who would be responsible?

During the handling of this application, the relevant personnel realized that the brain of the collaborative robot (the controller) could serve as a programmable logic controller (PLC).

“It issues all commands and receives all feedback,” Mead said. The robot looks for feedback from the camera. If it doesn’t find it, it indicates a problematic part; if it finds it, it indicates that the part is qualified and sorts it accordingly.

Once the entire device was developed, the final step was a risk assessment. The robot used was classified as a “collaborative” robot because its built-in safety system allows the robot arm to stop when encountering objects or people in its path. Zippertubing has a multifunctional team that includes statistical analysis, production, and engineering departments. This team identified two safety-related areas of concern.

Both areas are not part of the collaborative robot system. “We have tested the robot,” Mead said. The focus is on the auxiliary systems, which automatically trigger the robot’s snap machine and hopper. Light curtains prevent personnel from reaching into the hopper, and once someone enters the work area, the area scanner will slow the robot down. When the person leaves, the robot will return to normal speed.

Quick Tool Change

If the entire device needs to be programmed, Zippertubing requires less than a week. Hesselbacher said the collaborative robot enables a more flexible production process. “Unlike before when we needed to produce a large number of parts immediately, we can now operate at a more stable production level.”

Due to the need to change different tools, the company visited the collaborative robot manufacturer’s website, which has an online platform for certified plug-and-play products, and found the Milibar tool changer.

“The benefit of using this tool is the quick tool change; now, adding new tools to the end of the robotic arm is no longer an issue,” Mead said.

▎After inserting male and female snaps, the robot places the fabric under the vision camera lens for quality inspection, then classifies it as “qualified” or “unqualified.”

Having tasted the benefits of increased production efficiency, the company is seeking to automate other tasks. Sewing is one of them.

“This will be a unique challenge because we want the robot to use the same tool for snaps and sewing. We will place the snaps into the parts, fold them, and then convey them to the sewing machine. Triggering the sewing machine by the robot should be straightforward. The truly difficult part will be the head of the mechanical tool and how to make it work,” Mead said. He is very optimistic that his team will complete the sewing project soon.

Shareable Automation Applications

According to Zippertubing, the return on investment for purchasing collaborative robots is two years. “The ROI is not just in terms of the money invested in the robots and systems,” Hesselbacher emphasized, noting that the robots can continue working after hours, reducing the time needed to achieve ROI.

Zippertubing’s factory in China has also noticed the success of its Arizona facility. “Currently, our factory in Asia is entirely manual, and they have contacted us to see if we can build some of these robotic devices for them,” Mead said, as he plans to improve the next collaborative robot application and provide it to his colleagues in China.

Collaborative robot distributor In-Position Technology’s sales engineer, Seth Garrison, stated that it is not uncommon for companies without robotic programming experience to successfully use collaborative robots and put them into operation. “Most of our devices are handled by the customers themselves.

▎Sales engineer Garrison from Universal Robots distributor In-Position Technology stated that it is not uncommon for companies without robotic programming experience to start operating with Universal collaborative robots. Zippertubing took about a week to program the entire robot unit, including interfacing with the snap machine, safety scanner, and vision camera. Zippertubing plans to add a rotating workbench to double the number of products the unit can handle.

We typically work with them for about a day, teaching them how to use the robot, and then they can proceed with integration and device design based on that,” Garrison added that distributor experts sometimes provide more in-depth services. If this were a traditional industrial robot, it would be challenging for the customer to accomplish this alone.

Key Concepts:

■ Collaborative robots can be used for DIY applications.

■ Robot controllers can perform PLC functions in work units.

■ Robot manufacturers’ websites and distributors can provide training and services to users.

Think About It:

Does working with collaborative robot applications inspire you to collaborate with others?

– END –

This article is from Control Engineering China (CONTROL ENGINEERING China) March 2020 issue, originally titled: Integrating Collaborative Robots Yourself.

—— Recommended Conferences ——

Recommended Reading

“PID Tuning Guide” White Paper – The Ultimate Guide in the PID Field is Here! Free to Request!

Siemens Changes Leadership! Current CTO Bo Le Ren Will Succeed Kai Sa to Steer the “Slimmed Down” VersionSiemens

[Latest Progress] OPC UA Security Specification Version 1.00 Officially Released

Breaking News | There Will Be No Hannover Messe in Germany in 2020

How Much Money Do You Make? What Matters More Than Money? The 2019 US Control Engineer Career and Salary Survey Report is Out!

Good News!

We Invite You to Join the Industrial Automation Circle

Starting in 2020, to enhance communication between editors and readers, and among readers, we will establish various WeChat groups for professional readers in industrial automation technology.

We plan to form the following technical category groups:

TSN Network Group

PLC Group

DCS Group

Machine Vision Group

Robot Group

Industrial Software Group

Human-Machine Interface Group

Motion Control Group

Sensor Group

Industrial Safety Group

Instrumentation Group

AI/AR Group

Scan the QR code on the right

Send “Name + Technical Interest + City” to add the editor’s WeChat (cec_editor), and after review, you will be invited to join the corresponding technical group.