MEMS technology is currently the hottest sensor manufacturing technology and an important driving force for sensor miniaturization, intelligence, and low energy consumption. MEMS technology has greatly promoted the development of sensors; without MEMS technology, the future of sensors would be bleak.

This article includes the top 10 mainstream MEMS smart sensors:

What is MEMS? Basic Composition of MEMS Sensors

MEMS stands for Micro-Electro-Mechanical System. In simple terms, a MEMS chip is an electronic mechanical system manufactured on a silicon wafer using semiconductor technology. More vividly, it is a micron or nanoscale mechanical system that can convert external physical and chemical signals into electrical signals. What can this type of chip do? The most common application is sensing functions.

In the larger information system, it is somewhat analogous to the human sensory system. For example, MEMS microphone chips are like human ears, capable of perceiving sound; MEMS speaker chips are like human mouths, capable of producing sound; MEMS accelerometers, gyroscopes, and magnetic sensor chips are like the human cerebellum, capable of sensing direction and speed; MEMS pressure chips are like human skin, capable of sensing pressure; and MEMS chemical sensors are like the human nasal cavity, capable of sensing taste and humidity. Without MEMS chips, artificial intelligence and the Internet of Everything would be like a person without sensory organs.

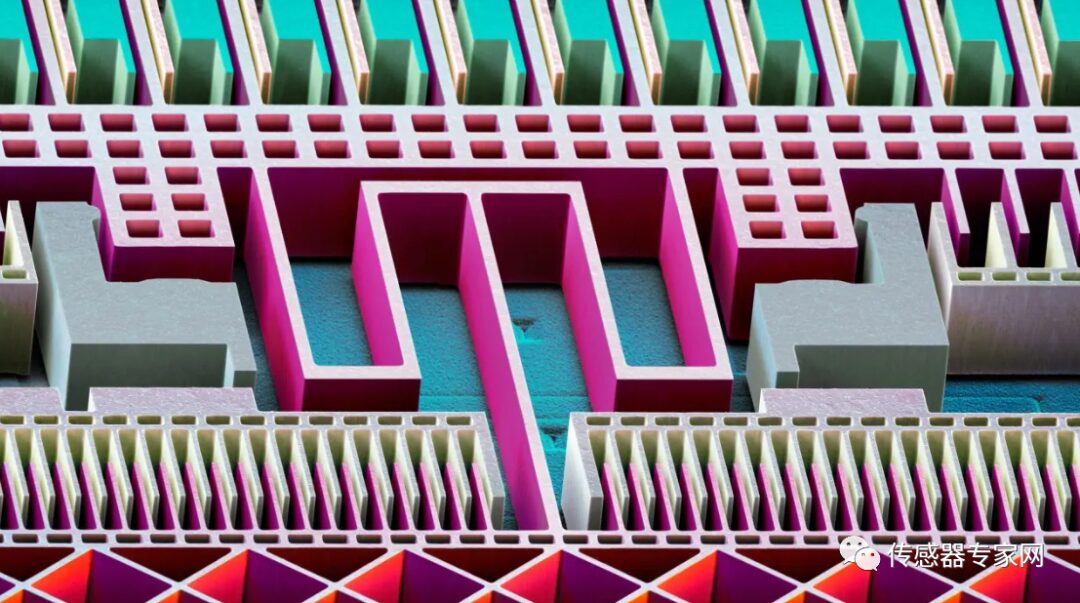

Through high-precision sensors, we can visually observe the movement of micron-level MEMS mechanical structures. It can be clearly seen that MEMS has conventional mechanical system structures, but the size has reached the micron level or even the nanoscale.

MEMS is considered one of the most promising technologies of the 21st century. If semiconductor micromanufacturing is regarded as the first micro-manufacturing revolution, MEMS represents the second revolution. By combining silicon-based microelectronic technology with micromechanical processing technology, MEMS has the potential for revolutionary industrial and consumer products.

It is important to emphasize that MEMS is a manufacturing technology; components such as levers, gears, pistons, engines, and even steam engines are manufactured using MEMS.

In fact, the term MEMS can be somewhat misleading because many micromechanical devices are not mechanical in any sense. However, MEMS is not just about the miniaturization of mechanical parts or making things out of silicon; it is a paradigm for designing, creating complex mechanical devices and systems, and integrating electronic devices using batch manufacturing technology. To be more specific, integrated circuit design utilizes the electrical properties of silicon, while MEMS utilizes the mechanical properties of silicon, or both the electrical and mechanical properties of silicon.

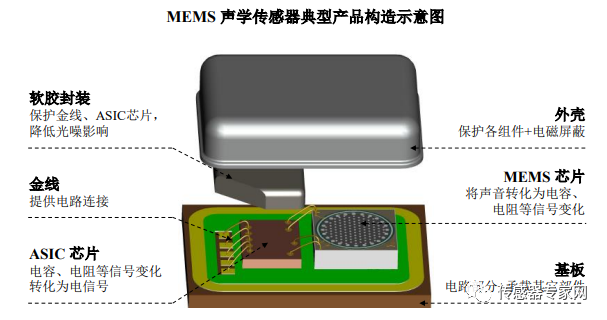

So what are MEMS sensors? MEMS sensors are devices formed by packaging a MEMS chip and a dedicated integrated circuit chip (ASIC chip) together.

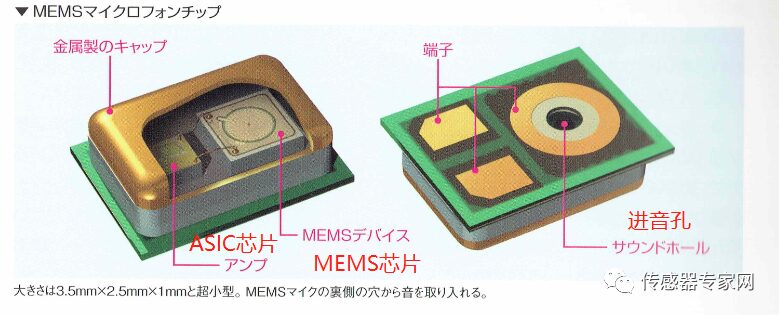

The following image is a typical internal structure diagram of a MEMS microphone, sourced from China’s largest MEMS manufacturer, GoerTek. This is a MEMS microphone, and it can be seen that the main components of this sensor are a MEMS chip and an ASIC chip, along with the substrate, casing, etc., packaged together to form a MEMS sensor. This is also the basic structure of most MEMS sensors.

MEMS chips convert sound into changes in capacitance, resistance, and other signals, while ASIC chips convert these changes into electrical signals, thereby realizing the functionality of MEMS sensors—converting external signals into electrical signals.

▲MEMS Acoustic Sensor Structure Diagram (from GoerTek’s prospectus)

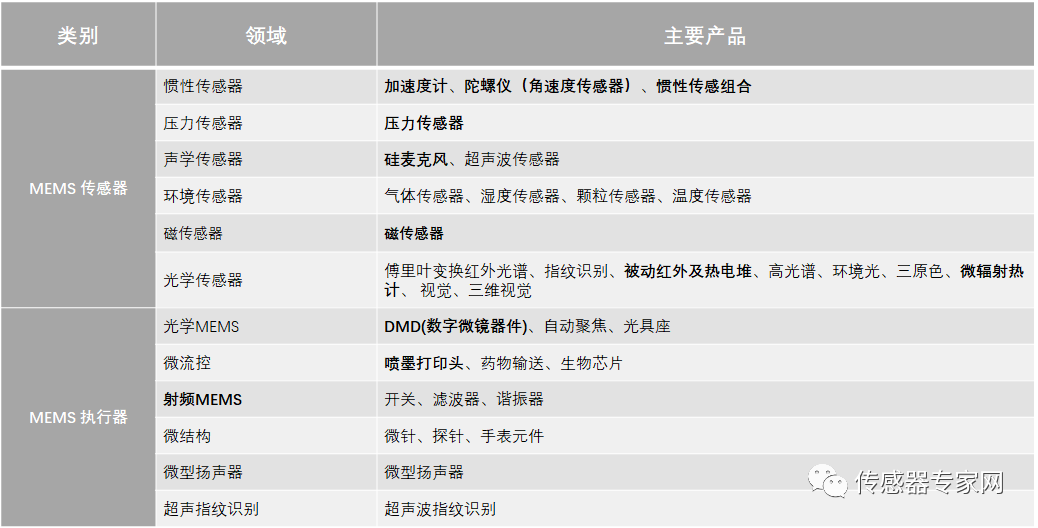

Common MEMS device products include MEMS accelerometers, MEMS microphones, micro motors, micro pumps, micro oscillators, MEMS optical sensors, MEMS pressure sensors, MEMS gyroscopes, MEMS humidity sensors, MEMS gas sensors, and their integrated products.

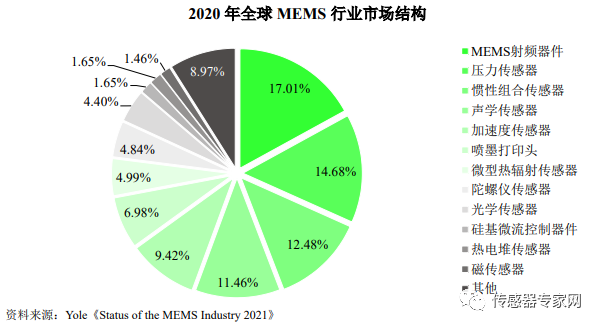

The most mainstream MEMS devices globally include: MEMS RF devices, pressure sensors, inertial combination sensors, acoustic sensors, accelerometers, inkjet printheads, micro thermal radiation sensors, gyroscope sensors, optical sensors, silicon-based microfluidic devices, thermoelectric pile sensors, and magnetic sensors.

Due to the microscopic characteristics of MEMS, it is difficult for us to visually understand the working conditions of each MEMS sensor. Below, a large number of animations have been specially collected to visually “see” the working principles of various mainstream MEMS sensors.

1. MEMS Acoustic Sensors

MEMS acoustic sensors primarily refer to silicon microphones and ultrasonic sensors, among which silicon microphones are the most widely used MEMS acoustic sensors.

A silicon microphone refers to a miniaturized microphone manufactured on a silicon substrate using MEMS technology, catering to the current trend of miniaturization and integration of 3C products, which is why TWS earphones and mobile phone microphones can achieve such integrated effects.

The above image shows the packaging structure of a MEMS microphone, consisting of three parts: the first part is the MEMS chip, the second part is the ASIC chip, and the third part is the metal casing, with signal terminals on the bottom PCB board

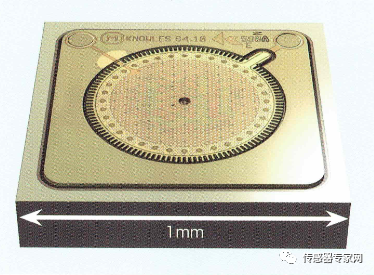

The following image is a MEMS chip, captured with a high-precision sensor, appearing square with a side length of 1mm.

Whether it is a traditional electret microphone or a MEMS microphone, their working principles are the same.

MEMS sensors consist of two layers forming a capacitor, with the upper layer being a perforated structure

The following image shows the internal structure of a MEMS chip, captured with a high-precision sensor, allowing us to clearly see that the MEMS bottom membrane vibrates with sound waves, converting sound pressure into capacitance and resistance signals, which are then processed by the ASIC chip and output as electrical signals. This is the entire process of how a MEMS microphone works.

The following image shows three MEMS microphones on the AirPods Pro wireless Bluetooth earphones, all supplied by China.

2. MEMS Pressure Sensors

MEMS pressure sensors measure pressure and are mainly divided into capacitive and resistive types.

With the emergence and popularity of MEMS pressure sensors, pressure sensors are increasingly used in smartphones, primarily to measure atmospheric pressure. The purpose of measuring atmospheric pressure is to calculate altitude based on pressure differences at different heights, combined with GPS positioning signals, achieving more precise three-dimensional positioning, such as detecting climbing heights and the number of stairs climbed.

The principle of MEMS pressure sensors is also quite simple; the core structure consists of a thin film element that deforms under pressure, causing changes in the electrical properties (resistance, capacitance) of the material. Therefore, a piezoresistive strain gauge can be used to measure this deformation and calculate the pressure applied.

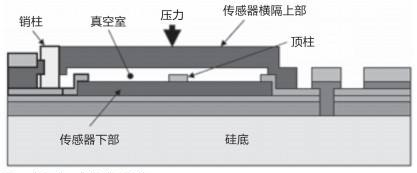

The following image is a structural diagram of a capacitive MEMS pressure sensor. When pressure is applied, the distance between the upper and lower diaphragms (the upper sensor diaphragm and the lower sensor diaphragm) changes, resulting in a change in capacitance between the diaphragms, which can be used to calculate the pressure.

The following image is an animation of a MEMS resistive pressure sensor, consisting of a base with a silicon thin film and a resistive structure mounted on it. When external force is applied, the voltage changes proportionally to the pressure, producing a measurement value.

The following image is a physical picture of a MEMS capacitive pressure sensor.

3. MEMS Accelerometers

MEMS accelerometers use acceleration to sense motion and vibration, such as the widely used body motion detection in consumer electronics, which is widely applied in game control, controller vibration and shaking, posture recognition, etc.

The principle of MEMS accelerometers is very easy to understand; it is based on Newton’s second law of motion. Force is the cause of acceleration, and the magnitude of acceleration is proportional to the external force and inversely proportional to the mass of the object: F=ma.

Thus, MEMS accelerometers are essentially a type of pressure sensor. To calculate acceleration, it is essentially measuring the inertial force generated due to changes in state. Common types of accelerometers include piezoresistive, capacitive, piezoelectric, and resonant types.

Among them, capacitive silicon accelerometers are currently the most mature technology and widely used due to their high precision and strong environmental adaptability. As MEMS processing capabilities improve and ASIC circuit detection capabilities enhance, the accuracy of capacitive MEMS accelerometers is also continuously improving.

Capacitive accelerometers are distance-change type capacitive sensors based on the principle of capacitance, where one electrode is fixed, and the other variable electrode is a flexible membrane. The flexible membrane displaces under external forces (air pressure, liquid pressure, etc.), causing changes in capacitance. This sensor can measure the vibration speed (or acceleration) of airflow (or liquid flow) and can further measure pressure.

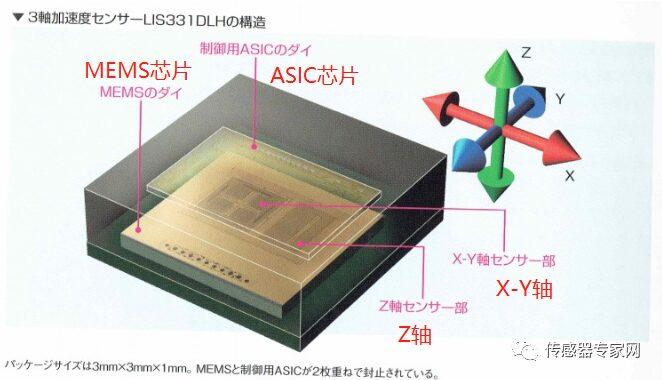

The following image shows the packaging structure of a 3-axis MEMS accelerometer, with the ASIC chip located above the MEMS chip. In the MEMS chip, the Z-axis and X-Y axes are structurally separated.

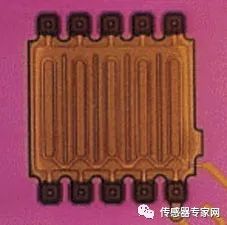

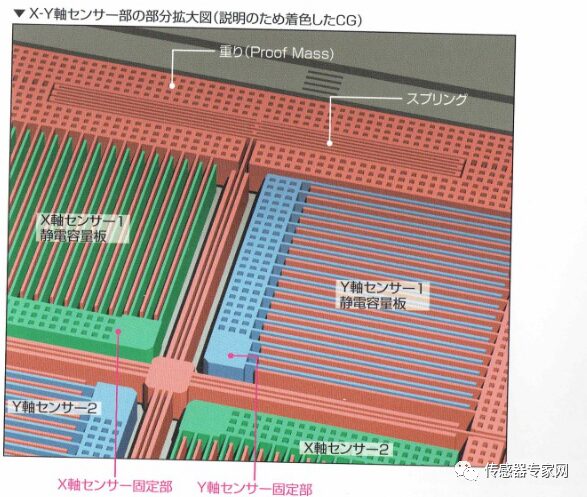

The following image is an internal structure diagram of the MEMS chip’s X-Y axis section, with comb structures arranged closely.

The following image shows the comb structure of the MEMS accelerometer under microscopic conditions.

When an object accelerates, it drives the comb structure to displace, causing changes in capacitance between the comb structures, thereby measuring the acceleration value.

4. MEMS Gyroscope Sensors

MEMS gyroscopes, also known as MEMS angular velocity sensors, are sensors that measure angular velocity, and their principles are relatively complex.

Measuring angular velocity is not an easy task; it requires finding a stationary anchor point within a moving object—this anchor point is the gyroscope. It has been found that gyroscopes in high-speed rotation maintain a large angular momentum, and their rotation axes do not change with the external motion state, remaining stable in a single direction.

What can gyroscopes do? Their greatest use is to maintain stability. In the animal kingdom, birds have the best stability, so many people joke that birds must have an advanced gyroscope in their heads; no matter how they move, their heads remain still. Gyroscopes can also maintain the stability of machines.

As for the structure of gyroscopes, the core is a rotor that spins continuously, serving as a stationary anchor for other moving objects. The following image shows a gyroscope maintaining balance along a line during high-speed rotation; this is the basic principle of gyroscopes.

Returning to MEMS gyroscopes, their working principles differ from traditional gyroscopes because the “micro-sculpting” technique fabricates a movable three-dimensional rotor on a silicon substrate, which is not an easy task.

MEMS gyroscopes utilize the principle of Coriolis force—the tangential force experienced by a rotating object during radial motion.This force exceeds the author’s high school physics level; how to describe this Coriolis force? One can imagine a rotating magic disk at an amusement park, where people are most stable near the rotation axis, but as the large disk’s rotation speed increases, people automatically slide toward the edge of the disk, as if pushed by a force that accelerates them along the direction opposite to the disk’s rotation; this force is the Coriolis force.

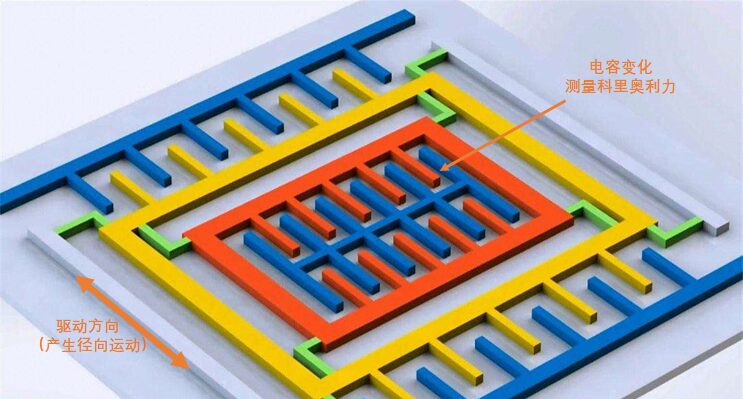

Thus, the structure of MEMS gyroscopes consists of an object on a disk that is driven and moves radially or oscillates continuously. Due to the radial motion in a rotating state, Coriolis force is generated. MEMS gyroscopes typically use two movable capacitive plates to measure Coriolis force through capacitance changes.

The following image shows the working animation of a MEMS gyroscope, where the sensor’s outer frame swings in the opposite direction during rotational motion. When the object rotates, part of the internal comb structure deflects, changing the distance between the comb structures, thereby altering capacitance to measure the angle of rotation.

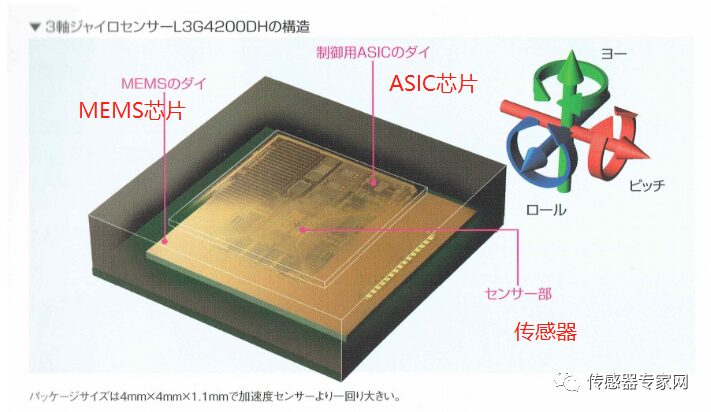

The following image shows a packaged 3-axis MEMS gyroscope, with the ASIC chip located above the MEMS chip. The entire device measures 4mmX4mmX1.1mm.

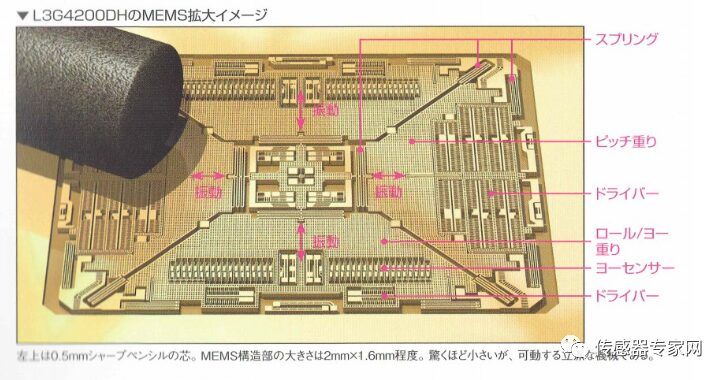

The following image shows the intricate structures of the MEMS chip, resembling a magnificent building. Note that the upper left corner contains a hair.

5. MEMS Inertial Combination Sensors

MEMS inertial combination sensors are not a new type of MEMS sensor, but rather a combination of accelerometers, gyroscopes, magnetic sensors, etc. By utilizing the characteristics of various inertial sensors, they can achieve all-around, three-dimensional motion detection.

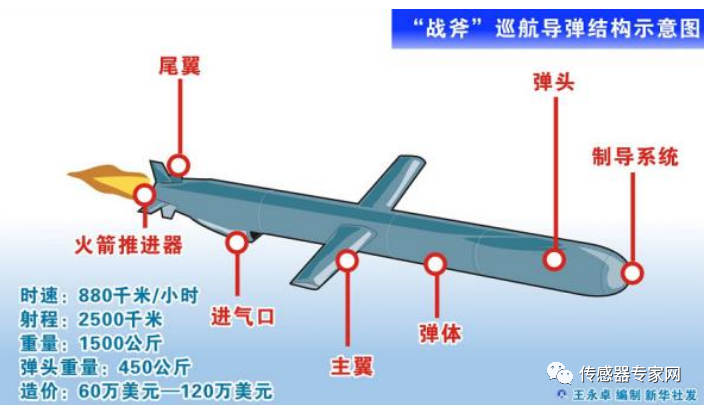

A well-known application field of combination inertial sensors is inertial navigation, such as aircraft flight control, posture control, yaw damping control applications, and inertial GPS navigation for guidance applications.

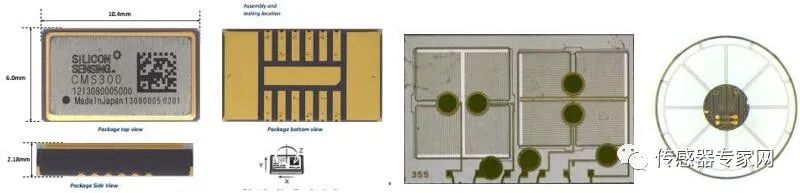

The following image shows an inertial combination sensor (left) and a MEMS chip (right), including an ASIC chip, a MEMS gyroscope chip, and a MEMS accelerometer chip, using a ceramic substrate and wire bonding.

6. MEMS Magnetic Sensors

Magnetic sensors are not merely devices for measuring magnetic field strength, but rather devices that detect external environmental changes based on variations in the magnetic properties of sensitive elements influenced by external factors, including magnetic fields, currents, stress, temperature, light, etc.

Magnetic sensors are mainly divided into four categories: Hall effect sensors, anisotropic magnetoresistive (AMR) sensors, giant magnetoresistive (GMR) sensors, and tunnel magnetoresistive (TMR) sensors.

Among them, magnetoresistive sensors represent the fourth generation of magnetic sensing technology, based on nanofilm technology and semiconductor fabrication processes, which accurately measure physical parameters such as current, position, direction, rotation, and angle by detecting magnetic field information.

Because MEMS technology can miniaturize traditional magnetic sensors, MEMS-based magnetic sensors have advantages such as small size, high performance, low cost, low power consumption, high sensitivity, and mass production. Their fabrication materials are primarily silicon, eliminating the need for special magnetic materials in sensor fabrication and their impact on the measured magnetic field.

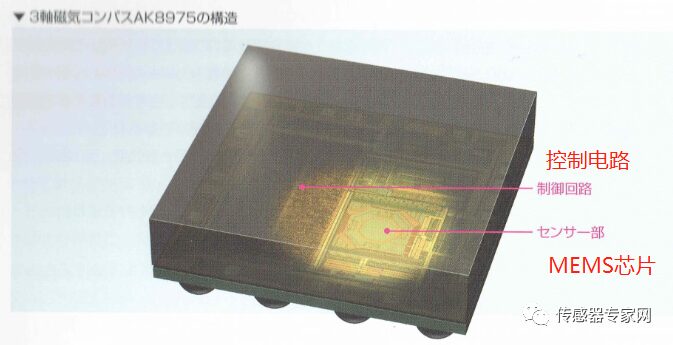

The following image is a packaging structure diagram of a 3-axis MEMS magnetic sensor, which includes a MEMS chip and control circuit.

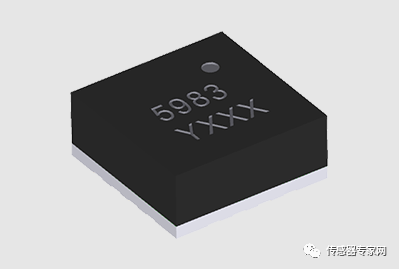

The following image is an AMR three-axis magnetic sensor, measuring only 3mmX3mmX1mm.

7. MEMS Microfluidic Systems

MEMS devices have a wide range of applications, mainly divided into sensors and actuators. The aforementioned devices belong to MEMS sensors, whereas microfluidic systems, RF MEMS, MEMS inkjet printheads, and DMD (Digital Micromirror Devices) are part of actuators, which are an important component of MEMS devices.

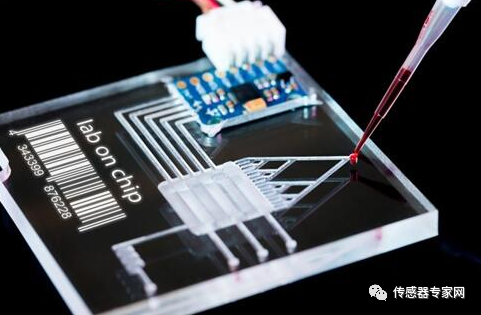

MEMS microfluidic systems are devices that control and manipulate the flow of liquids with high precision, using pipes on the scale of tens to hundreds of microns. They are generally aimed at micro-scale fluids and are used for high-precision and high-sensitivity separation and detection in biomedical diagnostics, featuring advantages such as low sample consumption, fast detection speed, easy operation, multifunctional integration, small size, and portability.

MEMS microfluidics are purely mechanical structures, and the main materials for making microfluidic chips include silicon, glass, quartz, polymers, ceramics, and paper.

A MEMS microfluidic chip, to put it simply, is a biochemical reaction occurring on a very small glass channel, with calculations performed by a chip and signals transmitted by sensors.

The following image is a structural example of a microfluidic chip, showing glass channels. Microfluidic chips are also known as “lab-on-a-chip” and have broad application prospects in areas such as gene sequencing, making them a very promising biosensor.

The following image illustrates the dynamic process of fluid flow and capture in microchannels.

8. RF MEMS

RF MEMS devices include MEMS filters, MEMS switches, MEMS resonators, etc.

The RF front-end module primarily consists of filters, low-noise amplifiers, power amplifiers, RF switches, and other devices, among which filters are the most important discrete component in the RF front-end, and the technology for filters is MEMS, accounting for over 50% of the RF front-end module, mainly produced by companies like Murata.

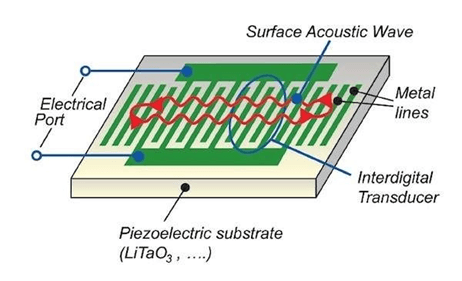

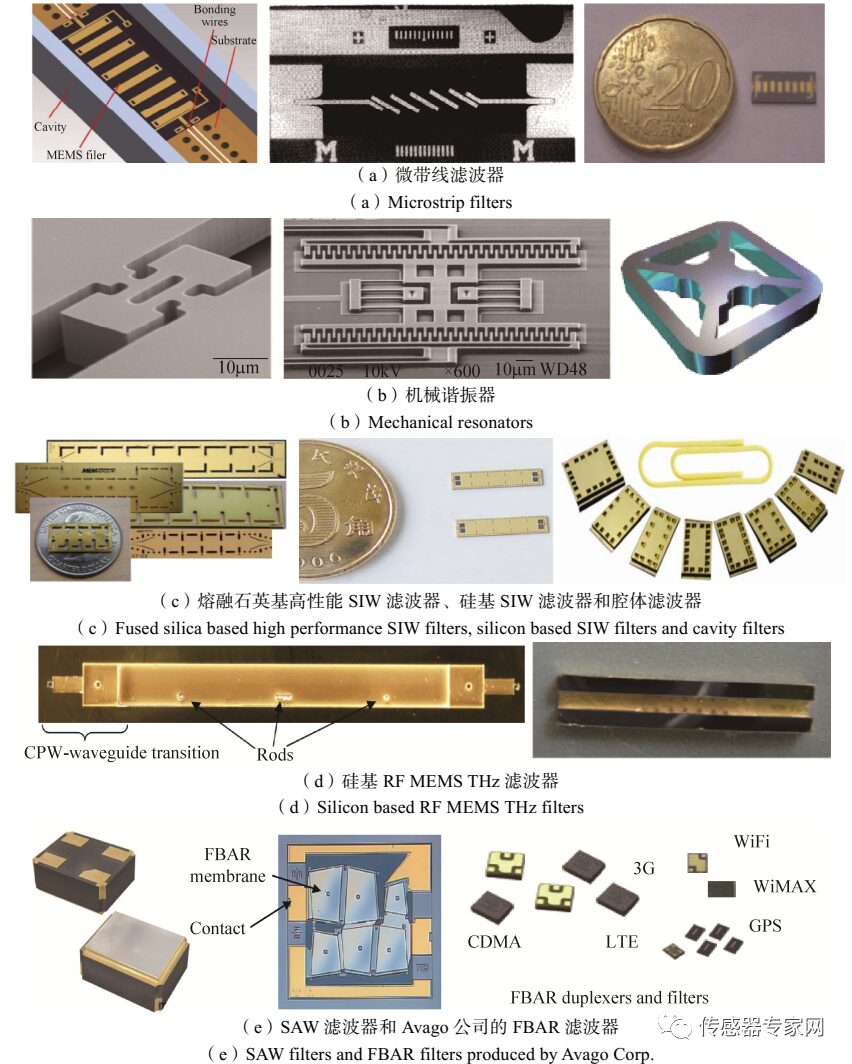

Filters (SAW, BAW, FBAR, etc.) are responsible for filtering RF signals in the receiving channel, outputting specific frequency signals from the various RF signals received while filtering out signals of other frequencies. For example, in SAW surface acoustic waves, unwanted frequency signals are filtered out through the conversion of electromagnetic signals to sound waves and back to electromagnetic signals.

The following image shows the microscopic structure and packaging forms of various MEMS filters, providing an intuitive understanding of the differences among various MEMS filters.

RF switches are not merely simple switches, but rather devices used to switch signals of different directions (receiving or transmitting) and different frequencies in RF devices, enabling channel reuse.

RF MEMS switches come in various types and can be driven by different mechanisms. Due to their low power consumption and small size, electrostatic drive is commonly used in RF microelectromechanical system switch designs. MEMS switches can also use inertial forces, electromagnetic forces, thermal forces, or piezoelectric forces to control their opening or closing.

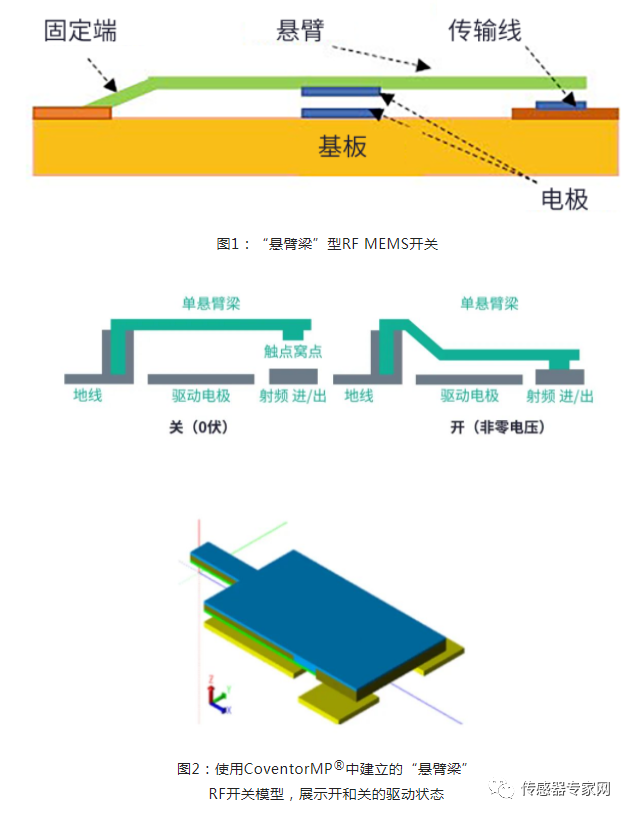

The following image shows a “cantilever beam” RF MEMS switch. In this configuration, a fixed beam is suspended above the substrate; when the beam is pressed down, the electrodes on the beam contact the electrodes on the substrate, placing the switch in an “on” state and closing the circuit.

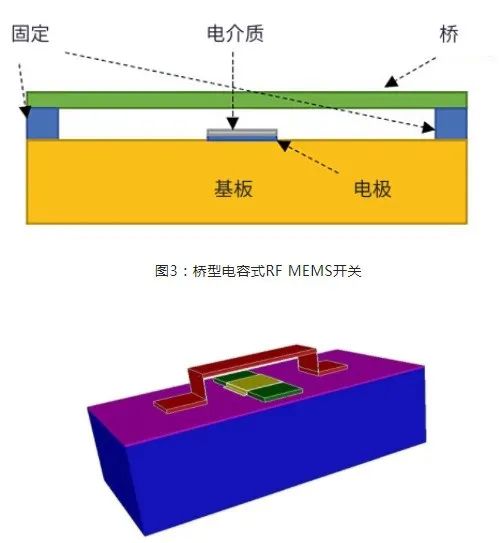

The latest generation of RF MEMS switches is mostly capacitive devices. Capacitive switches operate using capacitive coupling, making them very suitable for high-frequency RF applications.

During operation, force is applied to a beam suspended like a bridge above the substrate. When the beam is pulled down by this force (such as electrostatic force), it contacts the dielectric on the substrate, terminating the signal. The cross-section of the bridge-type capacitive switch is shown in the figure, where a 3D model of the capacitive RF MEMS switch is in an undeformed state, as shown in figure 4.

Oscillators/resonators convert DC power into AC power to generate AC signals of a certain frequency and are classified as active devices. Resonators filter signals of a specific frequency in a circuit and are classified as passive devices.

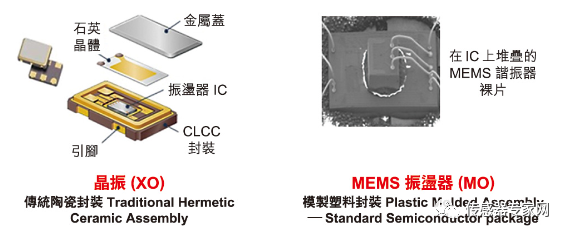

The following image compares MEMS resonators with traditional quartz oscillators, showing that MEMS resonators have higher stability, reliability, and smaller size.

9. DMD (Digital Micromirror Device)

DMD (Digital Micromirror Device) is an important category of optical MEMS, mainly applied in the field of DLP (Digital Light Processing), which involves image projection.

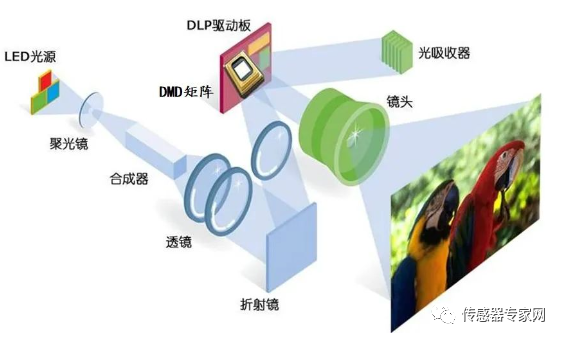

Projection, simply put, is the process of projecting digital image signals through a series of convergence and reflection.

In projection systems, the DMD chip is one of the core components.

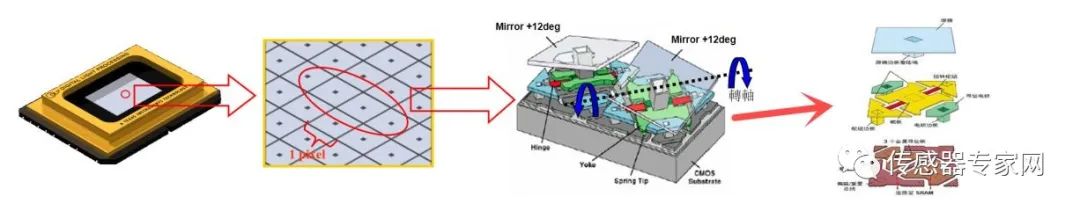

DMD technology controls hundreds of thousands to millions of tiny mirrors through digital information, projecting varying amounts of light. Each micromirror measures only 16×16 microns, arranged in a matrix. Each micromirror can flip at an angle of 10 degrees or -10 degrees under the control of binary 0/1 digital signals.

The following image is a packaging structure diagram of a DMD chip, which can be clicked to enlarge for viewing.

The following image shows the movement of each micromirror in the DMD chip. Such micromirrors can number in the millions within a single DMD chip, and each micromirror can independently flip, reflecting corresponding light, thus creating different colors and brightness. Each micromirror functions like each pixel in our television.

10. MEMS Inkjet Printheads

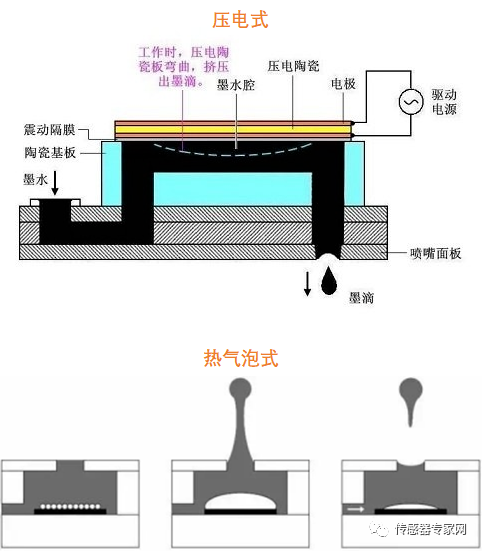

MEMS inkjet printheads are actually of the same type as the MEMS microfluidic systems previously discussed, both belonging to applications in the MEMS microfluidic domain. However, the difference is that MEMS microfluidic systems are primarily used in biological detection, while MEMS inkjet printheads are used in printers to control the ejection of ink.

Simply put, the function of inkjet printheads is to expel ink, which can be done either by vibrating a piezoelectric membrane to squeeze the ink or by using heating bubbles to expand and expel the ink within the chamber.

This content is reprinted and only represents the author’s views

It does not represent the position of the Institute of Semiconductors, Chinese Academy of Sciences

Editor: Renowned Weicheng Wei

Editor: Jiang Yu

Submission Email: [email protected]