Source: Sensor Expert Network

Original Author: Dynamic Sensing

In the past decade, technologies such as smartphones, smartwatches, and drones have rapidly entered our lives. In the next decade, various wearable devices, IoT devices, robots, and autonomous vehicles will integrate into our daily routines. Among these, sensor technology, as one of the foundational technologies for these advancements, is driving technological development, while these technologies are redefining the future demands for sensor technology: smaller, more integrated, smarter, and lower power consumption…What technologies will drive sensors forward in the future? This article summarizes the eight key technologies in sensor development, which may provide some insights.

New sensing technologies based on new principles and effects

New sensing technologies based on new principles and effects

Sensors are the crystallization of numerous high-tech advancements and the result of interdisciplinary knowledge convergence. Based on various physical, chemical, and biological effects and laws, we have developed sensitive components like force-sensitive, temperature-sensitive, light-sensitive, magnetic-sensitive, and gas-sensitive elements, resulting in over 26,000 types of sensors globally today.

Therefore, developing sensitive elements and sensors with new principles and effects to create new types of sensors is a crucial pathway for advancing high-performance, multifunctional, low-cost, and miniaturized sensors.

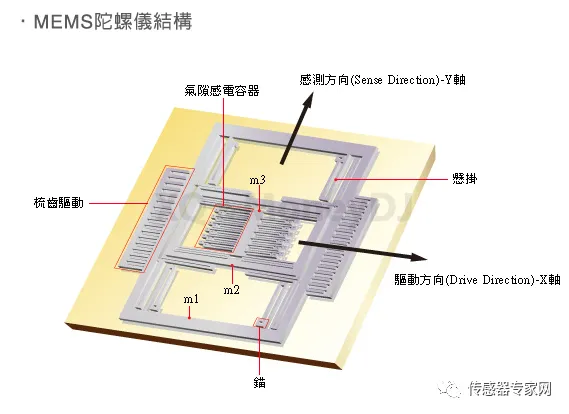

Take inertial sensors as an example. Inertial sensors apply inertial principles and measurement technologies to detect and measure acceleration, tilt, impact, vibration, rotation, and multi-degree-of-freedom (DOF) motion. An inertial system composed of accelerometers and gyroscopes can achieve real-time monitoring of the position and motion information of the carrier.

Different types of gyroscopes are driven by different physical principles, such as mechanical dry, liquid floating, semi-liquid floating, gas floating angular rate gyroscopes, flexible angular rate gyroscopes, MEMS silicon, quartz angular rate gyroscopes (including hemispherical resonant angular rate gyroscopes), mainly utilizing the Coriolis effect (Coriolis effect refers to the deflection of a moving object in a rotating coordinate system, with the Coriolis force proportional to the input angular rate).

Meanwhile, sensor technologies like fiber optic angular rate gyroscopes and laser angular rate gyroscopes mainly utilize another principle: the Sagnac effect (phase difference is proportional to the input angular rate).

These new principles and effects play a key role in promoting the development of sensor technology and expanding more sensor application areas.

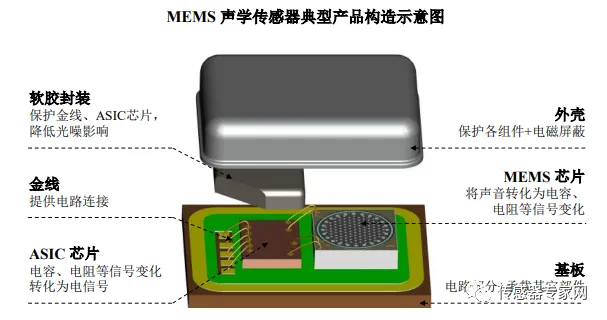

At the same time, new technologies from interdisciplinary fields also play an important role in sensor technology development. For example, integrated circuit technology significantly impacts sensor development. In MEMS sensors, high-performance application-specific integrated circuits (ASICs) can integrate thousands of transistor circuits into a single chip, reducing the impact of environmental factors and parasitic parameters on sensor performance, greatly enhancing MEMS sensor accuracy.

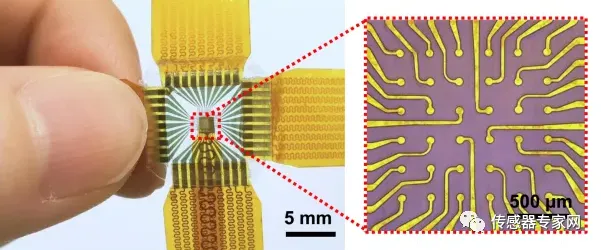

MEMS Acoustic Sensor Construction Diagram

Quantum sensors are one of the important applications of quantum technology. Previously, the U.S. National Science and Technology Council (NSTC) released a national strategy on quantum sensors titled “Putting Quantum Sensors into Practice”.

By utilizing effects from quantum mechanics, it is possible to design and develop quantum-sensitive devices such as resonant tunneling diodes, quantum well lasers, and quantum interference components, which exhibit advantages like high speed (1000 times faster than electronic sensitive devices), low power consumption (1000 times lower energy consumption than electronic sensitive devices), high efficiency, high integration, and economic reliability.

The development of nanoelectronics is also expected to trigger a new technological revolution in the field of sensor technology. Sensors made using nanotechnology are smaller, more precise, and significantly improved in performance. Nano sensors operate at the atomic scale, greatly enriching sensor theory, advancing sensor manufacturing levels, and broadening sensor application fields.

Miniaturization and Chip Technology of Sensors

The miniaturization and chip technology of sensors mainly includes MEMS technology and new generation solid-state sensor microstructure manufacturing processes, among which MEMS technology has been widely applied in sensors.

Micro-electro-mechanical systems (MEMS) are miniature systems or devices that integrate microstructures, micro-sensors, micro-actuators, control circuits, signal processing, communication, interfaces, and power supply, utilizing technology for the design, processing, manufacturing, measurement, and control of micro/nano materials.

MEMS materials include functional materials (usually semiconductor materials based on silicon), structural materials (such as piezoelectric materials, supermagnetic materials, light-sensitive materials, etc.), and smart materials (mainly shape memory alloys).

Key technologies in MEMS processes include deep reactive ion etching, LIGA technology, molecular assembly technology, bulk microfabrication, surface microfabrication, laser microfabrication, and micro-packaging technology.

Among these, silicon micromachining technology is the mainstream technology in MEMS. It is a precision three-dimensional processing technology and is the core technology for developing sensors, micro-actuators, micro-acting devices, and micro-mechanical systems, successfully applied in manufacturing various micro-sensors and multifunctional sensitive element arrays, such as micro silicon capacitive sensors, micro silicon mass flow sensors, aerospace dynamic sensors, micro-sensors, automotive pressure and acceleration sensors, and environmental micro-chemical sensors.

Deep reactive ion etching (DRIE) is one of the important processes in MEMS structure fabrication, mainly used for etching polysilicon, silicon nitride, silicon dioxide thin films, and metal films, belonging to a type of microelectronic dry etching process.

LIGA technology, which stands for lithography, electroforming, and injection molding, utilizes deep X-ray etching to form deep three-dimensional microstructures through electroforming and plastic molding.

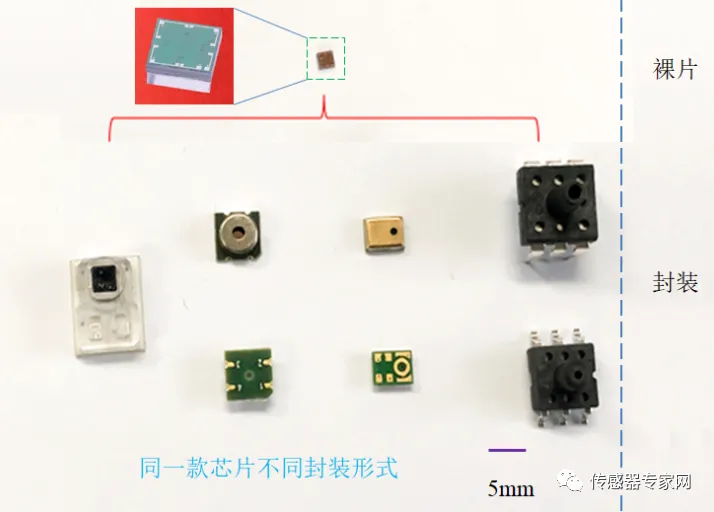

Currently, to adapt to the development of MEMS technology, many new MEMS packaging technologies and processes have been developed, such as anodic bonding, silicon fusion bonding, and eutectic bonding. MEMS packaging is typically categorized into several levels: bare chip packaging, device-level packaging, silicon wafer-level packaging, single-chip packaging, and system-level packaging.

Single-chip packaging (SCP) falls under the category of device-level packaging, referring to the creation of protective layers on a single chip, shielding delicate components and circuits from environmental impacts, and establishing pathways for active sensors/actuators to achieve electrical contact with the outside, meeting the device’s technical requirements for electrical, mechanical, thermal, and chemical aspects.

Multi-chip modules (MCM) represent a significant breakthrough in electronic packaging technology, classified as system-level packaging. MCM assembles two or more IC/MEMS chips or CSPs onto a single circuit board, forming a functional circuit board, i.e., a multi-chip module, which provides signal interconnection, I/O management, thermal control, mechanical support, and environmental protection for the various chips (components) within the module. MCM supports multiple chip types on the same substrate without altering the manufacturing processes of MEMS and circuits.

Sensor Arrays and Multi-Parameter Composite Integration Technology

This type of integration technology includes integrated processes and multi-variable composite sensor microstructure integration manufacturing processes, such as multi-variable composite sensors for industrial control, including pressure, static pressure, and temperature tri-variable sensors, and pressure, wind force, temperature, and humidity quad-variable sensors, micro silicon composite strain pressure sensors, and array sensors.

Integration refers to the combination of various sensing functions with data processing, storage, and bidirectional communication, achieving all or part of signal detection, conversion processing, logical judgment, functional calculation, bidirectional communication, as well as internal self-check, self-calibration, self-compensation, and self-diagnosis functions, characterized by low-cost, high-precision information acquisition, data storage and communication, automated programming, and functional diversification.

Sensor integration can occur in two ways: one is to construct multiple sensing modules on a single chip through microfabrication technology to form linear sensors (e.g., CCD image sensors); the other is to fabricate sensitive components with different functions on the same silicon wafer to create integrated multifunctional sensors, which have high integration, small size, and facilitate compensation and calibration.

Microfabrication technology and precision packaging technology significantly impact sensor integration.

Multi-sensor information fusion combines sensor application technology, data processing technology, computer hardware and software technology, and industrial control technology.

It employs computer technology for analysis, eliminating redundancy and contradictions that may exist between multi-sensor information, complementing them to reduce uncertainty, and obtaining a consistent interpretation and description of the measured object, featuring fault tolerance, complementarity, real-time performance, and cost-effectiveness.

Digital and Intelligent Technologies for Sensors

Intelligent technology encompasses intelligent sensor signal detection, transformation processing, logical judgment, functional calculation, bidirectional communication, and self-diagnosis, including intelligent multi-variable sensors, intelligent power sensors, various intelligent sensors, and transmitters.

Digital sensors include circuits for adjusting and processing signals and a network communication interface. They are typically produced in module form, containing sensors, DSP (digital signal processors), DSC (digital signal controllers), or ASICs (application-specific integrated circuits), and can also be made in system packaging or system-on-chip forms. The electronic components used to drive digital output typically include three types: mechanical relays, transistors, and bidirectional FET devices.

Intelligent sensors refer to sensors developed using artificial intelligence technologies such as hardware softening, software integration, virtual reality, and soft measurement, which possess anthropomorphic intelligent characteristics or functions. They are also active sensing systems with independent detection, signal processing, and transformation capabilities, capable of self-checking and communication.

Strong Environmental Adaptability Technology for Sensors

We know that sensors are ubiquitous, from automobiles to industry, from healthcare to aerospace, and from home appliances to testing and measurement. Many industry applications have high requirements for the environmental adaptability of sensors. For example, a magnetoresistive sensor produced by a German company used in the Mars rovers “Spirit” and “Opportunity” in 2004 can operate normally within a temperature range of +270°C to -133°C.

Strong environmental adaptability testing for sensor products includes electrical safety testing, failure analysis testing, corrosive gas testing, environmental performance testing, material testing, etc.

Advancements in sensor packaging materials and technologies have significantly enhanced the environmental adaptability of sensors.

Metal matrix composite packaging (AI/Si Cp) achieves the design of material physical properties by altering the type and arrangement of reinforcements, changing the alloy composition of the matrix, or altering the heat treatment process. This type of material has a low thermal expansion coefficient, matching that of electronic component materials while also exhibiting high thermal conductivity and low density.

Plastic packaging uses over 90% epoxy resin, offering advantages of large-scale production and reliability comparable to metal or ceramic materials. Sulfurized epoxy resin also features fast curing speed, low curing temperature, low moisture absorption, high moisture resistance, and heat resistance.

Ceramic packaging involves mounting one or more chips on a ceramic base or tube using adhesives or solder, employing flip-chip bonding methods to bond the packaging to the ceramic metal pattern layer, and sealing the package while providing suitable electrical connections.

Ceramics possess a high Young’s modulus, high insulation performance, and excellent high-frequency characteristics, demonstrating good reliability, plasticity, and ease of sealing. Their linear expansion coefficient is very close to that of electronic components, and they exhibit stable chemical properties and high thermal conductivity, making them suitable for multi-chip modules, solder arrays, and other packaging.

Wireless Sensor Network Technology

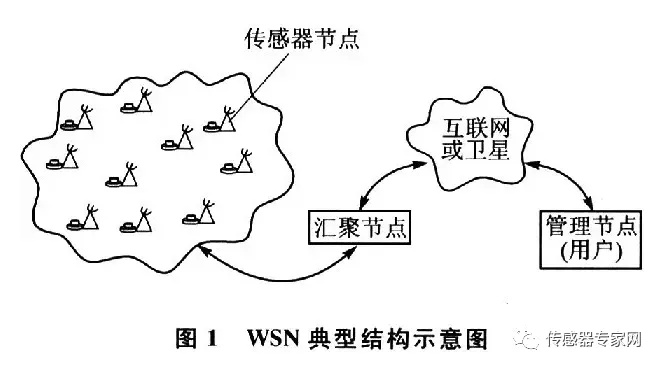

Wireless Sensor Networks (WSN) are multi-hop self-organizing network systems composed of numerous stationary or mobile sensors with sensing, wireless communication, and computing capabilities, capable of autonomously completing specified tasks based on the environment.

A large number of sensors form a distributed, intelligent information processing system through the network, monitoring, sensing, collecting, and analyzing events, phenomena, and environments in the covered area in real-time from multiple perspectives and in various modes, obtaining rich, high-resolution information, processing and transmitting this information to observers.

The elements of a wireless sensor network (WSN) include sensors, sensing objects, and observers. A WSN comprises sensor units, controllers, and wireless communication modules, realizing data collection, short-distance communication, data computation, and long-distance wireless communication functionalities.

WSN integrates sensor technology, embedded operating system technology, distributed information processing technology, wireless communication technology, energy harvesting technology, low-power technology, multi-hop self-organizing network routing protocols, positioning technology, time synchronization technology, data fusion and management technology, information security technology, and network transmission technology, crucially overcoming node resource limitations (energy supply, computing and communication capabilities, storage space, etc.) and meeting the scalability and fault tolerance requirements of sensor networks.

This technology has been ranked first among the top ten emerging technologies with a profound impact on human future life by MIT’s “Technology Review” magazine.

Sensor Digital Communication Bus Technology

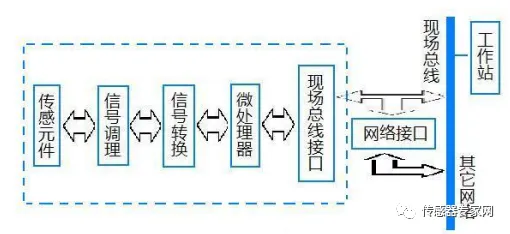

Fieldbus technology is an emerging control technology that integrates computer technology, communication technology, integrated circuit technology, and intelligent sensing technology. It is a digital, serial, multi-point communication data bus installed between field devices in manufacturing and process areas and automatic control devices in control rooms, representing a fully digital, open, bidirectional transmission, multi-branch, multi-station communication system, integrating field communication networks and control systems.

▲ Diagram of Intelligent Sensing Technology Based on Fieldbus

The key feature of fieldbus is its support for full digital communication, establishing a highly reliable data communication line in the control field to achieve data communication between intelligent sensors and between intelligent sensors and master control devices, transforming individual dispersed intelligent sensors into network nodes.

Fieldbus intelligent sensors must possess the following functions: sharing a single bus to transmit information, having various computing, data processing, and control functions to reduce the burden on the host; replacing 4-20mA analog signal transmission with digital signal transmission to enhance signal anti-interference capabilities; adopting a unified network protocol to become nodes in the FCS, enabling information exchange between sensors and actuators; the system can be verified, configured, and tested to improve system reliability; and standardizing interfaces to achieve plug-and-play characteristics.

Fieldbus intelligent sensors are expected to become mainstream instruments in future industrial process control systems.

Application Technologies of Sensors

The application technologies of sensors refer to the various technologies that apply sensors to downstream devices and scenarios. Individual sensors often cannot perform effectively on their own.

These technologies include: signal processing and interface technology; noise reduction and anti-interference technology; display and adjustment instruments; measurement and error handling; sensor selection and installation adjustment technology; detection technologies for mechanical quantities like displacement, force, torque, load, speed, acceleration; detection technologies for process quantities like temperature, pressure, flow, and level; humidity detection and gas analysis technology; detection, imaging, and safety prevention technologies; intelligent and automatic testing technologies; installation technologies for proximity sensors, pressure sensors, and inductive synchronizers; installation technologies for infrared, ultrasonic, and microwave detection anti-theft alarms, etc.

For consumer applications, the main technical difficulty in sensor fusion is how to control the product size, reasonably test the performance of each sensor, control the yield of the entire chip, and reduce costs.

For sensor fusion in industrial, military, automotive, and medical fields, considerations must also include how to ensure accuracy and reliability under various working conditions and how to utilize the characteristics of fusion to achieve compensation and calibration between sensors.

The internal noise of sensor circuits includes interference from electromagnetic components on the circuit board, low-frequency and high-frequency thermal noise, noise from semiconductor devices like bipolar transistors, resistors, and integrated circuit noise, while external interference includes power supply, ground, long-line signal transmission, and spatial electromagnetic waves.Thus, in circuit design, it is necessary to select low-noise semiconductor components based on different operating frequencies and choose appropriate amplification circuits according to different operating bands and parameters.

END

The content is reprinted and represents the author’s views only.

It does not represent the position of the Institute of Semiconductors, Chinese Academy of Sciences.

Editor: Renowned Wei Classmate

Responsible Editor: Six Dollar Fish

Submission Email: [email protected]

1. The Semiconductor Institute has made progress in the research on bionic coverage-style neuron models and learning methods.

2. The Semiconductor Institute has made significant progress in inverted structure perovskite solar cells.

3. Why is copper used as interconnect metal in chips?

4. What exactly is 7nm in chips?

5. Silicon-based integrated optical quantum chip technology.

6. How abnormal is the quantum anomalous Hall effect? It may bring about the next information technology revolution!