Introduction

Reading

To achieve long-range, full-area IoT coverage in factories and to realize intelligent and refined management of equipment and the environment, Advantech has built a real-time intelligent monitoring network based on LoRaWAN, centered around a “device-edge-cloud” collaborative architecture, creating a complete closed loop from data collection to intelligent decision-making.

In the Era of Industry 4.0

Is your factory still “blindly groping”?

With the accelerated advancement of Industry 4.0 and smart manufacturing, the manufacturing industry is undergoing an upgrade from core production processes to peripheral facilities, as well as a profound transformation from traditional manual management to digital management.

However, the increasing complexity of equipment and the dynamic changes in the production environment pose dual challenges for factory management: on one hand, traditional manual inspections struggle to capture real-time hazards such as equipment vibrations and current fluctuations, leading to losses of millions due to unexpected downtime; on the other hand, scattered environmental data such as temperature, humidity, water leakage, and access control lack unified monitoring, making it difficult to issue timely warnings for potential risks.Breaking down data silos to achieve comprehensive perception of equipment and environment has become a core proposition for enterprises’ intelligent upgrades.

LoRaWAN Constructs a Real-Time Intelligent Monitoring Network

Advantech’s real-time monitoring solution for equipment status and production environment based on LoRaWAN is centered around a “device-edge-cloud” collaborative architecture, creating a complete closed loop from data collection to intelligent decision-making.

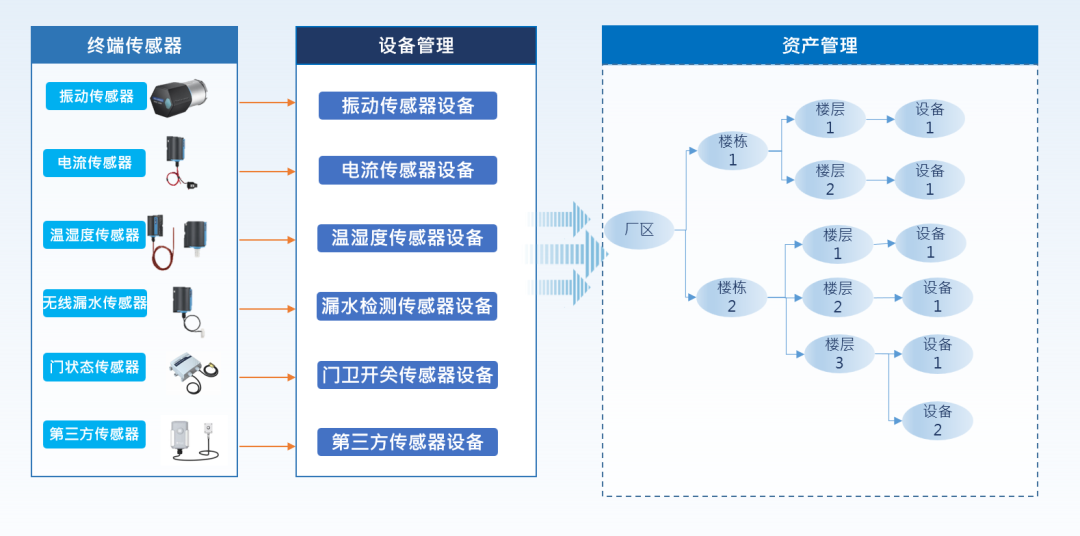

Edge Perception Layer

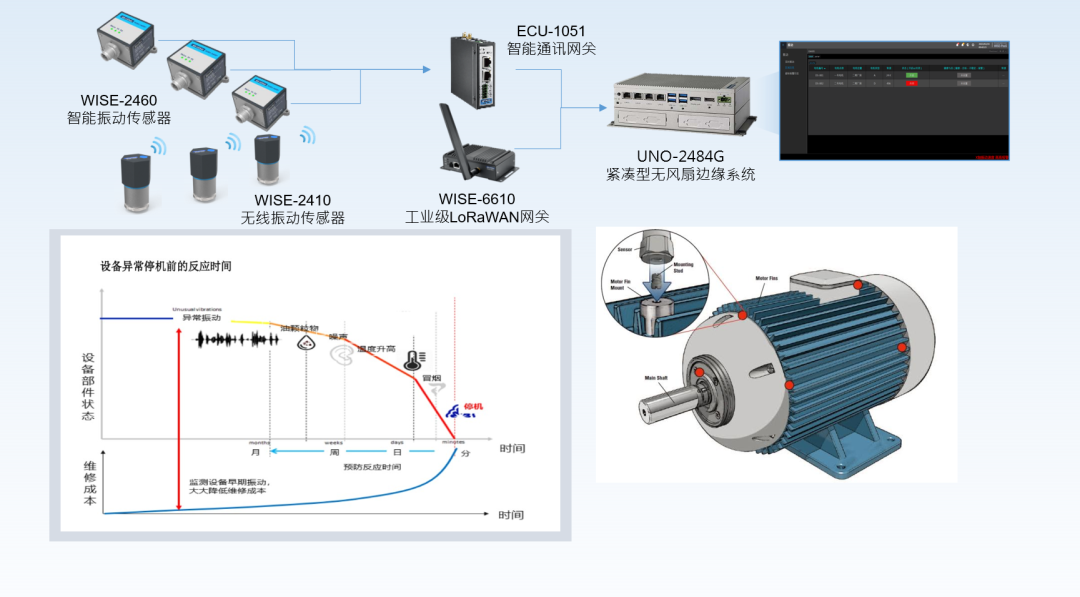

Relying on the LoRaWAN network, sensors such as vibration, current, and temperature/humidity capture the dynamic changes of equipment and environment in real-time, covering the vast and complex environment of the factory.On one hand, LoRaWAN ensures that the data collected by sensor nodes is transmitted stably and efficiently back to the monitoring center, providing a solid data transmission foundation for accurately monitoring equipment status and production environment; on the other hand, in industrial sites where wiring is difficult and the environment is complex, LoRaWAN sensor nodes leverage their low power advantages for ultra-long-distance transmission, continuously collecting and transmitting equipment operation data for years without interruption, ensuring the continuity of monitoring data.

Edge Computing Layer

Using the UNO-2484G compact fanless edge intelligent system, which deploys IoT Edge edge computing services, it serves not only as a data relay but also as the engine for edge intelligent decision-making.With industrial-grade reliability, flexible scalability, and efficient edge computing capabilities, it provides a solid localized intelligent foundation for the LoRaWAN real-time monitoring solution, helping enterprises transition from “passive maintenance” to “predictive control”.

Cloud Software Layer

Deployed on Advantech’s industrial cloud platform for device networking and asset management services, it integrates cloud capabilities such as data access, data analysis, data storage, data application, and data forwarding. The cloud platform, through cloud-edge collaborative services, brings data feedback and interaction, as well as OTA services down to the edge, meeting the needs for unified management of devices, real-time data access and monitoring on-site, data cleaning and computation, remote operation and maintenance management of devices, alarm notifications and event management, as well as 2D & 3D data visualization.

Data-Driven Intelligent and Refined Management

Part 1

Zone Management Simplifies Operations

Faced with the issue of diverse and widely distributed equipment in large industrial plants, this solution provides a zoned management model. Users can partition the factory, buildings, and floors according to actual needsand classify management of vibration sensors, current sensors, and other devices by area. This not only helps in quickly locating and addressing issues but also greatly improves management efficiency. Through a visual dashboard, managers can monitor the status of equipment in various areas in real-time, reducing unnecessary on-site inspection work, thus saving time and costs.

Part 2

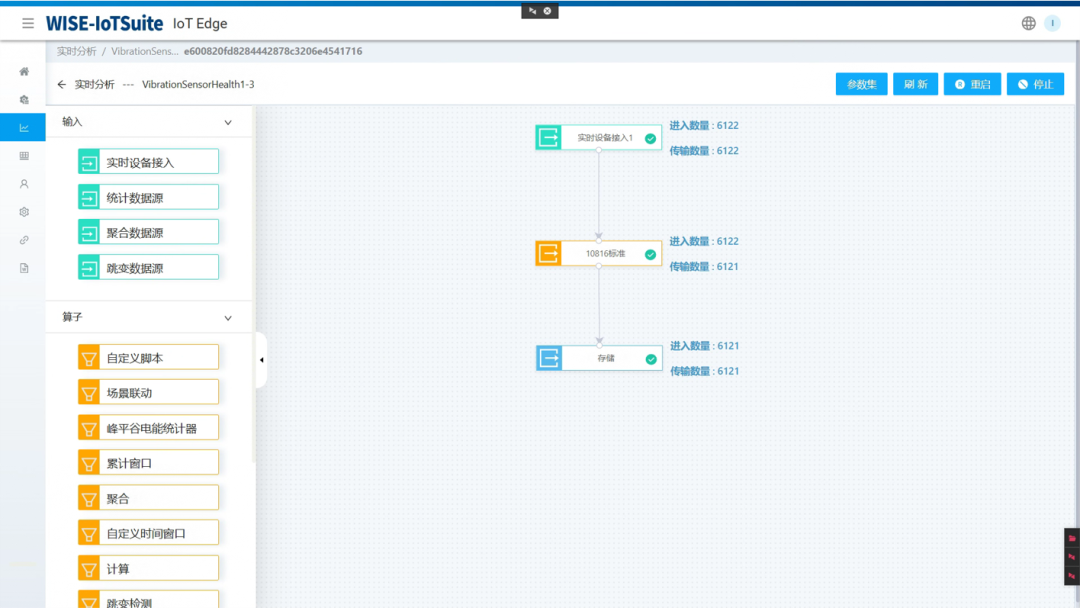

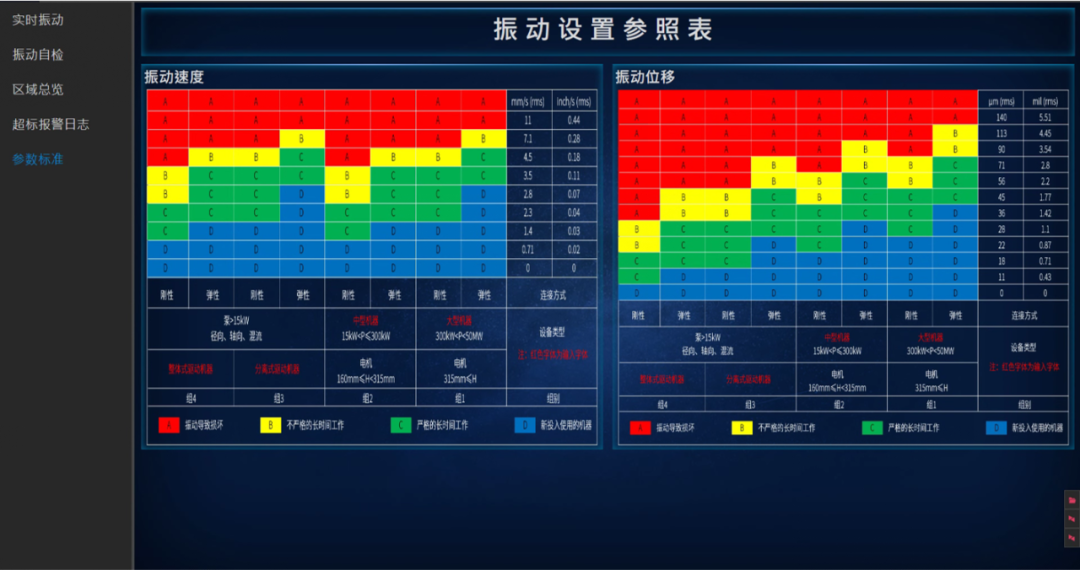

Vibration Analysis Prevents Failures

Vibration is one of the important factors affecting the stable operation of equipment. The solution achieves full-process monitoring from vibration to vibration severity analysis to equipment anomaly analysis through the severity analysis of vibration data.By matching the data collected from the WISE-2410 vibration sensor with the ISO-10816 standard, the system can accurately assess the operational status of the equipment.Once abnormal vibrations are detected, the system will immediately issue a warning, helping enterprises take measures before failures occur, effectively avoiding downtime or damage caused by abnormal vibrations.

Part 3

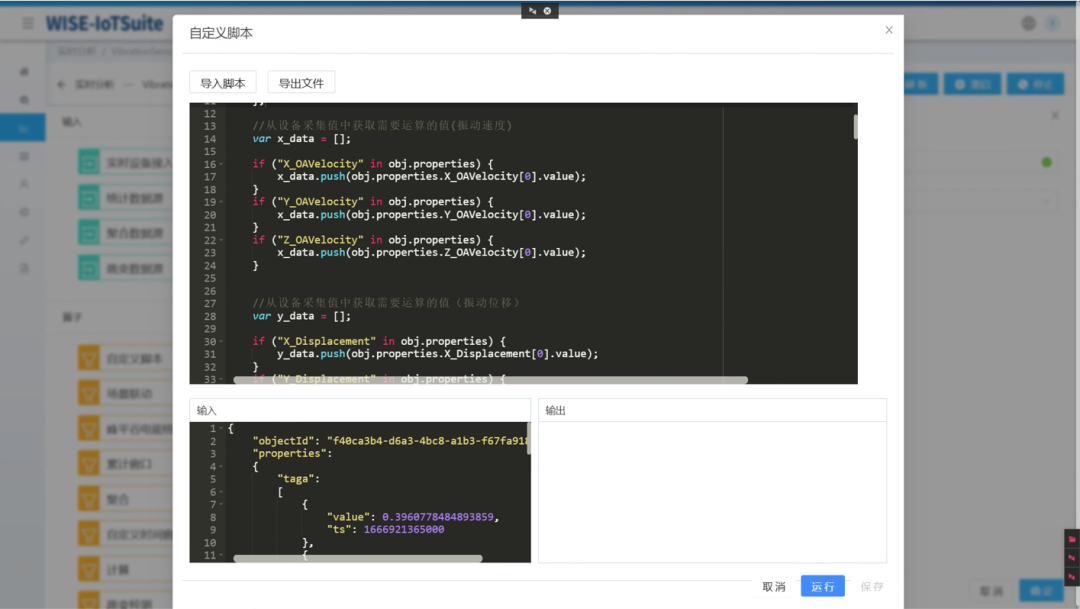

Data Analysis for Intelligent Prediction

The powerful data analysis capability is a major highlight of this solution.The system has built-in standard operator rules, allowing for quick drag-and-drop component modules for automatic analysis and judgment. For example, vibration data can be analyzed from multiple aspects such as vibration speed and displacement, matched with ISO-10816 to derive vibration condition assessment results, achieving full-process monitoring from vibration to vibration severity analysis to equipment anomaly analysis. At the same timeit supports custom script analysis, allowing users to flexibly set their own needs, run judgments independently, and predict potential failures in advance, significantly reducing the failure costs of unexpected breakdowns.

Swipe left to see more

Part 4

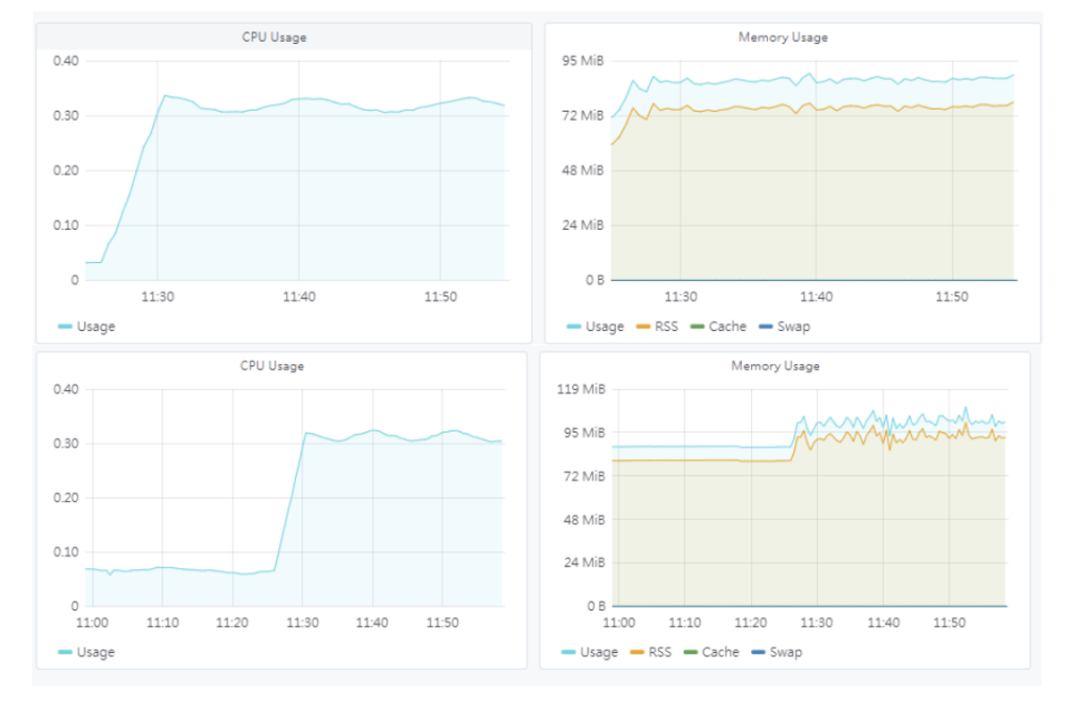

Robust Performance and Reliable Operation

Maintaining system stability during long-term operation is key to ensuring the continuity of industrial production.The solution supports data reporting of up to 4000 points, and the overall resource consumption of IoT Edge remains stable, ensuring efficient and reliable operation even under high load conditions.Using a compact fanless edge system (UNO-2484G) further enhances the system’s anti-interference capability and stability, effectively preventing system failures caused by environmental factors. This provides strong support for continuous monitoring in industrial plants, ensuring that enterprises can obtain continuous and reliable monitoring services.

FreeTrial

Download Materials

Advantech’s real-time monitoring solution for equipment status and production environment based on LoRaWAN hasbeen successfully applied in diverse scenarios such as semiconductor manufacturing, automotive production lines, power distribution, logistics warehousing, and food production. Whether it is real-time monitoring of precision equipment vibrations or early warnings of workshop environmental hazards, this solution can achieve precise control through data-driven methods, helping enterprises reduce costs and increase efficiency while ensuring production safety.In the future, with the deep integration of 5G, AI, and edge computing, the industrial IoT will advance to a higher level of intelligence. Advantech will continue to optimize the solution and promote the digital transformation of enterprises.

Further Reading

Break Through Traditional Manufacturing Bottlenecks! LoRaWAN Ignites Wireless Applications in Smart Factories

Advantech EVA-2000 Wireless LoRaWAN Smart Sensor Launched!

Advantech’s Equipment Vibration Monitoring Solution Easily Achieves Preventive Maintenance

Contact UsPhone: 020-85529978Email: [email protected] Website: http://www.yanxintech.com.cnAddress: 55 Huangcun Road, Tianhe District, Guangzhou