In the fertile land of Hunan, there is a place known as “The Silver Capital of China Without Silver Mines”—Yongxing. Although there are no natural minerals here, it has created an economic value exceeding 50 billion yuan through the transformation of waste into gold. Behind this is the gold mining legend written by companies represented by Yongxing Pengkun Environmental Protection Co., Ltd. (hereinafter referred to as Yongxing Pengkun).

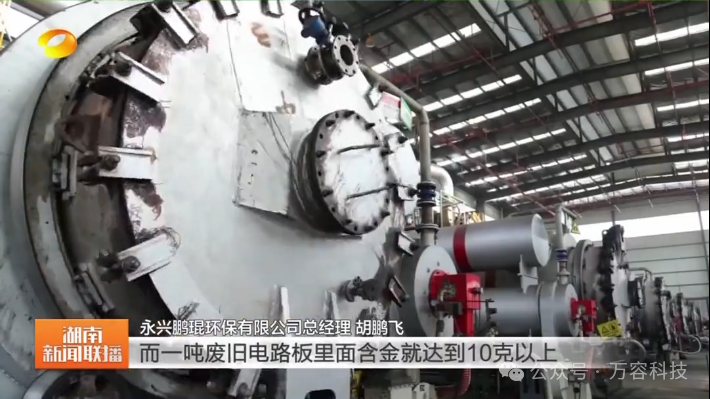

Looking globally, the wave of electronic product iteration is surging. According to a report by the International Data Corporation (IDC), by 2025, global waste electronic products are expected to surge to 54 million tons, which poses a significant environmental challenge but also harbors infinite resource opportunities. Especially high-value metals such as gold, silver, and copper found in waste circuit boards. As the world’s largest producer and consumer of electronic products, China’s processing volume of waste circuit boards is expected to reach 1.2 million tons by 2025. General Manager Hu Pengfei of Yongxing Pengkun vividly pointed out: “1 ton of ore can extract 5 grams of gold, which is already a rich ore, while 1 ton of waste circuit boards contains over 10 grams of gold and more than 100 grams of silver, making it extremely valuable.” How to transform these potential sources of pollution into green wealth in a circular economy is the mission of pioneering enterprises like Yongxing Pengkun.

Turning “Hazardous Waste” into “Gold”: The Magic and Wisdom of a Modern Factory

Entering Yongxing Pengkun, you will be shocked by the scene before you. This is not a traditional dirty and chaotic waste recycling station, but a modern green factory.On 158 acres of land, facilities such as waste circuit board warehouses, organic hazardous waste pyrolysis workshops, and copper-containing smelting workshops are arranged in an orderly manner, with each link revealing the rigor of technology and the determination for environmental protection.

The core competitiveness of transforming “circuit boards” into “gold” lies in the “Oxygen-Free Pyrolysis + Oxygen-Enriched Side-Blown Smelting” comprehensive processing technology independently developed by Wanrong Technology.

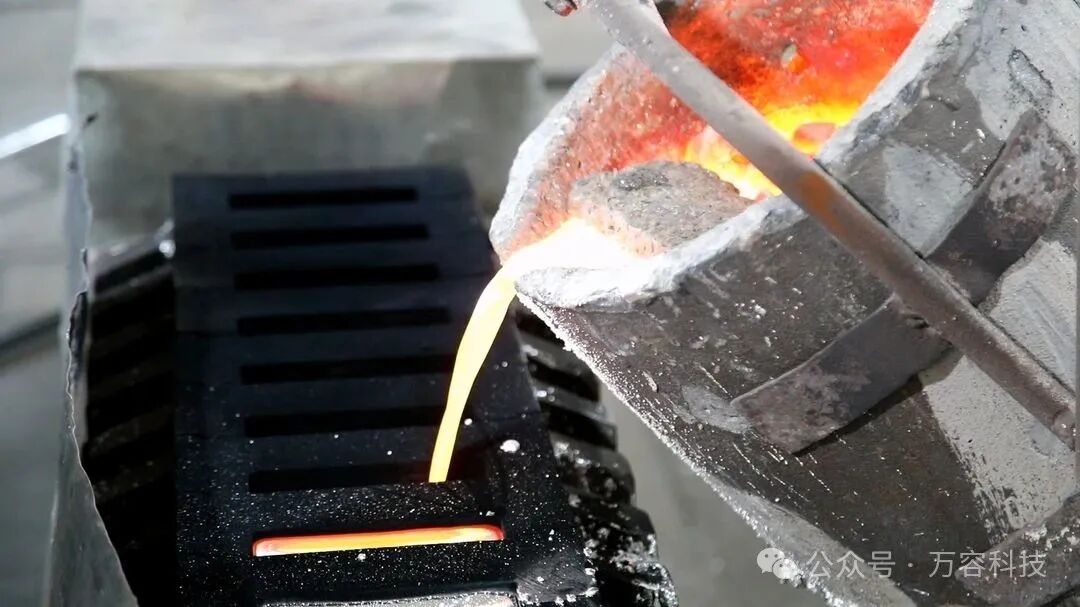

In an oxygen-free environment, the organic materials in waste circuit boards are converted into pyrolysis oil and combustible gas, while metals are concentrated in the pyrolysis carbon residue. Subsequently, the oxygen-enriched side-blown smelting technology efficiently recovers high-purity copper and accompanying precious metals such as gold and silver from these concentrated residues and various copper-containing materials.

This segmented collaboration ensures the comprehensive recovery of organic components and metal components, maximizing the utilization of waste value.

To ensure extreme environmental protection in recycling, and to eliminate the troubles of “toxins,” Wanrong Technology adopts a combination of flexible sealing technology, innovatively designed to solve the problem of dynamic sealing in large pyrolysis equipment, ensuring that pyrolysis occurs in an oxygen-free environment. Compared to the risks of highly toxic dioxins generated by high-temperature incineration, the oxygen-free environment blocks the oxygen supply for dioxin generation, while maintaining reduction to promote dioxin decomposition, and optimizing structural design to reduce dioxin precursors, greatly reducing environmental risks.

Wanrong Technology’s innovative hot air reuse technology efficiently utilizes high-temperature flue gas and low-temperature recirculated flue gas, precisely controlling the pyrolysis temperature, achieving a closed-loop reuse of pyrolysis gas, improving thermal efficiency while reducing flue gas purification investment, effectively lowering operating costs.

This combined process is energy-efficient, achieving self-sufficient green circulation. The combustible gas and pyrolysis oil produced can be directly used as auxiliary fuel in the smelting process, significantly reducing external energy dependence and operating costs. The oxygen-enriched side-blown technology itself, due to the increased oxygen concentration, makes combustion and metallurgical reactions more efficient, further reducing energy consumption.

This combined process can flexibly handle various industrial solid wastes, whether it is waste circuit boards containing organic matter, high polymer hazardous waste, or copper-containing sludge and residues, all can find efficient solutions, enhancing the factory’s material receiving capacity and market competitiveness.

Deputy General Manager Zhou Yi of Yongxing Pengkun once introduced:“We have achieved maximum extraction and transformation of waste into treasure, and more importantly, the product quality has been guaranteed, achieving a dual enhancement of social and environmental benefits.” The purity of the recovered copper products exceeds 99.999%, and after being made into copper powder, the added value increases by more than 20%; the alloy superconducting materials made from pure copper powder and pure silver powder have doubled in value! This is not only a success in economic terms but also the best interpretation of the concept of “green development.”

From Blueprint to Reality: Setting a Benchmark for Speed and Quality

The story of Yongxing Pengkun did not happen overnight. Construction of the project began in April 2018, and it officially went into production in January 2020. As a major industrial project in Yongxing County, it has set a new benchmark for quality and recycling with first-class engineering construction, advanced equipment, and high environmental emission standards.

The project is equipped with 6 sets of batch pyrolysis systems and 1 set of continuous pyrolysis systems, with an annual resource utilization of various industrial solid wastes of 187,800 tons, including 20,000 tons of circuit boards and 167,800 tons of industrial solid waste, producing 12,500 tons of copper powder and copper-containing alloys annually. It is not only an important part of Yongxing County’s “Silver Capital of China” strategy but also actively promotes the quality upgrade of the entire precious metal comprehensive recycling industry.

Xu Changhai, Director of the Science and Technology and Industrial Information Bureau of Yongxing County, stated:“We guide and encourage enterprises to widely carry out industry-university-research cooperation and innovation, break through core technologies, and focus on cultivating innovative enterprises… to lead the development of our entire industry.”

Yongxing Pengkun is the crystallization of this innovative spirit. In addition to waste circuit boards, Yongxing Pengkun can also process waste packaging bags, edge scraps, welding slag, waste lubricating oil, waste cutting fluid, waste resin residue, paint residue, waste filter cotton, waste gloves and rags, waste activated carbon, and other hazardous wastes, providing standardized hazardous waste collection, transportation, storage, disposal, and process management services for well-known large enterprises such as GAC Group, CIMC Group, Shengyi Technology, China Shipbuilding, Samsung Electronics, Foxconn, China Rebirth, Dongjiang Environmental Protection, and Sander Recycling, while implementing the highest environmental safety standards.

Commitment to a Green Future

The success of Yongxing Pengkun is a model of Wanrong Technology’s deep cultivation in the field of circular economy. This shows us that waste is not the end, but a new starting point empowered by technology.

In the future, Wanrong Technology will continue to innovate and expand the application of pyrolysis technology in emerging circular economy fields such as biochar, waste photovoltaic components, and retired wind turbine blades, driving global industrial sustainable development, and creating a green, low-carbon, and efficient circular economy era in collaboration with partner enterprises, achieving a win-win situation for both the economy and the environment.